Tebis

| Tebis

|

|

|---|---|

|

|

Tebis V4.0 |

|

| Basic data

|

|

| developer | Tebis Technical Information Systems AG |

| Current version | V4.0 Release 8 (December 2019) |

| operating system | Windows |

| category | CAD , CAM |

| License | commercially |

| www.tebis.com | |

Tebis ( T echnical E evelopment B dvice and I ndividual S oftware ) is a CAD / CAM program of the company Tebis Technische Informationssysteme AG, based in Martinsried , near Munich.

Not to be confused with the TeBIS system (process data acquisition) from Steinhaus Informationssysteme GmbH from Datteln.

Company key figures

- Foundation: 1984 (Tebis GmbH)

- Conversion: 1991 (Tebis AG)

- Headquarters: Martinsried near Munich

- Development locations: Martinsried and Norderstedt

- International locations: China, Spain, France, Great Britain, Italy, Portugal, Sweden, USA

- Employees:> 300 worldwide

Functionality

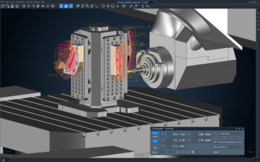

Tebis is a CAD / CAM software solution for e.g. B. Tool , mold or model making . The software is mainly used to generate toolpaths for machining such as drilling , milling and turning , but also for wire and die sinking . The tool paths control multi-axis CNC machines. Further applications are in the process planning , design , reverse engineering , quality control, CNC machine and bench assembly. The software has interfaces for neutral data formats as well as for file formats from other manufacturers ( STEP 203/214, VDA-FS , IGES , DXF , STL , Parasolid , CATIA V4 / V5, Creo , SolidWorks , Inventor , NX , JT , Nastran , Autoform ).

Industrial application

The programs are used by small and medium-sized companies through to OEMs in the automotive and aircraft industries and their suppliers. The following table contains a selection of companies that use Tebis as a CAM system.

History of Tebis

Tebis AG was initially founded as a GmbH in 1984. After initial consulting assignments and business software projects, Tebis specialized in CAD / CAM six months later. The first technical product was a PC-based station, with which foil plans could be digitized on a drawing board equipped with a position measuring system and converted into outline programs for milling machines.

The version sequence 1.0 to 1.0.4 formed the first Tebis CAD / CAM system. Tebis was one of the first 3D systems to run exclusively on a PC ( DOS ) basis. Two screens were necessary for operation. The current commands were displayed on one screen and the geometries were displayed in a 4-panel display on the other. The input commands were made using a digitizing tablet . The milling programs were only calculated for individual areas. Due to the low RAM (256 bytes) to the NC machines of the 80s presented Tebis a DNC connectors but ready next to the NC machine, the post-processing on a V24 to allow -Leitung.

In 1989, Tebis Version 2.0 appeared with a graphical user interface , which has been developed to this day and which differs from the usual Windows interfaces. Geometries on the screen could now be animated in real time. Version 2.1 included the Tebis Automill technology for the first time, with which it is possible to calculate milling paths across areas.

Tebis Version 3.0 was introduced in 1993. The system was modularized and expanded to include the SCO UNIX , HP-UX , IRIX and AIX operating systems . Version 3.1 contained the milling assistant, V3.2 interactive CAD and V3.3 for the first time contained a tool library and parametric management for all NC calculations. In version 3.4, the modules for the simulation of the machining on a virtual CNC machine, the construction of electrodes for die sinking , wire eroding and 2.5 D milling and drilling were added. As of version 3.5, the NC programming can be automated even better thanks to variable machining templates. For the first time, this version also contains the work plan as the central control element for all processing steps. The CAD module for BREP design was integrated into the software so that the Tebis software can accompany the entire production process in tool , mold and model making .

The current version 4.0 contains a new user interface specially developed for CAD / CAM applications, an industry-oriented product structure and a new platform for feature-based NC automation in 2.5D and 3D. For the first time, this version also supports CNC lathes and industrial robots, as well as laser hardening and laser deposition welding production technologies.

Tebis is one of the market leaders for CAM software.

By taking over a branch of ID Ingenieurgesellschaft für Datentechnik mbH, Tebis also offers a Manufacturing Execution System (MES) under the name ProLeiS, which can be fully integrated into the CAD / CAM application.

Individual evidence

- ↑ From the living room into the world

- ↑ [1]

- ↑ [2]

- ↑ Accelerating work processes, maschine + werkzeug, September 2017 edition, Henrich Publications GmbH, Gilching

- ↑ CIMdata 2017 Market Analysis Report Series CAM Market Analysis Report — Version 25, CIMdata, Inc., 3909 Research Park Drive, Ann Arbor, MI 48108, USA (English)

- ↑ Tebis takes over ProLeiS business from ID GmbH