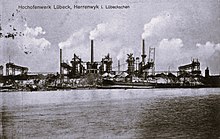

Lübeck blast furnace plant

The Hochofenwerk Lübeck AG , from 1954 Metallhüttenwerke Lübeck AG , was a steelworks in the Kücknitz- Herrenwyk district of the Hanseatic city of Lübeck ( Schleswig-Holstein ). It was founded in 1905.

After 1937 the company belonged to Friedrich Flick's group . From 1954 it was called Metallhüttenwerke Lübeck AG. In 1958 it was converted into a GmbH. In 1975 it was bought by the US Steel Corporation . In 1981 the company went bankrupt. The company with what was once the highest number of employees in Lübeck determined the lives of generations of people in the city.

history

founding

At the instigation of the board of the industry association, a commission consisting of Ewers, Meyer , Syndikus Siewert and Heinrich Thiel was formed for the "construction of a blast furnace near Lübeck". She commissioned Fritz Lürmann (1865–1914), a specialist in the field, to prepare an expert report to examine the project. This came to the conclusion that it was a “promising company”.

The company was founded at the instigation of the Lübeck industrial association . In 1902 he set up a commission to investigate the profitability of a steel mill in Lübeck. On behalf of the industrial association, Fritz Lürmann, a specialist in metalworking, calculated a dividend of 8.76 percent without own coke production and 13.66 percent with own coke production with investment costs of 4.5 million marks .

The stock corporation was founded on October 18, 1905 . It had a share capital of four million marks, in which the city of Lübeck invested 1.3 million marks after a senate resolution of September 20, 1905. The city's merchants took over a share of 100,000 marks. The board of directors included the businessman Carl Schlömer, who left in 1906, and Moritz Neumark . Neumark was the sole director and general director from 1906 to 1934. On July 30, 1906, the citizenship approved the sale of the required areas in Herrenwyk to the Lübeck AG blast furnace.

The plant was the only blast furnace plant north of the coal mining area at the northernmost point in Hörde (today a district of Dortmund ).

1906 to 1913

On May 8, 1906, the foundation stone for the first blast furnace was laid. In order to be able to move building material into the as yet undeveloped area on the Trave , the Lübeck Senate had a rail connection laid. In August 1907, production started with two blast furnaces and two groups of coke ovens . The first entry in the blast furnace journal was “The furnace was infected on August 7th at 5.45 by Susi Neumark”, Moritz Neumark's daughter. Friedrich Heinrich Bertling secured the exclusive rights as a ship broker and charterer . The ship brokerage department set up in 1907 with clearing points in Herrenwyk and Travemünde took over the organization and handling of all transport to and from the blast furnace until 1973.

The plant produced pig iron and coke. It also used tar and ammonia as by-products of the coking plant . The resulting slag was processed into cinder blocks, the so-called hüttenstein, and iron Portland cement. The third blast furnace was put into operation around 1909. Quality iron and quality steel iron were produced.

From 1906/1907 the first section of a factory settlement was built in Herrenwyk for the workers of the blast furnace plant, which was a good ten kilometers from the center of Lübeck's old town island. Construction of the Kücknitz colony began three years later. A large part of the ironworkers had been recruited from Upper Silesia, the Rhineland, Stettin and Galicia because there were no skilled workers in Lübeck. The second and third construction phases were realized between 1911 and 1920.

Other workers came from across the Trave by ferry from Schlutup . From Lübeck, workers reached the plant either via the first Herrenbrücke , the use of which cost five pfennigs even for pedestrians until 1918, or by train to Waldhusen . It was not until 1912 that the tram went to Kücknitz, and from 1924 to the blast furnace.

The employees were supplied via a department store, the Consum-Anstalt. The range included groceries, housewares and textiles. A notice board at the exit informed the colony residents about announcements and about offers and requests for sale from residents. There was also a slaughterhouse and a bakery. It was part of the work; the master baker had to offer an inexpensive type of bread.

On January 16, 1912, the company bought the Hochdahl ironworks . The site in Hochdahl was shut down and the pig iron quota of 3.72 percent transferred to Lübeck.

1914 to 1918

At the beginning of the First World War , the blast furnace plant had 944 employees. The number decreased during the war, but rose to 1,439 in 1917/18. During the war years women took on jobs that were previously done by men. A woman from a working-class family born in 1898 described: “I also had to work on the plant: we had to shovel out coke wagons, then I was in the cement factory, then I was in the cement silo, then I was in the cement laboratory. Everywhere you were sent and had to work. I was at the plant from 1914 to October 1918. "

1919 to 1932

In the post-war years, the blast furnace plant became an important factor in the strike movements. In addition to wage strikes, the workers took part in the general strike in March 1920 to suppress the Kapp Putsch and in 1922 in the strike following the murder of Foreign Minister Walther Rathenau . One worker, born in 1902, reported: “When there was a strike, there was a strike all over the plant, only the coking plant did not go on strike - it was excluded because of the gas supplies and the damage that occurs to the ovens when they get cold . A permit for emergency service was then usually given. ”The longest strike was directed against the lifting of the eight-hour day enforced in 1923. The workers called the five-week strike in March and April 1924 their "big strike". It failed due to strike breakers, some of whom were brought to the plant by rail from the Ruhr area .

In 1927 the plant had a total workforce of 1,354, of whom only 34 were women. They mostly made paper sacks to pack the blast furnace cement. In 1930 the world economic crisis hit the plant too. Mass layoffs were pronounced on April 1, 1932; only 300 to 400 workers remained.

1933 to 1945

When the Lübeck workers protested on February 3, 1933 with a one-hour general strike against the arrest of the Reichstag member, Lübeck SPD chairman and editor-in-chief of the Lübeck Volksbote Julius Leber , the workers at the blast furnace plant also took part. In 1933, in the Lübeck Senate , the National Socialists demanded that the management of the plant be Aryanized . General director Moritz Neumark , who had been targeted by the National Socialists because of his Jewish origins, resigned at the end of the 1933/34 financial year. Meanwhile, the economic situation of the blast furnace improved. From January 1933 to August 1933 the number of workers rose from 636 to 928. State subsidies, with which the armaments industry was promoted, also allowed the blast furnace to prosper . From 1936/37 it mainly produced steel iron for the armaments industry. In 1937 the industrialist Peter Klöckner became chairman of the supervisory board; the shares of the Jewish shareholders gradually passed into the possession of Friedrich Flick . The number of employees grew continuously from 1252 in 1934 to 1835 in 1938. Since late 1938 or early 1939, they also included forced laborers .

The first forced laborers in the blast furnace plant came from the Czech Republic and Poland. In 1941, 140 French prisoners of war, 125 civilian Soviet citizens, 70 Soviet prisoners of war and 150 slave laborers of other nationalities worked in the blast furnace plant. Six camps were set up on the factory premises for the forced laborers by 1942, in which they were housed according to nationality and status. Other warehouses were located outside the factory premises. From 1943 onwards, Italian soldiers and deported civilians as well as Dutch forced laborers were added. Many of the forced laborers died. After the end of the war, 462 Soviet prisoners of war and civilians who were buried in the Vorwerk cemetery were reburied at the request of the Soviet military government. Not all of them were buried, however. Corpses of Soviet prisoners of war also went to the Kiel Institute of Anatomy.

During the Second World War , the city of Lübeck was largely spared from attacks after the area bombed on the old town on Palm Sunday 1942; However, the war-essential blast furnace plant ten kilometers from the city center was deliberately bombed in 1942 by five aircraft of the Allied air forces in low flight. The attack caused severe damage. Six employees were injured, as well as crew members on two ships lying in the port. The copper smelter and the cement mills had to stop production, the tar distillation plant was completely destroyed. In April 1945 the plant employed 1,443 workers. At the end of the war, Herrenwyk was occupied by British and Canadian troops.

1945 to 1955

On May 22, 1945 the blast furnaces were shut down; other branches of production except for the destroyed tar distillation continued to work. Six days later, the Lübeck Chamber of Commerce and Industry, with the consent of the British military government, allowed the production of gas, pig iron and cement. Because there was a lack of coal, the coking plant had to be shut down on May 23, 1945. In May 1946 the plant employed 897 workers and 185 salaried employees. By the end of June 1946, 22 employees had been dismissed following denazification procedures; Board members remained in their positions.

The first blast furnace went back into operation on September 12, 1946. The plant was not affected by dismantling after Lübeck's mayor Otto Passarge (SPD) publicly stated that the plant was not an armaments factory and that this was confirmed by official statements from Sweden. Ore was supplied from Sweden; of 8000 tons of pig iron per month, most of it was exported to Sweden. The second blast furnace was blown in November 1948. In the post-war years, the plant received funds from the Marshall Plan and funds because of its location in the border area directly on the border with the GDR. The plant was expanded and modernized; the production of pig iron rose from around 200,000 tons in 1950 to around 250,000 tons in 1955. In 1954, the general shareholders' meeting decided to rename the company to Metallhüttenwerke Lübeck AG .

1956 to 1964

The entrepreneur Friedrich Flick had already bought shares in the company owned by Rawack & Grünfeld AG through his Mitteldeutsche Stahlwerke in 1937 with the help of the Lübeck company Possehl & Co mbH and then took over other shares such as those of Hahnschen Werke AG. In 1958 he had the stock company Metallhüttenwerke Lübeck converted into a limited liability company in order to circumvent the publication requirements of a stock corporation with this type of company. In 1957 pig iron production exceeded 300,000 tons for the first time. More workers were needed but were not available domestically. The 1958/59 annual report stated that 45 foreign workers, mainly Spaniards, had started work. In 1962 161 guest workers were employed. Dormitories were built for them; the first was built on the foundations of an earlier prison camp. In 1964 the first Turkish workers came to the metal works. In 1956/57, from October 30, 1956, the workers at the metalworking plant also took part in the strike over continued wages in the event of illness , which began with workers organized in IG Metall in Schleswig-Holstein.

1965 to 1974

In 1965 the company's economic zenith had passed after it no longer fitted into Flick's portfolio and pig iron production was increasingly relocated to the raw material countries. The metalworks were renamed HGI - Hessian Society for Industrial Enterprises Friedrich Flick GmbH ; the company headquarters was relocated to Wetzlar . At the same time, Leipziger Werkzeug- und Gerätefabrik GmbH took over the assets of the former metalworks, relocated its headquarters from Düsseldorf to Lübeck and took over the name Metallhüttenwerke GmbH. The only exceptions were shares in Buderus ' sche Eisenwerke Wetzlar AG, which had belonged to Metallhütte. The metal works and the Buderus'schen Eisenwerke merged. A subsidiary of Buderus'schen Eisenwerke, Buderusstahl GmbH, also based in Wetzlar, took over the Lübeck workforce and the production program. The background to the campaign was to be able to transfer the values of the metal works, the profits hidden in the balance sheet, so-called hidden reserves, tax-free to the HGI and Buderus balance sheets. One consequence of the actions was that the production facilities were now leased from Buderus'sche Eisenwerke and profits had to be transferred to them. The plant ran out of funds for investment or restructuring.

In 1968 the company had the highest number of employees in its history with 2,311 employees. In 1969 the company got into trouble when the city of Lübeck terminated the gas supply contract because the city's gas supply was to be converted to natural gas. With a new branch of production for metal powder production and its further processing, they wanted to create a balance, but the production was abandoned in 1971 and sold after six years of leasing. In 1971 the copper smelter was also closed. The company still had 1,554 employees. In 1974 it produced almost 470,000 tons, the highest amount of pig iron since it was founded. "This seemed to be the right time for the Flick Group to part with Metallhüttenwerke Lübeck GmbH."

1975 to 1981

In 1975 the US Steel Corporation bought the plant through its Dutch and French affiliates. In the same year only 280,000 tons of pig iron were produced, and prices for pig iron fell worldwide. In 1977 the bankruptcy was averted by support measures from the state of Schleswig-Holstein in the form of silent participations and integration grants from the state employment office. When the loss carried forward in the 1978 balance sheet rose to 49.4 million marks and the shutdown, including social plan costs and renovation costs, threatened as a result of decades of environmental pollution, US Steel sold 75.23 percent of the share capital of 33.1 million marks for two marks to a Wuppertal Lawyer. Another ten million marks were invested in the non-ferrous sector between 1979 and 1981, and a Swiss management consultancy was brought in to propose a restructuring of the company's management. In 1979 coke deals with the GDR gave hope, but there was no interested party for the company. In mid-1981 the losses amounted to 7.7 million marks. On August 18, 1981, the company filed for bankruptcy. The residential colony was initially sold to a Hamburg merchant and later transferred to the Lübeck Bauverein . He had the houses repaired and sold them to tenants and foreign buyers.

After 1982

In 1992 the plant was demolished. The city of Lübeck and the state of Schleswig-Holstein then rehabilitated the environmental damage caused by the industrial facilities for 70 million euros. The site was administered by Neue Metallhüttenwerke Lübeck GmbH , founded on April 20, 1982 . It was dissolved in 1991.

In 1994 the real estate company Metallhüttenwerke was founded, whose task was the marketing of the industrial wasteland. In March 2007, 78 percent of the 81 hectare industrial park had been marketed. At this point in time, the real estate company had raised 15.8 million euros through the sale of commercial space.

In the former department store of the factory colony, the Herrenwyk history workshop reminds us of the history of the blast furnace, the people who work there and life in the factory colony.

2009

In 2009, the 42 meter high former cooling tower built in 1978, the last remaining part of the production facilities, was demolished. The two hectare site on which the cooling tower stood was bought by the Lübeck port operator Hans Lehmann KG in 2003. The area is to be used to expand the port and serve as a parking and maneuvering area for trailers. The cooling tower had 25,000 m³ of enclosed space and weighed 120 tons. The demolition residues were crushed and placed on the surface to consolidate the soil.

literature

Scientific literature:

- Kim Christian Priemel: The "Aryanization" of the Lübeck AG blast furnace. Local initiative, individual opportunism, and general political weather, 1933–1938. Journal of the Society for Schleswig-Holstein History Volume 132, 2007, pp. 177-209.

- Josef Fahl: Lübeck's economic life in the present - an economic statistical study on the history of a commercial and industrial city. Max Schmid Römhild, Lübeck 1935.

- Wulf Schadendorf (Hrsg.): Life and work in Herrenwyk: History of the blast furnace factory Lübeck AG, the factory colony and its people. Schmidt-Römhild Verlag , Lübeck 1985, ISBN 3-7950-0101-3

Photos:

- N / A: Article in the blast furnace plant in Lübeck . In: Gießerei-Zeitung , Volume VII, No. 15, August 1, 1910, p. 468 ff. This article contains photos from 1910.

Web links

- Early documents and newspaper articles on the Lübeck blast furnace plant in the 20th century press kit of the ZBW - Leibniz Information Center for Economics .

Remarks

- ↑ Herrmann Meyer was the owner of the Schlutup chemical factory .

- ↑ Sebastian Prey: 100 years ago today, Lübeck's first blast furnace went into operation . In: Lübecker Nachrichten , issue August 7, 2007, p. 14.

- ↑ 150 Years of Bertling , p. 39

- ^ Wulf Schadendorf (ed.): Life and work in Herrenwyk: History of the blast furnace factory Lübeck AG, the factory colony and its people . Verlag Schmidt-Römhild, Lübeck 1985, ISBN 3-7950-0101-3 , p. 123.

- ↑ Life and work in Herrenwyk: History of the blast furnace factory Lübeck AG, the factory colony and its people , p. 233.

- ↑ Life and work in Herrenwyk : The exact date is questionable: According to page 289 the attack took place on June 16, 1942, according to page 290 (captions) on July 16, 1942, according to page 304 on April 16, 1942.

- ↑ Life and work in Herrenwyk , p. 332.

- ↑ See: Lübeck gas supply

- ↑ Life and work in Herrenwyk , p. 333.

- ↑ Kai Dordowski: From a huge legacy for thriving commercial area . In: Lübecker Nachrichten . March 23, 2007, p. 16.

- ↑ Torsten Teichmann: Demolition of the old cooling tower: Herrenwyks landmark falls In: Lübecker Nachrichten . 10/11 April 2009, p. 11.

Coordinates: 53 ° 53 ′ 58 ″ N , 10 ° 48 ′ 18 ″ E