Biogenic lubricant

A bio- lubricant (also called bio-oil ) is an environmentally friendly lubricant . Biodegradability is usually used as a criterion for environmental compatibility . The most common test method for this is the test according to OECD 301. This test is also required for the environmental labels relevant in this area ( Euromargerite , Blue Angel ).

Bio-lubricants are made from renewable raw materials or from mineral oil with heavy-metal-free additives. Mixtures of both raw material sources are also possible; most of the products on the market consist of such mixtures. Before the widespread use of coal and crude oil for the production of lubricants from the 19th century, only vegetable oils and animal fats were used for lubrication, for example in the storage of wheels on horse carts or at other mechanical friction points. There is also evidence of the use of vegetable lubricants in ancient Egypt to reduce the friction of the transport sled when transporting large stones.

There are also narrower definitions that only refer to products as bio-lubricants that consist of at least 50 percent renewable raw materials. Biogenic lubricants are also used in this context. Biolubricants can be used in all areas of application of lubricants and replace corresponding products based on petroleum , but have only a relatively small market share due to their often higher price and lower level of awareness.

Manufacture and composition

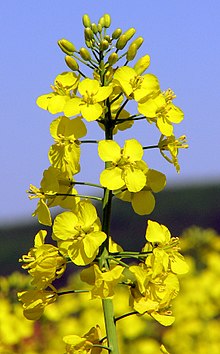

Biogenic lubricants can be made from various vegetable oils and animal fats (e.g. beef tallow ). In Germany, rapeseed oil is mainly used. In Germany, between 500 and 4,000 tons of oilseeds can be processed per day. This corresponds to a maximum annual production of around 6.5 to 8.8 million tons of vegetable oil per year. According to the Bavarian State Agency for Agriculture, 10.3 million tons of oilseeds were processed in 2007, the total production of vegetable oil was 3.5 million tons. The oil yield of the seeds averages 40 percent, the energy requirement around 1.7 Giga J per ton. In addition to this amount, larger amounts of palm , castor and soy are imported. The oils can be modified by transesterification and by adding various mineral oil components and additives according to their intended use.

The biogenic lubricants make up 46,500 tons of this amount. According to the Union for the Promotion of Oil and Protein Plants e. V. (UFOP) used around 90,000 hectares of the rapeseed area in 2005 to manufacture lubricants and chemical products such as surfactants for the detergent industry. Other oils that are frequently used are palm, soy, castor and sunflower oils . The oils are obtained in the conventional way in oil mills and processed in appropriate refineries , whereby, for cost and quality reasons, large-scale plants are used in which oils for biofuel production are also produced.

Mineral oil admixtures can occur in lubricants both for reasons of cost and due to special properties. Today, vegetable oils are only unable to replace mineral oils in very few properties. The technical necessity of admixing is accordingly only given in special cases in which application problems cannot be solved with the aid of other additives. An example of such a special case is provided by lubricants that are used in aircraft engines, in which mineral oil esters have to be added. These have to withstand operating temperatures of over 400 ° C and at the same time be compatible with various materials such as rubber, plastics and various metals. Further properties of these special mixtures are low viscosities at low temperatures, high shear stability and low susceptibility to oxidation .

Additives are additives that improve the physical or chemical properties of the oils or adapt them to the intended use. These include antioxidants , corrosion inhibitors , agents to increase performance under high pressure conditions, chelating ligands to bind metal ions, viscosity improvers, antifreeze agents, foam inhibitors and a number of other chemical agents. Lubricating greases also contain thickeners to give them a pasty consistency. Some additives contain heavy metals or other toxins and are therefore not environmentally friendly, which is why they are generally avoided in biogenic or biodegradable lubricants.

Benefits of biogenic lubricants

Theoretically, bio-lubricants can be used in all areas of application of lubricants and replace corresponding products based on petroleum . Depending on their composition, they are equivalent in terms of their properties and are inferior to mineral oil-based lubricants only in special applications and with extremely high temperature developments.

The main advantage over mineral oil-based oils is their applicability in environmentally sensitive areas. The equipment used here should, if possible, be biodegradable and not hazardous to water in order to avoid environmental pollution. According to Heinrich Theissen from the Institute for Fluid Power Drives and Controls at RWTH Aachen University , around 500,000 tonnes and thus around half of the lubricants used in Germany are released into the environment via evaporation, combustion and leaks.

Usage and market shares

The highest market share as saw chain oils (saw gate oils and saw chain adhesive oils) have the highest market share in forestry. The proportion of biogenic oils here is around 75 to 80%. Hydraulic oils also have a high proportion with 19% in mobile (vehicle) applications and 9% in stationary use. Cooling lubricants are 15% and general lubricating oils are 10%, while the proportions of gear oils and engine oils are each below 1%. The following table shows the annual quantities of lubricants used in Germany in 2005:

| Bio-lubricants and oils | Consumed) | Market share |

|---|---|---|

| Cooling lubricant | 11,800 | 15% |

| Hydraulic oils (mobile) | 11,000 | 19% |

| Hydraulic oils (stationary) | 9,000 | 9% |

| Saw chain oils | 6,200 | 75% |

| Loss lubricating oils and greases | 3,100 | 10% |

| Formwork oils | 2,500 | 8th % |

| Engine oils | 2,000 | <1% |

| Gear oils | 800 | <1% |

| Other oils | 100 |

Cooling lubricant

The largest amount of biolubricants is used as cooling lubricants or metalworking oils in the manufacturing industry. They make up 15% of the total. They are used in metal cutting such as turning , milling , drilling and grinding or in other metal working forms such as punching , pressing , deep drawing and wire drawing . In these processes, they are to the friction and thus heat generation between the workpiece and the tool reduce and tool material cool and, at the same time they provide for the removal of the chips. Bio-lubricants have no disadvantages compared to mineral oil-based lubricants with the exception of their higher price; For this reason, primarily mineral oil-based lubricants are currently used.

In Germany around 70,000 t of cooling lubricants are used annually, with the proportion of biogenic means increasing from 1 to 2% in 2003 to around 15% in 2005.

Hydraulic oils

In the case of hydraulic oils , market analyzes differentiate between mobile and stationary application areas, whereby mobile applications mean use in vehicles and stationary ones mean use in permanently installed systems. Biogenic hydraulic oils usually consist of rapeseed oil to which natural esters are added (Hydraulic Oil Environmental Triglyceride, HETG) and which is modified by transesterification (Hydraulic Oil Environmental Ester Synthetic, HEES). Compared to mineral oil-based hydraulic oils, HETG is biodegradable and is well suited for work vehicles with normal loads such as agricultural machinery ( combine harvesters , attachments ) or garbage trucks , but compared to HEES it has a lower tank temperature and resistance to cold. HEES can be used on heavier machinery, especially forest vehicles , excavators , bulldozers or earth drills .

The overall market for hydraulic oils represents the second largest area of lubricants after motor oils. In Germany, around 150,000 t are consumed annually, around 60,000 of which are used in mobile applications. The proportion of biogenic hydraulic oils has increased massively in recent years; in 2000 it was only around 3% and rose to almost 20% of the total market by 2005. One of the main reasons for this was the BMELV's market launch program for biogenic lubricants in agriculture, in which the switch to biogenic lubricants was specifically promoted.

Saw chain oils

Saw chain oil or saw chain adhesive oil and saw gate oil is used to reduce the friction between the saw chain and the bar in motorized chain saws and thus to reduce wear. The oil also acts as a release agent to prevent tree resin and sawdust from sticking to the saw chain. Modern saw chain oils are usually made on the basis of environmentally friendly, easily biodegradable and non-water-polluting vegetable oils (e.g. rapeseed or olive oils). These oils are marketed as "organic chain oil". The contact of such oils with human skin is also harmless to health. Already in 2003 80% of the saw chain adhesive oils and saw gate oils on the market were of biogenic origin and thus represent the only area of lubricants in which biogenic lubricants clearly outweigh mineral oil-based lubricants.

Loss lubricating oils and greases

Loss-lubricating oils and greases are used wherever friction reduction in open systems is the main focus. These are usually moving elements on vehicles such as agricultural and forestry machines, railways and their track systems or hydraulic engineering systems such as weirs and locks . All of these fats are removed and are released into the environment through abrasion, so biodegradability is advantageous here.

Around 36,000 tonnes of lubricating oils are used every year, whereby, due to the lack of reprocessing, particular attention should be paid to environmentally friendly degradation. Accordingly, the proportion of biogenic lubricants rose from just 0.9% (327 t) in 2003 to around 31,000 t and thus almost 10% in 2005.

Formwork oils

Formwork oils or mold release agents are mainly used to treat formwork . There it serves as a release agent so that the formwork can be removed easily and without damaging the concrete surface after the fresh concrete has hardened. Similar greases are used in the metal foundry to separate the metal and the mold during die casting. So far, mold release agents have only rarely been produced on a biogenic basis; mineral oil-based oils, which can also contain organic solvents, are the rule.

On German construction sites and in the manufacture of precast concrete parts, around 25,000 tons of formwork oil are used every year. At 2500 t, biogenic lubricants make up a share of 8 to 10%, but due to the demand for environmentally friendly oils, this share may increase significantly in the future.

Engine oils

Motor oils lubricate the moving parts of vehicle engines. There is a relatively large range of high-quality oils based on renewable raw materials for 2- and 4-stroke engines; these usually consist of synthetic esters based on vegetable oil. By doing without additives that are rich in zinc or phosphorus, you can also increase the durability of catalyst systems. Corresponding oils are being developed for diesel engines .

With around 50% of the total amount in Europe and around 32% in Germany, the total share of motor oils represents the largest single group of lubricants; the total amount has stagnated at around 344,000 tons per year since 2001. They are used in almost all cars and trucks . In 2003, the proportion of biogenic engine oils was only 0.02% and thus 61 t, although the oils have comparable properties. In 2005, the share was still well below one percent of the total market, but in terms of volume it had meanwhile reached 2000 t. The reason for the low share is likely to be the higher price and the fact that hardly any biodegradable oils are available for modern cars.

Gear oils

Gear oils lubricate the moving parts of the gearbox . Bio gear oils are mainly used in agricultural vehicles and their properties are comparable to oils based on mineral oil and can even exceed them due to their high viscosity .

In Germany, around 89,000 t of gear oil are consumed annually, with the proportion of biogenic oils at around 800 t, as with motor oils, being less than 1%.

Market situation and framework conditions

The EU- wide market potential for biogenic lubricants is forecast at 1.5 million tons per year, given a largely stagnating overall market for lubricants. Of these 1.5 million tons, only 0.1% are currently actually being used. The current market value of the lubricants sector is around 2.6 billion euros, of which around 21 million euros are attributable to the bio-lubricants sector. An increasing market share is forecast on the basis of higher raw material prices in the field of mineral oil-based lubricating oils and the further development of biogenic oil products. The main problems lie in the lack of knowledge about the properties and the lack of awareness of the presence of technically mature biogenic lubricants. An essential aspect is the prejudice that bio-oils are less efficient, as well as the fear of possible damage and malfunctions in the devices. Inadequate advice can lead to technical problems such as contamination with mineral oil or leaky hose lines, especially during the changeover and initial filling, and can permanently damage the image of bio-oils.

Biogenic lubricants only have a relatively small share of the overall lubricant industry market. The total German market for lubricants in 2003 was around 1.1 million tons (largely stagnating; 2007: 1,149,432 tons), of which, depending on the source, only 20,000 to 46,000 tons consisted partly of renewable raw materials. This amount varies in various studies due to the difficult basis for data collection, whereby Theissen only assumes around 20,000 t of biogenic lubricants per year in 2006 and relies on the data from the BMELV's market introduction program.

Due to increasing awareness as well as legal framework conditions such as the market launch program of the BMELV and regulations for the use of lubricating oil in environmentally sensitive areas, the share has increased in recent years. In Austria, 80,000 t of lubricating oils were used in 2005, of which around two thirds were hydraulic, engine and gear oils. Biogenic lubricants make up a share of around 5%, the potential is estimated to be around 15% of the total amount, which enables an increase of around 8,000 tons per year.

Due to the high cost of developing and marketing experience are especially large and medium-sized enterprises as the Fuchs Petrolub AG , the Interflon Germany GmbH the Panolin AG , the Kajo-Group and the Carl Bechem GmbH the market leader of the German Biolubricants and expand by biogenic lubricants their already existing product range. As a rule, the raw material producers are independent, agricultural operations that provide vegetable oil as a raw material for various uses (food industry, energetic and material uses) - plus international imports of palm and soybean oil.

Internationally, there is above all experience from Scandinavia and the Netherlands. The introduction of environmental labels such as the “Milieukeur” for hydraulic oils and loss lubricants in the Netherlands and the “Golden Swan” for environmentally friendly products in the countries of the Nordic Council had a positive influence on market development in these countries . In Sweden, there is also a positive list of environmentally friendly lubricating oils and the “Swedish Standard” label is awarded. In the EU, too, there is a transnational environmental seal with the Eco Label, which is awarded to lubricating oils with biogenic components (> 50% for hydraulic oils,> 45% for gear oils,> 70% for saw chain oils, concrete release agents and loss lubricating oils).

Individual evidence

- ^ Organization for Economic Co-operation and Development (OECD): OECD Guidelines for Testing of Chemicals 301: Ready Biodegradability.

- ↑ a b Heinrich Theissen: Vegetable oils and fats make you mobile. In: Agency for Renewable Raw Materials: 10 years Agency for Renewable Raw Materials - From research to the market. Agency for Renewable Resources 2004.

- ↑ S. Graser, N. Jack, S. Pantoulier (ed.) Agricultural markets 2007. Series of publications by the Bavarian State Agency for Agriculture 4/2008.

- ^ Union for the promotion of oil and protein plants e. V. (UFOP): Market information oilseeds and biofuels. May 2005 edition; quoted from Menred et al. 2006

- ↑ a b c d According to Lenz & Weber 2006

- ↑ a b Agency for Renewable Raw Materials e. V. (Ed.): Data and facts on renewable raw materials. Gülzow 2006; Page 57 ( PDF download )

- ↑ a b Christoph Strasser, Susanne Griesmayr, Manfred Wörgetter: nawaro: aktiv: Study on the greenhouse gas relevance of the material use of renewable raw materials. Final report. Published by the Austrian Bioenergy Center, 2006. ( PDF download ).

- ↑ Mineralölwirtschaftsverband e. V .: Official mineral oil data for Germany - December 2007 including correction 2006 ( download ( Memento from March 9, 2011 in the Internet Archive )).

- ^ Union for the promotion of oil and protein plants e. V. (UFOP): Renewable raw materials - biofuels & energy from biomass, excerpts from the 2004/2005 annual report.

- ↑ Heinrich Theissen: The market situation of biodegradable and biogenic lubricants in Germany 2006. Published by: Institute for fluid technology drives and controls (IFAS), Aachen 2006. ( PDF ).

literature

- Volker Lenz, Michael Weber: Lubricants and process materials . In: Market analysis of renewable raw materials. Fachagentur Nachwachsende Rohstoffe e. V., Gülzow 2006; Pages 239–261 ( PDF download )

- Klaus Menred, Thomas Decker, Andreas Gabriel, Sebastian Kilburg, Edmund Langer, Bettina Schmidt, Martin Zerhoch: "Industrial material use of renewable raw materials". Topic 4: "Products made from renewable raw materials - market, macroeconomic effects and consumer acceptance". Expert opinion on behalf of the German Bundestag Submitted to the Office for Technology Assessment at the German Bundestag (TAB), 2006.

- Keywords Lubricants and Lubricating Grease In: Hans Zoebelein (Ed.): Dictionary of Renewable Resources. 2nd edition, Wiley-VCH, Weinheim and New York 1996; Pages 176-178. ISBN 3-527-30114-3 .