Ferrites

Ferrites are electrically poorly or non-electrically conductive ferrimagnetic ceramic materials made of the iron oxide hematite ( Fe 2 O 3 ), more rarely of magnetite (Fe 3 O 4 ) and of other metal oxides . Depending on the composition, ferrites are magnetically hard or magnetically soft .

Basics

Ferrites are soft or hard magnetic ferrimagnetic , mostly ceramic materials made of iron (III) oxide ( hematite , Fe 2 O 3 ) or magnetite (Fe 3 O 4 ) and metal oxides - or metal carbonates as additives that determine the later properties of the respective Material are.

The chemical composition of ferrites can be described by the general formula MeO • Fe 2 O 3 = MeFe 2 O 4 , where Me for soft magnetic ferrites for the metals nickel (Ni), zinc (Zn), manganese (Mn), cobalt (Co ), Copper (Cu), magnesium (Mg) or cadmium (Cd), for hard magnetic ferrites it stands for barium (Ba), strontium (Sr) or cobalt (Co). In a ferrite there are about four oxygen atoms for every three metal. The metals and oxygen form a cubic crystal system within which the alloy components are embedded. The crystal systems then grow into grains of different sizes. Since the outer boundaries of the grains are made of non-conductive Fe 2 O 4 , they are electrically isolated from one another. This is particularly important for soft magnetic ferrites because it makes the ferrite material practically non-conductive and magnetic cores can therefore be produced with extremely low core losses .

Ferrimagnetism differs from ferromagnetism in the antiparallel, but quantitatively unevenly distributed magnetic order of the elementary magnets in the Weiss domains . The spins of paramagnetic ions that are oppositely aligned due to superexchange are only partially compensated for. The magnetizations of two neighboring elementary magnets therefore only partially cancel each other out. The macroscopic behavior is thus a weaker form of ferromagnetism, which explains the comparatively low saturation induction of ferrites.

properties

A distinction is made between soft magnetic and hard magnetic ferrites. Soft magnetic ferrites have as low a coercive field strength as possible , hard magnetic ferrites as high as possible. Whether a magnetic material is rather soft or hard magnetic can be determined using its hysteresis curve . For magnetically soft ferrites, the aim is to make (re-) magnetizability as easy as possible, which corresponds to a narrow hysteresis curve.

Soft magnetic ferrites

Soft magnetic ferrites are used in electrical engineering as magnetic cores in transformers , switched-mode power supplies , chokes and in coils . In the unsaturated case, a high magnetic conductivity (permeability) is possible.

Since they are hardly electrically conductive and therefore almost no eddy current losses occur, they are also suitable for high frequencies up to a few megahertz . Special ferrites suitable for microwaves consist of spinels and grenades .

The usual soft magnetic ferrite materials are:

- Manganese - zinc ferrite (MnZn) in the composition Mn a Zn (1-a) Fe 2 O 4

- Nickel- zinc ferrites (NiZn) in the composition Ni a Zn (1-a) Fe 2 O 4

Compared to NiZn, MnZn has a higher permeability and higher saturation magnetization. The electrical conductivity of NiZn is lower than MnZn, which is why NiZn is suitable for higher frequencies.

Hard magnetic ferrites

Hard magnetic ferrites are used as inexpensive permanent magnets, for example in loudspeakers . Compared to rare earth magnets , they have a smaller coercive field strength and smaller remanent flux density and thus have a significantly lower magnetic energy density . The usual hard magnetic ferrite materials are:

- Strontium ferrites in the composition SrFe 12 O 19

- Barium ferrites with the composition BaFe 12 O 19

- Cobalt ferrites in the composition CoFe 2 O 4

Barium ferrites are comparatively robust and insensitive to humidity .

Manufacturing

Soft magnetic ferrites

The starting materials for the production of magnetically soft ferrites are finely ground iron-oxygen compounds such as iron (III) oxide or hematite. These iron oxides are commonly known as rust. Finely ground metal oxides or metal carbonates are also added as additives. These powder materials are mixed with one another as evenly as possible either dry or in a water bath. The mixture is then subjected to a chemical process called calcination at around 1000 ° C. This process is out of date known as “pre-sintering” . During the calcination process, the oxygen or carbonate compounds are partially decomposed and the aggregates are stored in the cubic crystal system of the iron oxide. After calcination, the resulting powder is mixed again with water and a binder and ground into fine grains of the same size as possible with grain sizes of about 1 to 2 µm. These grains form the respective elementary magnets of the later material.

After the powder has dried, it is pressed into the desired shape using high and uniform pressure. The blanks are then sintered in a specially adapted atmosphere at 1000 to 1450 ° C. During the sintering, the volume of the core shrinks by about 40 to 50%. The chemical composition and above all the molecular structure of the pre-sintered product and the sintered product, a soft magnetic ceramic ferrite, differ greatly.

Ferrite cores that have an air gap must be precisely reground for dimensional accuracy. To maintain the insulation voltage and dielectric strength of the winding wire if the wire insulation is damaged, the ceramic ferrite cores are usually coated with a suitable insulation (parylene, epoxy resin or polyurethane). Ceramic ferrites are, like all ceramic materials, hard and brittle and therefore prone to breakage.

Another possibility to produce a soft magnetic ferrite is to mix the ground grains with a thermoplastic composite material and to bring this mass into a desired shape by means of an injection molding process. This can take place without sintering, ie without shrinkage, as a result of which very tight mechanical tolerances can be achieved. Subsequent processing with the usual methods for plastics is possible. The so-called "Plastoferrite" are produced as coil carriers, multi-hole cores and in the form of housings, plugs and foils. Typical application examples for plastoferrites are, in addition to their use as magnetic cores for inductivities, shields, interference suppression chokes and flexible antennas.

Hard magnetic ferrites

The starting products for the production of hard magnetic ferrites are also finely ground iron-oxygen compounds such as iron (III) oxide or hematite. This powder is mixed with finely ground barium , strontium or cobalt carbonate and then subjected to the calcination process described above. The reaction product is then ground as finely as possible (single-range particles, white areas , grain size 1 to 2 μm), shaped into pellets, dried and sintered. The compacts can be shaped in an external magnetic field, with the grains (preferably single-range particles) being brought into a preferred orientation ( anisotropy ).

For small, geometrically simple shapes, so-called “dry pressing” can also be used to shape workpieces; Here, the strong tendency to (re) agglomeration of the smallest particles (1 to 2 µm) is the cause of mostly poorer magnetic characteristics compared to the “wet” pressed parts. Pressed bodies formed directly from the starting materials can indeed be calcined and sintered in concert, but the magnetic properties of products manufactured in this way are very poor.

Hard magnetic ferrite base materials can also be mixed with a thermoplastic composite material and brought into the desired shape using an injection molding process. Plastomagnets are made as strips, plates, rings and hollow shapes. The best known application for plastoferrite are the magnetic strips in refrigerator seals.

history

The German chemist Siegfried Hilpert made the first research into the magnetic properties of oxides . In 1908, he described in a patent various magnetic oxides with electrically insulating properties for use as a magnetic core material. As a composition of such alloys he suggested M 2+ OFe 2 3+ O 3 , where “M” stands for various divalent metals such as Mn, Cu, Co, Zn, Ni and Mg. Because of the high losses of these experimental alloys at the time, this development was not pursued any further.

The sintering conditions and the post-treatment methods are decisive for the electrical and magnetic properties of the materials. The necessary fundamentals for the spinel crystal structure were described in 1915 by WH Bragg and K. Nishikawa

In 1930, T. Takei and Y. Kato at the Tokyo Institute of Technology in Sendai , Japan , synthesized the first ferrite alloys with zinc and iron. In 1932 the Japanese patent PAT-98844 was granted for this. In 1936 these scientists also developed the soft magnetic Si-Al-Fe metal powder Sendust as an alternative to permalloy in coils for telephone networks. To commercialize these materials, Kato and Katei founded TDK Corporation in 1935 . TDK began in 1937 with the mass production of magnetic cores and ferrite cores for coils in receiver circuits. The Japanese inventions were only used in Japan until the end of the war.

At the beginning of the 1940s, JLSnoek began researching copper-zinc ferrites at the Philips Natuurkundig Laboratorium after he had previously been able to significantly improve soft magnetic alloys. His first attempts resulted in a ferrite material with a high quality and a permeability of 10. Snoek recognized that these values could be improved considerably by changing the manufacturing processes and the basic components. In particular, this concerned the core losses at higher frequencies. The introduction of non-magnetic FeZn compounds into the magnetic spinel structure of magnetite from 1940 was the basic invention for the later soft magnetic ferrite cores.

The work of Snoek inspired the French researcher Louis Néel . After his fundamental discoveries in the field of antiferromagnetism and ferromagnetism in the mid-1940s, he formulated his theory of ferrimagnetism in 1948 . Neel was awarded for his work on magnetism, important insights in the solid state physics have led, in 1970 the physics - Nobel Prize .

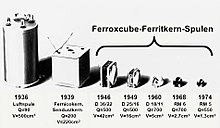

Snoek's research group developed a total of four different types of ferrites: CuFe ferrites, MnZn ferrites, Mg-Zn ferrites and NiZn ferrites. They were marketed by Philips under the trade name "Ferroxcube" (Fe = iron, ox = oxide, cube = cubic crystal structure). The first industrial breakthrough came in 1946 with an application in the telecommunications sector. The somewhat difficult situation after World War II with patent rights for ferrite inventions led in 1947 to an agreement between Philips and the American Western Electric in the form of a cross agreement, which was very successful for both parties.

The increasing demand for radio and later television sets accelerated the development of soft magnetic ferrites to ever new, application-specific properties. The first examples are the yoke rings in the deflection units of TV sets and the transformers for switched-mode power supplies. In the years 1960 to 2000 new types of ferrite were developed. Materials with a permeability of up to 30,000 and for applications up to 10 MHz have been developed. New developments in the field of nano-technology open up new perspectives, so that it seems that soft magnetic ferrites will also play an important role in the future.

The development of magnetically hard ferrites began with an unwanted mix-up. In 1950, while searching for a new semiconductor material, an assistant at the Philips Physics Laboratory made a mistake while preparing a sample of hexagonal lanthanum ferrite using barium . During his investigation, the good hard magnetic properties were discovered and the material was further developed into barium hexaferrite (BaFe 12 O 19 ). On the one hand, the material has a high coercive field strength and, on the other hand, is inexpensive. It was marketed under the trade name "Ferroxdure" from 1952 and quickly found its way into loudspeakers as a permanent magnet.

In the 1960s, Philips developed strontium hexaferrite (SrFe 12 O 19 ) with better properties than barium hexaferrite. Barium and strontium hexaferrite still dominate the market today because of their low cost. However, other materials with improved properties have been found. BaFe 2 + 2Fe 3 + 16O 27 came in 1980 and Ba 2 ZnFe 18 O 23 came in 1991.

application areas

Application For materials magnetic ferrite mainly in electrical engineering .

Soft magnetic ferrites:

- Ferrite cores in coils ( ferrite antennas ), chokes and transformers

- To change the cable properties , see Coiled cable

- in high frequency technology (HF) and antenna construction , e.g. B. Cores in baluns and circulators in diplexers , as well as in variable attenuators or absorbers .

- Pulse transmitters and signal transmitters for high frequencies, e.g. B. in baluns

- Magnetic heads in tape recorders ( erase heads ), video recorders, computer hard drives and floppy disk drives

- For sealing microwave devices (ferrite absorbs the electromagnetic waves emerging from the cooking space and thus prevents emissions to the outside)

- Stealth technology for camouflage (ferrite absorbs radar - waves )

A wide variety of designs are produced depending on the application:

Toroidal cores (picture) , rod cores, so-called bobbin cores, pot cores, E and U cores (in combination with similar or with I cores). The letter identification is based on the shape. Most of the mass ferrites are now manufactured in Asia. Enormous production capacities have been built up in China for several years.

Hard magnetic ferrites:

- Magnetizable coating on audio and video tapes (but not ceramic bonded here)

- Core memory in computers with magnetic rings threaded onto copper wires (outdated today)

- Permanent magnets of all kinds, e.g. B. Magnet segments in permanent magnetically excited electric motors in loudspeakers

- Composite materials (compounds) made Hartferritpulvern and thermal or thermosets , either injection molded , extruded or calendered be. In most injection-molded workpieces made from hard ferrite compounds, an external magnetic field is applied after injection into the tool in order to improve the magnetic characteristics. In the case of calendered, and sometimes also of extruded compounds, the alignment ideally takes place mechanically, whereby the platelet shape of the hard ferrite grains is used. Hard ferrite powder for injection-moldable compounds, on the other hand, should have grains that are as round as possible, since they should still be able to rotate in the very tough (highly viscous) plastic matrix when aligned in the external magnetic field.

literature

- S. Krupicka: Physics of Ferrites Vieweg Verlag Braunschweig, 1973, ISBN 3-528-0-8312-3 .

- J. Smit, HPJ Wijn: Ferrite Philips Technical Library - NV Philips´ Gloeilampenfabrieken, Eindhoven (Netherlands), 1962, without ISBN.

- W. Kampczyk, E. Roß: Ferrite cores Siemens Fachbuch Verlag, Munich 1978, ISBN 3-8009-1254-6 .

- Richard P. Feynman, Robert B. Leighton, Matthew Sands: Lectures on Physics. 3rd edition, Oldenbourg Verlag, Munich Vienna, 2001, ISBN 3-486-25589-4 .

- Hans Fischer: Materials in electrical engineering. 2nd edition, Carl Hanser Verlag, Munich Vienna, 1982 ISBN 3-446-13553-7

Web links

Individual evidence

- ↑ G. Bieser, Ferrites make furore, Bild der Wissenschaft, September 1, 1997 [1]

- ↑ Ekbert Hering, Karl-Heinz Modler (ed.): Basic knowledge of the engineer . Fachbuchverlag Leipzig, Munich 2007, ISBN 978-3-446-22814-6 .

- ↑ University of Freiburg, Lecture Metals [2]

- ↑ Synthesis and Magnetic Properties of Cobalt Ferrite (CoFe2O4) . arxiv : cond-mat / 0606631 .

- ↑ a b Soft Ferrites, A User's Guide PDF

- ↑ Magnetics, Learn More about Ferrite Cores PDF

- ↑ Neosid, Part 1, Introduction, General PDF ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ S. Hilpert, Genetic and constitutive relationships in the magnetic properties of ferrites and iron oxides. Chem. Ber. 42 (1909) 2248-2261

- ↑ a b c T. Stijntjes, B. van Loon, Scanning Our Past From The Netherlands, Early Investigations on Ferrite Magnetic Materials by JL Snoek and Colleagues of the Philips Research Laboratories Eindhoven, Proceedings of the IEEE, Vol.96, No.5 , May2008 [3]

- ↑ L. Jaswal, B. Singh, Ferrite materials: A Chronological Review Journal of Integrated Science & Technology, 2014, 2 (2), 69-71, [4]

- ↑ Marc de Vries, 80 Years of Research at the Philips Natuurkundig Laboratorium (1914-1994), p. 95, Amsterdam University Press, 2005 ISBN 9085550513 .

- ^ R. Gerber, CD Wright, G. Asti, Applied Magnetism, p. 335, Springer, 2013 ISBN 9401582637

- ↑ FK Lotgering, PHGM Vromans, MAH Huyberts, "Permanent magnet material obtained by sintering the hexagonal ferrite W = BaFe2Fe16O27", Journal of Applied Physics, vol. 51, pp. 5913-5918, 1980

- ^ Raul Valenzuela, Magnetic Ceramics, p. 76-77, Cambridge University Press, 2005 ISBN 0521018439 .