Colored paper

As colored paper is paper referred to, which has been processed manually or by machine by means of different techniques. The English technical term is decorated paper . The term is also used colloquially for industrially produced monochrome craft paper. Colored paper is used for wrapping, gluing and lining objects and packaging or as an artistic requirement. Colored paper does not include construction paper and cardboard that are made from fabric dyed directly in the mass.

history

Japanese Suminagashi paper from the Heian period (794–1185) is the oldest surviving example of colored paper production. Poems were written on decorated paper. Marble paper was also used for calligraphy in Persia . The oldest known German colored paper (a single color coated paper) is dated to around 1430. Marbled paper got to know Europe around 1600 through Turkey , where it was called "Ebru". In Europe, this colored paper was still often called “Turkish marble” or “Turkish paper” after its introduction.

Techniques and varieties (selection)

When decorating paper, a number of techniques can be used and combined with one another. The brand names partly reflect these techniques (e.g. "model printing paper", "roller printing paper", "stencil spray paper"), partly they name the appearance of the surfaces or the decor (e.g. "wood grain paper", "moiré paper") , " Calfskin paper ") or refer to raw materials and pigments ("metal paper", "mica paper", "wool velor paper"). Attempts are made again and again to imitate the appearance of historical techniques using other, often cheaper, methods.

Solid color paper

The paint can be applied manually or by machine, tool marks are not visible. In industrial colored paper manufacture, the design of the paper surface is of particular importance. Single-colored glossy and ice-cream paper are types of colored paper, the surface of which is smoothed by calendering , brushing or processing with the agate stone . These surfaces are often refined with embossing plates and rollers to create relief paper.

Monochrome coated paper

Paint is applied over the entire surface with a brush. The traces of the brush bristles can be seen.

Paste paper

With paste paper , paste colors are made from starch paste and from water-soluble colorants and allow specific gradations of the color intensity . Brushes, paint brushes and sponges are mainly used to apply the paint. Veined paste paper is created, for example, by the so-called pull-off process, but also with various dabbing techniques. With stamps, rollers, rollers, wooden sticks, combs or even fingers, patterns can be imprinted into the still wet paint (paste paper with displacement decoration, sometimes also called “ Moravian-style paper ”).

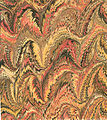

Marbled paper

With marbled paper or marble paper (historical names: "Tunk paper", "Turkish paper"), the color is first applied to the surface of water or a slime base made of carragheen moss or tragacanth , for example, by spraying or drops and using propellants that influence the surface tension and with the aid mechanical means (sticks, combs, etc.) distributed in the desired shape. The resulting carpet of color is then completely lifted off with a sheet of paper, whereby the pattern is transferred to the sheet in reverse. In Japanese Suminagashi paper, Indian ink is spread over water, with pine resin oil used as a propellant. In European marble paper, ox gall is often used as a propellant. In the case of marble paper, a distinction is made between a large number of patterns, which are only partially named after the shapes ("stone marble", "vein marble", "snail marble", "bouquet marble", "wave marble", "tiger eye marble"); other type names are "antique marble", "wall marble" etc. The term "marble" is not only applied to types that have been produced using the marbling process. This is historically proven and has also established itself internationally.

Printed paper

All printing techniques can in principle also be used to refine paper. Raised printing forms occur when high-pressure process , so any of these stamp paper, in Model printing paper and rolling paper with embossed printing plate used. In the gravure printing process , colored paper was produced as copperplate engraving or as roller printing paper with engraved rollers. The lithography gained under the surface printing method with lithographed paper for the bulk of the colored paper fabrication of the late 19th and early 20th century. Patterns, which in the past were often transferred onto the paper using stencils, are now often produced using screen printing . Paper colored using stencils is also historically referred to as "patronized paper". So-called "calico paper" is a special design form of model printing paper, in which models similar to those used for printing light cotton fabrics were used. "Domino animal paper" is similar in design to this and has the special feature that it was supplemented with hand-painted or hand-colored elements. Model printing paper is called " Rizzi paper " and was produced from around 1904 by Giuseppe Rizzi in Varese based on older Italian models.

Relief paper

A relief in the paper is created by embossing, the paper is deformed by means of a die . A patrix is mainly used in more modern embossing processes. Furthermore, a coating with noble metal or (more often) a striking metal can take place. Brocade paper belongs to this group. This could be embossed on monochrome or multi-colored paper. Multi-colored papers were designed with stencils (hist. "Cartridges").

Other typical examples are moiré patterns or special leather imitations, in which the embossing matrices are obtained by casting original leather samples.

Speckled paper

Sprinkle paper is the generic term for paper that is covered with mostly evenly distributed sprinkles of a similar size. Small (mostly black, rarely brown) splashes of paint on a beige painted background are characteristic of "lapwing paper", as their appearance is reminiscent of the birds' eggs. The combination of light and dark gray tones results in "granite paper". If you cover part of the ground with appropriately contoured stencils when spraying on or spraying on the paint, you can produce “stencil spray paper” with characteristic color gradients.

Batik paper

With batik paper, the pattern is created indirectly ( reserve technique). The areas where no color should be absorbed are covered by applying wax. After immersion in a dye bath and subsequent drying, the wax is removed by heat. As with the batik of textiles, patterns can also be achieved by tying them off ("plangi"). Some variants of the Japanese textile dyeing technique Shibori can also be carried out on suitable paper.

Manufacturer

Colored paper maker

Many of the artisanal colored paper makers in the early modern period are not known by name. However, many publishers of brocade paper have marked their products with an indication of the origin and order number. Brocade paper publishers include companies in Augsburg (Johann Georg Eder, Johann Christoph Ledergerber, Johann Christian Leopold , Abraham Mieser, Johann Carl Munck, Johann Michael Munck, Georg Christoph Stoy), Nuremberg (Georg Reimund, Georg Daniel Reimund, Johann Michael Reimund , Paul Reimund, Georg Nikolaus Renner) and Fürth (Johann Köchel). Even with model printing paper, e.g. B. French domino animal paper is often imprinted with an indication of the origin and order number. Since the end of the 19th century, a large number of artistically or traditionally handcrafted colored paper makers working in series production have been known. Even in the 21st century colored papers are handcrafted, for example by Gisela Reschke and Nedim Sönmez , on the one hand with artistic demands, on the other hand handcrafted colored papers are processed, for example for bookbinding.

Colored paper mills

In 1805, Gottfried Heinrich Wilisch (1771–1837) in Schneeberg took the first steps towards the production of colored paper on an industrial scale . In Aschaffenburg , the workshop of the Neuwied-born bookbinder Johann Daniel Knode, which was licensed in 1810, turned into the colored paper factory of the merchant and banker Alois Dessauer (1763-1850). A rapidly growing workforce - 50 (1815), 140 (1826), 200 (1832) - initially worked exclusively by hand. The sales took place not only within Europe, but also to South and North America and to Australia. Since 1843, not only sheets could be processed, but also paper in roll form. Roller printing paper was produced as cheap, mass-produced goods by both letterpress and gravure printing. Since 1856, brush coating machines have been used to produce single-color coated ice cream and chrome paper.

application areas

The areas of application for colored paper include book covers

- covering and decorating

- Folders and cardboard boxes

- Telescopes

- Musical instruments (e.g. bellows of hand-drawn instruments )

- Dollhouses

- the lining of

- Musical instruments (e.g. spinet )

- in modern times also design of art objects

Colored paper is used on the book as end paper and as cover paper. Marbling techniques can also be used to decorate the book cut .

Museums and collections

- Berlin, art library

- The Hague, Koninklijke Bibliotheek

- Düsseldorf, Goethe Museum (templates for island library )

- Gabriele Grünebaum Collection

- Kassel, Kassel State Museums, German Wallpaper Museum

- Leipzig, German Museum of Books and Writing (including parts from the Grünebaum Collection)

- London, British Library

- Munich, German Museum

- Nuremberg, Germanic National Museum

- Vienna, Museum of Applied Arts (Vienna)

Individual evidence

- ↑ Peter F. Tschudin: Grundzüge der Papiergeschichte , 2nd, additional edition. Hiersemann, Stuttgart 2012, pp. 223–232

- ↑ Richard J. Wolfe: Marbled paper: its history, techniques, and patterns; with special references to the relationship of marbling to bookbinding in Europe and the Western world . University of Pennsylvania Press, Philadelphia 1990

- ↑ André Jammes: paper dominotés ., 2010

- ↑ Dyed, combed, dipped, printed: the wonderful world of colored paper ; Catalog for the special exhibition in the Mainfränkisches Museum Würzburg October 22, 2011 to January 29, 2012, Frauke van der Wall (Ed.). Würzburg, 2011. ISBN 978-3-932461-29-3 , p. 42

- ^ Julia Rinck: Contemporary colored paper manufacturers. In: buntpapier.org. Accessed January 21, 2020 .

- ↑ Albert Stadelmann: The colored paper industry in Aschaffenburg , Würzburg, Univ., Diss., 1922, p. 23, or [1]

- ^ Frieder Schmidt: colored paper in the collections of the German Museum of Books and Writing. In: Dialogue with Libraries. H. 1, 2012, pp. 50-55 or online version .

- ↑ Olga Hirsch Collection of Decorated Papers online version ; Mirjam M. Foot: The Olga Hirsch Collection of Decorated Papers. In: British Library Journal. Vol. 7, 1981, N. 1, p. 12–38 or online version .

See also

literature

- Susanne Krause and Julia Rinck: colored paper - an identification book; Decorated Paper - A Guide Book; Sierpaper - Een gids . With the collaboration of Henk Pork, Frieder Schmidt and Ida Schrijver. 2nd, revised and expanded edition. Stuttgart 2016. ISBN 978-3-7762-0516-9 (1st edition 2009).

- André Jammes: Papiers dominotés: trait d'union entre l'imagerie populaire et les papiers peints (France, 1750 - 1820) , Paris 2010. ISBN 978-2-86742-176-1 , review: Wulf Dietrich von Lucius in Aus dem Antiquariat NF 9 (2011) No. 5, p. 242. * Ilona Hesse, Susanne Krause: About handmade colored paper. A summary , Hamburg 2007, ISBN 978-3-938423-15-8

- Marianne Moll: Old and New Colored Papers , Hamburg 2010, ISBN 978-3-938423-02-8

- Susanne Krause (ed.): Internationales Buntpapier , Hamburg 2007, ISBN 978-3-938423-20-2

- Susanne Krause: More paste paper , Hamburg 2006, ISBN 3-938423-07-2

- Traudel Hartel: Make colored paper yourself. Urania, Stuttgart 2004, ISBN 3-332-01547-8

- Gisela Reschke : Cloud paste, marble and brocade. Historical colored papers. Berlin State Library - Prussian Cultural Heritage, Berlin 1997

- Marie-Ange Doizy: De la dominoterie à la marbrure: histoire des techniques traditional de la décoration du papier. Art & Métiers du Livre Ed., Paris 1996, ISBN 2-911071-01-8

- Patty and Mimi Schleicher: Marbled Designs , Lark Books 1993, ISBN 0-937274-69-0

- Nedim Sönmez : Ebru. Marbled papers. Maier, Ravensburg 1992, ISBN 3-473-48104-1

- A Miura: the art of marbling. A guide to making marbled papers. Haupt, Bern, Stuttgart 1991.

- Anne Chambers: Marbled Paper. A practical guide. Haupt, Bern, Stuttgart 1988. ISBN 3-258-03961-5

- Gabriele Grünebaum: colored paper. History, manufacture, use. DuMont, Cologne 1982, ISBN 3-7701-1406-X

- Ernst Wolfgang Mick : Old colored paper. Harenberg Kommunikation, Dortmund 1979, ISBN 3-88379-140-7

- Albert Haemmerle : colored paper. Origin, history, techniques, relationships with art. 2nd Edition. Callwey, Munich 1977

- August Weichelt: Manufacture of colored paper. 3rd, arr. Edition. Verlag der Papier-Zeitung, Carl Hofmann, Berlin 1927.

- Josef Halfer: The progress of the art of marbling. 2., verb. u. probably edition. Wilhelm Leo, Stuttgart 1891

- Josef Phileas Boeck: The marble art. An instructional and manual for bookbinders, colored paper mills and related businesses. Unchangeable Reprint d. 2nd ed. [1896]. Schäfer, Hannover 1987, ISBN 3-88746-186-X

Web links

- buntpapier.org - Information and images on techniques, manufacturers of colored paper, forms of use and projects

- Working group colored paper

- Terminology colored paper

- Standard terms colored paper

- Types of colored paper in: Otto Lueger: Lexicon of all technology and its auxiliary sciences , Vol. 2 Stuttgart, Leipzig 1905., pp. 401–404.

- MATERIAL ARCHIVE: colored papers - extensive material information and pictures

- Julia Rinck: The paper garment of the book: colored papers in book design at the ZVAB , accessed on September 5, 2012