LED bulbs

LED light sources are electrical light sources , which for generating the light emitting diodes (in short LEDs , of English light-emitting diodes ) are running.

Like compact fluorescent lamps , they are also energy-saving light sources (ESL). The service life of LED lamps is stated to be up to 50,000 hours. At 2700 K, conventional incandescent lamps have a service life of around 1000 hours. In addition, LED lamps require less electrical power for the same brightness. So they achieve a higher degree of efficiency or they have a higher energy efficiency (better light yield ). When viewed over their entire service life, although they usually cause higher investment costs, they are much more economical than most other lamps due to the lower operating costs (energy costs and replacement costs) .

Designs

Retrofit lamps

LED retrofit lamps with different lamp bases replace conventional lamps. This applies to both building and automotive engineering. There is a large selection of lamps in different light colors and beam angles , which can essentially be divided into three categories:

Replacement for unbundled lamps

Retrofits for European building technology in the form of classic incandescent lamps usually have a screw base with an Edison thread . LED lamps with one or two-sided plug-in bases are also available. In the case of car lamps, bayonet sockets that are less sensitive to vibrations or plug-in sockets with safety clips are usually used.

Replacement for reflector lamps

With reflector lamps, the lampshade has a reflective coating in a certain area. Projection lamps with the illuminant in the focal point of an interior mirror coating are mostly used as spotlights. So-called dome mirror lamps or head mirror lamps (KSL) with the light source in the center of a reflective hemispherical shell, on the other hand, cast the light in the direction of the base and are therefore often installed next to reflective surfaces. Both types of conventional reflector lamps described can be replaced by LED reflector lamps.

Replacement for tubular fluorescent lamps

Rod-shaped LED lamps have several advantages over conventional fluorescent lamps . As a rule, they have a higher energy efficiency, they do not flicker when switched on and shine at full illuminance immediately after being switched on. One disadvantage is that they are not interchangeable. For safety reasons (contact protection when inserting) they have a one-sided power supply and the other end is replaced by a short-circuit bridge isolated from it. When replacing, at least the starter must be short-circuited (replacement with an identical short-circuit bridge). Some luminaires (luminaires with electronic ballast or dual circuit ) have to be rewired and the ballast is bridged or removed. This carries the risk that a fluorescent tube is accidentally inserted later, which leads to its destruction and a short circuit due to the non-current-limited gas discharge and possibly even to mechanical destruction of the lamp. If the old ballast is not removed, it forms an inductive load that is tolerated in the circuit and causes slight additional losses. Converting lights that have been manufactured and tested for fluorescent lamps may void the manufacturer's liability. This would mean that the person carrying out the work can then be made liable for possible dangers in terms of product liability . A modification must be marked.

An LED tube usually emits more directionally. Other photometric properties of the luminaire are also changed by the retrofit.

LED strips and ribbons

LED strips or flexible LED modules usually have series resistors built in for operation with DC voltages of 12 or 24 V. They can be operated with voltage-stabilized power packs or batteries. The strips can often be divided at marked points, so that whole-numbered sections, consisting for example of three LEDs and a series resistor, are retained when shortened. Due to the linear generation of light in a very small space, they offer many creative possibilities that conventional lamps would not or would be difficult to achieve, such as the lighting of handrails at stairways.

LED modules

LED modules are circuit boards that are equipped with several LEDs. They can be equipped with an optic and a heat sink. A ballast is usually required for operation. One or more LED modules for light generation are integrated in LED lights .

Other designs

- LED flashlights sometimes contain no current limitation or electronics. Then the current is limited by the internal resistance of the battery.

- For high-power LEDs or large units (e.g. street lighting ), LED power supplies (assemblies with an open design or with a closed housing) are used, which deliver constant current and can often be (remotely) controlled.

- For the operation of a white LED (forward voltage of about 3.3 V) to a single alkaline battery (1.5 V) or a NiMH rechargeable battery (1.2 V) are up-converter is used (z. B. solar lights ).

LED constant voltage power supplies are also available. As with other common voltage sources, only LED modules with integrated current limitation can be operated on these.

One or more LED modules are often permanently installed in the luminaire for better thermal management and thus a longer service life. However, LED lights are also available in which the module can be changed by specialists. Due to the low heat emission and small size, LEDs enable very narrow luminaire designs.

history

Between the early 1970s, when the first light-emitting diodes for signaling applications came onto the market, to the end of the 1990s, there was an exponential increase in efficiency, expressed in lumens per watt (lm / W) of supplied electrical power. This increase in efficiency was described by a research group headed by Roland Haitz at Sandia National Laboratories at the beginning of the 2000s : Haitz forecast luminous efficacies of around 100 lm / W by 2010 and around 200 lm / W in 2020. This relationship between the exponential increase in the efficiency of light-emitting diodes in this time range is also known as Haitz's law . In 2006, luminous efficacies of 100 lumens per watt were achieved under laboratory conditions.

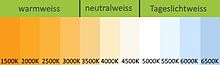

From 2007 the first LED lamps for the usual E27 and E14 lamp bases , so-called LED retrofits, came onto the market . At first they had a luminous flux of only up to 300 lm , which roughly corresponds to a conventional 30 W incandescent lamp. In addition to the insufficient brightness for many purposes, the initial bluish (“cold”) light color was also criticized. Since 2010, LED lamps have been available in warm white (2,700 to 3,300 Kelvin), neutral white (3,300 to 5,300 K) and daylight white (more than 5,300 K). Since then, so-called LED filament lamps have also been available on the market, which consist of a clear glass bulb and are modeled on historical incandescent lamps with single filaments, but consist of dozens of individual LEDs. Due to the mass production, the costs for the production of LED light sources decreased. The focus is no longer on higher efficiencies to increase efficiency. The quality of light - also in combination with light management systems and human centric lighting - is more important .

construction

The chip generates the light. It is made up of several semiconductor layers (epitaxy layer) and connection elements. When the diode is operated, light of one wavelength (blue light with white LEDs) is generated in the active layer via direct voltage. Electrons and holes recombine in the semiconductor. Electroluminescence turns electrical energy into electromagnetic energy, i.e. light. In addition to the chip, a package usually contains the housing, electrical contacts and the conversion layer (phosphor). This package is called together with the chip "LED". The package also includes functions such as protective circuits, optical lenses or elements for heat dissipation.

Binning

Due to the manufacturing process, LEDs of one type and manufacturer can have color differences in direct comparison. In general, all LED manufacturers indicate tolerances. The division into different finely graded classes is called "binning". In the case of white LEDs , this mainly includes the luminous flux or the luminous intensity , the voltage and the color location at nominal current. Colored LEDs are also offered with selected spectral tolerances. Information on which properties are assigned to which "bin" (degree of selection) can be found in the manufacturer's data sheets.

Integrated power supply

In addition to the light emitting diodes, the power supply module built into the lamp housing is an integral part of LED light sources. The ballast generates the stabilized direct current required for the operation of the LED from the mains voltage with a significantly lower direct voltage than the mains voltage.

With mostly inexpensive LED lamps, a capacitor power supply is integrated into the lamp base. The disadvantage is that mains voltage fluctuations lead to fluctuations in brightness. The mains current consumption is not sinusoidal, but rather distorted.

There are also analog constant current source circuits in the LED light sources. The IC PT6913 installed for this purpose, for example, achieves freedom from flicker and mains voltage-independent brightness with an additional capacitor. The solution generates harmonics, but otherwise no interfering emissions. The efficiency is basically dependent on the operating voltage - the voltage difference between the LED chain and mains voltage, multiplied by the LED current, is converted into heat.

Special switched-mode power supplies are used for better quality LED lamps and lights . Common circuit topologies are flyback converters , resonance converters and, in the case of light sources, in particular the non-galvanically isolating step-down converter . These often ensure a stable brightness of the LEDs. The flyback converter principle facilitates operation over a wide range of the line voltage, for example from 90 V to 250 V. Fluctuations in the line voltage and so-called flicker are compensated, which allows uniform brightness regardless of line voltage fluctuations. The temperature-dependent luminous flux of the LED can also be compensated.

Retrofits in the form of fluorescent tubes usually also have an integrated current limiter. Because of the contact protection when inserting LED retrofit tubes must have a one-sided power supply - on the other side the pins are isolated from the rest of the circuit and connected to each other. When replacing the conventional tube with LED tubes, the starter must therefore be replaced by a bridge. A conventional ballast remains in the circuit, its current-limiting inductance is no longer required. It does cause a loss of power, but it is much lower than when it was previously operated with fluorescent lamps, since the LED retrofit lamp requires less electricity. Operating LED tubes in lights with electronic ballasts or tandem circuits with a conventional ballast is not possible without converting the light. The ballasts are bridged or removed, which harbors the risk of accidentally reinserting a fluorescent tube, which leads to its destruction and can also cause personal injury. The luminaires must therefore be marked, and the person installing the system is fully responsible for the safety of the converted luminaire.

Dimmability

Only lamps marked as such can be dimmed . Some of the integrated circuits used recognize the control angle of an upstream dimmer (phase control or phase control) and reduce the LED current depending on the measured angle.

Performance data

Light output

As of 2016, LED light sources achieve a luminous efficiency of up to 134 lm / W. This means that they are more than 12 times as efficient as conventional incandescent lamps (6–19 lm / W), significantly more efficient than fluorescent lamps ( fluorescent tubes ) with approx. 89–104 lm / W and halogen lamps (19–18 lm / W). However, LED lamps have a lower luminous efficiency than sodium vapor lamps (SOX), which can reach up to 200 lm / W, but produce monochromatic light .

Luminance and current density

The output per LED chip can be increased by increasing the current density. This reduces costs and applications that require high luminance levels (bundling) can be developed. However, the higher the current density, the lower the efficiency and the service life. This results from a higher temperature of the LED chip as well as of the phosphor. The cooling requirements therefore increase to the same extent. Using chip-on-board -Assembly (COB LED) and PCBs with aluminum core. The service life ranges from a few hundred hours to over 50,000 hours and more. When designing, a compromise has to be found between low material costs, efficiency and thermal stress or limited ambient temperature. The luminance reaches or exceeds that of incandescent lamps. The blue component of the spectrum (this is the radiation component of the stimulating blue LED) causes photochemical damage to the retina of the eye if you look into the direct, unscattered light for a long time. Thermal damage to the retina can currently be ruled out. According to the EN 62471 standard, three risk groups are provided (RG1 to 3). In risk group 3, damage is to be expected even with short-term exposure; this group is currently not yet reached by LEDs. Risk group 2 leads to damage when viewed for between 0.25 and 100 s and is achieved by LED products. However, it is assumed that there is a turning away or a blink reflex .

Beam angle

LEDs are point light sources. In principle, they do not have an approximate all-round radiation like other light sources, but radiate with a solid angle of <2 π. A larger beam angle is achieved with an arrangement of several LEDs or diffusers.

Luminous flux

The luminous flux is measured in lumens (lm). It describes the power emitted by the light source in all directions in the visible range. The luminous flux of the luminaire is decisive for lighting planning: in contrast to the luminous flux of lamps, it already takes into account losses caused by the luminaire design.

With the same number of lumens, the brightness of a light source with a small angle of radiation is greater than that of a light source with a large angle of radiation. A statement about the actual illumination of a room cannot be made with it; it is given with the illuminance in lux. Example: The conventional E27 light bulb spreads the light at an angle of around 280 °. Due to their structure, retrofit lamps with this base often emit less light in the direction of the base; However, newer models can also achieve beam angles that are comparable to incandescent lamps.

Lifespan and degradation

The service life of LEDs and other light sources is specified with the rated service life (L). These light sources degrade and their brightness decreases. The rated service life describes the time after which the luminous flux falls to the value specified by the manufacturer, for example 80% of the new value as L80. The service life is usually specified for an ambient temperature of 25 ° C, which is unrealistically low for many luminaire designs. In addition to normal aging, there are early and spontaneous failures. The most common causes for this can be found in the LEDs, in the power supply (component selection) or in the construction (thermal management, contacts).

The lifespan according to the EU Ecodesign Ordinance, valid from March 2014, only requires that at least 90% of the units of an LED lamp model still shine after 6000 hours and then still deliver at least 80% of the original brightness. For switching resistance, it is required, as previously, that ≥ 15,000 switch-on / switch-off cycles are withstood if the declared LED service life is ≥ 30,000 hours, otherwise the LED luminaires or light sources must have at least half the number of specified hours of light on switching cycles withstand. The early failure rate must not exceed 5% after 1000 hours.

In a long-term test that ended in 2017, Stiftung Warentest found that LED lamps tested as good also worked after more than 30,000 burning hours. They shone almost consistently, had a constant color rendering index and withstood around a million switch-on and switch-off processes.

Advantages and disadvantages

LED lamps have the following advantages over compact fluorescent lamps , fluorescent lamps and high-pressure gas discharge lamps :

- Immediate full brightness after switching on, even at low temperatures

- insensitive to frequent switching on and off

- longer lifespan

- highest light output of all types of lighting

- lower heat load on the luminaire due to its higher efficiency and thus comparatively less waste heat

- partially better color rendering index (especially compared to high pressure mercury vapor lamps and high pressure sodium vapor lamps)

- in principle (however, depending on the type) continuously dimmable from a few percent to 100% without loss of efficiency or service life

- smart controllable

- directed, easy to direct light

- no UV and infrared radiation

- no mercury content

- high vibration and shock resistance , largely unbreakable

- lower total costs (investment costs and electricity costs) than with other light sources

LED lamps have the following disadvantages:

- In experiments on rats, the photochemical damage to the retina caused by cold white LED lamps led to macular degeneration , which can lead to blindness .

- The high luminance, especially in the blue part of the spectrum, is also dangerous for the human eye and must be reduced by the design of the luminaire or lamp. For this there is the EU Directive 2006/25 / EG

- If LED lamps with neutral or daylight white color temperatures are used in excess, their high blue content can contribute to light pollution . Warm white LEDs emit far less blue components and are recommended to avoid light pollution.

- At high ambient temperatures, the luminous efficiency drops and the service life is shortened.

- LED lamps show light flickering particularly frequently . The flicker, however, is strongly dependent on the type and can almost be absent.

disposal

In Germany, defective or disused LED lamps must be disposed of in electronic scrap as part of the recycling of old lamps due to the ElektroG . In this way, some of the raw materials used can be recovered, in particular aluminum (heat sink) and copper (winding goods). Valuable ingredients such as indium and rare earths cannot yet be economically recovered.

safety

Safety in the sense of protecting users of electrical equipment is defined in the European Union in various sets of rules (laws, ordinances, standards, rules and guidelines). The rules often refer to electrical equipment in general, mostly depending on the nominal operating voltage, as for example in the low-voltage directive 2014/35 / EU. In some cases, however, they are also issued for specific products or applications.

The following areas are relevant for lighting systems (lamps and lights):

- electric security

- thermal safety

- mechanical security

- Safety in terms of electromagnetic compatibility (EMC)

- photobiological safety

- Security against chemical and other influences.

Protection against accidental contact is also part of mechanical safety. The VDE describes inadequate insulation of live parts as the most common defect in LED lamps. Particularly in the design of the so-called corn cob lamp ( English corn lamp ), as well as LED replacement for halogen bulbs get bulbs occasionally and mostly via the online mail order on the European market, are where applicable safety regulations in respect not adhered to the contact protection. When buying LED lamps for direct mains operation, care should be taken to ensure that all electrical contacts are protected against contact by an insulating cover in accordance with IEC standards.

The photobiological safety includes u. a. the photochemical damage to the retina from short-wave light sources of high luminance . In this area too, LED lamps can pose a risk. In a research report on the photobiological safety of LEDs from 2012, all tested LEDs exceeded the luminance value of 10,000 cd / m 2 in the visible range . This value is considered a limit value below which no hazard can be assumed. Also in 2012, a white LED came on the market with a luminance of 48 Mcd / m 2 . With many LED lamps, the luminance is reduced by opal covers. This also reduces the risk of photobiological damage.

The DIN EN 62471 VDE 0837-471 - photobiological safety of lamps and lamp systems allows the evaluation of light sources with respect to different photobiological hazards. It complies with the European Directive 2006/25 / EC. The same assessment for luminaires with permanently integrated light sources is defined by DIN EN 60598-1 VDE 0711-1. LED products and a possible hazard from blue light (blue light hazard, photoretinitis) are listed as the main purpose. In DIN EN 62471 VDE 0837-471, measurement methods and limit values for radiance or irradiance are specified for all types of hazard. In this way, lamps can be divided into risk groups (RG) of levels 0 to 3. The RG2 as the second highest group describes a medium risk. Since looking into the light source is perceived as sufficiently uncomfortable, damage to the eye due to an averting reaction is prevented. During the short exposure period (the time until the eye is turned away from the light source), the eye is not damaged by the radiation if the specified limit value for radiance or irradiance is observed. In the above-mentioned research report on the photobiological safety of LEDs from 2012, it is stated in the summary that the examined white and blue light emitting LEDs achieve a maximum of RG2.

literature

- Dennis Köhler (Ed.): LED 2016 - Contributions to Technology . 1st edition. Highlight, Rüthen 2016, ISBN 978-3-945220-18-4 .

- LED: Basics - Application - Effect . In: licht.de (Ed.): Licht.wissen . tape 17 . Frankfurt 2018, ISBN 978-3-945220-03-0 ( Online [PDF]).

- Hans Rudolf Ris: Lighting technology for practitioners: Basics, lamps, lights, planning, measurement . 5th revised and expanded edition. VDE Verlag / Electrosuisse, Berlin / Offenbach 2015, ISBN 978-3-8007-3617-1 , 3.10 LED - Light Emitting Diodes. , S. 151-179 .

- Armin Scharf: The light that comes from the semiconductor: The light-emitting diode is state of the art . In: Deutsche Bauzeitung . tape 1–2 / 2015 , pp. 54-59 ( online ).

- Uwe Slabke: LED lighting technology: basic knowledge for planning, selection and installation . VDE Verlag, Berlin / Offenbach 2018, ISBN 978-3-8007-4451-0 .

- CH Zieseniß, F. Lindemuth, P. Schmits: Lighting technology for the electrician: lamps, lights and their application . 9th completely revised edition. Hüthig, Munich / Heidelberg 2017, ISBN 978-3-8101-0394-9 , 5 light-emitting diodes (LED), p. 65-72 .

Web links

- Explanatory video from licht.de on YouTube , accessed on October 6, 2018.

References and comments

- ↑ Christian Frahm: LED retrofitting for car headlights in the test. DER SPIEGEL (online), December 22, 2018, accessed on February 10, 2020 .

- ↑ The lighting with artificial light . In: licht.de (Ed.): Licht.wissen . No. 01 . Frankfurt 2016, ISBN 978-3-945220-03-0 , pp. 34 ( Online [PDF; 5.2 MB ; accessed on August 29, 2020]).

- ↑ a b ecobility.com ( Memento of the original dated November 10, 2017 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Safety instructions for LED retrofit lamps and the conversion of lights from ecobility GmbH. Retrieved Nov. 9, 2017

- ↑ Information about LED flashlights. In: taschenampe.xyz. Tom Koll, accessed January 8, 2017 .

- ↑ PREMA Semiconductor - Boost Driver. PREMA Semiconductor GmbH, accessed on January 8, 2017 .

- ↑ White light. elektroniknet.de, April 14, 2011, accessed on August 20, 2018 .

- ^ Roland Haitz, Fred Kish: The Case for a National Research Program on Semiconductor Lighting (PDF) In: Sandia Report . Optoelectronics Industry Development Association. 1999.

- ↑ The history of the LED. licht.de, accessed on August 20, 2018 .

- ↑ Interpolation between 25 W and 40 W, lumen data according to EC regulation No. 244/2009 of March 18, 2009 for the implementation of Directive 2005/32 / EC of the European Parliament and of the Council with regard to the definition of requirements for the environmentally friendly design of household lamps with unbundled light

- ↑ The basic principle of the LED. licht.de, accessed on August 20, 2018 .

- ↑ Binning guarantees constant light quality. licht.de, accessed on August 20, 2018 .

- ↑ dianyuan.com (PDF) and reverse engineering

- ↑ The ballast of an LED is similar to that of a gas discharge lamp - it limits and stabilizes the current.

- ↑ Dominik Schuierer: Test: Retrofit Filament LED from Greens dismantled. In: zerobrain.info. January 6, 2016, accessed January 7, 2017 .

- ↑ princeton.com.tw data sheet of the PT9613

- ↑ Data sheet dimmable LED driver LM3445. Retrieved January 8, 2017

- ↑ The lighting with artificial light . In: licht.de (Ed.): Licht.wissen . No. 01 . Frankfurt 2016, ISBN 978-3-945220-03-0 , pp. 34 .

- ↑ LED: Basics - Application - Effect . In: licht.de (Ed.): Licht.wissen . No. 17 . Frankfurt 2018, ISBN 978-3-945220-18-4 , pp. 24 .

- ↑ Karl Schulmeister, Hendrik Härter: Simplified safety assessment of light emitting diodes in ElektronikPraxis from October 30, 1912, accessed on December 23, 2019

- ↑ Comparison: Beam angle of a clear incandescent lamp and the selected LED lamp. Retrieved April 24, 2018 .

- ↑ 75W Frosted Incandescent Review. Measured values from a matt light bulb. In: ledbenchmark.com. June 11, 2013, accessed April 24, 2018 .

- ↑ Lifespan of LED lights. Retrieved January 8, 2017

- ↑ https://www.briloner.com/de/service/info-licht/index.php?navid=562397762580 Information from Briloner Leuchten GmbH & Co. KG , accessed on March 13, 2020

- ↑ Stiftung Warentest: This is how good LED lamps perform in long-term tests . In: test.de from March 30, 2017

- ↑ Benefits of LED lighting , accessed January 8, 2017

- ↑ How expensive is your lighting? SWR , October 18, 2016; accessed on October 27, 2016.

- ↑ A. Krigel et al .: Light-induced retinal damage using different light sources, protocols and rat strains Reveals LED phototoxicity . In: Neuroscience . tape 339 , 2016, p. 296-307 , doi : 10.1016 / j.neuroscience.2016.10.015 .

- ↑ LED lamps: harmful light for the eyes. In: ndr.de . September 17, 2018, accessed May 26, 2019 .

- ↑ New study shows: LED light is so dangerous for the eyes. In: tz.de . May 24, 2019, accessed May 26, 2019 .

- ↑ Christoph Schierz: Blue light damage to the retina of the eye - state of scientific knowledge , (PDF), publication of the TU Ilmenau 2018, accessed on December 23, 2019

- ↑ Night light: Street lights with LED have a downside In: welt.de, August 13, 2015, accessed on December 5, 2017.

- ↑ LED Practical Guide. International Dark-Sky Association , accessed on December 5, 2017 (English): "Use 'warm-white' or filtered LEDs (CCT <3,000 K; S / P ratio <1.2) to minimize blue emission."

- ↑ Guide to Directive 2014/35 / EU. (PDF, 1MB) November 1, 2016, p. 20 , accessed February 9, 2020 .

- ↑ Lighting technology, standardization and safety regulations - electrical engineering; Lighting practice. TRILUX GmbH & Co. KG, accessed on February 9, 2020 .

- ↑ Hendrik Schäfer: Consumer protection - lighting. VDE Testing and Certification Institute GmbH, May 17, 2019, accessed on February 9, 2020 .

- ↑ Nicole Krottenmüller: Be careful when buying lamps with uncovered LEDs. Bavarian State Ministry for the Environment and Consumer Protection, October 9, 2014, online , accessed on July 9, 2016

- ↑ Consumer information on LED lighting. Retrieved January 8, 2017

- ↑ Ljiljana Udovičić, Florian Mainusch, Marco Janßen, et al .: Photobiological safety of light-emitting diodes (LED) . Ed .: Federal Institute for Occupational Safety and Health. 1st edition. Dortmund, ISBN 978-3-88261-726-9 , pp. 71 ( baua.de [PDF; accessed December 23, 2019]).

- ↑ White multichip LED with 48 Mcd / m² luminance , report in ChannelE from May 28, 2013, accessed on Dec. 24, 2019

- ↑ DIN EN 62471 VDE 0837-471 - Photobiological safety of lamps and lamp systems (IEC 62471: 2006, modified); German version . Beuth, March 2009.

- ↑ DIN EN 60598-1 VDE 0711-1 - Luminaires - General requirements and tests (IEC 60598-1: 2014, modified + A1: 2017); German version EN 60598-1: 2015 + A1: 2018 . Beith, September 2018.

- ↑ Photobiological safety - electrical engineering; Lighting practice. TRILUX GmbH & Co. KG, accessed on February 9, 2020 .

- ↑ Ljiljana Udovičić, Florian Mainusch, Marco Janßen, et al .: Photobiological safety of light-emitting diodes (LED) . Ed .: Federal Institute for Occupational Safety and Health. 1st edition. Dortmund, ISBN 978-3-88261-726-9 , pp. 87 ( baua.de [PDF; accessed on February 9, 2020]).