OHC valve control

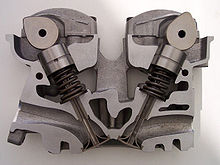

The overhead camshaft denotes a design of the valve control system of a reciprocating piston - four-stroke engine (for the exhaust valves of two-stroke diesel engines ), in which the actuation of the valves by a plurality of overhead or cam shaft (s) (English: O ver h ead C amshaft ) is carried out. The valves can be controlled by the cams directly via bucket tappets or indirectly via rocker arms or rocker arms.

The characteristic feature of the OHC engine is the position of the camshaft (s), which must / must be above the dividing line between cylinder and cylinder head ; For V , boxer , star and other engines with several cylinder banks as well as “hanging” ( crankshaft above) installed inline or V engines is meant by “above”: on the side of the dividing line facing away from the combustion chamber . In aircraft engines , which are often installed in a suspended manner , the overhead camshaft (s) is / are actually below the combustion chambers.

Alternatives are the OHV valve control ("hanging valves") or, mostly with older designs or small engines, the SV valve control with "standing" valves ("side valves").

Variants and Abbreviations

DOHC describes a design in which the valves are controlled by two overhead camshafts ( double overhead camshaft , also twin cam ) per cylinder bank. (DOHC V and boxer engines therefore have four camshafts.) The valves of DOHC engines are almost always controlled directly via bucket tappets or indirectly via rocker arms.

SOHC (English: Single Overhead Camshaft ) refers to two different types of four-stroke engine. On the one hand, the classic OHC control of the two-valve engine is sometimes mentioned, in which a single camshaft is arranged directly above the valves arranged in a line. The term SOHC is more common, however, for engines with three or four valves per cylinder, in which the valves, unlike the DOHC engine, are controlled by just one central overhead camshaft per cylinder bank . The camshaft is installed between the V-shaped inlet and outlet valves to save space, and the valves are usually operated using (roller) rocker arms. The cylinder head of a SOHC engine is therefore significantly more compact than that of a DOHC engine. Examples of four-valve SOHC engines are the Triumph Dolomite Sprint , the Husaberg FE 570 and the Chrysler Neon , three-valve SOHC engines can be found in the Honda NTV and various Mitsubishi Colt .

OHC engines, the camshaft of which is up on the side of the cylinder head, are specifically called CIH engines ( Camshaft In Head ). This design with conventional (hydraulic) tappets can be found z. B. in four- and six-cylinder engines of the Opel brand, which were manufactured from 1965 to the beginning of the 1990s. However, these motors are not as speed-stable as conventional OHC motors. They have rocker arms and tappets but no bumpers. With CIH engines, all valves are in a row.

A very similar solution, but with V-shaped overhead intake and exhaust valves - this arrangement enables a semi-spherical ( hemispherical ) combustion chamber - called Ford CVH -Motor ( C ompound V alve H emi, translated in the network (the camshaft) valves arranged , hemispherical combustion chamber), which was offered in Europe from 1.1 to 1.8 liters displacement and with approx. 50 to 132 hp rated power from 1980 to approx. 2000. In this OHC engine, the camshaft, which is driven by a toothed belt, sits centrally above the crankshaft in a light metal cylinder head between the valves. These are driven by hydraulic valve lifters ( mechanical on the Ford Escort RS1600i , roller lifters on the Sierra 1.8) and rocker arms. The more compact design - as with CIH - compared to the classic OHC engines was an advantage, the design-related maximum speed of approx. 8000 min −1 a disadvantage. Similar designs existed in the 1960s at BMW , NSU and later at Peugeot.

All of these four-stroke reciprocating piston engines are also OHV engines, since their valves - regardless of the position of the camshaft (s) - are arranged "hanging" in the cylinder head. However, in order to ensure a clear differentiation of the valve timing, OHV engines are only named that way if they do not have overhead camshafts.

SV engines have "standing" valves and no overhead camshaft.

In a radial engine , the camshaft is arranged as a " cam drum " or ring coaxially to the crankshaft. This special type of engine is therefore considered a " bottom-controlled " engine. In principle, camshafts can also be arranged in the cylinder heads in radial engines, but this is not implemented because of the high structural complexity.

In principle, valve controls without camshafts (e.g. via pneumatics) and even valve-free control of the gas exchange processes in the four-stroke engine using slide controls are possible.

drive

Overhead camshafts are usually driven with a toothed belt or a timing chain . Spur gear cascades and pairs of push rods ( Albert Roders ULTRAMAX control ) can only be found in historical engines, vertical shafts are expensive and rare ( Ducati up to approx. 1986, and Kawasaki W650 / W800 ). A combination of spur gear and chain drive is the so-called Weller drive developed by the Englishman John Weller (1877–1966; at the same time co-founder of the English car manufacturer AC Cars Ltd.). A pair of spur gears reduces the crankshaft speed by half, from there a chain drives the overhead camshaft (s) with a gear ratio of 1: 1. This drive was introduced in 1927 by the English motorcycle manufacturer AJS . John Weller has improved the tensioning and guiding devices of chain drives in many details.

Compared to chains, timing belts are cheaper, do not require lubrication (and therefore no oil-tight encapsulation) and run more quietly. The Dingolfing agricultural machinery and automobile manufacturer Hans Glas is considered the first to use the timing belt in series production . The disadvantage is the exact belt tension required and the greater risk of tearing compared to chains if the belt is incorrectly tensioned or material fatigue; Major engine damage is often the result of a broken timing belt. Regular checks and timely replacement are consequently necessary; typical replacement intervals for automobiles are between 60,000 and 120,000 km or four to ten years, depending on the type of engine. Sometimes replacement intervals of 240,000 km are planned (2-liter diesel from Peugeot / Ford / Volvo). In the case of motorcycles, due to the limited space available (smaller deflection pulleys, resulting in greater stress on the belts), significantly shorter change intervals are common (Ducati models up to 2012: 20,000 / 24,000 km, from 2014 partly 30,000 km).

The toothed belt drive of the new Ford EcoBoost 3-cylinder engine is an innovation : The two drive belts for the valve control and oil pump run in an oil bath. This should reduce running noise and consumption and at the same time increase the mileage of the belt.

history

At the beginning of the 20th century, OHC valve control was initially the most widespread form of valve control for stationary diesel engines. The camshaft is inclined above or next to the cylinder head and actuates the valves via rocker arms. The camshaft is usually driven by a vertical shaft. (See picture on the right.) This design has the advantage that the mass acceleration remains small, which has a positive effect on the possible rotational frequency.

One or two overhead camshafts have been known in high-performance engines since the beginning of the 20th century. An engine with an overhead camshaft was already installed in the Prinz Heinrich Type 9C produced by Deutz in 1909 . Another early example of such an engine was developed by Peugeot in 1912 with two overhead camshafts and four valves per cylinder for their Grand Prix racing car. Also Alfa Romeo built a 1913 Grand Prix model for 1914 with an overhead camshaft. 1914 also saw the development of the first aero engine with overhead camshaft Hispano-Suiza 8 . Two overhead camshafts are known from racing motorcycles on the Peugeot 500 Sport from 1913.

However, this construction method hardly played a role in the cars built before the Second World War. Because they were easier to maintain and were believed to be more reliable, SV motors were used instead. With these, a tearing valve or failure of the camshaft drive did not cause any expensive consequential damage. In addition, the vertical shafts used at the time with two pairs of bevel gears or gear cascades were far more complex to manufacture than simple pairs of spur gears or short timing chains. The vibration dampers for long timing chains or the toothed belts of today's engines were not yet invented or ready for series production.

Alfa Romeo equipped almost all of their engines in this way , starting with the RL Normale model presented in 1922 . Overall, however, there were only a few series-production engines with overhead camshafts until the 1940s, including the Fiat 509 engine from 1925 and that of the 1928 Morris Minor , the Jaguar XK -DOHC engine, vehicles from Singer , the eight-cylinder from Tatra ( Tatra 77 and 87 ) and from 1945 the Crosley CC with a king shaft driven camshaft. The Soviet four-valve, twelve-cylinder high-performance diesel engine W-2 from 1937 also has four king-shaft driven overhead camshafts and valves with bucket tappets. It was not until the late 1950s that OHC engines became popular in passenger cars. In addition to Alfa Romeo (DOHC, chains), in Germany Mercedes-Benz with the M 180 with timing chain and rocker arms , NSU with pushrod-driven camshaft ( Ultramax control ) and rocker arms in motorcycles and in the Prinz small car, the Borgward Group ( Lloyd Alexander with timing chain and rocker arms), like later BMW in the BMW M10 and in the USA Willys Motor Company with the Jeep Tornado engine. The first model with a toothed belt-driven camshaft in series was the Glas 1004 in 1962 , albeit without a breakthrough in the mass market. With toothed belt drive, the engine of the Fiat 125 with two overhead camshafts and the Vauxhall "slant four" with one appeared in 1966 .

Advantages and disadvantages

advantages

Motors with overhead camshafts offer good conditions for high speeds because of the small masses moved for valve actuation and can therefore achieve higher maximum outputs and a better power-to-weight ratio than other motors at a given mean pressure .

disadvantage

In the time of the early industrial diesel engines, the OHC valve control had the disadvantage that even with smaller engines, an operating platform had to be attached to the engine in order to be able to service the camshaft.

For the conversion to overhead camshafts, the vehicle manufacturers had to redesign engine blocks and cylinder heads and renew the production lines, which is why many manufacturers delayed the conversion and continued to offer their OHV engines for a long time.

If a toothed belt is used to drive the camshaft, this requires more effort for maintenance. These components have to be replaced regularly; the usual maintenance intervals are between 40,000 and 240,000 km depending on the engine (e.g. diesel engine with PSA ).

Long timing chains require guide and tension rails; often there are three or four in circulation. In particular, V-engines with extremely long timing chain circuits (from the crankshaft up to the first cylinder head, down to the deflection wheel, up to the second cylinder head, back down to the crankshaft) require maintenance or inspection. Because of their plastic layer on the chain side, slide rails are wearing parts that should be changed after approx. 150,000 to 300,000 km.

The complicated guidance of timing chains or toothed belts has long been a reason for the use of the OHV design in V-engines in trucks and many American vehicles. A central camshaft, which can be driven by the crankshaft via a short chain or a pair of gears, is sufficient here.

literature

- Peter Gerigk, Detlev Bruhn, Dietmar Danner: Automotive engineering. 3rd edition, Westermann Schulbuchverlag GmbH, Braunschweig, 2000, ISBN 3-14-221500-X

- Max Bohner, Richard Fischer, Rolf Gscheidle: Expertise in automotive technology. 27th edition, Verlag Europa-Lehrmittel, Haan-Gruiten, 2001, ISBN 3-8085-2067-1

- Peter A. Wellers, Hermann Strobel, Erich Auch-Schwelk: Vehicle technology expertise. 5th edition, Holland + Josenhans Verlag, Stuttgart, 1997, ISBN 3-7782-3520-6

- Hans Jörg Leyhausen: The master craftsman's examination in the automotive trade part 1. 12 edition, Vogel Buchverlag, Würzburg, 1991, ISBN 3-8023-0857-3

- Julius Magg : The controls of the internal combustion engines . Springer publishing house. Berlin. 1914. ISBN 978-3-642-47608-2 .