Biorefinery

A biorefinery is a refinery in which various intermediate and end products (e.g. chemicals , materials , bioenergy ) are sustainably produced from biomass while utilizing all raw material components as fully as possible . Food and feed can also be produced as by-products. An underlying holistic concept and the integration of various processes and technologies are important for a biorefinery .

Except for the raw materials, the principle of the biorefinery has many similarities with that of the petroleum refinery , in which the complex raw material petroleum is separated into individual fractions or components . In some cases, these are converted into other, more easily separable compounds by chemical processes.

An important goal of the “biorefinery” concept is to replace crude oil as an important raw material in the chemical industry in the long term and to move towards a bio-based industry. The United States Department of Energy identified industrial biorefineries as the most promising path to this goal.

The concept of the biorefinery with a holistic and high-quality use of biomass is currently still in development. However, this concept has already been implemented to some extent, e.g. B. in the production of sugar , bioethanol and biodiesel , where attempts are made to use high quality by- products or by- products .

Biomass as a raw material

The concept of a biorefinery depends largely on the raw material available. The main topics discussed are concepts that use wood, starch plants and other fresh or ensiled plants as a raw material basis.

Biomass is composed of numerous different organic compounds in very different proportions. Compounds that belong to the fats , carbohydrates or proteins (proteins) make up a large proportion of the mass . In addition, there are numerous other compounds, but they usually occur in smaller proportions, such as B. the secondary metabolites (or secondary plant substances ).

These proportions fluctuate depending on the biomass. Wood, for example, has a significantly different composition compared to starch plants (e.g. wheat , corn ), oil plants ( rapeseed , grass , soy ) or plant waste.

Basic principle

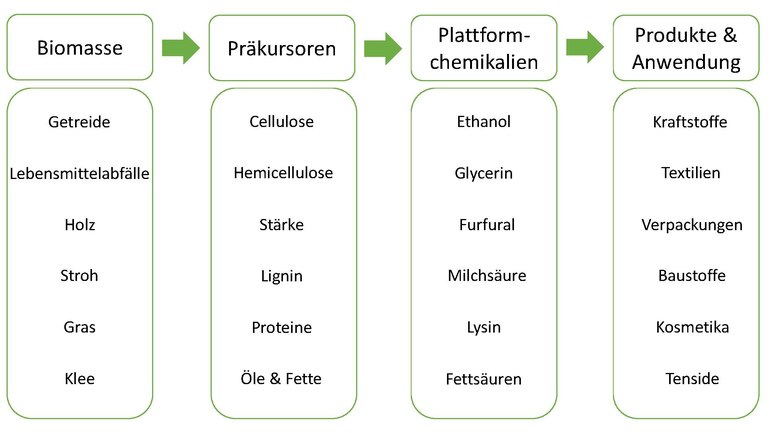

In a biorefinery, an attempt is made to isolate certain high-quality natural building blocks, the precursors, from the biomass. The synthesis input of nature is used either to replace costly, artificial manufacturing processes or to obtain complex compounds that cannot be artificially produced. These are further processed into platform chemicals, which serve as synthetic building blocks for a variety of higher-quality compounds. In this way, usable end products can be produced in several further stages.

From the remaining, unusable biomass z. B. food, feed, or less valuable chemicals can be obtained. After these materially usable parts have been obtained from the biomass, the remaining part can still be used for energy. It can e.g. B. Electricity and heat for the plant operation or for sale, or also biofuels or synthetic fuels ( BTL , methanol , biomethane etc.) can be generated.

In addition to the extraction of compounds that are present in the biomass, the generation of new compounds from the raw material is another field of activity within a biorefinery. Chemical processes, such as the production of synthetic fuels already mentioned, can be used here, but in particular also biotechnological approaches for the production of higher-quality compounds.

Stages of development

Biorefineries are divided into three different types depending on the diversity of raw materials, processes and main products:

| Refinery type | Diversity of raw materials |

Diversity of processes |

Diversity of products |

example |

|---|---|---|---|---|

| Phase I biorefinery | low | low | low | Biodiesel is produced from rapeseed oil through transesterification |

| Phase II biorefinery | low | high | high | Various starch products are made from grain through various processes |

| Phase III biorefinery | high | high | high | Various platform chemicals are produced from raw materials containing lignocellulose using various processes |

Unlike Phase I and Phase II biorefineries, Phase III biorefineries are not yet commercially implemented. The introduction is expected in Europe from 2020.

The four most common, discussed plant concepts for this are named after the respective raw material:

Phase III refineries

Lignocellulose biorefinery

A lignocellulosic biorefinery uses raw materials that contain lignocellulose - a structure made up of lignin , cellulose, and hemicellulose . This includes wood, but also straw and grass, as well as waste from the paper industry , such as. B. the lignin-rich black liquor , which occurs in large quantities , can be used.

Lignin mainly consists of derivatives of the aromatic compound phenol , which could be useful for the chemical industry.

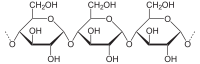

Cellulose is a polysaccharide (multiple sugar) made from the monomer glucose (a hexose ). This can lead to various basic chemicals, such as B. Ethanol and ethene as the starting product for the production of polyethylene (PE) and polyvinyl chloride (PVC) or to hydroxymethylfurfural as the starting product for the production of nylon , can be further processed. Glucose is also a substrate for biotechnological manufacturing processes through fermentation .

Hemicellulose is also a polysaccharide, but made up of different pentoses as a monomer. This can furfural - derivatives , nylon and other products are obtained.

The lignocellulose biorefinery is considered to be the most promising biorefinery. A major advantage is that it does not compete with food production , as only raw materials are used that are unsuitable for food.

Whole plant biorefinery

A whole plant biorefinery uses the whole crop , such as B. maize , wheat , rye , triticale etc. The plants essentially consist of the grain and the lignocellulose-rich straw, which are usually separated with a combine harvester during harvest .

The straw can be further processed in a lignocellulose biorefinery or converted into synthesis gas (syngas) by pyrolysis . This forms the basis for synthetic fuels such as biomass-to-liquid (BtL) or methanol .

The grain consists mainly of the glucose polymer starch , which can be further processed in a variety of ways. You can z. B. can be used directly as a raw material in the food or chemical industry. The production of bio-based plastics , such as B. thermoplastic starch and the use as a fermentation substrate are possible.

Green biorefinery

The green biorefinery uses plant material such as B. grass , clover , alfalfa or unripe ( green ) grain from agriculture. A major difference to the other two concepts is that the fresh plant is used, the ingredients of which are clearly different from wood or mature plants. The first processing step is to press the sap. The press cake mainly contains fibers (cellulose), as well as starch, dyes and pigments . Proteins, amino acids, organic acids etc. can be found in the pressed juice . B. products such as lactic acid , amino acids, ethanol etc. can be isolated. The press cake can be used as animal feed, to generate syngas and biogas or to obtain chemical compounds.

Examples

Green biorefinery demonstration plant in Utzenaich

In Austria, a green biorefinery was opened as a demonstration plant in May 2009. There is grass silage used to be derived from the amino acids and lactic acid. Fixed proportions are used to generate energy in a biogas plant. 4 tons of grass silage per hour or 100 liters of press juice can be processed per hour. 150 to 210 kg of lactic acid and 80 to 120 kg of crude protein (amino acids) can be obtained per ton of dry silage matter . The aim is to gain knowledge that supports the design of industrial plants.

Lignocellulose biorefinery pilot plant in Leuna

In one of the specialist agency for renewable raw materials e. V. coordinated project, process concepts for lignocellulose biorefineries have been developed since 2007. In a follow -up project, a first test facility is to be set up in Leuna (Saxony-Anhalt), which will process 1.25 t of wood every day. In the long term, plants with processing capacities of 400,000 t / a are considered possible.

Brensbach bio-value plant

The bio-value plant works with a principle based on the green biorefinery. Grass or grass silage is used as raw material. This is pressed and the liquid part is fermented in a biogas plant, which also supplies process energy and process heat. The press cake contains a high proportion of fibers, from which insulating materials or fibrous additives for plastic ( natural fiber-reinforced plastic ) are made.

Process and products

- (see also article refining , starch as a renewable raw material , sugar as a renewable raw material and renewable raw material )

A large number of processes are necessary in the biorefinery in order to process the raw material, to isolate certain fractions and to derive further connections with chemical, chemical-physical and biotechnological processes: In order for the biorefinery to work as sustainably as possible, methods of green chemistry should be used and their principles be respected.

- Processing z. B. by:

- Separating and isolating by (see also separation process (process engineering) ):

- Sieving and Filtration

- extraction

- Chromatography

- Etc.

With these processes, substances and compounds already present in the biomass can be obtained. The product range can be expanded significantly through chemical changes:

- Processing with chemical and chemical-physical processes:

- Pyrolysis for the production of synthesis gas

- Use of synthesis gas to synthesize new compounds, e.g. B. BtL and other hydrocarbons by Fischer-Tropsch synthesis

- Combustion to generate electricity and heat

- Chemical changes using biotechnological processes (see also biotechnology and white biotechnology ) :

- Use of the raw material or parts for fermentations , e.g. B. for the production of basic and fine chemicals , ethanol, biogas, raw materials for the production of bio-based plastics , vitamins , amino acids etc.

- Biocatalysis with isolated enzymes to modify certain compounds, e.g. B. with amylases for hydrolytic cleavage of starch to glucose

Health importance

In all of the refined vegetable oils are 3-MCPD-fatty acid ester to find, wherein the contents differ widely in part. In 2011, 3-MCPD was classified as a "possible human carcinogen " by the International Agency for Research on Cancer (IARC) .

perspective

According to a market study by Festel, in 2001 the share of biotechnologically produced chemicals was around 2.5% of the total market with US $ 30 billion. An increase of around 20% (US $ 310 billion with total sales of US $ 1,600 billion) was forecast by 2010. In 2007 the share was US $ 48 billion, which was 3.5%. The share of biotechnologically produced pharmaceuticals was 17% in 2010.

The development of the biorefinery has been intensively promoted in the USA in recent years. Around 360 million US dollars were invested in the promotion of biomass every year (2003: approx. 420 million US dollars, 2005: approx. 310 million US dollars). Experts there expect that by 2020 a quarter of the currently fossil-based organic raw materials and 10% of the oils and fuels will be produced using biorefinery technologies.

In the EU, a total of 74 million euros was invested in research into the use of biomass as part of the 6th Research Framework Program from mid-2002 to 2006. In the 7th Research Framework Program (2007-2013), the total annual budget was increased by 40%, so that an increase can also be expected for research into biomass use.

literature

- K. Arnold, D. Maga, U.Fritsche u. a .: BioCouple - Coupling of the material / energetic use of biomass - Analysis and evaluation of the concepts and the integration into existing provision and usage scenarios , final report from the Wuppertal Institute, Fraunhofer UMSICHT and Öko-Institut on the BMU-funded project FKZ no. 03 KB 006 AC, Wuppertal / Oberhausen / Darmstadt pdf file 6.5 MB .

- G. Festel et al .: The influence of biotechnology on production processes in the chemical industry , Chemie Ingenieur Technik 2004, 76, No. 3, pp. 307-312

- Biobased Industrial Products: Research and Commercialization Priorities (2000) Commission on Life Sciences (CLS). The text served as a technical template for the "Presidential Order" no .: 13101 for the launch of an R&D program of the same name in the USA up to 2010.

- B. Kamm, M. Kamm: Biorefinery-Systems, Chemical and Biochemical Engineering Quarterly 2004, 18 (1), pp. 1-6, pdf file .

- B. Kamm, P. Gruber, M. Kamm: Biorefineries - Industrial Processes and Products , Wiley-VCH, 2006, ISBN 978-3-527-31027-2 , comprehensive, two-volume work on the status quo and the future development of the biorefinery concept .

- A. Demirbas: Biorefineries. For Biomass Upgrading Facilities. Springer-Verlag, London 2010. ISBN 978-1-84882-720-2 .

Web links

- International Energy Agency (IEA) Bioenergy Task 42: Biorefineries .

- Fachagentur Nachwachsende Rohstoffe e. V. (FNR) , website of the specialist agency for renewable raw materials , publicly financed facility for research, development, market launch, public relations, etc. in the field of renewable raw materials, comprehensive information freely available as PDF or print versions

- MONITORING Industrial material use of renewable raw materials , monitoring of the office for technology assessment of the German Bundestag for "industrial material use of renewable raw materials"

- BIO-refined - useful things around the topic of biorefineries - forum of research institutions, interest groups and others, which wants to help the topics of biorefinery and white biotechnology to attract more attention

- biorefinica - conference and symposium network - conference and symposium network bio-based industrial products, processes and biorefineries, including presentations from various conferences

- FABRIK der Zukunft , Austrian, publicly funded project to support the development of sustainable technologies, such as B. Biorefineries; Current and background information on biorefineries

- Biorefineries are replacing petrochemicals , report from November 6th, 2009 on www. Pflanzenforschung.de, information portal of the Federal Ministry of Education and Research (BMBF)

- Chemicals from the biorefinery , comprehensive report in the Neue Zürcher Zeitung (NZZ), from November 21, 2007, available online

Individual evidence

- ↑ a b c d Arno Behr & Thomas Seidensticker: Introduction to the chemistry of renewable raw materials - occurrence, conversion, use Springer Spectrum, 2018, ISBN 978-3-662-55254-4 , pp. 340–351.

- ↑ Birgit Kamm: Biorefinery - Production of platform chemicals and synthesis gas from biomass. In: Angewandte Chemie , 139, 2007, pp. 5146-5149.

- ↑ Birgit Kamm: Biomass Economy and Biorefinery Systems. LIFIS ONLINE, 2008. / PDF ; Retrieved September 10, 2019. ISSN 1864-6972.

- ↑ a b c d e f Kamm, B. and Kamm. M .: Biorefinery-Systems (PDF; 200 kB), Chemical and Biochemical Engineering Quarterly 2004, 18 (1), pp. 1–6, English, accessed on February 28, 2010.

- ↑ a b Oliver Türk: Material use of renewable raw materials. Springer Vieweg, Wiesbaden, 2014, ISBN 978-3-8348-1763-1 , pp. 24–31.

- ↑ J. Michels, K. Wagemann: Lignin - key component in the lignocellulose biorefinery , Gülzower specialist talks, Volume 31: Material use of lignin , p. 170, conference on March 10, 2009, published on October 26, 2009, as a pdf.

- ↑ Fachagentur Nachwachsende Rohstoffe e. V: Biorefinery: Raw materials made from wood for the chemical industry ( Memento from February 11, 2013 in the web archive archive.today ), press release from July 5, 2007 on a three-year funding project, accessed on March 1, 2010.

- ↑ a b Brandenburg Environmental Reports (BUB): Grüne BioRaffinerie Brandenburg , B. Kamm et al., BUB 8 (2000) 260-269, ISSN 1434-2375, as pdf.

- ↑ a b World's first green biorefinery for grass silage opened. In: fabrikderzukunft.at. Retrieved March 1, 2010.

- ↑ a b Green biorefinery - processing and recycling of the grass fiber fraction. In: hilftwirtschaften.at. Reports from energy and environmental research (2006), accessed on March 1, 2010 (PDF; 1.1 MB).

- ↑ Fachagentur Nachwachsende Rohstoffe e. V .: New biorefinery could refine all wood components ( memento from February 11, 2013 in the web archive archive.today ), press release from November 4, 2009, accessed on March 1, 2010.

- ↑ Biowert GmbH: website of Biowert GmbH , accessed on 2 March of 2010.

- ↑ James H. Clark, Rafael Luque & Avtar S. Matharu: Green Chemistry, Biofuels and Biorefinery . In: Annual Review of Chemical and Biomolecular Engineering . tape 3 , 2012, p. 183-207 , doi : 10.1146 / annurev-chembioeng-062011-081014 .

- ↑ 3-MCPD esters in refined edible fats and oils - a newly recognized, worldwide problem. Chemical and Veterinary Investigation Office, Stuttgart, December 18, 2007.

- ↑ Federal Institute for Risk Assessment (BfR): Questions and answers on the contamination of food with 3-MCPD, 2-MCPD and glycidyl fatty acid esters . July 7, 2016, accessed July 8, 2016.

- ↑ a b Gunter Festel et al .: The influence of the biotechnology on production procedures in the chemical industry in: chemistry engineer technology in 2004, 76, No. 3, pp. 307-312.

- ↑ ec.europa.eu: Final Evaluation of the Lead Market Initiative - Final Report ( Memento of the original from February 22, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 3.3 MB) , July 2011, accessed December 25, 2011.

- ^ Biotechnology statistics 2010 .

- ^ EU research framework program: The German portal to the 7th EU research framework program , website of the Federal Ministry of Education and Research (BMBF), accessed on March 2, 2010.