Vegetable oils

Vegetable oils (or vegetable oils ) are made from oil plants derived fatty oils ( lipids ), unlike the essential oils that contain no fat and evaporate leaving a residue.

composition

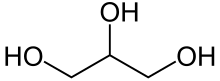

Vegetable oils are esters of glycerine (synonym: glycerol) with fatty acids, so-called triglycerides . Vegetable oils and fats consist of around 98% mixed triglycerides. Diglycerides are only contained in small amounts around 3%, monoglycerides only in traces (1%). The most important fatty acids for the structure are:

- Oleic acid C 17 H 33 COOH,

- Linoleic acid C 17 H 31 COOH and

- Linolenic acid C 17 H 29 COOH.

Vegetable oils contain different from animal oils and fats, no cholesterol , but instead, up to 65% linolenic acid and a lot of vitamin E . The distinction to the vegetable fats is the flowability , vegetable oils are liquid at room temperature (approx. 20 ° C).

Free fatty acids?

Contrary to popular belief, freshly obtained vegetable oils do not contain any free fatty acids ; the fatty acids are almost exclusively present as tri- or diesters of glycerine. Overlaid, spoiled, low quality vegetable oils often contain free fatty acids.

history

Vegetable oils have been part of human diet and culture for thousands of years. Poppy seed, canola , flaxseed , almond oil , sesame seeds, safflower and cottonseed been since at least the Bronze Age in the Middle East and Central Asia used. The Phoenicians brought in 2000 BC The olive tree from the Middle East to Greece . The Greeks then brought it to Italy, where it also played an important role with the Romans .

Economical meaning

According to the Food and Agriculture Organization of the United Nations (FAO), around 173 million tons of vegetable oils were produced worldwide in 2014 .

The following table gives an overview of the production of the 13 most important vegetable oils worldwide.

| rank | Vegetable oil | Quantity (in t ) |

|---|---|---|

| 1 | Palm oil | 57,328,872 |

| 2 | Soybean oil | 45,704,551 |

| 3 | Rapeseed oil | 25,944,831 |

| 4th | Sunflower oil | 15,848,036 |

| 5 | Palm kernel oil | 6,602,838 |

| 6th | Cottonseed oil | 5,036,141 |

| 7th | peanut oil | 5,031,479 |

| 8th | Corn oil | 3,189,137 |

| 9 | Coconut oil | 3,106,474 |

| 10 | olive oil | 3,050,390 |

| 11 | sesame oil | 1,634,327 |

| 12 | linseed oil | 686.498 |

| 13 | Safflower oil | 100,751 |

| total | 173.264.325 |

Manufacture and properties

For the production of vegetable oils, see oil mill .

The vegetable oils are obtained through various processes:

- Pressing ( cold pressing , hot pressing )

- Extraction with solvents ( hexane , petroleum ether ; previously benzene , gasoline, carbon disulfide, etc.)

- Extraction with supercritical fluids ( Supercritical Fluid Extraction = SFE) ( CO 2 )

- Support by microwaves or ultrasound is possible for all pressing and extraction processes.

- Cleaning / refining with alkalis

Vegetable oils often contain a higher proportion of unsaturated fatty acid residues than animal fats , which is why trans fatty acids can be formed when heated to a great extent .

The vegetable oils differ in a number of properties due to their different composition. These are determined with a series of parameters ( fat ratios ). Various contaminations are also measured.

Hardening and non-hardening oils

Hardening oils are often referred to as drying oils and occasionally as oxidizing , crosslinking or resinifying oils . The term “drying” does not mean evaporation, but the thickening (“resinification”) of the oil caused by oxidation with oxygen and subsequent polymerization ( crosslinking ) of the unsaturated fatty acids .

In connection with pigments , drying oils are used as oil paints and with the addition of resins as oil varnishes . Half oils and frequently also other oil paints are solvent added that dilute the oil and improve the processability. In this case, the evaporation of the solvent results in the physical drying of the paint in addition to the chemical crosslinking of the oil.

As the proportion of unsaturated fatty acid residues increases, a distinction is made between non- drying (e.g. olive oil) iodine number <100, semi-drying (e.g. soy or rapeseed oil) iodine number 100–170 and drying vegetable oils (e.g. linseed or poppy seed oil Iodine number> 170.

Drying oils harden completely. Depending on the layer thickness and the type of oil, the time it takes for it to harden is between a few hours, several months or years. Some oils, such as linseed oil, require a certain amount of light to harden. In complete exclusion of light, such as inside closed cupboards or in the rebates of windows and doors, the oil gels, but often does not harden completely.

Hardening oils are used in wood preservation and many other areas as binders for impregnation , painting media and other coatings as well as for putty , filler and plastics such as linoleum . Natural and artificial resins such as alkyd resin can usually be mixed with oils and oil paints in any ratio . Resins are sometimes referred to as modified oils .

In addition to linseed oil, which has been used in craftsmanship for centuries, many other oils are also used for wood treatment, which, such as wood oil and stand oil, offer better weather resistance or, such as walnut oil , soybean oil , sunflower oil and tall oil, dry more transparently and do not yellow as much as linseed oil.

The networking takes place in two phases. In the first stage, the oil absorbs a larger amount of oxygen and increases in volume. When storing hardening oils, there should only be a small volume of air in the container above the oil so that the oil does not gel due to the incipient crosslinking. In the second stage of crosslinking there is a decrease in volume. This can cause cracks in the paint layer.

Isolating oils

When it comes to drying oils, a distinction is made between isolating oils with isolated double bonds and conjuene oils with conjugated double bonds .

- Isolene oils: linseed oil , soybean oil , sunflower oil , safflower oil , rapeseed oil , fish oils ( Tran )

- Konjuenöle: tung oil , oiticica , castor oil , isomerized Isolenöle

- other oils: tall oil

Spread value

The spreading value describes the flow of an oil, it is especially important when mixing oils.

Quality features

At elevated temperatures and long storage times, the quality of vegetable oils decreases, some of the triglycerides decompose and “free fatty acids” are formed. This undesirable aging process can be measured by determining the acid number .

The quality of vegetable oils depends on both the method of production of the oil and the cultivation of the oleaginous fruits and seeds. The cultivation of the oil plants takes place either in conventional farming or in organic or organic farming . While chemical pesticides , mineral fertilizers and green genetic engineering are used in conventional farming , they are not used in organic farming.

Manufacturers use various organic seals to label oils that are made from organically grown fruits or seeds and to which no other additives or auxiliary materials have been added during processing . Refined oils do not meet these criteria.

With all unrefined oils, the quality of the raw material is decisive for taste, smell, color and vitamin content . With refined oils, these properties are reduced regardless of the quality of the raw material.

Refined oils

The oil is first hot-pressed at temperatures of over 100 ° C. With chemical or physical refining , valuable secondary plant substances, taste characteristics and the typical color are lost. The refined oil is largely tasteless, light in color, long-lasting and universally applicable.

Unrefined oils

The raw material is cold-pressed; a small amount of heat during the pressing up to approx. 60 ° C is possible. Some of these oils are steamed to increase their shelf life . In steaming, as in refining, undesirable accompanying substances are reduced.

Cold pressed oils

Cold-pressed oils are produced in mostly decentralized oil mills without the supply of heat, only through pressure or friction . The pressing is usually followed by a filtration . The oils contain all ingredients. These have a positive influence on quality criteria such as taste, smell, color and vitamin content.

Native oils

Native oils are natural and cold-pressed without additional heat. (with olive oil also virgin ) The cold pressing without heat avoids oxidation. The oil is filtered. Neither oil nor raw materials are pre- or post-treated, for example by refining, steaming or roasting the seeds. All ingredients are retained. The distinct fruit or seed taste, smell and intense color are characteristic.

Oils from peeled seeds

The seed is peeled off in peeling mills . The kernels are then processed into cold-pressed, native oil. Refining can be dispensed with. The oil obtained is a pure seed oil. As with the cold-pressed or native oils, the ingredients, flavors and vitamins are retained. The peeling reduces undesirable adverse effects on taste and cloudiness that emanate from the peel.

use

Vegetable oils are used in a variety of ways, including as

- Food , edible oil (e.g. salad oil, margarine )

- Cosmetics raw material

- Basic material for the chemical industry ( oleochemicals )

- Basic material for the production of oil paints and varnishes

- Biogenic lubricant

- Biofuel ( vegetable oil fuel or, after further processing, biodiesel or hydrogenated vegetable oil )

- Fuel in vegetable oil burners , vegetable oil stoves or oil lamps

- Medical

See also

literature

- Sabine Krist: Lexicon of vegetable fats and oils. 2nd edition, Springer, Vienna 2013, ISBN 978-3-7091-1004-1 .

- Sven Geitmann: Renewable energies and alternative fuels. 2nd edition, Hydrogeit, Kremmen 2005, ISBN 3-937863-05-2 .

Vegetable oils in the household

- Ruth von Braunschweig: vegetable oils. Over 50 strong helpers for enjoyment and skin care. 6th edition, Stadelmann, Wiggensbach 2018, ISBN 978-3-943793-68-0 .

- Anne Iburg: DuMont's little lexicon vinegar & oil. Origin, taste, use, recipes. Nebel (DuMont), Eggolsheim 2004, ISBN 3-89555-201-1 .

- Sabine Pohl: The Oil Book. Vegetable oils explained in a nutshell. 4th edition, Stadelmann, Wiggensbach 2015, ISBN 978-3-943793-45-1 .

- Helmut Göppel: Handbook of vegetable oils - for practice, wellness and medicine cabinet. Param, Ahlerstedt 2013, ISBN 978-3-88755-053-0 .

- Sabine Kirschner, Helmut Göppel: Handbook of vegetable oils. Param, Ahlerstedt 2014, ISBN 978-3-88755-714-0 .

Web links

- Physical properties of fats and oils (PDF; 157 kB), on dgfett.de, accessed on March 10, 2017.

- Fatty Acid Composition Of Some Major Oils on chempro.in, accessed March 12, 2017.

Individual evidence

- ↑ https://www.spektrum.de/lexikon/chemie/fette-und-fette-oele/3304 .

- ^ Alfred Thomas: Fats and Fatty Oils. In: Ullmann's Encyclopedia of Industrial Chemistry. Wiley, 2000, doi : 10.1002 / 14356007.a10_173 .

- ↑ a b Data> Crops processed. In: FAO production statistics for 2014. fao.org, accessed on February 24, 2019 .

- Jump up ↑ Gopinadhan Paliyath, Marica Bakovic, Kalidas Shetty: Functional Foods, Nutraceuticals and Degenerative Disease Prevention. Wiley-Blackwell, 2011, ISBN 978-0-470-96082-0 , Chapter 7.2.

- ↑ a b George Molinsk: Oil Wood: What you should know. In: dds specialist magazine for carpenters, joiners, window and interior fitters. Accessed May 2019 .

- ↑ Dr. Martin Pracher: Oil paint as an artist's medium , In. Kunst-Gutachter.de. Accessed August 2020

- ↑ Entry of oils to be dried. In: Römpp Online . Georg Thieme Verlag, accessed on May 30, 2014.