Scythe (tool)

The Sense ( Old High German . Segensa =, the cutting end '; Schwaben designate regional sometimes still called "Säages", said like long and is a short spoken; in high Alemannic dialects it is called, among other things, Sägesse' emphasizes the like on the) is a tool for mowing of grass , grain and small bushes .

Components

Scythe leaf

The scythe common in Central Europe has a forged steel blade, which is approx. 60–80 cm long, broad at the back and tapering towards the front, inward (towards the mower) and slightly curved in profile, for normal grassland mowing , the so-called scythe leaf. Usually a slight upward bend towards the tip is incorporated over the entire length of the leaf to enable clean gliding in the swing and to prevent it from getting stuck in the ground. Scythe blades for bush or cutout scythes are usually shorter (approx. 50 cm) and more massive; Experienced mowers use longer blades (over 80 cm in length), blades up to 1.30 m long are sometimes used for scythe mowing competitions. The scythe blade can be subdivided into the cutting edge with the pestle (an approx. 5 mm wide part of the cutting blade with the actual cutting edge), facing away from the back , which is set up to stiffen the blade, and the hammer , the approach with which it is connected to the handle becomes. On top of the hammer is the wart , a forged elevation that engages in a hole on the handle and fixes a certain basic position of the blade during assembly. The part of the cutting edge opposite the tip is called the beard . The vast majority of blades available are designed for right-handers, meaning in practice the blade will cut from right to left as you move. Some models are also available as left-handers, which then cut from left to right.

Scythe throw

A wooden or metal handle is used to guide the scythe , which is regionally known as "Worb", "Litter", "Scythe tree", "Scythe handle" or "Scythe handle". The length depends mainly on the height of the user and the area of application of the scythe. The scythe tree can be straight or curved in an S-shape. Two handles protruding at right angles are attached to the handle approximately hip-width apart, the front handle is usually attached to an L-shaped extension in order to enable relaxed and ergonomic work through the resulting angle of inclination. The rear handle is usually attached directly to the scythe throw. Depending on the region, very different techniques and materials are used to make the handles. At the lower end, the scythe tree is connected to the scythe leaf. With the method of fastening common in Central Europe, the hammer of the scythe blade is clamped with the grub screws of the scythe ring from below against the throw or its fitting plate; a certain basic position is achieved by the protruding protrusion from the hammer , which engages in a corresponding hole in the throw or fitting plate. This type of fastening allows the angle between the blade and the throw to be adjusted within certain limits. An older type of fastening uses a metal ring and a wooden wedge.

Reef

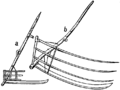

The reef was a rake-like attachment made of wood to the scythe for the grain harvest . It consisted of a wooden hanger and rungs. With each cutting movement the stalks of grain were collected by the device and swathed aside. A scythe equipped with a reef was also called a basket scythe . The cutting edge of the scythe blades used in basket scythes was directed upwards at an angle, depending on the intended stubble height; this also resulted in an oblique, pulling cut through the stalks.

production

High-quality scythe blades are forged by hand in a so-called hammer mill. Hammer mills that specialize in the production of scythes are also known as scythes. During production, from the raw material ( “Sensenbröckl” ) to the finished blade, more than 20 work steps and several “heatings” (reheating of the workpiece to forging temperature) are required. There are also cheap scythe blades, mainly in hardware stores, available that are simply punched and rolled by machine or formed in a simplified forging process without any special technical requirements ( "semi- forged " ) and therefore do not provide the mowing performance, edge retention and service life of a good hand-forged scythe blade. Often the cutting edges of such cheap scythes are forged so thick that peening is not possible because the cutting edge is too thick for cold forming or because of its brittleness cracks develop.

Use and maintenance

Mowing technology

The mowing person stands with his feet in the direction of his mowing path. The rotary motion is generated from the trunk and arms. The leaf is in swinging movements (cutting direction usually from right to left), gliding in an arched manner close to the ground, quickly, but without excessive use of force, through the clippings to be harvested, depending on the space and terrain, approximately a semicircle with 180 degrees is described. Avoid chopping or plucking movements, as these are often signs of insufficient sharpness of the scythe. The sequence of movements is shown incorrectly in numerous films today: Here the worker often takes a swing like a golf club and moves the scythe away from the ground in a sweeping motion when swinging back. This representation arises from an amateur's idea of working with a scythe.

Sharpening the Edge

The scythe blade needs regular care when in use. This means on the one hand resharpening with a scythe brush or a whetstone in a water-filled whetstone holder (" Kumpf ") at shorter intervals , and on the other hand " peening ", whereby the peening is either carried out using the fin of the peening hammer on a flat anvil or hammered out with the flat path of the hammer on a narrow anvil from the beard to the tip and back. The peening is used to drive out (thinning) and harden the cutting edge, which results in a sharpening and a significantly longer service life . This type of cold deformation can also drive out nicks up to about 5 millimeters deep in the cutting edge. With the scythe, which is common in Central Europe, only a well-executed pestle makes it possible to maintain good sharpness over a longer period of time in the field with only brief interruptions to the scythe. So-called grinding scythes, which were originally common in Scandinavia and North America, are not peened, but just sharpened wet with a whetstone and then re-sharpened during use.

Setting the scythe

In addition to a sharp scythe blade, correct setting and assembly of the blade on the scythe throw, also in relation to the height of the mower, is important for a good mowing result. One of the points is to check the angle between the long axis of the blade and the scythe throw. As an experiment, the scythe is swiveled with the throw downwards around the rear handle as the center of rotation and using a reference mark (e.g. attached to a house wall) observes whether the level of the cutting edge both at the tip and on the beard during the swiveling back and forth is at the same level. If this is the case, the scythe is “in a circle” . For longer leaves the sheet should be something in set will be (more point to be mowed down). Adjusting it (= tip is closer to the pivot point than the beard when swiveling or points more towards the mowing person) causes less cutting progress per mowing turn, but less effort. Another point is setting the correct cutting height. In the basic mowing position, the cutting edge should be 5 to 10 mm away from the ground when the scythe blade is on the ground. This value is corrected by processing the scythe throw on the contact surface of the hammer or by adding a small hardwood wedge between the contact surfaces of the throw and hammer. This wedge can be moved before the final tightening of the clamping screws of the scythe ring so that the cutting edge is correctly spaced from the ground.

history

The first two-handed scythes appear in Central Europe at the beginning of the Iron Age . At first with a relatively short stem, with the leaf and stem on the same level. Work was probably only possible in a stooped or crouched position. In the Latène period , the modern scythe with a longer stem and angled leaf was developed from these forerunners, so that the plants could be cut close to the ground in an upright position. These scythes were then also used by the Romans , Celts , Teutons and Slavs .

In addition to sickles and other harvesting tools, images of scythes can already be found in early medieval monthly pictures . During the Peasant Wars , the scythe was used as a simple weapon by the rebelling peasants .

The scythe is also known as the tool of the reapers and the godfather (the " grim reaper ").

Nowadays the scythe in the agricultural sector has been replaced by the combine harvester , the cutter bar or the rotary mower for large-scale harvesting . Lawn mowers and brushcutters now dominate households with a garden . However, it is still the method of choice for mowing in inaccessible areas, even in poorer countries it is still impressive today, as it requires neither fuel nor extensive maintenance. Even in the Alpine countries, the scythe has not yet had its day among mountain farmers . The scythe is also experiencing a renaissance among hobby farmers, nature conservationists and gardeners, as it is well suited to maintaining natural and bee-friendly flower meadows; there is an increasing demand for mowing and plowing courses.

In forestry , special forms of the scythe, the so-called release scythe, are increasingly being used for the care of young stands. It is a heavy scythe with a short and strong blade. Due to the robust construction, this scythe can also mow raspberry and blackberry bushes to prevent them from suffocating the young trees in a reforestation. The clearing scythe has the advantage over the brush cutter that it is possible to gently and purposefully encircle the young trees without damaging them.

Medieval mowing with a tied whetstone

Museums

In Achern (Baden-Wuerttemberg) you will find the Scythe-Handwerk-Stadtmuseum Achern . During the tour, the museum visitor can see how a resiliently oscillating scythe is created from a small piece of steel in 30 steps. At the same time he gets an insight into the history of technology. The manufacturing process shown here can be viewed as a prime example of early industrial manufacturing and working conditions.

In the open-air museum in Hagen , the production of scythes and sickles by a water- powered hammer forge is shown. The production is similar to that in Achern. The scythes are produced in a shortened process in a heat in order to shorten the processing time. The Freudenthaler Sensenhammer industrial museum in Leverkusen-Schlebusch also shows an industrial scythe hammer powered by water power.

The Upper Austria is located in Micheldorf in Upper Austria. Scythe forge museum . The corporate culture as well as the working and living environment of the scythe forge are shown in four buildings . Everyday scenes and historically significant moments from the life of the "Black Counts" and their blacksmiths, their wives and children are retold with over 40 life-size groups of figures.

There is a scythe workshop in Walsheim, a village in the Bliesgau biosphere region . The scythe workshop is a museum workshop that is dedicated to the care and transmission of old craftsmanship as well as ecological conservation of nature and the landscape. In the workshop itself, all kinds of equipment, tools and photo documents related to mowing with a scythe are on display.

heraldry

The scythe can be found as a common figure in heraldry in many municipal coats of arms . Two representations are common. Once the scythe with handle is taken into the coat of arms and is often shown in a crossed shape with other agricultural implements. The rake or pitchfork are well suited for this. The second form in the coat of arms is the representation of only the scythe leaf. Often there are up to three of these cutting blades in stakes , but one color for everyone. The position and direction of the blades must be reported in the description . Otherwise all heraldic colors are possible for the tinging . The stem is often colored in gold. The scythe is said to embody agriculture in the coat of arms.

See also

literature

- Bernhard Lehnert: Dengeln - the art of sharpening scythe and sickle . 2005, BOD. ISBN 3-8334-2586-5

- Bernhard Lehnert: Simply mow with a scythe , Ökobuchverlag. ISBN 978-3936896343

- Anna Offner: Land of hammers with a future - from scythe factory to global player. A structural analysis of the alpine scythe industry . ISBN 3-8364-7572-3

Web links

- Website of the Sensenverein Germany

- Website of the Austrian scythe club

- Website of the scythe museum in Achern (Baden)

- Website of the Geyerhammer scythe museum in Scharnstein, Austria

- Website of the Sensenschmiede Museum in Micheldorf, Austria

- Website of the museum workshop “Sensenwerkstatt” by Bernhard Lehnert in Gersheim

- Website Learn to mow with a scythe - build scythes yourself - Thomas Hipp in Lichtenstein (Reutlingen)

- Website Learn scythe mowing "scythe workshop" - Georg Hahn in Holzkirchen (Miesbach district)

- Website of the Freudenthaler Sensenhammer industrial museum in Leverkusen-Schlebusch

- Magazine article about mowing with a scythe in the Salzburger Land.

Individual evidence

- ↑ Fitting the Snath , rules for determining the length of the scythe throw and the positions of the handles on scytheconnection.com by Peter Vido (English, accessed July 8, 2013)

- ^ German dictionary by Jakob Grimm and Wilhelm Grimm, entry Reff , meaning 2)

- ↑ Reallexikon der Germanischen Altertumskunde (J. Hoops), vol. 7, p. 520 Reff , but described here as a comb for cutting off the ears after the harvest with a sickle

- ↑ Image: Sense with Reff ( Memento of the original from September 26, 2015 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Fig. 2: Scythe with reef from below

- ^ Paul Schweigmann: The agricultural machines and their maintenance . 1st edition, Pfanneberg, Gießen 1955, reprinted by Bulldog-Press, Limburg ad Lahn 1993, ISBN 3-9803332-1-3 , p. 464

- ↑ The history of a scythe on the website of the Geyerhammer scythe museum, Scharnstein im Almtal

- ↑ Bernhard Lehnert: Dengeln: The art of sharpening scythe and sickle . S. 43 f . ( google.at ).

- ↑ Torsten Capelle: Scythe. In: Reallexikon der Germanischen Altertumskunde (RGA). Volume 28, Walter de Gruyter, Berlin / New York 2005, pp. 177–178

- ↑ Comeback of the scythe - young and old learn traditional mowing technology , article on FAZ.NET from August 5, 2017