Meltdown

1. 2B connection

2. 1A connection

3. cavity

4. loose fragments of the core

5. crust

6. molten material

7. fragments in lower chamber

8. possible uranium-depleted region

9. destroyed passage

10. perforated shield

11th layer of molten material on surfaces of the bypass channels

12. Damage to the upper grille

A core meltdown is a serious accident in a nuclear reactor in which some (“partial core meltdown”) or all of the fuel rods overheat and melt. All power reactor types whose reactor core contains metal parts such as fuel rod cladding tubes are affected by the risk of a core meltdown .

A core meltdown can occur if the reactor cooling system and any emergency cooling system fail. The decay heat - it is inevitable after the nuclear fission has been interrupted - then causes the fuel elements to heat up and melt and the melted material ( corium ) converges at the bottom of the reactor.

If the reactor vessel is destroyed in such an accident, highly radioactive material can enter the environment in an uncontrolled manner and endanger people and the environment - an accident known as a worst-case scenario .

Causation and process

Accidents

A core meltdown can occur if the thermal output generated by the fuel rods can no longer be dissipated via the cooling and emergency cooling systems. The prerequisite for this is either a failure of the cooling systems or an overload due to an incident that could not be intercepted by a reactor shutdown .

Even if the reactor was switched off due to excessive heat output or a cooling failure, the risk of a core meltdown is not eliminated. During the operation of the reactor, approx. 6.5% of the output results from the radioactive decay of the fission products ( decay heat ). A reactor with an electrical output of 1300 MW generates almost 4000 MW of thermal output; about 260 MW of this power comes from the decay heat. The decay heat only decreases gradually after the reactor has been switched off. After one hour it is still approx. 1.6% of the heat output in normal operation (65 MW), one day after switching off it is still 0.8% (32 MW), and several months after switching off it is still approx. 0.1% of the output (4 MW). This service must be transferred. If this does not succeed, the reactor core continues to heat up until it finally melts. The core meltdown can hardly be avoided without cooling.

Example: Core meltdown due to cooling failure in a light water reactor

If the cooling fails (e.g. failure of the emergency power supply during a power failure in the public grid with the reactor switched off and failure of the two independent power supply units), the following scenario can occur:

Overpressure

In the event of a cooling failure, the heat generated in the reactor core can no longer be transported away. Even if it is possible to shut down the reactor, the decay heat is sufficient to strongly heat the reactor core.

- If the temperature in the reactor core rises above the normal operating temperature , the pressure in the reactor pressure vessel rises . This pressure increase can reach values that endanger the stability of the reactor pressure vessel. To prevent bursting, pressure must be released into the surrounding containment . Since the heat production from the decomposition of the fission products continues, critical pressures are repeatedly reached in the reactor pressure vessel, so that pressure has to be released into the containment again and again.

- This increases the pressure in the containment. If the pressure is released from the reactor pressure vessel several times, critical pressure values can arise in the containment, which endanger the stability of the containment. This means that pressure must also be released from the containment. Depending on the type of reactor construction, the pressure is released either into a surrounding reactor building or directly into the atmosphere ( venting ).

- Cooling water is lost when the pressure is released from the reactor pressure vessel ( venting ). If it is not possible to replenish the cooling water, the level of the coolant in the reactor pressure vessel drops. This can ultimately lead to the fuel rods no longer being completely covered with water, so that the upper region of the fuel rods protrudes from the cooling water and is only surrounded by water vapor. Water vapor dissipates heat much worse than liquid water. The fuel rods thus heat up particularly strongly in this area.

Formation of hydrogen

- If temperatures of over 900 ° C are reached in the exposed fuel rod areas, the strength of the fuel rod cladding tubes decreases. The fuel rods begin to burst. Gaseous and volatile radioactive fission products escape from the fuel rods into the reactor pressure vessel. If pressure has to be released from the reactor pressure vessel and from the containment, more radioactive substances are released into the environment.

- The cladding tubes of the fuel rods are made of a zirconium alloy . At temperatures above 1000 ° C, the zirconium reacts with the surrounding water vapor. It is formed of zirconium oxide and hydrogen . This chemical reaction is exothermic , which means that it releases additional energy that heats the fuel rods. As the temperature rises, the reaction increases in strength, and hydrogen production increases.

- The additional heating of the steam and the formation of hydrogen increase the pressure in the reactor pressure vessel. In order not to damage the reactor pressure vessel, this overpressure must be released into the containment. Because of the bursting of the fuel rods, the concentration of gaseous and highly volatile fission products in the cooling water has risen and the radioactive contamination in the containment rises when the pressure is released.

- By releasing hydrogen-containing water vapor into the containment, an ignitable oxyhydrogen gas mixture can form from the hydrogen and the oxygen present in the containment . If there is an explosion of this oxyhydrogen gas mixture, not only the containment but also the reactor pressure vessel can be damaged. For this reason, the containment of some reactor types is filled with an oxygen-free protective gas. Even if an oxyhydrogen explosion in the containment can be avoided, releasing the hydrogen-containing vapor increases the pressure in the containment, so that critical pressure values can be reached.

- If the overpressure is released from the containment, the radioactive pollution of the environment increases on the one hand, since more radioactive substances enter the containment due to the bursting fuel rods. On the other hand, outside the containment, the hydrogen comes into contact with the oxygen in the air. This can lead to the formation of an explosive oxyhydrogen gas mixture and hydrogen explosions.

Destruction of the fuel elements

- If the temperature of the exposed fuel rod ends continues to rise, the fuel rods burst to a greater extent from 1170 ° C. The release of fission products into the reactor core increases. Likewise, the formation of hydrogen on the cladding tubes of the fuel rods intensifies with increasing temperatures; from temperatures of 1270 ° C it becomes relatively strong, with the result that steam containing hydrogen and fission product has to be discharged into the containment more frequently because the reaction the fuel rod cladding generates additional heat with the water vapor, the heating of the fuel rods accelerates.

- The control rods begin to melt at temperatures between 1210 ° C and 1450 ° C. Neutrons can no longer be intercepted here. A chain reaction only takes place because the water has evaporated in these areas and there is no longer any moderator .

If it were now possible to feed more water back into the reactor pressure vessel , it would be essential to ensure that this water is mixed with sufficient neutron-intercepting substances such as boron . Because the water fed in would again make a moderator available, but because of the melted control rods there would no longer be a neutron absorber . Without the addition of boron, the chain reaction would begin in an uncontrolled manner , with the risk that the reactor core would be more severely damaged or even destroyed.

If liquid water is still present in the lower area of the reactor core, the control rod melt solidifies again here. - The cladding tubes of the fuel rods begin to melt at temperatures of approx. 1750 ° C. The nuclear fuel pellets located inside the fuel rod tubes can then become free and move downward with the molten fuel rod cladding. If the molten fuel rod material comes into cooler areas, e.g. B. in the water still present below, it can solidify again.

- From temperatures of approx. 2250 ° C, the structures of the fuel elements are destroyed, fuel pellets, melted cladding tubes and all other fuel element materials are no longer stable and fall down. These fuel element debris collect on still stable fuel element parts that are still in the water, or they fall right down to the bottom of the reactor pressure vessel. Nuclear fuel thus collects in the lower part of the reactor pressure vessel, where u. U. there is still water.

Partial meltdown

- The piles of debris consisting of fuel pellets, molten fuel rod cladding and other fuel assembly materials can lie on top of still undestroyed fuel assembly parts, debris can fall between the fuel rods or collect at the bottom of the reactor pressure vessel.

Since these debris hinder the flow of cooling liquid, the fuel pellets inside the piles of debris are cooled much worse than in intact fuel assemblies. The heat that is generated by the decomposition of the fission products can hardly be dissipated, the mountains of rubble heat up further inside. - If temperatures of over 2850 ° C are reached, the fuel pellets begin to melt. A core meltdown forms. If there is still water in the lower area of the reactor pressure vessel or if it is possible to feed water back into the reactor pressure vessel, the melting of the fuel elements can initially be limited to the area of the reactor core that protrudes from the water. A partial core meltdown occurs. The molten material forms a molten lump which is heated inside by the decomposition of the fission products and which can only be cooled from the outside via its surface.

- The heat output generated by such a molten lump depends on how big the molten lump is, i.e. the amount of decomposing fission products it contains. The heat output generated also depends on the time elapsed between the shutdown of the reactor and the formation of the melt. The heat output generated decreases with increasing time.

The heat output given off by a melt lump depends on the size of the surface of the melt lump, it depends on the quality of the heat transfer at the surface of the melt lump and on the temperature at the surface of the melt lump.

A state of equilibrium is created between the heat output generated inside and the heat output on the surface. A poor heat transfer on the surface of the lump means that a relatively high surface temperature is required in order to dissipate the generated heat output via the surface. With good heat transfer, such as. B. on the border with liquid water, a relatively low surface temperature is sufficient to give off the generated heat output. If the surface temperature is below the melting temperature, the surface of the lump remains solid and the lump remains stable. Is the heat transfer poor, such as B. at the border to air or water vapor, the surface temperature must be relatively high in order to dissipate the heat output. If the melting temperature on the surface is exceeded, the lump is liquid overall and moves downwards. - If it is possible to feed in water after the formation of a partial core melt and thereby cool the melt to such an extent that it solidifies on the surface, the spread of the core melt is initially stopped. Inside, however, the molten lump remains liquid. This cooling must be maintained for months, at least until the thermal output generated by the decomposition of the fission products has decreased so far that the melt lump remains solid even without effective cooling. However, if the effectiveness of the cooling drops or if the cooling is interrupted, the surface of the melt lump becomes liquid again and the lump moves further down.

- The same processes take place on the surface of a cooled partial core melt as on overheated fuel rods. If surface temperatures of 900 ° C are exceeded, the zirconium and water vapor present in the melt form hydrogen, which must be drained off. There is again the risk of oxyhydrogen explosions.

- If it is not possible to cool a partial core melt sufficiently, the melt moves downwards. If the melt meets the water that is still present, this evaporates to a greater extent. The core meltdown affects ever larger areas of the reactor core, the size of the melt lump grows. With increasing size, the amount of heat-generating fission products increases, the heat output generated increases proportionally to the volume. However, the surface of the melt lump does not grow to the same extent, that is, the power generated per surface increases, the surface temperature of the melt lump increases. In order to stop the spread of the melt, that is, to lower the surface temperature below the melting point, ever greater cooling efforts are required. In the case of very large molten lumps, it can happen in extreme cases that the generated heat output becomes so great that the surface temperature exceeds the melting point even under water, so that the molten lump would also be liquid under water.

Complete meltdown

- If the entire fuel element material is affected by the core meltdown, it is referred to as a complete core meltdown. The molten material then collects on the bottom of the reactor pressure vessel. Melting through of the reactor pressure vessel can only be prevented if it is cooled from the outside, e.g. B. by flooding the surrounding containment .

- If cooling measures for the reactor pressure vessel are not successful, the core meltdown can melt the wall of the reactor pressure vessel and flow under the reactor pressure vessel onto the inner concrete layer of the containment. The behavior in concrete depends heavily on whether the concrete is integrated into the melt or not.

If the concrete is melted and the melted concrete combines with the melt, this increases the size of the melt lump and the size of its surface without increasing the heat output generated. This lowers the surface temperature. If the concrete layer is sufficiently thick, the size of the lump could grow to such an extent that the surface falls below the melting temperature. The melt would have stopped.

But if the molten concrete does not bond with the fuel rod melt, e.g. B. by floating as "slag" on the fuel rod melt, then the size of the lump to be considered remains unchanged, the surface temperature of the lump does not change. The melt would continue to move down through the concrete. The molten lump would cross the concrete foundation, and all radioactive substances contained in it would end up in the ground. - Possibilities to stop such a melt would be:

- Surface enlargements (e.g. over shallow tubs into which such a lump pours) ( core catcher ). By increasing the surface, the surface temperature can be reduced; in the case of a good case, the melting point would be below the surface and the melt would solidify on the surface.

- Divide into as many small melt lumps as possible. This also increases the surface area. The surface temperature drops, ideally below the melting point.

consequences

A particularly serious variant of the course of the accident is the high pressure core meltdown . This occurs - due to the higher system pressure, especially in pressurized water reactors - if it is not possible to lower the pressure in the reactor sharply at first. The red-hot melt of the reactor core can then severely weaken the wall of the reactor vessel and escape from the reactor vessel with a simultaneous, also explosive pressure increase, for example accompanied by an oxyhydrogen gas explosion . The high pressure generated in the containment can lead to leaks, which means that radioactive material can get into the environment. Corresponding scenarios were published in 1989 in the "German Risk Study Nuclear Power Plants Phase B" and led to extensive discussions (see article on nuclear power plants ). To reduce the risk of an explosion, z. In German pressurized water reactors, for example, the previously only passively responsive reactor pressure relief valves are replaced by controllable ones from the control room, so that very high pressures in the reactor system should be controlled and degraded in good time.

In order to prevent the containment from failing even at lower pressures, the so-called Wallmann valve was prescribed in many places , with which gas and steam can be filtered and released into the atmosphere. To avoid oxyhydrogen explosions, German NPPs must also be equipped with facilities for hydrogen degradation; These either cause a controlled combustion (deflagration) by igniter (" potter candles ") or the recombination of hydrogen and oxygen to form water by means of catalysts .

The mentioned side effects of the core meltdown, such as steam and hydrogen explosions, typically, but not necessarily, occur in a core meltdown.

Even without an explosion, the regular cooling devices are likely to be rendered unusable by a melt. Since further heating threatens to melt through the outer protective container, the melted core must be temporarily cooled under all circumstances in order to avoid serious damage to people and the environment. This cooling may be necessary for months until the remaining decay heat no longer causes a significant increase in temperature.

According to a study by the Max Planck Institute for Chemistry from 2012, the risk of core meltdowns such as in Chernobyl and Fukushima in the 440 nuclear reactors is significantly higher than previously estimated. These can occur once in 10 to 20 years, 200 times more often than assumed in US estimates in 1990.

Avoidance of core meltdowns

Because of the devastating potential consequences of a core meltdown, the operation of inherently safe reactors, especially decentralized high-temperature reactors (HTR) with reduced power, is now being tested , especially in Asia . Critics of HTR technology point out that HTR-specific types of accidents such as water or air ingress can lead to catastrophic radioactivity releases and that there is no inherent safety despite the avoidance of core meltdowns. For all commercial nuclear reactors currently in operation in Europe, the risk of a core meltdown can be significantly reduced by additional safety measures, but cannot be excluded in principle.

In newer reactor designs, special devices, so-called core catchers , are intended to catch the reactor core in the event of a core meltdown, prevent the release of the fission material inventory and thus contain the consequences of a core meltdown. In addition, the containment of pressurized water reactors of the third generation (e.g. European pressurized water reactor ) with a wall thickness of 2.6 m are designed to protect against hydrogen explosions. The weak point in these concepts is the above. High pressure core meltdown, in which a spontaneous failure of the pressure vessel could lead to the destruction of all barriers.

List of known core meltdown accidents

Accidents with core meltdown are listed on the International Assessment Scale for Nuclear Events (INES) from level 4.

Total meltdown

In the case of a total core meltdown, the reactor core is completely destroyed and the reactor is so badly damaged that repair is impossible.

- On April 26, 1986, a catastrophic reactor accident occurred in the graphite-moderated pressure tube reactor of reactor block 4 of the Chernobyl nuclear power plant (then in the Soviet Union , since the dissolution of the Soviet Union in 1991 in Ukraine ) . As a result of an uncontrolled increase in output to more than a hundred times the nominal output, there was a total core meltdown and a hydrogen explosion within the reactor core . During the graphite fire that followed, large amounts of radioactive substances were released. This disaster is rated at INES 7 on the International Nuclear Event Rating Scale and is considered the worst nuclear accident in history. The impact was so severe because the reactor is not a safety container equipped (containment).

Partial meltdowns

In the event of a partial core meltdown, the reactor core remains partially intact. Individual fuel rods or entire fuel assemblies melt or are severely damaged by overheating. Most plants are shut down after such an accident (especially older nuclear reactors); some have been repaired and continued to operate in the past.

- On December 12, 1952, the 25 MW nuclear reactor at Chalk River Laboratories in Ontario, Canada, melted .

- On October 10, 1957, the graphite moderator of one of the two reactors used for plutonium production caught fire in the British Windscale . It damaged fuel elements and contributed to spreading the radioactive substances released (for example 131 iodine, 132 tellurium , 137 cesium , 90 strontium , 210 polonium and 133 xenon (→ Windscale fire )) in the atmosphere.

The accident was classified as INES 5 and as a result both reactors were shut down. - On July 26, 1959, a 30 percent core meltdown occurred in the Santa Susana Field Laboratory (USA) due to a clogged cooling duct. Most of the fission products could be filtered off, but large amounts of iodine 131 were released .

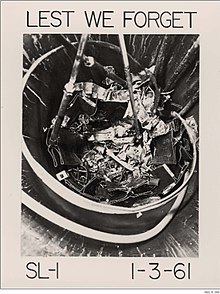

- On January 3, 1961, the military research reactor SL-1 (Stationary Low-Power Reactor Number One), Idaho Falls, USA, by manually pulling a control rod, briefly increased its power to around 20 GW, which melted parts of the core within a few milliseconds. The reactor was designed for a thermal output of 3 MW. The operating team was killed in the accident and the reactor destroyed.

- In February 1965 there was a loss of coolant accident on the nuclear icebreaker Lenin . After the shutdown to replace the fuel elements, the coolant of the second reactor was drained off before the fuel elements were removed , presumably due to an oversight by the operator . Some fuel rods melted due to the decay heat generated in them ; others deformed.

- On October 5, 1966, the prototype of the fast breeder Enrico Fermi 1 (65 MW) in Michigan (USA) suffered a core meltdown in some parts of the reactor core due to a fragment in the cooling circuit. The reactor was repaired, continued to operate and shut down in November 1972.

- On January 21, 1969, there was a serious accident in the Swiss underground experimental nuclear power plant Lucens (8 MW el ). A failure of the cooling system due to corrosion led to core meltdown and fuel element fire with subsequent release from the reactor tank. The radioactivity was essentially restricted to the cavern and the surrounding tunnel system. The reactor was shut down in 1969. The clean-up work in the sealed tunnel lasted until 1973. In 2003, the waste containers were removed from the site.

- On October 17, 1969, shortly after the reactor was put into operation, 50 kg of fuel melted in the gas-cooled graphite reactor of the French nuclear power plant Saint-Laurent A1 (450 MW el ). The reactor was then shut down in 1969. The current reactors of the nuclear power plant are pressurized water reactors .

- On February 22, 1977, some fuel elements melted in the Bohunice A1 (150 MW el ) nuclear power plant in Slovakia due to incorrect loading. The reactor hall was radioactively contaminated. The reactor was not restarted and officially shut down in 1979.

- In 1977 half of the fuel elements in Unit 2 of the Russian Belojarsk nuclear power plant melted . The repairs took a year and Unit 2 was shut down in 1990.

- In March 1979, a pump failed in the non-nuclear part of the reactor block 2 of the Three Mile Island nuclear power plant (880 MW el ) near Harrisburg (Pennsylvania) . Since the failure of the emergency cooling system was not noticed in time, the reactor could no longer be controlled a few hours later. An explosion was prevented by releasing the released radioactive vapor into the environment. Investigations of the reactor core, which were only possible three years after the accident due to the accident, showed a core meltdown in which around 50% of the reactor core had melted and which had come to a standstill before the reactor pressure vessel melted . This accident was classified as INES 5 on the International Nuclear Event Rating Scale.

- In March 1980, a fuel element melted in the second block of the Saint-Laurent nuclear power plant in France, releasing radioactivity inside the facility. The reactor block was repaired, continued to operate and shut down in 1992.

- In March 2011, the operating company Tepco announced that following a series of accidents at the Fukushima I nuclear power plant in Units 1, 2 and 3 there had been a partial meltdown.

List of lesser known meltdowns

- On December 12, 1952 in the NRX reactor in Ontario, Canada

- In 1955 in Idaho, USA, in the Experimental Breeder Reactor I (EBR-I)

In addition, some Russian nuclear-powered submarines suffered core meltdowns. This became known from the submarines K-278 Komsomolez (1989), K-140 and K-431 (August 10, 1985).

The name China Syndrome

In the USA, a reactor accident with a core meltdown that is able to eat its way through the concrete foundation and into the groundwater unchecked is colloquially known as the “China Syndrome ”.

The origin of the expression is often explained by the fact that the People's Republic of China, viewed from the USA, is roughly on the opposite side of the earth ( antipode ) according to popular opinion (which is actually not the case, since both states are north of the equator ) and it is believed that the melted reactor core will melt deep into the earth in the direction of China. The name was popularized by the movie The China Syndrome .

Other assumptions are aimed at the formation of a porcelain-like shell around the molten reactor core (porcelain means china in English ).

See also

- Design basis accident (GAU)

- List of accidents in nuclear facilities

- International Nuclear Events Rating Scale (INES)

- International Atomic Energy Organization (IAEA)

- Civil protection

- Nuclear Power Plant Safety

Web links

- GRS: short explanation “What is a meltdown?” GRS: What is a meltdown? ( Memento from April 11, 2011 on WebCite )

- BIU Hannover: Core meltdown accidents in German nuclear power plants and their effects on people and the environment.

- Kurt Kugeler: Does the disaster-free nuclear reactor exist? ( Memento from July 17, 2003 in the Internet Archive ) Physikalische Blätter 57 (2001) No. 11 (PDF; 776 KiB).

- Chronicle of the nuclear power plant crisis - fears of a meltdown in two reactors. Current and very thorough article by the science department of Deutschlandradio on the occasion of the events in Japan on March 11, 2011.

- Article of March 29, 1993 on the planned controlled core meltdown in Cadarache / southern France on December 3, 1993.

- Article of April 30, 1994 on the risks of controlled core meltdown in Cadarache / southern France due to earthquakes.

- The new word: China Syndrome. ( Memento from January 22, 2012 in the Internet Archive )

- The China Syndrome - from a nightmare in a film to a reality? Süddeutsche Zeitung .

- How pop culture foresaw disaster. The world .

Individual evidence

- ↑ C. Journeau, E. Boccaccio, C. Jégou, P. Piluso, G. Cognet: Flow and Solidification of Corium in the VULCANO facility . In: 5th World conference on experimental heat transfer, fluid mechanics and thermodynamics, Thessaloniki, Greece . 2001 ( plinius.eu [PDF]). Flow and Solidification of Corium in the VULCANO facility ( Memento of the original from July 20, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Nuclear fission and decay heat. ( Memento of April 3, 2011 in the Internet Archive ). Society for Plant and Reactor Safety (GRS) mbH, March 2011.

- ↑ What is a meltdown? ( Memento of April 3, 2011 in the Internet Archive ) Gesellschaft für Anlagen- und Reaktorsicherheit (GRS) mbH, March 18, 2011.

- ↑ German Risk Study Nuclear Power Plants - Phase B. In: GRS.de. 1989, accessed March 20, 2011 .

- ↑ German Risk Study Nuclear Power Plants - Summary. In: GRS.de. 1989, accessed March 20, 2011 .

- ↑ Michael Sailer : Safety Problems of Light Water Reactors, Darmstadt 1990.

- ↑ The nuclear disaster is more likely than expected. In: Press release from the MPI for Chemistry. May 22, 2012. Retrieved May 23, 2012 .

- ↑ J. Lelieveld, D. Kunkel, MG Lawrence: Global risk of radioactive fallout after major nuclear reactor accidents . In: Atmos. Chem. Phys. tape 12 , no. 9 , May 12, 2012, p. 4245-4258 , doi : 10.5194 / acp-12-4245-2012 ( PDF; 10.7 MB [accessed September 19, 2012]).

- ^ R. Moormann: AVR prototype pebble bed reactor: a safety re-evaluation of its operation and consequences for future reactors. ( Memento from July 19, 2011 in the Internet Archive ) Nuclear technology (2009).

- ↑ Chernobyl Accident. In: World Nuclear Association. March 14, 2011, accessed March 14, 2011 .

- ^ H. Wagner: The reactor accident in Idaho. In: Physikalische Blätter, Vol. 17, 1961, doi : 10.1002 / phbl.19610170906 .

- ↑ Thomas P. McLaughlin et al: A Review of Criticality Accidents. (PDF) Los Alamos National Laboratory , May 2000, p. 97 , accessed on February 4, 2017 (English).

- ^ Fermi, Unit 1. In: US Nuclear Regulatory Commission (NRC). March 18, 2011, accessed March 18, 2011 .

- ↑ Nuclear Power Reactor Details - LUCENS. In: International Atomic Energy Agency (IAEA). March 14, 2011, archived from the original on June 4, 2011 ; accessed on March 14, 2011 (English).

- ^ A b Accidents: 1960's. In: Nuclear Age Peace Foundation. March 14, 2011, accessed March 14, 2011 .

- ^ Nuclear Power in Switzerland. In: World Nuclear Association. March 14, 2011, accessed March 14, 2011 .

- ^ Nuclear Power in France. In: World Nuclear Association. March 14, 2011, accessed March 14, 2011 .

- ^ Nuclear Power in Slovakia. In: World Nuclear Association. March 14, 2011, accessed March 14, 2011 .

- ^ Three Mile Island Accident. In: World Nuclear Association. March 14, 2011, accessed March 14, 2011 .

- ↑ Spiegel.de May 24, 2011: Fukushima nuclear power plant: Tepco reports core meltdown in reactors 2 and 3.