Nickel-metal hydride accumulator

A nickel-metal hydride accumulator (NiMH) is an accumulator with a positive electrode made of nickel (II) hydroxide and a negative electrode made of a metal hydride . The technical fundamentals were developed by Stanford R. Ovshinsky and Masahiko Oshitani from 1962 to 1982 to make the cell ready for the market.

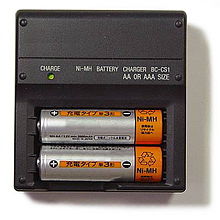

NiMH accumulators are widely used in the usual designs of standard batteries and deliver a nominal voltage of 1.2 V per cell with a typical end-of- discharge voltage of 1.0 V. They can usually be used as a rechargeable alternative to replace the common alkaline batteries in common household devices. Advantages over nickel-cadmium batteries (NiCd), which are no longer freely available for sale, are the lack of toxic cadmium and a higher energy density .

NiMH accumulators with low self-discharge have been on the market since 2006 , which are characterized by a significantly reduced self-discharge compared to conventional NiMH batteries .

properties

The energy density of a NiMH cell is around 80 Wh / kg, which is almost as large as that of an alkali-manganese cell and more than twice as large as that of a NiCd battery. For the size Mignon (AA) capacities from 800 to 2850 mAh are available. For replacement purposes to replace NiCd cells, there are also special versions with only 600 to 900 mAh, which should be more compatible with old charging circuits. NiMH batteries of the size Micro (AAA) are available with up to 1,100 mAh, baby cells with up to 6,000 mAh and mono cells with up to 12,000 mAh capacity. The typical end-of-discharge voltage of NiMH cells is 1.0 V.

In contrast to zinc-carbon cells, the low-resistance NiMH rechargeable batteries (lower internal resistance compared to batteries) can release their stored energy within a short period of time with almost constant voltage.

Like NiCd batteries, NiMH accumulators have a nominal voltage of 1.2 V per cell. Nevertheless, they are used in many applications as a replacement for zinc-carbon and alkaline batteries, which have a nominal voltage of 1.5 V per cell. In some applications, however, the lower nominal voltage can be a disadvantage. For example, unregulated flashlights designed for 1.5 V batteries usually shine significantly less brightly with 1.2 V batteries due to the lower voltage. Under high loads, the battery can achieve a higher level with the advantage of its lower internal resistance Keep tension.

restrictions

NiMH batteries are sensitive to overcharging, overheating, incorrect polarity , deep discharge (current consumption until the charging capacity is almost completely exhausted) or deep discharge with polarity reversal, as is the case for example. B. can occur with cells connected in series. The possible decrease in the amount of electrical charge ( capacity ) cannot be reversed by taking special measures such as complete discharging (down to 1 V under load) or even repeated charging and discharging (this even has the negative effect of reducing the service life the limited number of possible charging cycles). An intelligent charger is indispensable for achieving the target service life of typically 500 charging cycles (corresponding to ten years with weekly charging) .

NiMH batteries are not suitable for operation at temperatures below 0 ° C. Already in the vicinity of the freezing point they show a significantly higher internal resistance due to the reduction in the mobility of the electrons, through which the voltage collapses under load and only low currents (power) can be drawn. The performance drops below −10 ° C. They can no longer be charged at temperatures above 50 ° C.

Instead of the memory effect , which is particularly relevant with older NiCd batteries, after frequent partial discharges, NiMH batteries experience a battery inertia effect , a drop in the achievable discharge voltage, which is largely reversible.

Comparison with NiCd batteries

Compared to nickel-cadmium batteries (NiCd batteries), NiMH batteries offer roughly twice the energy density at the same voltage. They have largely replaced NiCd batteries, which are covered by an EU-wide trade ban in certain applications and designs such as mignon cells. NiMH batteries can do without the toxic heavy metal cadmium .

However, NiMH batteries also have disadvantages compared to NiCd batteries: lower cycle stability, lower maximum charge and discharge current, smaller temperature range and lower robustness against inferior charging processes or deep discharge as well as more difficult charge end detection.

functionality

construction

The picture on the right shows the components of an opened NiMH battery. The perforated foil (left) serves as a carrier for the metal - alloy or the metal hydride powder, the negative electrode is formed. For example, an alloy with the ratio formula La 0.8 Nd 0.2 Ni 2.5 Co 2.4 Si 0.1 is used for this. The separator (middle) absorbs the electrolyte , a 20 percent potassium hydroxide solution with a pH value of 14, and prevents direct contact with the positive electrode. This consists of a sheet of nickel (II) hydroxide and black nickel oxide hydrate ( nickel (III) hydroxide ) (right).

The foils are wound up with an external negative electrode and encased with a metal cylinder (sawed open, bottom left). The housing is electrically connected to the negative electrode and forms the negative pole of the battery. An electrical lead from the nickel oxide sheet (right, blue-insulated metal strip) leads to the head of the cell and forms the positive pole.

Electrochemistry

During the charging process, H + ions ( protons ) are reduced to hydrogen at the negative pole , which is reversibly bound by the metal alloy and stored as a metal hydride . During the charging process, nickel of oxidation level + II (in the form of nickel (II) hydroxide ) is oxidized to nickel of oxidation level III (to nickel (III) oxide hydrate NiO (OH)) at the positive pole .

When discharging, the hydrogen bound in the metal hydride (M + H - ) is oxidized to a proton (H + ) and a metal of oxidation state 0 (M 0 ) is formed. The protons produced react with the OH - ions ( hydroxide ions ) in the potassium hydroxide solution to form water . The redox potential at pH 14 is approximately −0.83 V (1) . Due to the free electrons that are also generated during the reaction, this pole becomes the negative pole. At the other pole, nickel of oxidation level + III (NiO (OH) or Ni 2 O 3 · H 2 O ) is reduced to nickel of oxidation level + II (Ni (OH) 2 ) . Free electrons are bound, so that this pole becomes the plus pole. The redox voltage is approx. +0.49 V (2) . The total voltage of the sum reaction is 1.32 V (3) .

(1) Oxidation: |

−0.83 V | ||

(2) Reduction: |

+0.49 V | ||

(3) Redox reaction: |

Sum: 1.32V | Open circuit voltage |

To prevent the metal from oxidizing instead of the hydrogen towards the end of the discharge, a negative electrode is installed that is much larger than the positive electrode. The latter thus determines the capacity of the battery: The nickel (III) oxide hydroxide on the smaller positive electrode is exhausted before the hydrogen on the larger negative electrode is completely used up.

Charging

Self-discharge

Conventional NiMH batteries have a self-discharge rate of five to ten percent on the first day and then stabilize at half a percent to one percent per day at room temperature. This high self-discharge prevents the use of such batteries in devices where a battery life of several months or years is desired, such as watches, remote controls or even safety-related devices such as fire alarms or flashlights for emergencies. The ambient temperature has a strong influence on the level of the discharge rate, lower ambient temperatures result in a lower self-discharge rate, and higher ambient temperatures result in a higher self-discharge rate. The capacity also has an influence on the self-discharge rate: maximum capacity cells (> 2700 mAh for cells of AA size) have the highest self-discharge rate.

In 2006 a new type of NiMH rechargeable battery was presented, NiMH with low self-discharge , which has a significantly lower self-discharge rate thanks to the use of new separators. They can be sold pre-charged and do not need to be charged before first use like conventional batteries. Your self-discharge rate should be only 15 percent per year when stored at room temperature. They can be charged in conventional chargers and have similar charging cycles (500 to 1000) as previous NiMH batteries. Sanyo was the first on the market with such batteries (Eneloop), and other manufacturers soon followed.

Battery inertia effect

The battery inertia effect (or English lazy battery effect ) denotes a reduction in performance, primarily affecting NiMH batteries, and a slight drop of 50 mV to 100 mV in the achievable discharge voltage. This does not suddenly drop sharply long before the nominal charge amount is reached, as is the case with the memory effect, which is particularly relevant to NiCd batteries , but remains somewhat lower over the entire discharge process than with a healthy cell. However, the amount of charge that can be drawn (current intensity multiplied by time) is almost the same.

This is due to various causes such as continuous charging or storage, and less so to constant partial discharge. In practical use, the effect only causes problems when devices require higher minimum voltages or when e.g. For example, digital cameras react very sensitively to insufficient voltage, assume the battery is discharged too early and then switch off to avoid supposedly deep discharge.

A Swedish research group discovered in 2018 that they can almost completely prevent the aging process of NiMH batteries by adding oxygen, which restores the lost electrode balance and replaces the lost electrolyte. This is problem-free with these batteries, as all cells share the same gas space.

The battery inertia effect is reversible: it can be eliminated by about five complete charging and discharging cycles with a suitable charger . (First full discharge with a current of approx. 1/10 C / h up to approx. 0.9 V under load. For the subsequent full charge, higher charging currents of 0.5 to 1 C / h are recommended.)

use

Comparable to NiCd batteries , NiMH batteries are used wherever there is a high energy requirement and high battery costs are to be avoided.

- Small lights, LED lights

- Toys

- Remote controls

- Audio, photo and video equipment

- Electric toothbrushes and razors

- Cordless DECT telephones

- Airsoft guns

- GPS devices

- Power tools

- Electric cars

- Flashlights

NiMH batteries are also used as energy storage in emergency lighting systems .

NiMH batteries were first used as traction batteries in the General Motors EV1 . GM later sold the majority stake in Ovonics, which controlled the production of NiMH batteries by means of patents, to the Texaco oil company . This severely restricted further development and use. The Toyota Prius , for example, uses 228 series-connected 6.5 Ah NiMH batteries with a total voltage of over 200 V to supply a 60 kW electric motor. The upper limit for the cell capacity permitted by patent is 10 Ah. Various legal disputes, including those with Matsushita , are pending. Alternatively, large batteries can be purchased from Cobasys, a subsidiary of Ovonics.

literature

- Chapter 22: Michael Fetcenko, John Koch: Nickel-Metal Hydride Batteries. In: Thomas B. Reddy (Ed.): Linden's Handbook of Batteries , 4th Edition, McGraw-Hill, New York 2011, ISBN 978-0-07-162421-3

- Claus Daniel, Jürgen O. Besenhard: Handbook of Battery Materials. Wiley-VCH, Weinheim 2011, ISBN 3-527-32695-2 .

- Chapter 2.4. The nickel-metal hydride accumulator. In: P. Birke, M. Schiemann: Accumulators: Past, Present and Future of electrochemical energy storage , H. Utz Verlag, Munich 2013, ISBN 978-3-8316-0958-1 , pp. 153-164

- Dell, Rand: Understanding Batteries , Royal Society of Chemistry, 2001, ISBN 0-85404-605-4 , pp. 138-141

Individual evidence

- ^ Uday A. Bakshi, Varsha U. Bakshi: Basic Electrical Engineering . 2., revised. Technical Publications Pune, Pune 2009, ISBN 978-81-8431-694-0 , chap. 1, p. 67.

- ↑ slowflyer.ch: Temperature dependence of LSD-NNiMH batteries. ( Memento of the original from September 3, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Retrieved August 30, 2014.

- ↑ The electrification of the powertrain: basic knowledge . Springer-Verlag, 2014, ISBN 978-3-658-04644-6 , pp. 58 ( books.google.de ).

- ↑ Valentin Crastan: Hybridization and regulation of a mobile direct methanol fuel cell system . Forschungszentrum Jülich, 2010, ISBN 978-3-89336-642-2 , p. 28 ( books.google.de ).

- ↑ Yang Shen: Development of metal hydride surface structures for high power NiMH batteries: Also extended cycle-life and lead to more effective recycling methods . Stockholm 2018 ( diva-portal.org [PDF; accessed January 6, 2019]).