Lithium iron phosphate accumulator

The lithium iron phosphate battery is a version of a lithium ion battery with a cell voltage of 3.2 V or 3.3 V. The positive electrode consists of lithium iron phosphate (LiFePO 4 ) instead of conventional lithium cobalt (III ) oxide (LiCoO 2 ). The negative electrode consists of graphite (hard carbon) with incorporated lithium. Such an accumulator has a lower energy density than the conventional one , but does not tend to thermal runaway - even in the event of mechanical damage .

Development and function

LiFePO 4 was first proposed as a material for a lithium-ion battery in 1997. It replaces the lithium cobalt oxide used in conventional lithium batteries.

In 2010, Süd-Chemie (now Johnson Matthey ) built the world's largest plant (2500 t per year) in Canada for the production of lithium iron phosphate using a wet chemical process. Production started in April 2012.

Early LiFePO 4 cathodes suffered from low electrical conductivity for ions and electrons , which inhibited power density. The conductivity was through the use of LiFePO 4 - nanoparticles with and coating carbon can be improved. The doping of LiFePO 4 for example with yttrium - (LiFeYPO 4 ) or sulfur atoms improves the technical properties as well.

In contrast to conventional lithium-ion cells with lithium cobalt (III) oxide (LiCoO 2 ), no oxygen is released during the chemical reaction . In lithium-ion accumulators with lithium-cobalt oxide cathodes, this can lead to thermal runaway, which under unfavorable conditions leads to the cell igniting automatically.

Compared to conventional cathode materials (LiCoO 2 ), the entire lithium content is used in the lithium iron phosphate battery. In batteries with LiCoO 2 cathode, only 50–60% of the lithium is used, otherwise the layer structure would be unstable. When using Li 2 Mn 2 O 4 cathodes, only 50% of the existing lithium can be used, the rest is built into the crystal.

The mass fraction of lithium in LiFePO 4 is approx. 4.5% by weight. For an accumulator with an energy content of 1000 Wh , only approx. 11.3 mol (≈ 80 g) lithium are required for the lithium iron phosphate battery, compared to approx. 20 mol or 140 g for the lithium cobalt or lithium Manganese accumulator. The energy density of lithium iron phosphate batteries is 90 Wh / kg to 110 Wh / kg. With lithium accumulators with LiCoO 2 cathode, almost twice as high an energy density can be achieved.

LiFePO 4 accumulators have no memory effect like the nickel-cadmium accumulator, for example . A so-called anomaly during discharge is very small and insignificant in normal operation. LiFePO 4 cells can be temporarily stored , discharged and charged at any time. Long storage times are detrimental to life expectancy only when fully charged and almost discharged.

properties

Cell voltage range

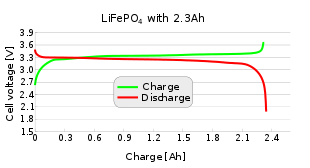

The exact voltages differ slightly between the cell types and manufacturers; in the application, they can be found in the respective data sheet. The end-of-charge voltage is usually 3.6-3.65 V. The protective circuits against overcharging usually respond at 3.8 V.

The end-of-discharge voltages vary depending on the type and are mostly 2.0 V, with some types also just above it in the range of 2.5 V. In the charge range of 10% to 90%, the cells show both charging and discharging only a slight change in the cell voltage, as shown in the adjacent diagram with the cell voltage as a function of the charge for a LiFePO 4 cell with a nominal capacity of 2.3 Ah. In the area of the end of discharge, in the diagram the end in the course of the red line in the right area of the image, and in the area of the charge end, in the diagram the end in the course of the green line in the right area of the image, there is a strong voltage reduction (during discharge) or a strong voltage increase (when charging) available. Slightly reduced end-of-charge voltages (3.4-3.5 V) and reduced depths of discharge have a positive effect on the usable number of cycles and thus the service life.

Designs

There are only a few standardized designs. A basic distinction can be made between round cells and flat cells.

- Round cells are mainly offered in the single-digit to low double-digit Ah range. There are also designs that correspond to unofficial industry standards for round cell dimensions and are similar to device batteries. For example, batteries of the types 18650 and 26650 are used more often, the type designation of which reflects the approximate size, for example 18650 means approx. 18 mm diameter and 65 mm length, 26650 is approx. 26 mm in diameter and approx. 65 mm long. There are also cells of the type 38140, these are 38 mm in diameter and approx. 140 mm long. The weight is around 400 grams per cell and has an M6 screw connection on the poles. These cells are mainly used in industry.

- Flat cells are available for almost all capacity sizes. They are sold in the form of film cells and cuboid cell blocks.

- The former are produced in the form of flat foil covered cells and also as a film cells , respectively. However, this design is only an intermediate product that needs to be handled with care for the assembly of battery packs or for direct installation in a housing. Sizes range from the mAh range to the double-digit Ah range.

- The large cuboid shapes with plastic housing and screw connections (range approx. 20–1000 Ah), which are often referred to as single cells, consist of several foil cells combined in parallel in a common housing. They are much easier to handle than pure film cells, but here too there are no standardized dimensions or grid dimensions.

Anomaly in the discharge voltage curve

Small bumps can be detected in the course of the discharge voltage curve of LiFePO 4 accumulators. This anomaly was called the "memory effect" by the discoverers. The effect is due to the phase transition of individual particles of the active material and, according to previous knowledge, only occurs with LiFePO 4 cathodes and similar olivine cathodes . This so-called "memory effect" cannot be compared with the generally known memory effect in NiCd and NiMH batteries . It occurs from the first discharge, is limited in time and can be reversed by charging the battery. The performance and service life of the battery are not directly affected by the anomaly, but the effect can lead to the charge status display being falsified. By researching the LiFePO 4 - "memory effect", the previously difficult determination of the state of charge of LiFePO 4 accumulators can be improved in the future.

Advantages and disadvantages

LiFePO 4 accumulators have clear advantages over lead accumulators in terms of cycle stability , size, capacity and weight. The disadvantage is the higher purchase price of LiFePO 4 accumulators compared to electrically equivalent solutions with lead accumulators. In addition, there are the balancers , which are not necessary with lead-acid batteries.

The following list refers in particular to the differences to the widely used lithium cobalt (III) oxide (LiCoO 2 ) cells.

advantages

- High safety: Due to the solid electrolyte and the cell chemistry, LiFePO 4 cells are considered intrinsically safe, i.e. H. a thermal runaway and a Membranschmelzung as lithium-ion batteries are considered to be excluded.

- Partial high power density , with continuous streams of 20 C and pulse load up to 50 C .

- High charging currents possible (0.5 C - 3 C), pulse charging currents up to 6 C (10 s)

- High cycle stability: I) Sony Fortelion: 74% remaining capacity after 8,000 cycles with 100% degree of discharge (DoD) II) still 80% original capacity (nominal capacity, NC) after 1000 cycles and 60% capacity after 2000 cycles. Also in cylindrical (18650) cells,> 85% residual capacity was achieved after 10,000 cycles with 100% DoD. Other manufacturers state more than 5000 cycles with a respective discharge to 70% (Depth of Discharge, DoD) and 10,000 cycles with minimal discharge to just 90%, resulting in a long service life and low operating costs.

- High electrical efficiency for a total cycle of charge and discharge of> 91%

- Flat voltage profile for charging and discharging

- Lower sensitivity to deep discharge

- Wide temperature range for storage (e.g. −45 to +85 ° C, −15 to +60 ° C). Practical experience shows that use up to approx. +10 ° C is problem-free; below this, a high current consumption above 0.5 C (traction application) leads to greater voltage drops, but without a noticeable loss of capacity of the battery.

- The self-discharge has been improved by doping and is low at around 3–5% per month

- Better environmental compatibility and conservation of resources by not using cobalt

disadvantage

- Lower nominal voltage of 3.2 volts - while Li-Cobalt cells deliver 3.7 V.

- Lower energy density due to the lower voltage and capacity - around 90 Wh / kg. The volumetric energy density is only about half that of lithium co-batteries. This results in almost twice the weight and space requirement for the same capacity. (→ energy density and efficiency )

- There are only a few common designs, which makes use and replacement difficult.

- The flat voltage curve makes it difficult to determine the state of charge.

- As with all lithium-ion batteries, balancer circuits and battery management systems are necessary for safe operation , as these cells are not overcharge-proof or deep-discharge-proof.

Interchangeability with other battery types

The nominal voltage of two-cell LiFePO 4 batteries is in the same order of magnitude as that of 6 V lead-acid batteries . The same applies to multiples z. B. 12 V, 24 V, 48 V etc. LiFePO 4 batteries are well suited for replacing conventional lead batteries. In spite of the higher capacity and resilience, space and weight can often be saved, which is offset by the higher costs of LiFePO 4 batteries in relation to lead batteries. Protective and control electronics are seldom available in lead-acid batteries, as these are overcharge-proof in a large area.

However, replacing other lithium-ion battery technologies or converting them to LiFePO 4 batteries is made more difficult by the different typical cell voltage of 3.2–3.3 V (3.6 V for lithium-ion batteries to cobalt Base , 3.7 V for the lithium polymer battery ). Existing battery management systems, balancers and chargers for use with cobalt-based lithium-ion batteries can only rarely be reconfigured to use LiFePO 4 batteries.

Manufacturer

A123Systems , which went bankrupt in 2012 , offered lithium iron phosphate batteries as round cells under the name of lithium nanophosphate batteries. A123Systems participated in the development of the serial plug-in hybrid sports car Fisker Karma from Fisker Automotive .

GAIA Akkumulatorenwerke GmbH in Nordhausen, Thuringia, manufactures cylindrical cells with 18 Ah and 38 Ah in LFP (iron phosphate) technology, which are assembled into starter batteries or customer-specific traction batteries.

The company Winston Battery Ltd (formerly Thunder Sky Ltd) from China manufactures a wide range of prismatic battery cells based on LiFePO 4 , especially with yttrium doping (LiFeYPO 4 ) to increase durability and performance.

The Chinese company BYD is the world's largest manufacturer of lithium batteries with a production capacity of over 10 GWh per year. The subsidiary BYD Auto installs the cells in its own electric vehicles and in stationary electricity storage systems. The BYD ebus is the world's first battery bus with lithium iron phosphate batteries.

According to EuPD Research, the southern German company Sonnen is the leading company on the German and European home storage market, which exclusively uses lithium iron phosphate cells, with a market share of around 24%.

The Varta AG with the Varta Storage GmbH is a leading European company that delivers energy storage systems based on lithium iron phosphate cells offering for domestic and industrial applications.

Applications

The largest cell blocks up to 30,000 Ah are used in submarines , in uninterruptible power supplies and in the storage of regenerative energy. Due to its high reliability, the lithium iron phosphate accumulator has an outstanding position in new stationary storage systems for grid stabilization: measured by the output in MW of all Li-ion storage power plants planned in 2014, 39% of them are based on lithium iron phosphate. 40 MWh are used in a battery storage power plant in Hong Kong .

Other fields of application are power tools and the $ 100 laptop . LiFePO 4 batteries are also used in RC model making , as they can be fully recharged within 15–20 minutes and have a higher cycle stability. Ordinary lithium polymer batteries often require more than an hour to charge if you don't want to compromise on their service life.

Further applications are starter batteries in internal combustion engines, where prismatic lithium iron phosphate blocks or assembled round cells are used. Porsche is the first automobile manufacturer to offer a LiFePO 4 starter battery ex works for a surcharge .

Influences on service life and economy

Depending on the application, the lithium iron phosphate accumulators are optimized for high energy density for storing large amounts of energy, e.g. as a traction battery for purely electric vehicles or for the delivery of high currents, e.g. for buffer batteries in hybrid electric vehicles or as starter batteries. With the appropriate design and operating mode, lithium iron phosphate batteries have the prerequisite to function for the entire life of the vehicle without being replaced. In order to increase economic efficiency and service life, various factors can be specifically influenced:

- Although a higher temperature generally has a positive effect on the mobility of the electrons and the course of the chemical processes (current stability), it also increases the formation of surface layers on the electrodes of LiFePO 4 batteries and thus the aging or the gradual loss of capacity and the reduction in the current carrying capacity . Since this is particularly the case above about 40 ° C, the temperature influence is usually less than that of other factors and primarily affects cells that continue to heat up themselves due to cyclical and permanent high loads. Investigations have shown that aging disproportionately deteriorates performance and usability, especially at low temperatures. A study in which cells were aged at 50 ° C and then measured at different temperatures summarizes the results as follows:

“Capacity fade after 600 cycles is 14.3% at 45 ° C and 25.8% at −10 ° C. The discharge pulse power capability (PPC discharge) at 45 ° C does not decrease with cycling (namely, there is little power fade) from 0 to 600 cycles, whereas the power fade after 600 cycles is 61.6% and 77.2%, respectively, at 0 and −10 ° C. The capacity and power fade evidently becomes more severe at lower temperature due to greatly increasing cell resistance. In particular, the power fade at low temperatures (eg, 0 and −10 ° C) rather than capacity loss is a major limitation of the LiFePO 4 cell. "

“The decrease in capacity after 600 cycles is 14.3% at 45 ° C and 25.8% at −10 ° C. There is only a slight decrease in current carrying capacity at 45 ° C after 600 cycles, while the power decrease after 600 cycles is 61.6% and 77.2% at 0 and −10 ° C. Capacity and current carrying capacity decrease more at low temperatures. In particular, the decrease in current capacity at low temperatures (e.g. 0 and −10 ° C) is a major limitation of the LiFePO 4 cell. "

- The regularly used depth of discharge has a major influence on the cyclical service life. When the voltage level is low, irreversible processes start in the cells. Storage in a discharged state is therefore also harmful. Shallow discharge depths multiply the achievable number of cycles, the possible energy consumption and thus increase the service life compared to operation with full cycles. The lower voltage limit is usually monitored by the battery management system with limitation of the power that can be drawn and shutdown, but often at a very low voltage level in order to enable high amounts of energy to be drawn. The manufacturer Winston recommends designing the capacity of a traction battery so that regularly only a discharge of less than 70% is required.

- Even in the area of the upper voltage limit of the cells specified by the manufacturer , irreversible chemical processes set in, which in the long term lead to a decrease in capacity and thus cell wear. Overcharging beyond this voltage limit damages the cell irreversibly. In current applications, the upper charging voltage is often set high when balancing , as this allows the charging states of the individual cells to be better determined and the entire capacity to be used, at the expense of service life. Even with balancers with balancing currents that are too low, voltages are often reached in the uppermost operating range of the cells. Maintenance or continuous charging with constant voltage with the upper voltage limit is not necessary due to the low self-discharge and is detrimental to the service life. It is therefore recommended that the charging current be switched off after the full charge criterion has been reached.

- The current load should be as uniform as possible; extreme current load peaks (especially with smaller batteries, e.g. in hybrid vehicles) increase wear. The manufacturer's limit specifications are the technical maximum values that the battery can provide, but whose regular use shortens the service life. It is less about the currents of the on-board chargers, which are usually limited in their performance, but rather about extreme current peaks, for example during acceleration, but also through recuperation or fast charging processes with currents> 1 C, for example with CHAdeMO , whose high-current charging therefore to protect cells at around 80% of the nominal capacity is terminated.

A study from 2012 on high-current A123 cells in hybrid application states:

“The longest lifetime is observed for cells cycled with low peak currents and a narrow SOC range. In addition, high charge current is found to affect the cycle life profoundly. On the contrary, a moderate temperature increase did not result in a shorter cycle life. "

“The longest service life is achieved for cells that are used with low current peaks and in a narrow area of the SOC. In addition, high charging currents have a very strong impact on the service life. In contrast, a moderate increase in temperature did not result in a shorter service life. "

Web links

- Trends in lithium-ion batteries , interview with Norbert Schall, YouTube, accessed on July 6, 2012

- LiFePO4 - LiFeYPO4 cell cycle voltage levels GWL, representation of the use of the voltage range of LiFePO 4 cells

- Litrade: Charging a LiFePo4 on a car alternator, voltage 14.4V

Individual evidence

- ↑ MC Rao: Novel Cathode Materials for Rechargeable Batteries. (PDF) International Journal of Science and Research (IJSR), 2014, accessed December 28, 2016 .

- ↑ Süd-Chemie, July 12, 2010: World's largest production facility with a new, high-quality manufacturing process for lithium iron phosphate , accessed July 10, 2013.

- ↑ Clariant AG, April 2, 2012: Phostech Lithium Plant Officially Opens ( Memento of the original from December 10, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 226 kB), accessed July 10, 2013.

- ↑ Yingke Zhou, Jie Wang, Yuanyuan Hu, Ryan O'Hayre, Zongping Shao: A porous LiFePO 4 and carbon nanotube composite . In: Chem. Commun. tape 46 , no. 38 , September 21, 2010, p. 7151-7153 , doi : 10.1039 / C0CC01721C .

- ↑ a b 产品 规格 书 (product specification). (PDF) Retrieved December 28, 2016 .

- ↑ a b c d e Gaia GmbH: Handling of LFP cell 38Ah ( Memento of the original from January 10, 2017 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 697 kB), inserted on March 14, 2012.

- ↑ a b c d e f Winston Battery: WB-LYP100AHA data sheet cell 3.2 V 100 Ah , added on February 3, 2012.

- ↑ Tsuyoshi Sasaki, Yoshio Ukyo, Petr Novák: Memory effect in a lithium-ion battery . In: nature materials . April 14, 2013, doi : 10.1038 / NMAT3623 .

- ↑ ZeitOnline, April 16, 2013: Lithium-ion batteries have a memory effect. accessed July 22, 2013.

- ↑ ev-power.eu: CALB 100Ah test report , PDF, accessed July 1, 2013.

- ↑ https://lithiumwerks.com/power-cells/

- ↑ Sony LifePO 4 battery page 8: after 8000 charging cycles with 100% DoD 74% remaining capacity (note: battery came onto the market in 2009), accessed on February 6, 2015.

- ↑ Investigations of polarization effects on lithium-ion batteries In: Doctorate Dr. Marcel Wilka December 19, 2013.

- ↑ 3xe-electric-cars.com: Winston Battery ( Memento of the original dated February 3, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ a b GWL-Power: Winston 90Ah over 10,000 / 13,000 cycles , PDF, inserted on February 21, 2012.

- ↑ online February 23, 2008: Large-Format, Lithium Iron Phosphate ( Memento from December 2, 2008 in the Internet Archive ).

- ↑ Winston Battery: WB-LP12V90Ah, data sheet block battery 12V 90Ah LiFePO4 , added on February 21, 2012.

- ↑ Gaia GmbH: HP 601300LFP 18Ah / 58Wh PDF data sheet , inserted on March 14, 2012.

- ↑ Gaia GmbH: HP 602030LFP 38Ah / 122Wh PDF data sheet , inserted on March 14, 2012.

- ↑ a b Gaia GmbH: Applications , inserted on March 14, 2012.

- ^ Tunder-Sky / Winston Battery: Company website , accessed February 1, 2012.

- ↑ Sonnen, E3 / DC, Senec and LG Chem dominate the German PV home storage market - pv magazine Germany. Retrieved January 13, 2018 (German).

- ^ The market is talking about Tesla, German battery storage companies leading in market shares . ( eupd-research.com [accessed January 13, 2018]).

- ↑ Europe's Energy Storage Market Is in Transition . ( greentechmedia.com [accessed January 13, 2018]).

- ↑ Nicole Wörner: Varta newcomer to the stock exchange: Lithium-ion batteries drive profit. In: markt-technik.de . 22nd November 2017.

- ↑ Company website Varta Storage GmbH with product overview , accessed on November 22, 2017.

- ↑ Winston Battery: Intelligent Uninterruptible Energy Storage Cabinet , added February 8, 2012.

- ^ Carole Jacques: Li-ion Dominates the Booming Grid Storage Market With 90% of 2014 Proposals. Lux Research, Inc., March 4, 2015, accessed September 30, 2015 .

- ↑ Porsche press release with the market launch date for January 2010 of November 23, 2009.

- ↑ a b c Jens Groot, Chalmers University of Technology, Göteborg, 2012: State-of-Health Estimation of Li-ion Batteries: Cycle Life Test Methods , PDF, accessed July 1, 2013.

- ↑ Cycling degradation of an automotive LiFePO4 lithium-ion battery In: Journal of Power Sources 196, (2011), 1513–1520, doi: 10.1016 / j.jpowsour.2010.08.070 .