Hyundai KIA Alpha

| Hyundai / KIA | |

|---|---|

Alpha II CVVT 1.6 ( G4ED ) |

|

| Alpha, Alpha II, Alpha II CVVT | |

| Manufacturer: | Hyundai / KIA |

| Production period: | 1991 – today |

| Design: | Inline four-cylinder |

| Engines: | 1.3 L (1341 cm³) 1.4 L (1399 cm³) 1.5 L (1495 cm³) 1.6 L (1599 cm³) |

| Cylinder firing order: | 1-3-4-2 |

| Previous model: | none |

| Successor: | Gamma (4-cylinder) |

| Similar models: | none |

The Hyundai KIA Alpha series is a four-cylinder petrol engine with a single ( SOHC ) or double overhead camshaft ( DOHC ) and accordingly three or four valves per cylinder. The engines for Hyundai models are built in Ulsan , those for KIA in Hwaseong (both South Korea ). The Alpha engines for the Hyundai plants in Russia , India , Turkey and China come from Shandong (China).

general characteristics

The 1.5-L engine is the only one to have both versions, with two camshafts for the 99 HP and above versions. The 1.3 L editions have the SOHC design throughout, while the 1.4 and 1.6 L added with the Alpha II series have the DOHC cylinder head . A knock sensor is always included in both designs .

The Alpha series is the first engine series developed in Korea. Previously, Hyundai only installed Mitsubishi engines manufactured under license . Instead of naming planets by planets, Hyundai opted for Greek letters. This makes it easy to differentiate between in-house developments and license production.

The engine block is made of gray cast iron , its cylinder head is made of light metal . The pistons are also made of aluminum, their attachment to the crankshaft and the connecting rods are made of steel. The weights of the motors can be found in the table below . Alpha engines use a MAP sensor (Manifold Absolute Pressure) to measure the air volume .

The idle speed of the Alpha series is 800 revolutions per minute, with the air conditioning switched on it increases to 850 revolutions. In the more precisely manufactured Alpha II series, the speed drops to 750, in the Alpha II CVVT again to 720 and in its automatic version with the D rive shift position finally to 660.

The intake and exhaust camshafts of the DOHC models are connected by a timing chain . Power is transmitted from the crankshaft to the cylinder head by means of a toothed belt . Its inspection is planned for model presentations before 2005 every 60,000 km (95,000 km) or 30 months, in newer models only replacement every 100,000 km (145,000 km) or 48 (108) months (details in brackets only apply to the Hyundai Accent MC ) The motors are not free runners . The ancillary units are driven by a total of three V-belts , which, depending on the model, are to be inspected every 32,000 to 48,000 km or 16 to 24 months. The valve clearance inspection is planned every 24,000 km or 12/24 months (models with Alpha / Alpha II and Alpha II CVVT), and the hydraulic valve lifters are replaced as required.

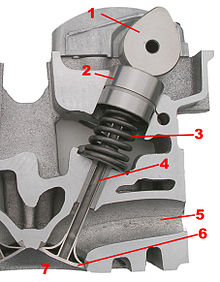

The valves are operated via hydraulic valve lifters without rocker arms or rocker arms. This form of valve clearance compensation is maintenance-free until the hydraulic valve lifters wear out. This is created by removing the contact surface between the cam and hydraulic valve lifters. The distance is initially compensated for by a spring that presses the top of the plunger flush upwards. Continuous ticking indicates that this is no longer sufficient and that the cam no longer rests constantly on the hydraulic valve lifter, but only reaches it once per revolution - the occurrence generates the ticking noise. When replacing the tappets, they are replaced by slightly longer ones in order to compensate for the removed cam material. If the replacement is not carried out, the cams are also increasingly worn, which ultimately results in a "broken-in camshaft". results. Then this would have to be exchanged in addition to the tappets. A ticking can also be caused by unsuitable oil viscosity or failure to comply with the change intervals. If the oil channel in the hydraulic valve valve runs empty because the oil level is too low, the valve clearance will also be too large (see) and the valve will no longer open completely. The result is a smaller amount of air and thus a little less performance. Even after a long standstill, the noise is possible if the oil ducts have run empty. This is not a sign of wear and tear and disappears after a few seconds ( see special features of hydraulic valve lifters ).

Development of the Alpha range

Although Hyundai and KIA appear primarily as car manufacturers in Europe, they only started manufacturing vehicles decades after they were founded. The controlled economy of the country was decisive for these swings in the product strategy. The military government assigned the existing large corporations tasks from 1961, which they performed almost monopoly. For KIA that was the role of truck and machine builder from 1962, while Hyundai started in the construction business, which it expanded to relatives after the Korean War , including steel production. This was also suitable for his vehicles manufactured from 1967 onwards. Faced with a choice in 1980, the Hyundai founder decided on the experiences of his youth and thus car manufacturing, which he learned to repair in his parents' car workshop. In the same year, he turned the merger with Daewoo against the will of the government. The government's goal of avoiding competition on a large scale served to cover all areas of need as much as possible with the few industrially qualified employees. These were missing due to the agrarian economy . Today South Korea has one of the most demanding education systems in the world.

The founding of the Hyundai Motor Company was followed by the Cortina in 1968 , just one year after the company was founded and therefore still made entirely from imported components. It was not until 1974 that the first vehicle from South Korean production, the Pony , was created, which was also not a mere replica, but further developed the base Morris Marina in terms of chassis and design. In order to achieve independence as quickly as possible, Hyundai also primarily carried out completely uneconomical projects. With this request, the CEO moved on the line of the state government. Both wanted an industry that could manufacture its own products independently of non-Korean companies and that also achieved this goal when the country changed from an importer to an exporter in the course of the 1980s. Against this background, the development of an own engine series with only 100,000 vehicles sold annually can be seen. Hyundai could only raise the costs by taking them from other areas of the group. Development was independent of the company's economic situation, with constant support from the founder. This procedure was made possible by the owner-managed decision-making structure in the company. The government paid attention to this quality in 1961 when allocating tasks.

Despite its $ 125 million development cost, Hyundai gained advantages from its own engine. Initially there were no license fees; 90 US dollars per engine would have added up to 17 million for the 1994 Accent alone . Anticipating these numbers, the license recipient sent his incomprehension to the Alpha project in 1984, saying that Mitsubishi would also be ready to deliver technology in the future. In the aftermath, he added doubts about the ambitious project goals. This was what moved the engineers in Seoul too. In view of the previous experience, some voted for a carburetor system, while others favored an injection engine. The departments, whose increase was seen in exports with increased consumption and reduced sales, but in corporate planning with a gain in prestige, were also seen in efficiency. The top management decided in summer 1984, following the latter, for an injection system and at least a sporty top engine. Mitsubishi's doubts arose from this decision, as no car manufacturer had previously provided a three-valve cylinder design with a turbocharger.

In order to bridge the gap between existing and desired skills, the alpha designer Hyun Soon contacted Lee Bosch to develop a motor control system. The asking price approached after Bendix was invited to the negotiations. The collaboration with Bosch now includes the controls of several engine series and their environment, including the ISG automatic stop-start system . Before the project began, Lee was poached by GM , where he developed engines as before at Chrysler . From Great Britain, Ricardo plc Ricardo engineer Clions was at his side for three years . Ricardo has supported Hyundai's development of commercial vehicle diesels since 1978. Hyundai had previously used the concept of targeted purchases of a lack of specialist skills when developing the Pony .

The first prototype was completed in September 1985. This stage of development went through initial emissions tests, during which 11 drives at $ 25,000 each broke. As the first own gearbox was developed at the same time, it added to the list of possible causes of errors. The investigation into the causes led to the phase of the largest design corrections, 156 in 1986 alone. The result was tested on 83 engines in the Sonoran desert around Phoenix the following summer and together with the subsequent tests by Bosch in Germany, in the Canadian winter in early 1988 and on the Rocky Mountains in July 1989 implemented in 288 corrections across the project.

After 300 engines and 200 gearboxes, Hyun Soon Lee's first seven-year project ended. It was followed by other crucial ones for the company, including hybrid drives and the Hyundai Genesis , whose introduction in 2008 he described as the final point of the change from the fully dependent manufacturer, which began with the Alpha project in 1983.

"Until 1991, when we developed our first engine, we had no technology; we relied totally on Mitsubishi. The Alpha gave us a tremendous boost of confidence, and we now can build anything we want. "

At the end of the development in March 1991 the first engine from South Korean development stood. Hyun Soon Lee left Hyundai in 2011 as a prominent figure in the Korean automotive industry.

Engine models

alpha

For the presentation of the in-house development, Hyundai chose as sporty an environment as possible. The alpha debut in the Hyundai S-Coupé was therefore followed by its turbo version in 1992. Its starting price was the lowest of any turbo model in the US market. Participation in the Pikes Peak Hill Climb should dispel any concerns about its athleticism . The driver Rod Millen won for it in 1992 and repeated it in 1993. However, the vehicle’s nearness to series production remained unknown. In the street version , a Garrett TB1501 turbocharger works , which increases torque and fuel consumption by 30 percent.

As a result of their premiere, Alpha engines replaced the license-manufactured Mitsubishi drives of the same displacement. However, this was initially exhausted after two models; due to performance, they were the smallest in the model range. Only strengthening and noise reduction of the Alpha II engines promoted further spread. First, however, the 1.5-liter Alpha replaced the Mitsubishi Orion (Mitsubishi Code 4G15 / Hyundai Code G4DJ) in the Hyundai S-Coupé and Accent , which in turn was the first model to use only Hyundai's own engines. The Alpha with 1.3 liter displacement also made its debut here in 1994.

The 1.3 L with 71 hp is a special model in the series. He uses a carburetor to produce the mixture . This makes it the only engine from South Korean development that has a carburetor. Domestic competitors did not follow suit until the mid-1990s with engines from our own development. The then applicable emissions standards made the decision between carburettor and injection system less. The "Alpha 1.3 CON" can be found in non-European Accent X3 .

While an electronically controlled nozzle opens and closes in injection systems, in the carburettor the air flow in the intake system draws the fuel out of a pipe. In both systems, tiny droplets are created, but never a gas in terms of its physical state , but always that of a fuel mist.

The 1.5 liter engine was also manufactured in a special version. In 1999 a fuel-saving variant made its debut in the Korean market, which was also offered in the north of the country in the course of the opening . A later winning advertising campaign communicating the effektivierende measure gasoline poor North Korea: the mixture formation was lean ( lean-burn ). In part-load phases, less gasoline is injected than the oxygen in the cylinder could burn. The 1.5-liter fuel consumption of the 1.3-liter drive is an improvement of 16% in the South Korean driving cycle. Under full load, it uses the usual amount of fuel again and thus also provides the performance of the normal engine. The reason for the failure to export lies in partial load operation. Meanwhile, the excess oxygen atoms from the lean mixture react with the nitrogen in the air to form nitrogen oxides. The task of a storage catalytic converter would be to collect these and periodically neutralize them. However, the Hyundai did without, whereby the engine exchanged the saved CO 2 for smog- generating NO x emissions . Due to this effect, almost all manufacturers forego such engines, one of the exceptions was Honda with the first Insight , whose lean-burn engine also meets European emission standards using a nitrogen oxide catalytic converter.

The 1.5 liter engine received a new cylinder head in 1996 for the 99 hp version. With it, a separate camshaft opens the valves on the inlet and outlet side instead of the only one that was previously centrally located. The number of camshafts is listed across manufacturers in the designation S ingle, D ouble, or Q uad O ver h ead C amshaft. With the DOHC design, the exhaust side also received a second valve, which allows more gasoline to be mixed through. The combustion chamber below was given the shape of a flat roof ( semi pent roof ) instead of the previous high roof ( pent roof ). This also improves the mixture throughput, as the valves can open further into the cylinder without meeting in the middle. Hyundai adopted this shape from the Beta series for all Alpha DOHC models.

Alpha II

With the handover of the business from the company's founder to his son, the focus changed from growth to quality in 1999. In the same year, the Alpha series underwent a number of simplifying and noise-reducing measures and thus became Alpha II. This can be seen in the displacement, which grew by a tenth of a liter to 1.4 and 1.6 l.

After the debut in the Elantra in early 2000, the revised versions replaced the previous ones in the course of facelifts and new releases. The last newly released model with an Alpha II engine is the Accent MC from 2006.

To improve running smoothness, the cylinder block was given more material bracing and the crankshaft was doubled to eight counterweights for balancing. The engine itself was better decoupled from the body with the change from rubberized to hydraulic bearings. Its cylinder head only had to be sealed in one layer instead of multiple layers thanks to more precise production. The pistons were given a graphite coating, which reduces friction and thus noise and oil consumption.

Overall, the alpha design has been reduced to fewer components, the manufacturing tolerances of which can therefore add up less. This simplified production and maintenance, the latter also through rearrangements such as that of the ignition system, which now works at the top of the engine block. It still consists of two contactless and therefore low-wear coils. The intake manifold has been shortened and now consists of one component. This minimizes the possibility of sucking in "external air" that cannot be regulated and thus interferes with the engine control. On the exhaust side, the catalytic converter is now welded directly to the exhaust manifold , which heats it up faster and simplifies the exhaust system under the vehicle. The accelerator pedal and idle speed control sensor have been combined in one component. The fuel supply received a return-free system with higher fuel pressure for better torque at low speeds. Since then, this has been the standard for all of the manufacturer's new engine series.

The motors of this series formed the basis for the subsequent Gamma series . It has been gradually replacing the Alpha engines since 2006.

Alpha II CVVT

In 2004, the largest Alpha engine, like that of the Beta series a year before , received a camshaft adjustment called CVVT. It comes from the technological collaboration with Daimler-Chrysler as part of the Global Engine Manufacturing Alliance . The CVVT varies the opening time of the intake valves (by 40 ° of a crankshaft revolution), but not the valve lift and thus the opening duration . It thus influences the overlap between the inlet and outlet side and is comparable to BMW single VANOS technology .

This addition resulted in fuel savings and better torque in the lower speed range. The performance increased by 4 percent (see also background ). On the emissions side, nitrogen oxide levels in particular have been reduced by using the exhaust gas recirculating effect of a large overlap - exhaust gas that has already been emitted is sucked back into the combustion chamber.

Since 2006, the Gamma family has been gradually replacing the Alpha range in new models. These are only used for cost-sensitive models or markets. In Europe, their use ended with the Rio model change in spring 2011.

Technical specifications

| series | Engine code | Cylinder head |

Displacement (cm³) | Stroke × bore (mm) | Dry weight (kg) |

Power at (1 / min) | Torque at (1 / min) | cylinder | compression | Charging | injection |

|---|---|---|---|---|---|---|---|---|---|---|---|

| alpha | G4EA | SOHC | 1341 | 83.5 x 71.5 | 99.7 | 71 at 5500 | 110 at 3000 | 4th | 9.5 | - | Carburetor |

| alpha | G4EH | SOHC | 1341 | 83.5 x 71.5 | 107.7 | 60/75 / 82,84,86 1 for 5000/5400/5500/5500 | ? / 114/117/119 1 at? / 3000/3200/3000 | 4th | 9.5 | - | MFI |

| alpha | G4EK-TC 2 | SOHC | 1495 | 83.5 x 75.5 | -? - | 115 at 5500 | 171 at 4300 | 4th | 7.5 |

Turbo (+ 0.6 bar) |

MFI |

| alpha | G4EK | SOHC | 1495 | 83.5 x 75.5 | -? - | 88/91 3 at 5600/5500 | 127/130 3 at 4000/3050 | 4th | 10.0 | - | MFI |

| alpha | G4EB | SOHC | 1495 | 83.5 x 75.5 | 106 | 90 at 5600 | 130 at 3050 | 4th | 10.0 | - | MFI |

| alpha | G4ER | DOHC | 1495 | 83.5 x 75.5 | -? - | 99 at 5900 | 134 at 4700 | 4th | 10.0 | - | MFI |

| alpha | G4EC (-G) 4 5 | DOHC | 1495 | 83.5 x 75.5 | 115.1 | 101 at 5800 | 133 at 3000 | 4th | 10.0 | - | MFI |

| Alpha II | G4EE | DOHC | 1399 | 78.1 x 75.5 | 116 | 75/97 at 5500/6000 | 125 at 4700 6 | 4th | 10.0 | - | MFI |

| Alpha II | G4ED (-G) 4 | DOHC | 1599 | 87 x 76.5 | 115.4 | 103/105/106/107 7 for 4500/5800/5800/5800 | 141/143/144/146 7 for 4500/4500/3200/3000 | 4th | 10.0 | - | MFI |

| Alpha II CVVT | G4ED | DOHC | 1599 | 87 x 76.5 | -? - | 112 at 6000 | 146 at 4500 | 4th | 10.0 | - | MFI |

commitment

The Alpha engines installed worldwide for each model are listed; not all of the configurations listed were offered in every country.

Hyundai Accent

- Accent X3

- G4EA, G4EH (all performance levels), G4EK: 1994–2000

- G4ER: 1996-2000

- Accent LC

- G4EH (75 PS): 1999-2003

- G4EH (86 hp): 2003-2005

- G4EB, G4EC: 1999–2003 (replaced by the facelift in Europe in 2003, today production in Egypt and India )

- G4ED (105 PS): 2003 – today ( replaced by Accent MC in Europe in 2005 , today production in Egypt and Russia )

- Accent MC

- G4EE, G4ED (112 PS): 2005 – today ( replaced by i20 in Europe in 2009 )

Hyundai Coupe

- Coupe RD2

- G4ED (107 hp): 2001-2002

- Coupé GK

- G4ED (105 hp): 2002-2005

Hyundai Lantra

- Lantra J2 / RD

- G4EK: 1995–2000 (South Korea only)

Hyundai Elantra

- Elantra XD

- G4ED (107 PS): 2000-today (replaced in 2004 in Europe by the facelift with 105 PS, this will continue to be produced in Venezuela with the older 107 PS engine )

- G4ED (105 hp): 2004-2006

- G4ED (112 PS): 2011 – today (China only)

Hyundai Getz

- Getz TB

- G4EH / G4EH60 (82 hp): 2002-2004

- G4EH / G4EH63 (86 hp): 2004-2005

- G4ED (105 hp): 2002-2005

- Getz TBi

- G4EE, G4ED (106 PS): 2005-today ( replaced by i20 in Europe in 2009 , today production in Malaysia, Venezuela and Egypt )

Hyundai Matrix

- Matrix FC

- G4ED (103 HP): 2001-today (discontinued in Europe in 2010, today production in Malaysia and Egypt)

Hyundai S-Coupe

- Scoupe L1

- G4EK-TC: 1992-1995

- G4EK: 1991-1995

KIA Cerato

- Cerato LD

- G4ED (105 hp): 2003-2006

- G4ED (112 hp): 2004–2006 (South Korea), 2005-present (China)

KIA Rio

- Rio DE

- G4EE (97 hp), G4ED (112 hp): 2005-2011

- CL 1.3, CV 1.3, CN 1.3

- G4EH (62 kW; 83 PS): 1996–1999

Web links

- Automotive industry in South Korea (South Korean automobile history) in the English language Wikipedia

Individual evidence

- ↑ Production in Ulsan and Hwaseong ( Memento of the original from December 27, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 145 kB)

- ↑ Production in Shandong

- ↑ Launch of the alpha and beta engine series

- ↑ Change from engine production under license to in-house development at Hyundai

- ↑ Materials of the Alpha components

- ↑ Idle speed Alpha and Alpha II series (PDF; 1.9 MB)

- ↑ Idle speed Alpha II CVVT manual Hyundai Accent MC chapter 9, page 3

- ↑ Inspection interval of the timing belt of the Alpha series according to the Hyundai Accent X3 manual, chapter 5, page 4

- ↑ Inspection interval of the timing belt of the Alpha II series according to the Hyundai Accent LC manual, chapter 5, page 5

- ↑ Inspection interval of the timing belt on the Alpha II CVVT according to the Hyundai Accent MC manual, chapter 5, page 5

- ↑ Drive of the auxiliary units in the Alpha

- ↑ Drive of the auxiliary units in the Alpha II

- ↑ Video with ticking sound of worn plungers

- ↑ Explanation of a worn camshaft

- ↑ Video of a hydraulic valve lifter with an explanation of the oil channel

- ↑ a b c d e f g h i j k Development of the Alpha series (PDF)

- ↑ Hyundai Motor started as a Korean assembly department for the Ford Cortina

- ^ Economic goals of the military government at the time Hyundai was founded

- ↑ Hyundai sales figures 1984 ( Memento of the original from June 5, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ a b Hyun Soon Lee announces departure from Hyundai

- ↑ base price of the Scoupe GT in North America >

- ↑ Promotional video for the Scoupe Turbo's 1992 Pikes Peak ride ( memento of the original from June 15, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Press release on the Hyundai Scoupe GT

- ↑ Exact description of the turbocharger ( Memento of the original from July 5, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Advertising campaign in North Korea for Alpha Lean Burn

- ↑ Driving report of a Lantra Lean Burn ( memento of the original from March 15, 2016 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Driving report of the Insight with measurement of the mixing ratio

- ↑ Explanation of combustion chamber shapes ( Memento of the original dated November 12, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. >

- ↑ Change of Hyundai leadership in 1999 New leadership, new focus ( Memento of the original from February 26, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Effects of a graphite coating on pistons

- ↑ Engine mounting in the Alpha II

- ↑ a b c Changes from Alpha to Alpha II

- ↑ Ignition system of the Alpha series

- ↑ Explanation of the Hyundai CVVT technology including images

- ↑ Engine codes I

- ↑ Motor codes II ( Memento of the original from October 3, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Engine codes III ( Memento of the original from October 3, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ autoextrem.de

- ↑ Accent license production in Egypt ( Memento of the original from June 12, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ Accent production in India

- ↑ Accent license production in Egypt ( Memento of the original from June 12, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Accent license production in Russia ( Memento of the original from August 24, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Elantra license production in Venezuela ( Memento of the original from May 30, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Elantra production in China ( Memento of the original from June 30, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Getz production in Malaysia

- ↑ Getz license production in Venezuela ( Memento of the original from May 19, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Getz license production in Egypt ( Memento of the original from June 12, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ Matrix license production in Malaysia

- ↑ Matrix license production in Egypt ( Memento of the original from June 12, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.