Rio-Andirrio Bridge

Coordinates: 38 ° 19 ′ 17 ″ N , 21 ° 46 ′ 22 ″ E

| Rio-Andirrio Bridge | ||

|---|---|---|

| Official name | Charilaos Trikoupis Bridge | |

| use | Road bridge | |

| Convicted | A5 | |

| Crossing of | Gulf of Corinth | |

| place | Patras , Rio | |

| construction | Cable-stayed bridge | |

| overall length | 2883 m | |

| width | 27.20 m | |

| Longest span | 3 × 560 m | |

| Clear height | 52 m | |

| start of building | 1999 | |

| opening | August 12, 2004 | |

| location | ||

|

|

||

The Rio-Antirrio bridge ( Greek Γέφυρα Ρίου-Αντιρρίου Gefyra Riou-Andirriou ) or officially Charilaos Trikoupis Bridge (Γέφυρα Χαρίλαος Τρικούπης) is a road bridge in Greece over the Strait of Rio-Antirio (Στενό Ρίου-Αντιρρίου) that the Forms entrance to the Gulf of Corinth . It was opened in 2004 and connects Andirrio on the north bank with Rio in the Peloponnese , eight kilometers east of Patras . It caused a sensation because for a long time it was considered impossible to build a bridge in an earthquake area over a 2.5 km wide and 65 m deep strait without a stable ground.

description

The cable-stayed bridge, supported by four pylons with fan-shaped cable arrangements, has two lanes in each direction with a hard shoulder as well as a pedestrian and cyclist path outside the cable fastenings.

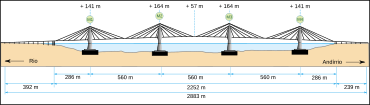

The total of 2883 m long bridge consists of the 2252 m long main bridge over the sea, the 392 m long ramp bridge for the access at Río and the 239 m long ramp bridge at Andírrio. The main bridge has spans of 286 m, three times 560 m and 286 m. The two middle pylons are a total of 230 m high, they stand in 65 m deep water and rise another 164 m above sea level. The two outer pylons are in slightly less deep water and reach a height of 141 m above sea level. This gives the bridge deck an upward curvature that spans the entire strait. The middle passage has a clear height of 52 m. Based on the length of the main bridge, it is the second longest cable-stayed bridge in the world (after the 2460 m long Viaduc de Millau ).

Technical details

The almost 2.5 km wide and mostly about 65 m deep entrance to the Gulf of Corinth has geologically extremely difficult conditions. Even 100 m below the sea floor, no stable rock was found, the floor consists rather of sand , silt and clays . The entrance lies above a tectonic fracture zone that removes the Peloponnese by several millimeters from the Greek mainland every year and causes numerous earthquakes. The driveway is also known for frequent storms and has heavy shipping traffic.

The planning therefore had to meet the following criteria and load assumptions:

- Foundation in 65 m water depth on unsound soil;

- Earthquake of magnitude 7 on the Richter scale ;

- tectonic displacements of the piers of up to 2 m in any direction during the planned lifespan of the bridge of 120 years;

- Impact of an unloaded 180,000 tdw tanker at 16 knots ;

- Impact of a loaded 80,000 dwt bulk carrier with 16 knots ;

- Wind speeds on the road deck of 180 km / h (50 m / s), which means that wind tunnel tests must demonstrate the flutter stability of the deck up to wind speeds of 266 km / h (74 m / s).

A foundation of the bridge with the conventional means of civil engineering was ruled out for the water depth; the techniques used in the construction of offshore drilling platforms had to be used. First of all, the ground was stabilized at the points provided for the pylons by ramming up to 30 m long steel pipes with a diameter of 2 m at intervals of 7 m on a circular area of over 100 m in diameter. In this way, around 200 pipes were installed on each circular area, which despite the similarities do not have the function of a bored pile foundation , but only that of soil stabilization. The circular areas were then covered with a 2.75–3.00 m thick layer of aggregates (10/80), which was leveled exactly to the specified height - a new challenge at a depth of 65 m. This layer is intended to serve as a slide bearing for the pylons in the event of an earthquake and to prevent violent lateral impacts from being transmitted to the pylons.

The base of the pylon, which has no fixed connection to the ground, rests on this plain bearing. It is a round concrete structure with a diameter of 90 m, which consists of a flat base plate, 9–13.5 m high side walls and a cover that rises conically towards the center. The structure is reinforced inside by ring walls and radial partition walls. It was reinforced concrete used with a steel content of 300 kg / m³.

This round concrete structure carries the pillar, which in its lower part has a round, conical profile with a diameter of 38–26 m. At the surface of the water it merges into a vertical, octagonal pillar, which expands under the deck to form an inverted pyramid about 15 m high, which ends in the square girder of the superstructure, which has a side length of 38 m. This inverted pyramid is structurally the most difficult section of the pillar. The concrete here has a steel content of 475 kg / m³, locally even 700 kg / m³. The corners of this square serve as the basis for the four legs of the upper part of the pylon, which consist of 4 × 4 m wide hollow boxes and unite in the form of an A in a high point, in which a large metal box with the rope anchors is housed.

The 27.2 m wide and 2.82 m high bridge deck is held in place by a total of 368 steel cables. Each fan on each side thus consists of 23 ropes that are between 77 m and 293 m long. The ropes are fitted with dampers just above their anchoring on the road deck, which are intended to prevent uncontrolled vibrations in the event of an earthquake.

The bridge deck is a composite system consisting of a steel frame with two 2.20 m high longitudinal girders and cross struts inserted every 4 m as well as a reinforced concrete slab for the roadway. The bridge deck is a continuous construction over its full length of 2252 m without interruptions. The deck does not rest on the pillars, but hangs by the ropes. The damper elements are blocked so that it is not pressed against the legs of the pylons by side winds. However, the blocking rings should break off in the event of a large earthquake, so that the entire deck can vibrate and thereby compensate for the movements of the pylons. Between the ends of the bridge deck and the access ramps were extremely large joints provided that not only the enormous thermal expansion can take the long bridge decks, but also tectonic shifts. The transition structures developed for this are currently the largest of their kind.

The bridge is equipped with numerous sensors and measuring devices that record external influences on the bridge and its condition and forward the data to the monitoring station. Earthquakes should be recognized as early as possible and the bridge should be automatically closed to traffic if necessary.

Individual aspects of the construction phase

In order to be able to ram the steel pipes into the seabed, a barge was converted into a tension-leg platform , which was held in the correct position with steel cables attached to concrete blocks weighing 750 tonnes on the seabed. The platform was equipped with a 140 t crane with which the ram was operated.

Since the construction of the pillars could not begin in 65 m deep water, two pillar feet were initially concreted in a dry dock next to the bridge, with the high construction crane being placed on the center of the base plate. The feet became buoyant as soon as the cover and the first approach of the rising pillar were made. They were then towed to a calm spot in the sea and built further until they had reached the height necessary for lowering. Then they were towed to their final position, lowered onto their gravel bed on the seabed and then finally completed. The crane in the center of the piers was lifted out as soon as the four sloping legs of the top part were started and repositioned on the square beam outside the legs. The large metal box with the rope anchors was welded together on land in the construction site area and lifted as a whole to the top of the pylon by a floating crane . The tugs and floating crane were provided by the Dutch company Smit .

The bridge deck was built from prefabricated, 12 m long segments, which were also brought into position by the floating crane and held in place by a specially made fastening device until they were permanently connected to the already installed bridge deck and the tensioning cables.

Building history

First ideas

The idea of a connection across the western end of the Gulf of Corinth comes from the then Greek Prime Minister Charilaos Trikoupis ( Greek : Χαρίλαος Τρικούπης) in 1880 . As early as 1880 he proposed to the Greek Parliament to build a bridge over the Gulf near Patras . However, major technical difficulties stood in the way of realizing this vision from the start. Nonetheless, in 1889 (the year the Firth of Forth railway bridge in Scotland was completed) Trikoupis commissioned Greek engineers to study the possibilities of building a bridge from Rio to Andirrio . Although the technicians of the time were not aware of the possibilities such as soundings on the seabed or seismic records of the tectonic activities and were therefore not fully aware of the actual difficulties, they had to capitulate to the local conditions. The Gulf of Corinth is still around 2.5 km wide at its narrowest point and the water is up to 65 meters deep. In addition, there are very strong currents in Patras, and earthquakes and violent storms occur time and again in the region . Given the state of the art at the time, building a bridge was out of the question, and the engineers had to inform the Prime Minister of the disappointing results of their investigations. The idea disappeared in the drawer for over 100 years.

In 1992 the Greek Chamber of Engineers came to the conclusion in a new investigation that the construction of a bridge at this point was almost impossible. In addition to the problems already known, the expertise revealed further difficulties. The biggest obstacle was the completely inadequate foundation conditions on the sea floor. The entire subsoil consists of sand, silt and rubble, and even when drilling to a depth of more than 100 meters, no rock with sufficient load-bearing capacity could be found. The seismic activities were examined in more detail and also gave little cause for optimism: within 100 years there had been seven earthquakes with a magnitude of 4.5, and the Peloponnese drifts away from the mainland by several millimeters every year. In the event of a violent quake, the distance could in extreme cases increase by one to two meters. Another problem was the significant increase in shipping traffic since the first investigation, which required a height of over 50 meters and a large span for the bridge.

Despite the negative verdict of the Greek Chamber of Engineers, the vision of building the bridge could no longer be stopped. However, due to the particular difficulties, completely new, unusual solutions and construction methods had to be found. The Charilaos-Trikoupis Bridge therefore became a technically extremely interesting and innovative structure in which many details were breaking new ground.

Tender, award and contract structure

In 1992 the project was tendered as part of an operator model based on a concession from the Greek state for 42 years. It was the first concession project by the Greek state. The concessionaire should plan and build the bridge for the first seven years and operate and maintain it for the next 35 years. Since the future income from the bridge toll was not enough to finance the bridge, a loan from the European Investment Bank was required in addition to start-up financing from Greece , which, however, did not want to share in the construction risks. The offer made in 1993 by the French company Vinci was successful.

After extremely complex negotiations, the concession agreement between the Greek state and the Franco-Greek company Gefyra SA , founded especially for this project, was signed on January 3, 1996, and came into force on December 24, 1997 after the financing agreements had been concluded.

The almost two years long phase between the signing of the contract and the entry into force was used by the engineers to discuss and review the project with outside experts, which led to some fundamental changes.

Vinci owns 57.45% of the concession company Gefyra SA and the Greek companies Aktor Concessions 22.02%, J&P AVAX 12.14% and Athena 8.39%. The Gefyra SA commissioned, also established for the project joint venture Kinopraxia Gefyra (Vinci Construction Grands Projets 53.00% 15.48% AKTOR J & P AVAX 11.20%; Athenas 7.74%; Proodeytiki 7.74%; Pantechniki 4.84%) with the planning and construction of the bridge. The Gefyra Litourgia SA (with the same shareholders as the Gefyra SA ) has been commissioned by it with the operation, maintenance and repair of the bridge.

Conception and planning

The conception of the project and its engineering planning was carried out by Vinci Construction Grands Projets and companies belonging to the group such as Freyssinet International. Vinci worked closely with the engineering offices Ingerop, Géodynamique & Structures and Domi (Greece) and numerous other experts. Berdj Mikaëlian from Ingerop was the architect responsible for the external design of the bridge.

The Canadian engineering office Buckland & Taylor Ltd. was appointed as a design checker , i.e. as an independent test engineer . from Vancouver, which was reinforced by a number of American specialists. The British office Faber Maunsell Limited was commissioned as the supervision engineer , i.e. with the construction supervision. Both had to report not only to their client Gefyra SA, but also to convince the Greek state and the banks involved that the project was properly planned and implemented.

construction time

The first groundbreaking took place on July 19, 1998 by the Greek Prime Minister Konstantinos Simitis . In June 2004 the last segment of the bridge deck was used. The cost of the project was 771 million euros. The bridge was opened on 7/8 Officially inaugurated on August 13th , 2004 with a big ceremony and a fireworks spectacle - in time for the Olympic Games starting on August 13th , but a good four months before the contractual completion date. During this celebration, Otto Rehhagel , the coach of the Greek national soccer team , Irena Szewińska , the Polish Olympic champion, and Stratos Apostolakis , the coach of the Greek soccer team for the Olympic Games, carried the Olympic flame over the bridge. On August 12, the bridge was opened to traffic.

Up to 1200 people were working simultaneously on the construction site. Despite this, there was not a single serious accident with permanent physical damage during the work up to a height of 165 m during the five-year construction period.

Operating time

On January 28, 2005, the bridge was initially closed for an indefinite period of time for safety reasons. After thunderstorms and storms with wind force 9, one of the 368 suspension ropes caught fire and was cut. On February 1, the bridge was opened to traffic again, but until the end of the replacement of the suspension cable with only one lane in each direction.

In 2005 the structure and the architects and engineers responsible received the Outstanding Civil Engineering Achievement Award from ASCE and in 2006 the Outstanding Structure Award from IABSE .

The operating period ends on December 24, 2039 - 42 years after the concession agreement came into force. The bridge must then be handed over to the Greek state in a contractually fixed condition.

location

While the east of mainland Greece is relatively well developed, the sparsely populated and mountainous north-west of the country could hardly be reached by major road and rail connections. In the late 1990s, two major motorway construction projects were started to improve the connection to the northwest and begin in Ioannina . These are the east-west axis A2 ( Egnatia Odos ) , which connects the Epirus with Macedonia and Thrace (this is largely completed), as well as the north-south connection the A5 ( Ionia Odos ) . The Rio-Andirrio bridge is to connect the future A5 with the existing A8 in the Peloponnese, until then the bridge will be used as a national road (blue signs).

The place Rio is an eastern suburb of Patras and since 1998 with incorporations a city (Dimos). This is where the University of Patras campus is located . Next to the motorway is a station for the meter-gauge Peloponnesian Railway. The regular-gauge new line under construction will have a stop in Rio.

The place Andirrio is much less important than Rio and has always played its role only as a transition to the Peloponnese and as a port.

use

Car drivers have to pay € 13.50 for a single trip over the bridge (as of August 2019); at the end of 2012 it was € 13.20.

Until the bridge was built, only ferries were available to cross the inlet . The owners of the ferries have been compensated, but are still allowed to operate the route. The crossing (approx. 45 minutes) costs half the bridge toll and offers a view of the bridge.

Web links

- The Rion-Antirion bridge . Gefyra SA, website of the concessionaire (Greek, English, French)

- German site with information on the construction of the bridge

- Rio-Andirrio Bridge. In: Structurae

Individual evidence

- ↑ a b c Pont de Rion – Antirion, Le nouveau titan grec . (PDF; 820 kB) Grands projets, n ° 21, June-September 2004 (Vinci in-house newspaper)

- ↑ a b c d Design and Construction . ( Memento of the original from November 15, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Gefyra SA

- ↑ a b c Le Pont de Rion-Antirion: L'Innovation, une nécessité ( Memento of the original dated December 30, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 1.4 MB) In: Entretiens Louis Le Grand , 2005, Enseignants de Sciences Economiques et sociales - Entreprises: Les entreprises, acteurs de la recherche et de l'innovation

- ↑ a b c d e f La force et la grâce ( Memento of the original from September 29, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF); Construction Moderne, Annuel ouvrages d'art, 2004/1 (technical construction report)

- ↑ Computerized Visual Inspection System & Structural Health Monitoring of Rion Antirion Viaduct ( Memento of the original from July 19, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 7.8 MB) with numerous photos of the bridge

- ↑ A great dream ( Memento of the original from November 15, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. on the website of Gefyra SA

- ↑ Jean-Paul Teyssandier, Jacques Combault, Alain Pecker: Rion-Antirion, le pont qui les challenges mankind séismes on La Recherche

- ↑ J&P AVAX is a subsidiary of the Cypriot J&P ( J&P History )

- ↑ Gefyra SA ( Memento of the original from November 15, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Toll Rates, Simple Crossing ( Memento of the original from November 15, 2012 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. on Gefyra SA