Hyundai KIA Delta

| Hyundai / KIA | |

|---|---|

|

|

| delta | |

| Manufacturer: | Hyundai / KIA |

| Production period: | 1998-2010 |

| Design: | 60 ° V |

| Engines: | 2.5 L (2493 cm³) 2.7 L (2656 cm³) |

| Cylinder firing order: | 1-2-3-4-5-6 |

| Previous model: | none |

| Successor: | Hyundai KIA Mu |

| Similar models: | Hyundai KIA Mu |

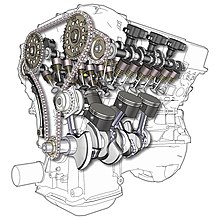

Delta is a gasoline engine series from the South Korean manufacturer Hyundai with six cylinders in a V configuration . It has four overhead camshafts and 4 valves per cylinder. The engines were built in Asan (South Korea) and Shandong (China).

The 2.5-liter engine, released in 1998, was the first V6 engine developed entirely by Hyundai. It has a stroke of 75 mm and a bore of 84 mm. In 2001 a drilled 2.7-l variant followed with the same stroke and 86.7 mm bore.

In contrast to those of the previously built Sigma, the engine block and cylinder head are made of aluminum . The 2.5 l version therefore weighs 145 kg (2.7 L 148 kg) over 40 kg less than the Sigma of the same size. The idling speed with the air conditioning switched off varies between 880 (2.5 L) and 850 (2.7 L), in the D rive switch position between 625 (2.5 L) and 750 (2.7 L).

The inlet and outlet camshafts of each cylinder bank are connected by a timing chain , and the power is transmitted from the crankshaft to the cylinder head by means of a toothed belt . This has an automatic retensioning system, its inspection is scheduled every 30,000 km, the timing belt replacement every 90,000 to 100,000 km, depending on the model. The motors are not free runners .

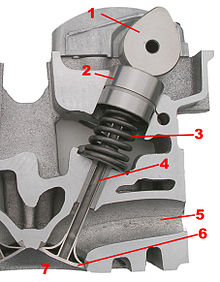

The valves are operated via hydraulic valve lifters . This form of valve clearance compensation is maintenance-free until the hydraulic valve lifters wear out. This is created by removing the contact surface between the cam and hydraulic valve lifters. The distance is initially compensated for by a spring that presses the top of the plunger flush upwards. Continuous ticking indicates that this is no longer sufficient and that the cam no longer rests constantly on the hydraulic valve lifter, but only reaches it once per revolution - the occurrence generates the ticking noise. When replacing the tappets, they are replaced by slightly longer ones in order to compensate for the removed cam material. If the replacement is not carried out, the cams are also increasingly worn, which ultimately results in a "broken-in camshaft". Then this would have to be exchanged in addition to the tappets. A ticking can also be caused by unsuitable oil viscosity or failure to comply with the change intervals. If the oil channel in the hydraulic valve valve runs empty because the oil level is too low, the valve clearance will also be too large and the valve will no longer open completely. The result is a smaller amount of air and thus a little less performance.

Even after a long standstill, the noise is possible if the oil ducts have run empty. This is not a sign of wear and tear and disappears after a few seconds.

delta

In 1998 the third independently developed engine series after Alpha and Beta made its debut in the fourth Hyundai Sonata . Like this, it was developed at the headquarters in Yongin (South Korea) and was a first for Hyundai in two fields: V6 engine construction and its all-aluminum construction. Previously, Hyundai produced slightly modified Mitsubishi series in the V6 segment as well as in the V8 series Omega . The V6 series was still based on gray cast iron and went back to the Mitsubishi Cyclone series that was created in the late 1980s. At Hyundai, it was further developed in parallel as the Sigma series. Since the debut of the Delta engines, Hyundai has only used the upper range of the Sigma series up to 3.5 L and modified these engines roughly in the direction of rotation of the crankshaft. Since then, they have not been identical to Mitsubishi. Sigma engines were found in the Kia Opirus until 2006 and were only replaced with the self-developed Lambda series in 2004 .

The larger engine of the Delta series was manufactured in two versions at the factory: one for gasoline and one for liquid gas . The latter was only offered in South Korea and is intended as a particularly smooth-running alternative to the similarly economical diesel engine .

The connecting rods, manufactured using cost-intensive powder metallurgy , were joined to the crankshaft forged from one piece with six counterweights using the " cracking process ", which was still new at the time . In order to attach the connecting rods to the crankshaft, their recess must consist of two parts joined together. By deliberately breaking apart, these “semicircles” are given a similarly brittle contact surface as porcelain . The half-parts therefore fit into one another in a form-fitting manner, the gap becomes almost invisible and the forces acting are distributed over the entire recess. The half-parts were previously sawn apart, which reduced the power transmission and thus the durability. Powder metallurgy also allows more precise production and thus reduces the need for balancing. For the Hyundai Coupé, the crankshaft was also cast using the more expensive “non-twist” process. Here, the mold already corresponds to the finished crankshaft, which makes removal from it more complex. In the twist process, on the other hand, the shaft is cast in one plane and only then is the crank pin forged. This can change the grain structure in the metal in such a way that weak points arise. With better process control, however, this advantage has been minimized in recent years, according to a spokesman for Lunati, a crankshaft manufacturer for racing.

Delta engines have a variable intake system (Variable Intake System). This takes into account the pulsation of the air in the intake manifold, which occurs when the valves are opened and closed. If these negative and positive pressure impulses find their way into the engine compartment that is adapted to their rhythm, a slight resonance charging effect occurs, similar to a turbocharger . To achieve this, a suitable, short air path opens at low and high speeds. At medium speeds, the longer air duct is used by means of a flap, which results in consistently high torque.

The better thermal conductivity of aluminum compared to gray cast iron leads to the operating temperature being reached more quickly and reduces friction due to unevenly extended cylinders.

The V-orientation of the two three-cylinder banks has the advantage of being shorter in length than in- line six-cylinders , such as those installed by BMW . In addition, the crankshaft now only has to be half as long as each crank pin drives two pistons. The disadvantage of being divided into two banks is that there are duplicate components at the other end of the piston - in the cylinder head, around four instead of two camshafts have to operate the valves, which increases maintenance costs slightly. Another component is required for smooth running, since the three-cylinder banks emit more vibrations at high speeds. This is helped by a balancer shaft that rotates against the crankshaft at the same speed. A small second-order free mass moment remains , as in in-line four-cylinder engines.

The engines of this series were offered almost exclusively with a four- speed automatic transmission . The larger Delta engine was developed in 2005 by more than one mu to the series of the same name. This is the only one from the manufacturer with only one motor.

Data

| series | Engine code | Displacement (cm³) | Stroke × bore (mm) | Power at (1 / min) | Torque at (1 / min) | cylinder | compression | Charging | injection |

|---|---|---|---|---|---|---|---|---|---|

| delta | G6BV (-G) 1 | 2493 | 75.0 x 84.0 | 160/169 2 at 6000 | 225-230 at 4000 | 6th | 10.0 |

VIS (2 way) |

MFI |

| delta | G6BA (-G) 1 | 2656 | 75.0 x 86.7 | 165/167/173/175 3 at 6000 | 245-250 at 4000 | 6th | 10.0 | VIS (2 way) |

MFI |

| delta | L6BA 4 | 2656 | 75.0 x 86.7 | 144 at 5000 | 226 at 4000 | 6th | 10.0 | VIS (2 way) |

MFI |

commitment

Listed are the Delta engines installed worldwide for each model, with the exception of the KIA Opirus, these were also offered in Europe.

Hyundai Coupe

- Coupé GK

- G6BA (167 hp): 2002-2006

- Coupé GK facelift

- G6BA (165 hp): 2007-2009

Hyundai Santa Fe

- Santa Fe SM

- G6BA (173 hp): 2001-2006

- L6BA: 2000-2005

Hyundai Sonata

- Sonata EF

- G6BV (160 hp): 1998-2001

- Sonata EF-B

- G6BA (173 hp): 2001-2004

Hyundai Trajet

- Trajet FO

- G6BA (173 hp): 2001-2008

- L6BA: 1999-2004

Hyundai Tucson

- Tucson JM

- G6BA (175 hp): 2004-2010

KIA Magentis

- Magentis GD

- G6BV (169 hp): 2001-2005

KIA Opirus

- Opirus LD

- G6BA (175 HP): 2002–2006 (in Europe only with 3.5 L Sigma)

KIA Sportage

- Sportage JE

- G6BA (175 hp): 2004-2010

Individual evidence

- ↑ Production in Shangdong

- ↑ Production in Asan ( Memento of the original from December 27, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 145 kB)

- ↑ Delta motor data (PDF; 1.9 MB)

- ↑ Timing chains and toothed belts in the delta motor ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Delta Motors 1998 Change interval of the toothed belt ( Memento of the original from August 13, 2009 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Delta Motors 2005 Change interval of the toothed belt ( Memento of the original from November 11, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Type of valve clearance compensation

- ↑ Video youtube.com

- ↑ habenweiss-was.de

- ↑ Video youtube.com

- ↑ Hydraulic valve lifters #Special features

- ↑ Development site of the delta series ( Memento from November 12, 2011 in the Internet Archive )

- ↑ Modifications of the Sigma series compared to the Mitsubishi Cyclone series ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Delta Manufacturing Process ( Memento of the original from November 22, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Non-Tist crankshaft in the Hyundai Coupé

- ↑ Advantages of the non-twist procedure ( Memento of the original from November 13, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Lunati: Twist process catches up with non-twist production

- ↑ Gas exchange # four-stroke reciprocating engine

- ↑ engine codes