EMC test

EMC tests or EMC investigations have the purpose of characterizing the electromagnetic compatibility of an electrotechnical or electronic product or device. This includes examining the immunity of a device or system to external interference. EMC measurements are a sub-area of EMC testing that usually deals with the determination of interference emissions. Shielding attenuation measurements also fall within the scope of EMC measurements.

A distinction is made between conducted interference and interference from electrical and magnetic fields as well as radio waves (immunity and emission).

conditions

EMC tests follow different requirements for electrical or electronic systems. Influencing factors are the desired reliability for trouble-free operation, legal regulations, the expected interference environment or the required operational safety of a system. For example, higher reliability requirements are placed on aviation equipment than on entertainment electronics. There are different regulations depending on the area of application:

- Industrial technology

- Consumer electronics

- Automotive engineering

- Aerospace and military technology

- Medical technology

- Information technology

Just as different as the general EMC requirements of the industries are their special test and measurement methods, limit values, frequency ranges and other boundary conditions. Most EMC tests can be subdivided similar to the principles described below.

A general distinction is made between interference immunity tests (SF) and interference emission measurements (SA). Depending on the area of application, different limit values can be provided in product standards. The limit values specified in these standards for the electrical field strength of interference received or emitted through the air are the rms value of the electrical field.

Legal basis for product groups:

- ECE regulations No. 10 for vehicle EMC

- R & TTE (Radio Equipment and Telecommunications Terminal Equipment)

- Medical Devices Directive

- EMC directive for all other products

The respective tests can be differentiated according to the type of coupling or transmission path

- galvanic

- capacitive

- inductive

- about the electromagnetic field

The first three types of coupling deal with conducted or conducted interference, while the fourth transmission path takes place via an electromagnetic field ( radio wave ). This applies to the test procedures - in practice, conducted interference can of course also lead to radiation.

Another type of coupling that is not quite as common in EMC tests is shaft coupling .

In addition, there are options to carry out development-accompanying and qualitative EMC measurements using electrical or magnetic near-field probes . These relative measurements are used to identify possible problem areas as early as possible during product development and consequently to avoid problems in the subsequent EMC conformity tests.

Galvanically coupled tests

Testing the galvanically coupled interference is necessary to determine how immune equipment or systems are to interference on their connection lines (operating voltage, signal inputs and outputs) or how much such interference they generate on the lines. These measurements are often necessary as part of the CE marking.

The tests simulate supply voltage dips ( English voltage dips ), effects of switching noise ( English bursts ), electrostatic discharges (ESD) Coupling of interference from adjacent devices and lightning strikes in the vicinity ( English surges ).

The power supply and signal lines are measured in the conducted emission measurements. A network simulation is used for the power supply line and some signal lines - a device for mains supply with a defined source impedance that corresponds to the typical impedance of the power network or signal network. The network simulation has measurement outputs at which the interference signals are picked up and z. B. can be examined with a spectrum analyzer .

Capacitive coupled tests

SF: An interference signal is injected via a defined coupling capacitance. For this purpose, a conductive channel 1 m in length is often used, into which a lead from the test object is insulated. This device is called capacitive coupling path or capacitive coupling clamp, although its structure is not reminiscent of a clamp.

SA: The interference level decoupled via a defined coupling capacitance is measured (e.g. also contained in a network simulation).

Inductively coupled tests

At least one current coupling clamp is placed around the wiring harness or individual lines of the test item. The current coupling clamp is mostly used in the frequency range 1 MHz to 400 MHz, sometimes also below 1 MHz to 2 GHz.

SF: The magnetic field of the coupling clamp impresses a high-frequency current in the wiring harness. Usually, a second coupling clamp is used as a current measuring clamp to check whether the high-frequency current applied by the first coupling clamp has reached the desired size at the measurement location of the cable harness (setpoint / actual value comparison). The device under test must function in spite of the high-frequency current. The common name of this measurement method is BCI , English Bulk Current Injection , current injection into the cable harness .

There is also the variant of impressing a single pulse with a certain repetition frequency instead of a high-frequency current.

SA: The magnetic fields that form around the cable harness of the test object are converted into current and measured by the coupling clamp (clamp meter).

Radiation Coupled Tests

These measurements take place in the area of the far field where the physical distance between the test object and the measuring antenna has already significantly exceeded the effective range of the capacitive and inductive coupling, i.e. H. all measurable effects are based on the effects of electromagnetic fields in space.

Radiation-coupled tests can take place in different measurement and test environments. Among the known environments include, for example, the open area test site , the absorber chamber , the screen chamber , the GTEM cell , the TEM cell and the reverberation chamber .

Antenna measurement

The best known form is that of antenna measurement, i. H. An antenna is positioned at a defined distance from the test item (usually 1, 3 or 10 meters). The frequency range to be tested extends from 30 megahertz to 1 ... 18 gigahertz for civil applications in Europe . The antennas used differ depending on the frequency range.

Different measuring stations are suitable for measuring the interference field strength. Historically the oldest is the open area test site (OATS ). It is assumed here that the external radiation is small enough not to significantly influence the measurement and that no undesired reflections of the interference radiation of the test object occur, which, depending on the phase position, superimpose or cancel the direct interference radiation. The floor between the test object and the antenna is covered with a fully reflective metal plate and the antenna is height adjustable.

In order to be even more independent of the weather and external disturbances, absorber rooms (English anechoic chamber ) are usually used today.

The tests are often very time-consuming because the measurements, which are already long due to the short frequency steps and the holding time, often have to be carried out with different antenna polarizations , antenna heights ( elevation ) and different angles of rotation of the test object ( azimuth ).

SF: During the immunity test, a defined field strength is generated at the location of the test item or its cable harness (if available). The test item must prove that its function is given in spite of the applied HF field.

SA: In the case of emitted interference, the interference field strengths emitted by the test item and, if applicable, the cable harness (if present) are measured.

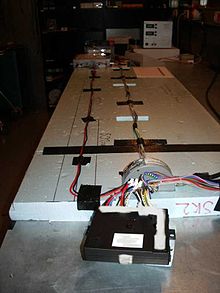

Stripline

The stripline , English stripline , is in the design as a component stripline good for measurements on devices with wiring harnesses, as here, an EMC perspective mostly exists a vulnerability. The strip line is preferably used in the lower frequency range up to a few hundred megahertz, designs with higher impedances (90 Ω, 120 Ω) also up to 1 GHz and more.

SF: A high frequency is fed into the strip-shaped conductor (septum). Is thereby formed between strip conductors and the underlying ground plane (English ground plane a defined homogeneous RF field). The field homogeneity decreases with increasing frequency, which is also dependent on the impedance of the stripline. The impedance in turn depends on the distance between the ground plane and the septum and the width of the septum. The HF is applied to the wiring harness and device to be tested. The device must work under the influence of HF.

SA: The device to be tested is put into the operating state that allows the highest level of interference to be expected. At the feed point of the stripline it is measured which interference radiation is generated by the device.

TEM cell

The TEM cell ( TEM = T ransversal E lektro M agnetic wave) is a widened line portion of a coaxial conductor with two coaxial connectors, can propagate in the transversely electromagnetic waves. The expansion is so large that a test or measurement object can be introduced into the expanded volume. When measuring radiated emissions, the fields radiated by the object to be measured couple directly into the TEM mode of the TEM cell and are typically measured at one of the two coaxial ports of the TEM cell. In immunity tests, the test item is also placed in the test volume of the TEM cell. A TEM wave is applied to the test volume and the immunity of the test object is recorded. As a rule of thumb, the dimensions of the test object or test object should not be more than a third of the distance between the inner and outer conductors. According to the intended use, there are different types of TEM cells on the market, which geometrically in cross section can differ greatly from the above description. A flat, wide inner conductor surrounded by a square outer conductor is common. The dimensions are chosen so that the line impedance is 50 ohms. The field wave resistance of the TEM wave is 377 ohms. The usable frequency range of a TEM cell depends on its size. The larger the usable test volume, the lower the maximum permissible frequency. For example, TEM cells for tests on ICs or circuit boards have a usable frequency range of 0 Hz to 2,500 MHz, while with larger test objects and correspondingly larger TEM cells, the maximum frequency can be only a few 100 MHz.

GTEM cell

The areas of application of the GTEM cell ( GTEM = G igahertz T ransversal E lektro M agnetic wave) correspond closely to those of the TEM cell. The GTEM cell is a further development of the TEM cell. It has an extended, usable frequency range up to over one gigahertz and, depending on the design and septum height, can accommodate larger test objects. The GTEM cell can completely replace SF and SA measurements with antennas in an absorber hall. For large test items in large GTEM cells, for. B. higher modes stimulated by the test object or the expansion of the cell, as in a waveguide , which limit the field homogeneity and the usable upper frequency range. Compared to antennas, this is not a general disadvantage of the GTEM cell. Antennas also generate a restricted, homogeneous field at short test distances.

SF and SA: see stripline

Surveillance, monitoring and protection

EMC measurements in a laboratory environment

EMC measurements are almost always carried out in shielded and partially absorbing HF chambers in order to prevent

- During SF tests, the high field strengths generated in the HF chamber are released into the environment

- With SA tests from outside, the fields of the environment (radio transmitters, radio interference) penetrate inwards and falsify the measurement result there

- People in the vicinity of the test item could be endangered by the HF field ( EMVU )

- People in the vicinity of the test object falsify the measurement result through their presence (consistency of the human body)

Due to their principle, these HF chambers cannot be seen from the outside due to their good shielding, so that direct optical and acoustic monitoring of the test object is usually not possible. Input and output signals between the interior and exterior are carefully filtered and grounded, as otherwise the shielding level of the HF chamber would be considerably reduced.

Often, as many supply sources as possible as well as input and output signals are accommodated within the RF chamber. Digital signals ( CAN bus , LIN bus Ethernet, etc.) for communication are partially routed to the outside via fiber optic cables , as signal filtering is not possible. This ensures communication (sending commands, receiving feedback) between the test item in the chamber and monitoring outside the chamber without interference.

EMC measurements in the operating environment

The real electromagnetic conditions are determined with EMC measurements on site (factory hall, home area, surroundings of transmission systems). This may be necessary for various reasons, e.g. B .:

- Size of the test item

- Analysis of the quality of the mains voltage

- Checking the radio coverage

- Analysis of radio interference

- Proof of compliance with the regulation on electromagnetic fields . ( EMVU )

For these EMC measurements, measuring equipment corresponding to the frequency range to be examined and the interference emission (e.g. conducted, radiated etc.) is used, as is also used in EMC laboratories.

See also

- Interference immunity and emitted interference

- Radio interference suppression

- Shielding attenuation

- High frequency and high frequency technology

- Antenna technology and field strength

- Frequency band

- EMVU

- Measurement of electromagnetic fields EMF measurement

literature

- Adolf Schwab, Wolfgang Kürner: Electromagnetic Compatibility . 5th edition. Springer, Berlin / Heidelberg / New York 2007, ISBN 978-3-540-42004-0 .

- Georg Durcansky: EMC-compliant device design . Franzis, Poing 1995, ISBN 3-7723-5386-X .

- Lamedschwandner, Preineder, Pühringer: The new EMC generic standard series EN 61000-6 transitional period expired on July 1, 2004 . In: D&V Compendium. The annual reference book for electronics development . Publish Industry Verlag, September 2004, ISSN 1861-8545 , p. 260-263 .

Web links

- EMF monitoring / EMF database Online research by the Federal Network Agency of series of measurements and fixed radio systems

- Possibilities for accelerating the field strength measurement Technical article EMC Kompendium 2003 (PDF file, German; 324 kB)

- EMC test system of the European Space Agency ESA

Individual evidence

- ↑ List of harmonized European standards ( Memento of the original from November 5, 2012 in the Internet Archive ) Info: The archive link was automatically inserted and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Tabular overview of basic EMC standards (PDF; 55 kB)

- ↑ http://www.atlasce.com/specific_obj_detail.aspx?obj_objid=4 ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Regulation No. 10 of the United Nations Economic Commission for Europe (UN / ECE) - Uniform conditions for the approval of vehicles with regard to electromagnetic compatibility in accordance with Regulation (EU) No. 407/2011 of the Commission of April 27, 2011 amending the regulation (EC) No. 661/2009 of the European Parliament and of the Council with regard to the inclusion of certain UN / ECE regulations for the purposes of type approval of motor vehicles, motor vehicle trailers and of systems, components and independent technical units for these vehicles

- ↑ Directive 99/5 / EC (PDF)

- ↑ Directive 93/42 / EEC (PDF)

- ↑ Directive 2004/108 / EC (PDF)