Hyundai KIA R

| Hyundai / KIA | |

|---|---|

|

|

| R. | |

| Manufacturer: | Hyundai / KIA |

| Production period: | 2009-present |

| Design: | Inline four-cylinder |

| Engines: | 2.0 L (1995 cm³) 2.2 L (2199 cm³) |

| Cylinder firing order: | 1-3-4-2 |

| Previous model: | Hyundai KIA D |

| Successor: | none |

| Similar models: | none |

The R series are four-cylinder diesel engines with direct injection , turbocharger , two overhead camshafts ( DOHC ), and four valves per cylinder. The engines are manufactured in ( South Korea ).

The R engines belong to the fourth fully self-developed four-cylinder passenger car diesel series of the group after the A , J and U series.

The engine block and cylinder head are made of aluminum , whose tendency to vibrate, together with the piston size and thus the piston mass, necessitates a balance shaft . This runs in the opposite direction to the crankshaft and thus reduces noises, the cause of which would be energy losses in the single-digit PS range, which are also avoided. The shaft is housed in the crankshaft housing, whose integrated ladder frame further minimizes vibrations.

The cylinder dimension starts with a bore of 84 mm and a stroke of 90 mm, which are increased to 84.5 and 96 mm for the larger version. Weight and idle speed have not yet been published.

The camshafts are driven by the crankshaft by means of a maintenance-free timing chain , the auxiliary units by a serpentine belt. Its inspection and replacement intervals are noted in the manual.

The valves are operated via roller rocker arms that act like a rocker. The cam rests on its apex. During its rotation it pushes one side and thus the valve downwards, while the hydraulic valve valve, which is stretched by means of a built-in spring, is always flush on the other . This form of valve clearance compensation is maintenance-free, even an inspection is not included in the maintenance schedule. Wear would be communicated by a ticking sound.

Vehicles with R engines have an electric auxiliary heater ( PTC ) for faster heating of the interior . This is attached to the air flow and heats it up as required via an electrical resistor. This achieves significantly faster heating than a diesel engine alone or with an auxiliary heater for the cooling water circuit could achieve . Such a cooling water auxiliary heater, however, has the advantage of being an essential component of an auxiliary heater , which could be retrofitted with it at low cost. The built-in electric auxiliary heater, on the other hand, requires a complete auxiliary heater set.

R.

history

The development of the R series began in 2006 after the completion of the S V6 and cost 140 million euros. It was carried out in the European Powertrain Center in Rüsselsheim, and was presented at the end of 2008 in the Namyang Powertrain Center in Hwaseong . 150 employees were employed on the 500 prototypes of the series for 42 months.

To reduce weight, the manufacturer is using the all-aluminum construction for its diesel engines for the first time. He also makes cylinder head covers, intake tracts and oil filter housings out of plastic. However, there is no information on the total weight, which means that the progress over the predecessor cannot be quantified.

The roller finger followers in the valve train have a needle bearing . In contrast to the ball bearings that are otherwise used in roller cam followers , the element to be supported runs directly on thin rods, which, due to their size, are reminiscent of needles. This saves the space for an inner ring in between and minimizes the size.

Ceramic glow plugs are intended to ensure that the engines can be started quickly, bringing the diesel-air mixture to auto-ignition temperature even at low temperatures. An auxiliary heater is integrated for faster heating of the interior (see introduction )

The serpentine belt runs over a vibration-damping Metaldyne pulley . It filters the vibrations of the crankshaft and makes the drive of the auxiliary units gentler and quieter. The EPDM rubber is used to improve the durability of the pulley itself . The damping takes place via a secondary mass that is rotatably coupled to the primary mass ( inert mass ). It levels out brief torsional vibrations in the crankshaft.

The series started in autumn 2009 with the 2.2 L engine in the KIA Sorento , followed a quarter later by the 2.0 L variant with 184 hp. In 2010 it appeared in a version with 136 hp and a different turbocharger . Its manufacturer BorgWarner also supplies the glow plugs for this version.

injection

The third generation Bosch injection system ("CRS 3.2" or "CRS3-18") used is equipped with piezo injectors. Their advantage over magnetic injectors is that the injection ends more quickly. This means that a larger amount of fuel can be introduced with sufficient timing. This results in more performance with still low-residue combustion. Depending on the situation, the number of injections per ignition process can be increased to eight. This subdivision improves the running smoothness, as the combustion process in the cylinder is prolonged. In addition, smaller amounts of fuel are better distributed in the cylinder. This reduces soot and nitrogen oxides through less inhomogeneous areas of oxygen deficiency and excess. In addition to pilot injections shortly before ignition and the main charges for the actual piston movement, the post-injections serve to partially burn off any soot particles that have arisen.

The direct injection is controlled by a 32-bit chip. The nozzles are supplied by a fuel line for all cylinders ( common rail ) in which the diesel is present at 250 to 1800 bar. This was the highest pressure level in 2009, and at the premiere it achieved the most homogeneous mixture formation available with the lowest oxygen-rich, nitrogen-oxide-producing and low-oxygen, soot-producing nests.

Pollution reduction

This series has soot filtering , but no nitrogen oxide reduction in the exhaust gas aftertreatment. This consists of a closed particle filter , which is preceded by an oxidation catalytic converter in the same housing . Both are positioned directly after the turbocharger. This helps the catalytic converter to reach its operating temperature quickly.

The oxidation catalytic converter replaces the three-way catalytic converter that is common there due to the high levels of oxygen in the exhaust gas compared to the gasoline engine. Unlike the latter, it lets the nitrogen oxides pass and thus works as a two-way catalytic converter. Like its counterpart, it uses oxygen to convert carbon monoxide (CO) into carbon dioxide (CO 2 ) and hydrocarbons (HC) into carbon dioxide and water. The nitrogen oxides are left out, because the excess oxygen reacts with the carbon monoxide first (2 CO + O 2 to 2 CO 2 ). This carbon monoxide is no longer available to nitrogen oxides (NO x ) for reduction into pure nitrogen (CO and NO to N 2 and CO 2 ).

The lean operation typical of diesel engines, exhaust gas recirculation (→ next paragraph) and the closed diesel particulate filter of these engines reduce soot . In contrast to open systems, this type cannot be retrofitted because the motor recognizes the fill level of the filter via a sensor system and has to regenerate it if necessary. In return, the filter performance increases from around 30 to over 95 percent of the particle mass, the same applies to the number of particularly relevant nanoparticles (see particle emissions ). The breakdown of the particles takes place in two stages. The passive regeneration is an oxidation of the soot filtrate. This only works at exhaust gas temperatures such as those that occur on longer motorway journeys. In this case, soot particles are oxidized to CO 2 in the filter by means of NO 2 formed in the oxidation catalytic converter from 200 ° C. The excess nitrogen dioxide escapes. Active regeneration must intervene if this temperature is not reached and the filter is filled to around 45% of its capacity. Then the engine control artificially creates a temperature of 600 ° C by injecting diesel directly after the ignition process, which does not lead to any additional power, but the necessary exhaust gas temperatures. This increases consumption by three to eight percent (depending on frequency), and the soot is burned. After active regeneration, some ash remains in the filter from the soot filtrate; no information about the shelf life was given. Regeneration takes around 25 minutes without stop-and-go traffic at a speed of over 2000 tours from third gear. If these journeys are not made, a warning light flashes in the cockpit from 75% of the filter fill level, which indicates to the driver that regeneration is necessary. If this continues to flash after the journey described, a workshop must be visited to carry out the regeneration. If this is not done either, there is a risk of damage to the particle filter, which, like all closed filters, does not have a pressure relief valve.

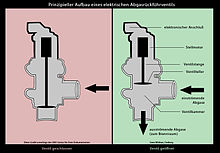

These engines use exhaust gas recirculation to reduce nitrogen oxide . In the partial load range, this guides up to 60% of the exhaust gas back into the intake system. The nitrogen oxides contained therein are thus neutralized, the same applies to soot particles and not yet burned hydrocarbons (e.g. PAH ). However, if too much exhaust gas is introduced, there will be a lack of oxygen in the cylinder for complete combustion. That led to more soot. Therefore, exhaust gas recirculation is only partially possible in the partial load range. In the Euro5 standard achieved by this series, the permitted amount of nitrogen oxide remains three times that of a gasoline engine. The feedback is controlled electrically. This minimizes the deviation from the desired return rate. The oxygen value in the exhaust gas is also evaluated using a lambda probe. Cooling the recirculated exhaust gas also lowers the combustion temperature, reducing nitrogen oxides. The air volume, which is denser by means of cooling, nevertheless provides enough oxygen in order not to favor soot. Nitrogen oxides promote the formation of smog and ozone as well as acid rain , nitrogen dioxide has an irritant effect. Diesel engines work with excess oxygen to reduce soot, which leads to very high local temperatures in the cylinder. These favor the generation of nitrogen oxides.

Compared to its predecessor, compression has been reduced from 17.3 to 16.5 to 16.0 ( see table ). This gently reduces the pressure and thus the temperature in the cylinder. This results in less nitrogen oxides.

turbocharger

All engines in the range have a turbocharger with variable geometry. This minimizes the acceleration delay after depressing the accelerator pedal. The invariable turbocharger is a resonance system that must first be excited. Only a lot of exhaust gas does the turbine accelerate in the exhaust gas flow so strongly that it delivers the required amount of air into the cylinder on the intake side. This delay is called “turbo lag” and must be taken into account by the driver when accelerating. To remedy this, a VGT system also accelerates small exhaust gas flows by directing them onto the turbine through a temporarily narrowed air path. For this purpose, the VGT guide vanes are attached like on a shovel excavator wheel and extend into the exhaust gas flow. Folded almost in a circle, they direct exhaust gas faster or unfolded more slowly to the turbocharger's turbine. This accelerates or brakes accordingly. The latter is used at higher engine speeds, since there is hardly any need for more air. On the contrary, this would exceed the intended pressure in the cylinder and thus mechanically damage the engine components. As with this engine, the VGT control usually makes the pressure relief valve ( wastegate ) of the non-variable turbocharger superfluous.

The turbocharger of the 136 hp variant is supplied by BorgWarner . This belongs to the manufacturer's fourth VGT generation. Their characteristic are the S-shaped guide vanes ("S-Vane"). According to the manufacturer, they favor controllability.

The turbocharger of the 150 hp version added in 2010 is not mentioned in the press materials of the turbo manufacturers and is therefore still unknown.

The two more powerful variants use a Garrett GTB1752VLK. This has a turbine diameter of 17 mm on the exhaust side and 52 mm on the intake side. Instead of the pneumatic one, it uses an electrical guide vane adjustment and thus enables more precise control. Hyundai indicates this with the designation e -VGT. This belongs to the third generation of the turbo manufacturer, which, with its new guide vane shape and new turbine wheel, is supposed to provide a third more air delivery with greatly reduced exhaust back pressure. The turbo is also used in a similar form (GTB1752V) in the 3.0 l diesel engine with 275 hp from Jaguar / LandRover , but there in combination with an upstream, smaller charger as a sequential biturbo . One of these is also mentioned in the contract signed in 2005 for the R series, but has so far only been presented in a trade fair model. Series production is to follow in 2011.

Data

| series | Engine code | Displacement (cm³) | Stroke × bore (mm) | Power at 1 / min | Torque at 1 / min | cylinder | compression | Charging | injection | Particle filter | Nitrogen oxide filter |

|---|---|---|---|---|---|---|---|---|---|---|---|

| R 1 | D4HA | 1995 | 90 × 84 | 136 at 4000 | 304/320 2 at 1800-2500 | 4th | 16.5 | VGT Turbo 3 |

Piezo CRDI 1800 bar |

closed | - |

| R. | D4HA | 1995 | 90 × 84 | 184 1 at 4000 | 383/392 4 at 1800-2500 | 4th | 16.0 | e-VGT Turbo 3 |

Piezo CRDI 1800 bar |

closed | - |

| R. | D4HB | 2199 | 96 x 84.5 | 150 at 3800 | 412 at 1800-3500 | 4th | 16.0 | e-VGT Turbo 3 |

Piezo CRDI 1800 bar |

closed | - |

| R. | D4HB | 2199 | 96 x 84.5 | 197 at 3800 | 421/436 4 at 1800-3500 | 4th | 16.0 | e-VGT Turbo 3 |

Piezo CRDI 1800 bar |

closed | - |

commitment

The R engines installed worldwide for each model are listed; not all of the configurations listed are available in every country.

Hyundai ix35

- ix35 LM

- D4HA (184 hp): 2009-present

- D4HA (136 hp): 2010-present

Hyundai Santa Fe

- Santa Fe CM

- D4HA (184 hp): 2009-2012

- D4HB (197 hp): 2009-2012

- Santa Fe DM

- D4HB (197 hp): 2012-present

KIA Carnival

- Carnival VQ

- D4HB (197 hp): 2010-2011

KIA Sorento

- Sorento XM

- D4HA (184 hp): 2009-2014

- D4HB (197 hp): 2009-2014

KIA Sorento

- Sorento UM

- D4HB (200 hp): 2015-present

KIA Sportage

- Sportage SL

- D4HA (136 hp): 2010-present

- D4HA (184 hp): 2011-present

Individual evidence

- ↑ a b Design of the engine

- ↑ Start of production

- ↑ a b c d e Development of the R-Motors ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ See figures valve closed ( Memento from July 16, 2014 in the Internet Archive ), valve open ( Memento from February 21, 2014 in the Internet Archive )

- ↑ p. 28 Valve actuation of the R motors ( Memento of the original from February 22, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ a b Implementation of the development

- ↑ Presentation of the R-Motors ( Memento of the original from April 25, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Glow plugs of the R engines ( Memento of the original from March 31, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 867 kB)

- ↑ Description of the Metaldyne pulley

- ↑ Using the Metaldyne Pulley

- ↑ Premieres of the R engines

- ↑ Glow plugs of the R 2.0 136 hp

- ↑ p. 18 Generations of the Bosch Common Rail System (CRS) 2004

- ↑ Overview of the CR systems from 2010 ( memento of the original from December 25, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ P. 28 CRS used for R motors ( Memento of the original from February 22, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Information on the motor control chip of the R motors

- ↑ p. 29 Injection pressure of the R engines ( Memento of the original from February 22, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Principle of passive regeneration, identical for closed and open filters

- ↑ KIA cee'd manual, Chapter 7, p. 99 Regeneration process of a Hyundai / KIA particle filter

- ↑ Explanation of the lambda probe in diesel

- ↑ p. 29 Exhaust gas recirculation of the R-engines ( Memento of the original from February 22, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Animation of the comparable VGT element in the D-Diesel

- ↑ R-series turbocharger 2.0 136 hp

- ↑ Meaning of the manufacturer's designation ( Memento of the original from June 18, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Garrett 3rd Generation VNT-Turbo ( Memento of the original from March 21, 2008 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ R-series turbocharger 2.0 184 and 2.2 197 hp designation and further use in a similar form

- ↑ R-series turbocharger 2.0 184 and 2.2 197 HP information and delivery contract ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ R 2.2 "Dual-Stage Serial Sequential" Turbo version 2009 Seoul Motor Show

- ↑ R 2.2 “Dual-Stage Serial Sequential” Turbo series start

- ↑ Use of the motor name in the model name