Itaconic anhydride

| Structural formula | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||

| General | |||||||||||||

| Surname | Itaconic anhydride | ||||||||||||

| other names |

|

||||||||||||

| Molecular formula | C 5 H 4 O 3 | ||||||||||||

| Brief description |

colorless crystalline solid or white to pale yellow crystal powder |

||||||||||||

| External identifiers / databases | |||||||||||||

|

|||||||||||||

| properties | |||||||||||||

| Molar mass | 112.09 g mol −1 | ||||||||||||

| Physical state |

firmly |

||||||||||||

| Melting point | |||||||||||||

| boiling point | |||||||||||||

| solubility |

soluble in acetone and chloroform , slightly soluble in diethyl ether , reacts with water |

||||||||||||

| safety instructions | |||||||||||||

|

|||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||||||||

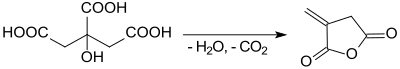

Itaconic anhydride is the cyclic anhydride of the unsaturated dicarboxylic acid itaconic acid and is obtained from the pyrolysis of citric acid . Itaconic anhydride (as a derivative of the so-called bio-based platform chemical itaconic acid), which is propagated as a versatile monomer and building block because of its easy accessibility from inexpensive renewable raw materials , has not yet met the expectations placed on it.

Manufacturing

In the distillation of citric acid, one of the products obtained as early as 1836 was the so-called “pyrocitric acid”, or correctly itaconic anhydride.

According to an organic synthesis procedure, rapid heating of citric acid monohydrate gives itaconic anhydride in modest yield (37-47%). The thermodynamically more stable citraconic anhydride is obtained as a by-product.

Even when anhydrous citric acid is heated to 260 ° C in a vacuum, a mixture of itaconic and citraconic anhydride is achieved “in good yield”.

Much more productive are processes based on itaconic acid, which is easily accessible from biotechnology, which is produced at temperatures of 165-180 ° C and pressures of 10-30 mmHg in the presence of catalytic amounts of strong acids, such as. B. concentrated sulfuric acid , exclusively itaconic anhydride in yields of up to 98%.

To avoid overheating and thus higher proportions of citraconic anhydride, the dehydration reaction can also be carried out in higher-boiling aromatic solvents, such as. B. toluene or xylenes in the presence of acidic montmorillonite or cumene in the presence of methanesulfonic acid .

In both variants, yields of 95-97% of itaconic anhydride are achieved.

A more recent process of cyclizing dicarboxylic acids with diethyl carbonate in the presence of a chromium - salen complex with μ-nitrido-bis (triphenylphosphine) chloride as cocatalyst gives itaconic anhydride quantitatively contaminated with citraconic anhydride (18%) in 1 millimolar batches at 40 ° C but technically uninteresting because of its expensive catalysts.

properties

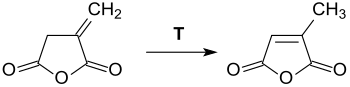

Itaconic anhydride is a colorless, crystalline solid that dissolves in many polar organic solvents and hydrolyzes with water to form itaconic acid. The substance should therefore be stored under exclusion of moisture and in an inert atmosphere. At temperatures above its melting point, itaconic anhydride is rearranged into citraconic anhydride. Even at significantly lower temperatures, such as B. in boiling chloroform, this isomerization can take place in the presence of tertiary amines.

The fluctuating values of the specified melting points are due to the inevitable contamination of the product with citraconic anhydride in practice.

Applications

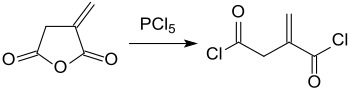

By reacting itaconic anhydride with phosphorus pentachloride PCl 5 , itaconic acid dichloride (itaconyl chloride) is obtained,

from which polyamides with reactive vinylidene groups can be formed with diamines .

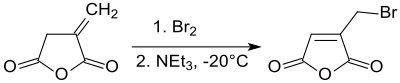

Bromination of itaconic anhydride at -20.degree. C. and subsequent dehydrobromination yields 2-bromomethylmaleic anhydride in a pure yield of 70% with the double bond being shifted into the five-membered ring.

Otto Diels and Kurt Alder described the addition ( Diels-Alder reaction ) of the dienophile itaconic anhydride to the diene cyclopentadiene as early as 1928 .

Furfuryl alcohol , which is available from renewable raw materials, also reacts as a diene with the formation of the Diels-Alder adduct, with a lactone and a carboxylic acid group forming through reaction of the alcohol group with the cyclic anhydride structure , i.e. H. the cyclic half ester of itaconic acid forms.

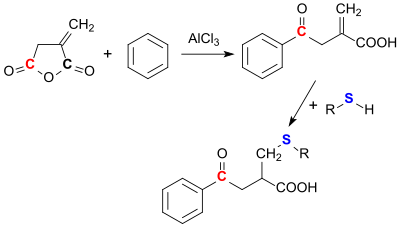

In a Friedel-Crafts acylation , itaconic anhydride reacts with aromatics, such as. B. Benzene always so that the ring opening takes place at the carbonyl group which is further away from the methylene group (3-position).

Can be connected to the methyl group nucleophiles such. B. Add thiols easily.

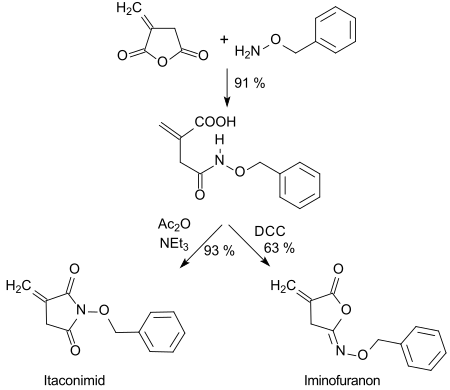

With nucleophiles such as B. alcohols , ammonia , amines and hydroxylamine reacts itaconic anhydride regioselectively in the 3-position to the corresponding esters, amides and hydroxamic acids .

The hydroxamic acid formed with O -benzylhydroxylamine can be cyclized in high yields with dicyclohexylcarbodiimide DCC to give five-membered isoimides (iminofuranones) or with acetic anhydride Ac 2 O to give imides .

The postulated replacement of maleic anhydride by itaconic anhydride in the alkenylsuccinic anhydrides , which are widely used for paper sizing , has not yet been technically implemented.

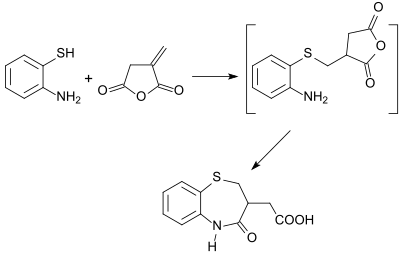

Also a number of five-, six- and seven-membered heterocycles , such as. B. Benzothiazepines, is accessible from itaconic anhydride in useful yields.

Polymers with itaconic anhydride

As an unsaturated cyclic anhydride, itaconic anhydride can form polymers both during free-radical polymerization and through polycondensation with diols or diamines. The two different polymer formation reactions can also be carried out sequentially - first polymerization, then polycondensation or vice versa.

Itaconic anhydride polymers and copolymers produced by free radicals are hydrolyzed under alkaline conditions to polyitaconic acids with ring opening or converted into polymeric acid amides or esters by polymer-analogous reactions .

The copolymers obtained show properties that make them interesting as biomaterials for therapeutic systems and prostheses.

An elegant way of producing functional polymers exclusively from biogenic monomers is the ring-opening metathetic polymerization ROMP of an oxanorbornene ester formed from itaconic anhydride and furfuryl alcohol by Diels-Alder lactonization with the aid of a Grubbs II catalyst .

Individual evidence

- ↑ a b c d e Itaconic anhydride data sheet from Sigma-Aldrich , accessed on September 28, 2018 ( PDF ).

- ↑ a b Entry on Itaconic Anhydride at TCI Europe, accessed on September 28, 2018.

- ↑ JL Belletire, RJ Rauh: Itaconic anhydride . In: e-EROS Encyclopedia of Reagents for Organic Synthesis . 2001, doi : 10.1002 / 047084289X.ri086 .

- ↑ a b c R.L. Shriner, SG Ford, LJ Roll: Itaconic anhydride and itaconic acid In: Organic Syntheses . 11, 1931, p. 70, doi : 10.15227 / orgsyn.011.0070 ; Coll. Vol. 2, 1943, p. 368 ( PDF ).

- ↑ B. Kamm: Production of platform chemicals and synthesis gas from biomass . In: Angew. Chem. Band 119 , no. 27 , 2007, p. 5146-5149 , doi : 10.1002 / anie.200604514j .

- ↑ Birgit Kamm: The concept of the biorefinery - the key to resource efficiency. GDCh current newsreel, April 14, 2008, accessed on October 1, 2018 .

- ↑ Jim Lane: The DOE's 12 top biobased molecules - what became of them? BiofuelsDigest, April 30, 2015, accessed October 1, 2018 .

- ↑ S. Baup: About a new pyrogenic citric acid, and about the naming of pyrogenic acids in general . In: Justus Liebigs Ann. Chem. Band 19 , no. 1 , 1836, p. 29-38 , doi : 10.1002 / jlac.18360190107 .

- ↑ RL Shriner, SG Ford, LJ Roll: Citraconic anhydride and citraconic acid In: Organic Syntheses . 11, 1931, p. 28, doi : 10.15227 / orgsyn.011.0028 ; Coll. Vol. 2, 1943, p. 140 ( PDF ).

- ↑ Patent US2258947 : Production of itaconic and citraconic anhydrides. Applied September 21, 1939 , published October 14, 1941 , Applicant: National Aniline & Chemical Co., Inventor: JH Crowell.

- ↑ Novamont SpA: Final Report Summary - BIO-QED (Quod Erat Demonstrandum: Large scale demonstration for the bio-based bulk chemicals BDO and IA aiming at cost reduction and improved sustainability). CORDIS, 26 July 2018, accessed 1 October 2018 .

- ↑ a b Patent GB854999 : A process for the production of itaconic anhydride. Applied on April 6, 1959 , published November 23, 1960 , applicant: Chas. Pfizer & Co., Inc ..

- ↑ Patent US5260456 : Process for producing itaconic anhydride. Applied on April 21, 1992 , published on November 9, 1993 , Applicant: Rhone-Poulenc Chimie, Inventors: M. Alas, M. Gubelmann, J.-M. Popa.

- ↑ Patent WO9506026 : Dehydration of itaconic acid. Applied on August 25, 1994 , published on March 2, 1995 , applicant: Akzo Nobel NV, inventor: AG Talma, AG Bovenkamp-Bouwman, HP Verlaanhooft.

- ↑ C. Robert, F. de Montigny, CM Thomas: Tandem synthesis of alternating polyesters from renewable resources . In: Nature Commun. tape 2 , 2011, p. 1-6 , doi : 10.1038 / ncomms1596 .

- ↑ MC Galanti, AV Galanti: Kinetic study of the isomerization of itaconic anhydride to citraconic anhydride . In: J. Org. Chem. Band 47 , no. 8 , 1982, pp. 1572-1574 , doi : 10.1021 / jo00347a041 .

- ^ W. Petri: Contributions to the knowledge of itaconic acid, mesaconic acid and citraconic acid . In: Ber. German Chem. Ges. Volume 14 , no. 2 , 1881, p. 1634-1637 , doi : 10.1002 / cber.18810140213 .

- ↑ C. Wang, X. Wang, Z. Wie, X. Zeng: Synthesis and characterization of poly (p-phenyleneitaconamide) . In: Polym. Mater. Sci. Closely. tape 34 , no. 6 , 2018, p. 9–15 , doi : 10.16865 / j.cnki.1000-7555.2018.06.002 .

- ↑ J. Nokami, T. Tamaoka, H. Ogawa, S. Wakabayashi: Facile synthesis of 2-methylene-4-butyrolactones . In: Chem. Lett. tape 15 , no. 4 , 1986, pp. 541-544 , doi : 10.1246 / cl.1986.541 .

- ↑ O. Diels, K. Alder: Syntheses in the hydroaromatic series . In: Justus Liebigs Ann. Chem. Band 460 , no. 1 , 1928, pp. 98-122 , doi : 10.1002 / jlac.19284600106 .

- ↑ AD Pehere, S. Xu, SK Thompson, MA Hillmyer, TR Hoye: Diels-Alder reactions of furans with itaconic anhydride: Overcoming unfavorable thermodynamics . In: Org. Lett. tape 18 , no. 11 , 2016, p. 2584-2587 , doi : 10.1021 / acs.orglett.6b00929 .

- ↑ K. Kameo, K. Ogawa, K. Takeshita, S. Nakaike, K. Tomisawa, K. Sato: Studies on antirheumatic agents: 3-benzoylpropionic acid derivatives . In: Chem. Pharm. Bull. Volume 36 , no. 6 , 1988, pp. 2050-2060 , doi : 10.1248 / cpb.36.2050 .

- ↑ H. Takeda, T. Tachinami, S. Hosokawa, M. Aburatani, K. Inoguchi, K. Achiwa: Efficient Preparation of Optically Active (S) - (-) - 3-Methyl-γ-butyrolactone by Catalytic Asymmetric Hydrogenation Using Chiral N-Substituted Pyrrolidinebisphosphine Rhodium Complexes . In: Chem. Pharm. Bull. Volume 39 , no. 10 , 1991, pp. 2706-2708 , doi : 10.1248 / cpb.39.2706 .

- ↑ M. Akiyama, K. Shimizu, S. Aiba, F. Banba: Synthesis of N-Hydroxymaleimide and N-Hydroxyitaconimide and their related derivatives . In: J. Chem. Soc. Perkin I . tape 0 , 1980, p. 2122-2125 , doi : 10.1039 / P19800002122 .

- ↑ AM Medway, J. Sperry: Heterocycle construction using the biomass-derived building block itaconic acid . In: Green Chem. Band 16 , 2014, p. 2084-2101 , doi : 10.1039 / c4gc00014e .

- ↑ D. Stawski, S. Polowinski: Polymerization of itaconic acid . In: Polimery . tape 50 , no. 2 , 2005, p. 118-122 ( ichp.pl ).

- ↑ FH Isikgor, CR Becer: Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers . In: Polym. Chem. Band 6 , 2015, p. 4497-4559 , doi : 10.1039 / c5py00263j .

- ↑ T. Okuda, K. Ishimoto, H. Ohara, S. Kobayashi: Renewable biobased polymeric materials: Facile synthesis of itaconic anhydride-based copolymers with poly (L-lactic acid) grafts . In: Macromolecules . tape 45 , no. 10 , 2012, p. 4166-4174 , doi : 10.1021 / ma300387j .

- ↑ T. Otsu, J.-Z. Yang: Radical polymerization of itaconic anhydride and reactions of the resulting polymers with amines and alcohols . In: Polymer Int. tape 25 , no. 4 , 1991, pp. 245-251 , doi : 10.1002 / pi.4990250408 .

- ^ S. Shang, SJ Huang, RA Weiss: Comb-like ionomers from sustainable resources: Copolymers of itaconic anhydride-co-stearyl methacrylate . In: polymer . tape 52 , no. 13 , 2011, p. 2764-2771 , doi : 10.1016 / j.polymer.2011.04.025 .

- ↑ Y. Bai, JH Clark, TJ Farmer, IDV Ingram, M. North: Wholly biomass derivable sustainable polymers by ring-opening metathesis polymerization of monomers obtained from furfuryl alcohol and itaconic anhydride . In: Polymer Chem. Band 8 , no. 20 , 2017, p. 3074-3081 , doi : 10.1039 / C7PY00486A .