Hyundai KIA S.

| Hyundai / KIA | |

|---|---|

|

|

| S. | |

| Manufacturer: | Hyundai / KIA |

| Production period: | 2006-present |

| Design: | 60 ° V |

| Engines: | 3.0 L (2959 cm³) |

| Cylinder firing order: | -? - |

| Previous model: | none |

| Successor: | none |

| Similar models: | Isuzu DMAX V6 |

The S series is a six-cylinder diesel engine with direct injection , turbocharger , four overhead camshafts ( QOHC ), and four valves per cylinder. The engines are manufactured in South Korea .

The S series is the group’s first V6 diesel series for passenger cars . It is a fundamentally revised version of an Isuzu make.

The engine block is made of sintered vermicular graphite - gray cast iron , its cylinder head is made of light metal . The cylinder size has a bore of 84 mm and a stroke of 89 mm. Weight and idle speed have not yet been published.

The camshafts are driven by the crankshaft by means of maintenance-free timing chains , the ancillary units by a serpentine belt.

The type of valve actuation was not described, but it does include a hydraulic valve lifter . It is thus either like that of the D or that of the Delta series.

S.

history

Hyundai did not manufacture its own V6 diesel cars before the S engine, the existing J engines only came close to the target in terms of displacement (2.9 l). However, they were four-cylinder and had been in use since 1998. As a result, they lacked the necessary modern technology in addition to the smooth-running V format. In 2004 it was decided to add this to an engine outside the group. The Isuzu DMAX V6 "6DE1" was therefore the starting point for development . This engine has already been licensed to Renault by the manufacturer , and has also been used in the Opel Vectra C and Saab 9-5 since GM bought the patents . Injection and turbocharger were changed. Like the latter, the glow plugs also come from the BorgWarner Group, here from the subsidiary BERU . They should also enable starts at −25 ° C and help to achieve a cultivated sound through clean combustion. The glow plugs are operated by a control unit ( G low C ontrol U nit) and are supported by a heater in the intake tract to bring the diesel-air mixture to auto-ignition temperature in cold start phases.

The S-engine took 26 months to develop and cost $ 222 million. It was coordinated by the Namyang Powertrain Center in Hwaseong , carried out in the European Powertrain Center in Rüsselsheim.

The V-orientation of the two three-cylinder banks has the advantage of shorter length than in- line six-cylinders , such as those installed by BMW . In addition, the crankshaft only has to be half as long as each crank pin is driven by two pistons. The disadvantage of being divided into two banks is that there are duplicate components at the other end of the piston - in the cylinder head, around four instead of two camshafts have to operate the valves, which increases maintenance costs slightly.

injection

The third generation Bosch injection system (CRS 3.0) is equipped with piezo injectors. Their advantage is that the injection is terminated more quickly, which means that a larger quantity of fuel can be introduced with sufficient timing. This creates more power with low residue combustion. The "Variable Swirl Control System" has the same effect. It always swirls the air before it enters the cylinder so that a homogeneous distribution of the diesel is supported. For this purpose, the air is directed through a narrower intake manifold at low speeds and at a low inflow speed and thus accelerated. At higher speeds, a wider path opens up. As a result, the face velocity and thus the turbulence remain constant regardless of the speed.

Direct injection takes place via nozzles reaching into the cylinder vertically from above. This minimizes diesel condensate on the relatively cool inner wall of the cylinder, which would turn into soot. The nozzles are supplied by a fuel line for all cylinders ( common rail ) in which the diesel is present at 250 to 1600 bar. More recent diesel engines increase the pressure further, which leads to an even more homogeneous mixture formation and thus less oxygen-rich, nitrogen oxide-producing and oxygen-poor, soot-producing nests.

Pollution reduction

This series has soot filtering , but no nitrogen oxide reduction in the exhaust gas aftertreatment. This consists of a closed particle filter , which is preceded by an oxidation catalytic converter .

The oxidation catalytic converter replaces the three-way catalytic converter that is common there due to the high levels of oxygen in the exhaust gas compared to the gasoline engine . Unlike the latter, it lets the nitrogen oxides pass and thus works as a two-way catalytic converter. Like its counterpart, it uses oxygen to convert carbon monoxide (CO) into carbon dioxide (CO 2 ) and hydrocarbons (HC) into carbon dioxide and water. The nitrogen oxides are left out, because the excess oxygen reacts with the carbon monoxide first (2 CO + O 2 to 2 CO 2 ). This carbon monoxide is therefore no longer available to nitrogen oxide (NO x ) for reduction into pure nitrogen (CO and NO to N 2 and CO 2 ).

The lean operation typical of diesel engines, exhaust gas recirculation (→ next paragraph) and the closed diesel particulate filter of these engines reduce soot . It is standard on European markets. In contrast to open systems, this type cannot be retrofitted because the motor recognizes the fill level of the filter via a sensor system and has to regenerate it if necessary. In return, the filter performance increases from around 30 to over 95 percent of the particle mass, the same applies to the number of particularly relevant nanoparticles (see particle emissions ). The breakdown of the particles takes place in two stages. The passive regeneration is an oxidation of the soot filtrate. This only works at exhaust gas temperatures such as those that occur on longer motorway journeys. In this case, soot particles are oxidized to CO 2 in the filter by means of NO 2 formed in the oxidation catalytic converter from 200 ° C. The excess nitrogen dioxide escapes. Active regeneration must intervene if this temperature is not reached and the filter is filled to around 45% of its capacity. Then the engine control artificially creates a temperature of 600 ° C by injecting diesel directly after the ignition process, which does not lead to any additional power, but the necessary exhaust gas temperatures. This increases consumption by three to eight percent (depending on frequency), and the soot is burned. After active regeneration, some ash remains in the filter from the soot filtrate; no information about the shelf life was given. The regeneration takes about 25 minutes without stop - & - go traffic at a speed of over 2000 tours from third gear. If these journeys are not made, a warning light flashes in the cockpit from 75% of the filter fill level, which indicates to the driver that regeneration is necessary. If this continues to flash after the journey described, a workshop must be visited to carry out the regeneration. If this is not done either, there is a risk of damage to the particle filter, which, like all closed filters, does not have a pressure relief valve.

These engines use exhaust gas recirculation to reduce nitrogen oxide . In the partial load range, this guides up to 60% of the exhaust gas back into the intake system. The nitrogen oxides contained therein are thus neutralized, the same applies to soot particles and not yet burned hydrocarbons (e.g. PAH ). However, if too much exhaust gas is introduced, there will be a lack of oxygen in the cylinder for complete combustion. That led to more soot. Therefore, exhaust gas recirculation is only partially possible in the partial load range. In the Euro4 standard achieved by this series, the permitted amount of nitrogen oxide remains three times that of a gasoline engine. The feedback is controlled electrically. This minimizes the deviation from the desired return rate. The oxygen value in the exhaust gas is also evaluated using a lambda probe. Cooling the recirculated exhaust gas also lowers the combustion temperature, reducing nitrogen oxides. The air volume, which is denser by means of cooling, nevertheless provides enough oxygen in order not to favor soot. Nitrogen oxides promote the formation of smog and ozone as well as acid rain , nitrogen dioxide has an irritant effect. Diesel engines work with excess oxygen to reduce soot, which leads to very high local temperatures in the cylinder. These favor the generation of nitrogen oxides.

turbocharger

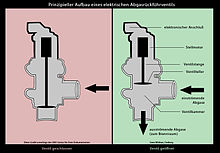

This engine uses a BorgWarner BV50 turbocharger with variable geometry. This minimizes the acceleration delay after depressing the accelerator pedal. The invariable turbocharger is a resonance system that must first be excited. Only a lot of exhaust gas does the turbine accelerate in the exhaust gas flow so strongly that it delivers the required amount of air into the cylinder on the intake side. This delay is called “turbo lag” and must be taken into account by the driver when accelerating. To remedy this, a VGT system also accelerates small exhaust gas flows by directing them onto the turbine through a temporarily narrowed air path. For this purpose, the VGT guide vanes are attached like on a shovel excavator wheel and extend into the exhaust gas flow. Folded almost in a circle, they direct exhaust gas faster or unfolded more slowly to the turbocharger's turbine. This accelerates or brakes accordingly. The latter is used at higher engine speeds, since there is hardly any need for more air. On the contrary, this would exceed the intended pressure in the cylinder and thus mechanically damage the engine components. As with this engine, the VGT control usually makes the pressure relief valve ( wastegate ) of the non-variable turbocharger superfluous. The change from pneumatic to electrical guide vane control also enables more precise control of the air flow. Hyundai identifies them as e -VGT.

BorgWarner developed this turbocharger at its headquarters in Kirchheimbolanden and in its South Korean joint venture SeohanWarner Turbo Systems together with Hyundai. It is made by SeohanWarner in Pyongteak. This cooperation already existed with the A and J engine series. The BV50 turbocharger with an alloy adapted to the higher exhaust gas temperatures of a gasoline engine has also been used in the Porsche 997 since June 2006 , three months before the premiere of the S V6 in September 2006

A variant of the engine that was 80% soot and 90% nitrogen oxide reduced was under development until 2008. With it the approval of the engine on the US market according to Tier 2 Bin 5 norm should be achieved. However, the project was discontinued in early 2009. This means that in 2010 only individual, adapted diesel engines from German manufacturers will be available in the US car market.

Data

| series | Engine code | Displacement (cm³) | Stroke × bore (mm) | Power at (1 / min) | Torque at (1 / min) | cylinder | compression | Charging | injection | Particle filter | Nitrogen oxide filter |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S. | D6EA | 2959 | 89 × 84 | 239/249 1 at 3800 | 451/540 at 1750-3500 / 2000 | 6th | 17.3 |

e-VGT-Turbo 2 (+ 1.9 bar) |

Piezo CRDI 1600 bar |

closed | - |

commitment

The S engines installed worldwide are listed for each model; this is not offered in every country.

Hyundai ix55

- ix55 EN

- D6EA (239 hp): 2007-present

KIA Mohave

- Mohave HM

- D4EA (249 hp): 2009-present

Individual evidence

- ↑ a b Design of the engine

- ↑ Start of production

- ↑ Origin of the S V6 ( Memento of the original from January 23, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Materials of the S series ( Memento of the original from December 22, 2009 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 714 kB)

- ↑ Timing chains and serpentine belts of the S series ( Memento of the original from December 22, 2009 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 714 kB)

- ↑ Element of valve actuation S V6

- ↑ Development time of the S V6 ( Memento of the original from December 22, 2009 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 714 kB)

- ↑ Use of the 6DE1 ( Memento of the original dated February 13, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Mention of the glow plug control I nstant S tart S ystem (PDF; 1.3 MB)

- ↑ explanation of the glow plug control I nStant S tart S ystem ( Memento of the original on 18 September 2010 at the Internet Archive ) Info: The archive link is automatically inserted and not yet tested. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Coordination of the development ( Memento of the original of December 22, 2009 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 714 kB)

- ↑ a b c Implementation of the development

- ↑ p. 18 Generations of the Bosch Common Rail System (CRS) 2004 (PDF; 735 kB)

- ↑ a b data of the S V6 (PDF; 1.3 MB)

- ↑ Origin of the injection system

- ↑ cf. Deposition rates in the three-way catalytic converter with the oxygen content in the exhaust gas increasing to the right ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Particle filter as standard on European markets

- ↑ Principle of passive regeneration, identical for closed and open filters

- ↑ KIA cee'd manual, Chapter 7, p. 99 Regeneration process of a Hyundai / KIA particle filter

- ↑ Explanation of the lambda probe in diesel

- ↑ Specification of the turbocharger ( Memento of the original from January 15, 2016 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Animation of the comparable VGT element in the D-Diesel

- ↑ p. 8 Cooperation in the development of the turbocharger ( Memento of the original from January 24, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Previous cooperation in turbocharger development

- ↑ Further use of the turbocharger ( Memento of the original from January 15, 2016 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Tier 2 Bin 5 norm on dieselnet.com

- ↑ Surrender of the S-Diesel version for the USA ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Development status for Tier 2 Bin 5 achievement in 2007 ( Memento of the original from November 28, 2009 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Development status for Tier 2 Bin 5 achievement in 2008 (PDF; 1.3 MB)

- ↑ Diesel car offer for the US model year 2010 ( Memento of the original from September 20, 2010 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Diesel car offer for the US model year 2011 ( Memento of the original from September 20, 2010 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.