Windscale brand

On October 10, 1957, a fire broke out in a British nuclear reactor in Windscale (now Sellafield , England ). This put a cloud with significant amounts of radioactive material released, extending across the UK and mainland Europe distributed . This accident is classified as a serious accident (level 5) on the seven-level international assessment scale for nuclear incidents (INES) that is currently in force, i.e. an accident with effects outside the company premises and serious damage to the reactor core (such as that of Three Mile Island ). By 2005, the radiation in the reactor had dropped to around one percent of the very high level after the fire.

Historical background

After the USA tried to prevent the proliferation of nuclear weapons after the end of World War II , other countries were denied access to nuclear technology by the McMahon Act, which was passed in 1946 and came into force on January 1, 1947 . The former allies, however, pushed ahead national nuclear technology programs, so that Great Britain had its own nuclear weapons from 1952 , the Soviet Union from 1949. In order to catch up with the American scientific and technical lead, research and production had to be driven forward under great time pressure; Safety aspects played a lesser role, although the dangers of radioactivity were now well known.

In order to build a British bomb, plutonium production was a top priority. The site selected was the site of a former munitions factory in Windscale on the Irish Sea ( Cumbria , north-west England ), which had sufficient cooling water from the Wastwater and Ennerdale lakes and was located far away from areas with more densely populated areas. The region was delighted with the construction of the facility, as the decline of earlier industries and mining had created economic difficulties; the new industry was expected to provide a considerable upswing.

Despite the post-war austerity measures, construction of the Pile No. 1 nuclear reactor began in the autumn of 1947 and was commissioned in October 1950. Pile No. 2 , identical in construction , went into operation eight months later. Both reactors together produced around 35 kg of weapons-grade plutonium-239 per year. At the same time, the first reprocessing plant B204 was built to extract the plutonium. The construction work was under great time pressure due to the political framework.

In February 1952, the first pieces of plutonium were delivered to the Aldermaston factory near Oxford , and in October the first British atomic bomb hurricane exploded off the coast of Australia.

technology

Reactors

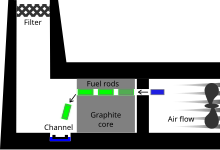

In order to produce plutonium from natural uranium as quickly as possible , graphite-moderated , air-cooled reactors with a thermal output of 180 MW were used. The reactor core consisted of 1,966 tons of graphite blocks with 3,444 horizontal channels arranged in an octagonal area in the center of the core. The core had a diameter of 15 m, was 7.5 m thick and surrounded by 2.7 m thick reinforced concrete as a radiation shield. Metallic natural uranium, which was enclosed in 28.5 cm long, 2.5 cm thick aluminum capsules, served as fuel. For better heat dissipation, each capsule was provided with radial cooling fins. In order to increase plutonium production, the wall thickness of the aluminum capsules was subsequently reduced by milling, the resulting lower stability of the capsules was accepted. In each channel of the reactor 21 such fuel assemblies were loaded from the front. There were also other channels for isotope capsules and control rods . The isotope capsules contained lithium and magnesium . Tritium , which was urgently needed for the British hydrogen bomb , was bred from the lithium by neutron capture .

Used fuel elements were pushed back out of the core with the help of steel rods, where they fell into buckets in a water basin and were transported via a water channel shielded by meter-thick concrete walls into the decaying basin B29 , which is used jointly for Pile 1 and 2 . The cooling was carried out by two fan houses which were connected to the front of the reactor core by shafts. The exhaust air was released into the environment through a 125 m high chimney , which was fitted with filters at the top to hold back radioactive particles. The entire reactor structure had a mass of about 57,000 tons.

The two reactors each produced around 35 kg of plutonium per year. In the period from 1951 to 1957, approximately 385 kg of plutonium were produced in the processing plant B23 .

Moderator

When the reactors were planned in 1946, all that was known was that the graphite moderator in the reactor expands at low temperatures, which is known as the Wigner effect . Otherwise little was known about the behavior of graphite under neutron bombardment.

Two years after the Pile 1 was put into operation, it was found that there were repeated spontaneous temperature rises in the core, which was ultimately attributed to the fact that the moderator's graphite, when it expands through neutron bombardment, stores Wigner energy, which later becomes uncontrollably spontaneous is released. Since higher temperatures are dangerous for the air-cooled graphite as well as for the isotope and fuel elements because of the fire hazard, the core began to be baked out at regular intervals in 1952 in order to reduce the Wigner energy. For this purpose, the core temperature was slowly increased above the normal operating temperature. By October 1957, this process had already been successfully carried out fifteen times on Pile 1 and 2, but it turned out to be increasingly difficult and sometimes required reheating of the core in order to release the Wigner energy. In October 1957, when Pile 1 was baked out for the ninth time, a disaster occurred .

Course of the reactor accident of October 1957

On October 7, 1957, the technicians began the bakeout process , which should be completed after three days. The shutdown reactor of pile 1 was started up at 19:25 with the fans switched off and stabilized at 250 ° C. The released Wigner energy should raise the temperature to the intended maximum value of 350 ° C.

On October 8, the displays indicated that the intended temperature had not been reached. Since the heating was not taken into account in the planning, temperature measuring points were missing in both reactors in order to be able to adequately monitor the not yet fully understood heating process. The operating personnel was therefore dependent on empirical values and the temperature measuring points provided for normal operation. Although some measuring points indicated rising temperatures, the operator decided at 10:30 a.m. to continue heating the reactor. At 11:05 a.m. there was a sudden increase in temperature of 80 Kelvin, otherwise everything remained calm for the next one and a half days, although the graphite of the reactor core was probably already burning.

On October 9th at 10:15 p.m. the measured temperatures were still too high, some of them over 400 ° C.

On October 10 at 5:40 a.m., measuring devices on the chimney and on the premises indicated that the reactor was releasing radioactivity. The radiation from the 120 meter high exhaust chimney above the reactor rose sharply. In addition, the core temperature rose sharply. At first it was assumed that an isotope capsule filled with lithium and magnesium had ruptured and tried to locate the problem with a remote-controlled measuring device, the operating linkage of which had already jammed due to the heat.

Only at 3 p.m. did the operating team alert the factory management. Since no instructions were received by 4:30 p.m., a technician in a protective suit opened a shaft at the front of the reactor core and saw the red-hot fuel elements. It was clear that the reactor needed to be cooled. The fans could not be used for cooling, however, as they would have supplied the graphite fire with additional oxygen and released even more radioactive substances into the environment because of the fuel elements and isotope capsules damaged by the fire. Neither could water be used as it would react with the molten and burning uranium, the other metals, and the graphite to form hydrogen and ethyne , which would have caused an explosion . Therefore, after a tanker had arrived from the nearby Calder Hall nuclear power plant, attempts were made to extinguish the fire with 25 tons of liquid carbon dioxide , but this had no effect. At 8:30 p.m. it was observed through the inspection hatches in the roof of the reactor core that blue flames were shooting out of the core.

1300 ° C were reached on October 11 at 01:53 a.m. In the meantime, an alarm had been triggered on the factory premises. Although radioactivity had been released all day, the public was still not informed. Fortunately for the operators, the wind blew the radioactive cloud of 131 iodine , plutonium, cesium and strontium out onto the Irish Sea.

Despite the danger of an oxyhydrogen gas explosion that would have destroyed the entire reactor and released the radioactive material in the core over a large area, attempts were finally made on October 11 at 8:55 a.m. to fight the fire with water, but this did not bring the desired result. Through the inspection hatches, the technicians found that the water shot through the channels in the core without any effect. It was not until the water pressure was reduced at 9:56 a.m. that the water flowed into the core and cooled it down, but the resulting huge cloud of steam released further amounts of radioactivity. The fire did not go out until the air supply to the reactor was cut off at 10:10 a.m.

On October 12th at 3:10 p.m., the plant fire brigade cut off the water supply. A radioactive lake had gathered around the reactor from the 9,000 m³ of extinguishing water.

Release of radioactivity and deaths

The cloud released in the fire moved over Great Britain and from there to mainland Europe. During the fire there were two releases, first from the burning uranium and later from the water vapor during the extinguishing process.

However, the population was not warned until the day after the end of the fire, the milk was collected from 17 surrounding farms and dumped into the Irish Sea .

On October 12th, radioactive milk that exceeded a limit of 3,700 Bq per liter was also collected from an area of 500 km² and destroyed. Although milk more distant farms by 131 was contaminated iodine, it was sold and record of it held by the government under wraps to the people not to worry. A total of around 2 million liters of 131 iodine-contaminated milk were thrown into the sea.

According to the latest investigations, it is estimated that the fire caused, among other things, 900 to 3700 TBq 131 iodine, 280 to 6300 TBq 132 tellurium , 90 to 350 TBq 137 cesium , about 0.2 to 3.1 TBq 90 strontium and 14 to 110 TBq 210 Polonium and 8 to 80 PBq 133 Xenon were released.

The effects of the released radioactivity were so far only insufficiently known. A cautious British report from 1982 named at least 40 related deaths, while others of the more than 70 investigation reports named around 100 fatalities in the accident. Today's model calculations come to the conclusion that around 240 people died of lung cancer as a result of the accident at the time.

An even greater contamination was prevented by the physicist John Cockcroft's insistence, prior to putting Pile 1 into operation, that filters be installed on top of the chimneys, which many of the engineers at the time considered unnecessary (they even spoke of Cockcroft's foolishness , Cockcroft's follies ) .

closure

1958-1961

The area around Pile 1 was decontaminated and the intact fuel elements were removed from the core. As far as possible, the steering and control rods were inserted into the destroyed core and the additional equipment on the reactor removed. A 80 cm thick layer of concrete was placed over the mechanical feedthroughs in the radiation shield to seal the core. The roughly 20 percent of the core that was destroyed still contains about 6,700 fuel elements damaged by the fire and 1,700 isotope capsules. Furthermore, the fans and filters for air cooling were removed from buildings B3, B4, B13 and B14 and the air shafts to the reactors were bricked up.

For safety reasons, Pile 2 was taken out of service after the fire and the fuel elements were removed.

Until the mid-1980s, the still active core of Pile 1 was only monitored.

Phase 1

The planning of the first phase of dismantling began in the late 1980s and work began in 1993. The shielding around the reactor was sealed, the contaminated air intake and exhaust ducts closed and the water channels that transported the used elements to the cooling pool B29 were sealed. In addition, the radioactive sludge was removed from the water channels to the cooling pool, which were heavily contaminated by the fire. 210 old fuel elements were still found in the canals.

This phase was completed in 1999 so that the reactor core is now completely separated from the supply and exhaust air systems and the ducts to the cooling pool.

The exhaust chimney of Pile 2 has already been removed in the course of this work.

Phase 2

The original plan was to remove the remaining 13 tons of nuclear fuel from the reactor core between 2008 and 2012 . Then the reactor core itself should be dismantled and prepared for safe final disposal .

As part of the dismantling work, a new risk assessment of the existing risks was carried out. This risk assessment showed that a renewed criticality of the reactor core can be excluded. The risk of fire or a graphite dust explosion, which had been feared in previous investigations, does not appear to exist either. The dismantling of the reactor core was therefore postponed in order to initially concentrate on major risks on the site.

The final dismantling of the reactor is planned by around 2040.

Cultural adaptation

- Sarah Aspinall: Windscale: Britain's Biggest Nuclear Disaster . BBC , 2007 (documentary)

- In their song radio activity , the German music group Kraftwerk also mentions Sellafield as a metonym for the damaged nuclear power plant with the call to stop radioactivity .

See also

- Chernobyl disaster

- List of accidents in nuclear facilities

- List of accidents in European nuclear facilities

literature

- Lorna Arnold : Windscale 1957: Anatomy of a Nuclear Accident. Macmillan, London 2007, ISBN 0-230-57317-7 .

- Atomic Energy Research Establishment: An airborne radiometric survey of the Windscale area, October 19-22nd, 1957 (AERE reports; no.R2890)

- MJ Crick, GS Linsley: An assessment of the radiological impact of the Windscale reactor fire, October 1957 . In: International journal of radiation biology and related studies in physics, chemistry, and medicine 46 (5), Nov 1984, pp. 479-506 (first 1982 NRPB Reports).

- HJ Dunster, H Howells, WL Templeton: District surveys following the Windscale incident, October 1957 . In: Proceedings of the Second United Nations International Conference on the Peaceful Uses of Atomic Energy, Volume 18: Waste Treatment and Environmental Aspects of Atomic Energy (Geneva: United Nations), 1958, pp. 296-308. Reproduced in the Journal of Radiological Protection, Volume 27, Number 3, September 2007 . August. doi : 10.1088 / 0952-4746 / 27/3/001 .

- Paul Dwyer: Windscale: A nuclear disaster . BBC News, October 5, 2007.

- Rob Edwards: Windscale fallout blew right across Europe . In: New Scientist , October 6, 2007

- Marcus Franken, Manfred Kriener : Windscale burns! In October 1957, the atomic inferno threatened England's northwest coast. It is the first serious reactor accident in history. A protocol. In: The time . No. 41 , October 4, 2007, p. 92 (Zeitlaufte) ( Windscale burns! [Accessed December 12, 2012]).

- Fuller, John: We Almost Lost Detroit. Balantine - Random House, New York 1975, p. 79.

- JA Garland and R. Wakeford, Atmospheric emissions from the Windscale accident of October 1957 , In: Atmospheric Environment , Volume 41, Issue 18, June 2007, Pages 3904-3920. doi: 10.1016 / j.atmosenv.2006.12.049

- Walter C. Patterson: Chernobyl: worst but not first . In: Bulletin of the Atomic Scientists . August / September 1986

- United Kingdom Atomic Energy Authority: The deposition of strontium 89 and strontium 90 on agricultural land and their entry into milk after the reactor accident at Windscale in October, 1957 (AHSB)

- Richard Wakeford: The Windscale reactor accident — 50 years on . In: Journal of Radiological Protection, Volume 27, No. 3, September 2007 . Retrieved May 21, 2011.

Web links

- Safety and Dose Management During Decommissioning of a Fire Damaged Nuclear Reactor ( English , PDF; 66 kB) irpa.net. May 7, 2000. Retrieved May 21, 2011.

- THE 1957 WINDSCALE FIRE ( English ) lakestay.co.uk. Retrieved May 6, 2015.

- Windscale Britains Biggest Nuclear Disaster ( English ) Accessed April 15, 2018. BBC documentary by Paul Dwyer, 2007 on youtube

Individual evidence

- ↑ Windscale / Sellafield - a shining example of Great Britain . ask1.org. March 5, 2006. Archived from the original on March 18, 2011. Retrieved May 21, 2011.

- ^ William Penney et al. a., Report on the accident at Windscale No. 1 Pile on October 10, 1957, Journal of Radiological Protection, Volume 37, 2017, p. 791, after which a limit of 0.1 per liter was set. Values of 0.8 per liter were achieved.

- ↑ Atmospheric Environment, Vol. 41, p. 3904, 2007

- ↑ Duncan Leatherdale: Windscale Piles: Cockcroft's Follies Avoided Nuclear Disaster , BBC News, Dec. 4, 2014

- ↑ Nuclear Safety Advisory Committee Meeting of RG2 with Windscale Pile 1 Decommissioning Project Team ( English , PDF; 37 kB) hse.gov.uk. September 29, 2005. Retrieved October 10, 2017.

- ↑ Getting to the core issue ( English ) theengineer.co.uk. May 14, 2004. Retrieved October 10, 2017.

- ↑ THE UNITED KINGDOM'S FOURTH NATIONAL REPORT ON COMPLIANCE WITH THE OBLIGATIONS OF THE JOINT CONVENTION ON THE SAFETY OF SPENT FUEL MANAGEMENT AND ON THE SAFETY OF RADIOACTIVE WASTE MANAGEMENT ( English ) onr.org.uk. September 2011. Retrieved October 10, 2017., page 43, paragraph A.3.83.

- ↑ Nuclear Safety Advisory Committee Meeting of RG2 with Windscale Pile 1 Decommissioning Project Team ( English , PDF; 37 kB) hse.gov.uk. September 29, 2005. Retrieved October 10, 2017.

Coordinates: 54 ° 25 ′ 29.5 ″ N , 3 ° 30 ′ 0 ″ W.