Cerium (IV) oxide

| Crystal structure | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

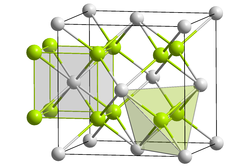

| __ Ce 4+ __ O 2− | ||||||||||||||||

| Crystal system |

cubic |

|||||||||||||||

| Space group |

Fm 3 m (No. 225) |

|||||||||||||||

| General | ||||||||||||||||

| Surname | Cerium (IV) oxide | |||||||||||||||

| other names |

Ceria |

|||||||||||||||

| Ratio formula | CeO 2 | |||||||||||||||

| Brief description |

light yellow solid |

|||||||||||||||

| External identifiers / databases | ||||||||||||||||

|

||||||||||||||||

| properties | ||||||||||||||||

| Molar mass | 172.11 g mol −1 | |||||||||||||||

| Physical state |

firmly |

|||||||||||||||

| density |

7.3 g cm −3 |

|||||||||||||||

| Melting point |

approx. 2000 ° C |

|||||||||||||||

| solubility |

almost insoluble in water |

|||||||||||||||

| safety instructions | ||||||||||||||||

|

||||||||||||||||

| Toxicological data | ||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | ||||||||||||||||

Cerium (IV) oxide or ceria is an oxide of the rare earth metal cerium . In addition to this, there is also cerium (III) oxide (Ce 2 O 3 ) and the dark blue mixed oxide cerium (III, IV) oxide (Ce 3 O 4 ). In 1808, the English chemist Sir Humphry Davy showed that the rare earth cerite is not an element, but a combination of metallic elements, silicon and oxygen . Between 1839 and 1843, Carl Gustav Mosander succeeded in separating and proving that it is a mixture of different metal oxides with silicon dioxide or an island silicate ((Ce, La, Ca) 9 (Fe 3+ , Mg) [(OH) 3 | SiO 3 (OH) | (SiO 4 ) 6 ]).

properties

Like all rare earth oxides, cerium (IV) oxide emits a strong light when heated. It crystallizes in the fluorite structure . In its purest form, the oxide is cream-colored to light yellow. If it contains impurities (e.g. neodymium, praseodymium), the oxide can also take on brown shades. The brown color is mostly ceria, which is used for grinding and polishing purposes. The purity is irrelevant here.

Reactions

Cerium (IV) oxide is formed by heating cerium (III) nitrate , Ce (NO 3 ) 3 or cerium (III) oxalate Ce 2 (C 2 O 4 ) 3 .

When heated, the reaction of ceria with conc. Sulfuric acid cerium (IV) sulfate :

use

catalyst

Cerium (IV) oxide is used in catalytic converters in motor vehicles and, in the event of a lack of oxygen, oxidizes carbon monoxide and excess hydrocarbons according to:

If there is an excess of oxygen in the exhaust gas, the catalytic converter is reactivated:

Nanocrystalline cerium (IV) oxide tubes with a diameter of around 0.75 μm can be used for catalytic reactions, for example for the direct carboxylation of methanol with carbon dioxide to form dimethyl carbonate .

Mantles

An optimal light yield can be achieved from a mixture of approx. 99% thorium (IV) oxide and 1% cerium (IV) oxide. This is used in the manufacture of incandescent mantles for gas lamps (gas incandescent light or Auer light ) by soaking them in the appropriate nitrate solutions. When burning, the oxides are created, which ensure the high light output.

Abrasives

Polishing agent based on cerium (IV) oxide is used as opaline in the optical industry for polishing glasses. It is usually supplied as a dry, white powder and has a density of about 1.6 g / cm³. The mean grain size is about 1 µm. The polishing suspension , which is made with deionized water, contains approximately 60 g of Opaline per liter of water.

Similarly, cerium (IV) oxide-based polishing suspensions are also used in semiconductor technology. They are mainly used for chemical-mechanical polishing (CMP) of silicon dioxide. However, the mean grain size is significantly smaller, it is only around 50 to 150 nm. Since the cerium (IV) oxide particles sediment relatively quickly, organic additives such as polyelectrolytes are used to stabilize the suspension. There are also commercial products that use other organic substances, such as certain amino acids , in order to achieve an increased material selectivity between the removal rates of silicon dioxide and silicon nitride. The background is that silicon nitride layers are used as a stop layer in SiO 2 -CMP and should not be removed during polishing.

Further

The cerium (IV) oxide-cerium (III) oxide process is being developed for the future production of hydrogen using solar energy .

CeO 2 is also used as a UV absorber in paints . This serves to improve the lightfastness of exposed surfaces; Otherwise paints will be decomposed by the UV radiation .

Risk assessment

In 2015, cerium (IV) oxide was included in the EU's ongoing action plan ( CoRAP ) in accordance with Regulation (EC) No. 1907/2006 (REACH) as part of substance evaluation . The effects of the substance on human health and the environment are re-evaluated and, if necessary, follow-up measures are initiated. Cer (IV) oxide uptake was driven by concerns about cumulative exposure , environmental exposure , other hazard-related concerns and widespread use, as well as the potential dangers of carcinogenic and mutagenic properties. The reassessment is to be carried out by Germany from 2020 .

literature

- Paul Trust , Michael Schimmels : Introduction to chemistry - on the simplest basis; Part II Systematics of Inorganic Chemistry on the Basis of the Periodic Table of Basic Materials . 2nd edition Herrosé, Wiesbaden 1956.

- The New Encyclopædia Britannica; Macropæedia Vol. 15th 15th Ed. Encyclopædia Britannica, Inc., 1974.

Individual evidence

- ^ WH Weber, KC Hass, JR McBride: Raman study of CeO 2 : Second-order scattering, lattice dynamics, and particle-size effects. In: Physical Review B. 48, 1993, pp 178-185, doi: 10.1103 / PhysRevB.48.178 .

- ↑ Data sheet cerium (IV) oxide at AlfaAesar, accessed on April 5, 2010 ( PDF )(JavaScript required) .

- ↑ a b c Entry on cerium (IV) oxide in the GESTIS substance database of the IFA , accessed on June 18, 2017(JavaScript required) .

- ↑ a b c data sheet cerium (IV) oxide (PDF) from Merck , accessed on June 18, 2017.

- ↑ Data sheet Cerium (IV) oxide from Sigma-Aldrich , accessed on June 12, 2011 ( PDF ).

- ↑ Entry on cerium (IV) oxide in the ChemIDplus database of the United States National Library of Medicine (NLM), accessed on June 18, 2017.

- ↑ Mineral Atlas: Cerit

- ^ JJ Schneider, M. Naumann, C. Schäfer, A. Brandner, HJ Hofmann, P. Claus: Template-assisted formation of microsized nanocrystalline CeO 2 tubes and their catalytic performance in the carboxylation of methanol . In: Beilstein Journal of Nanotechnology . No. 2 , 2011, p. 776-784 , doi : 10.3762 / bjnano.2.86 .

- ↑ Reinhard Conradt, Ulf Dahlmann, Sonja-Michaela Groß, Fritz Klocke, Stefan Hambücker: Optimization of the chemical influences in the mechanical polishing of glass. Final report on the research project in collaboration with the Arbeitsgemeinschaft industrial research eV, Institute for Rock Metallurgy Fraunhofer Institute for Production Technology, 2001 ( PDF , AiF project: 12063 N).

- ↑ Technical Information L-NI 1: Nanotechnology Additive ( Memento from February 14, 2010 in the Internet Archive )

- ↑ Community rolling action plan ( CoRAP ) of the European Chemicals Agency (ECHA): cerium dioxide , accessed on March 26, 2019.