Hyundai KIA Beta

| Hyundai / KIA | |

|---|---|

| Beta II 1.8 ( G4GB ) | Beta II 1.8 ( G4GB )

|

|

| Beta, Beta II, Beta II CVVT | |

| Manufacturer: | Hyundai / KIA |

| Production period: | 1995 – today |

| Design: |

Inline four-cylinder |

| Engines: | 1.6 L (1599 cm³) 1.8 L (1795 cm³) 2.0 L (1975 cm³) |

| Cylinder firing order: | 1-3-4-2 |

| Previous model: | none |

| Successor: |

Theta (4-cylinder) |

| Similar models: | Mitsubishi Sirius (4-cylinder) |

The Beta series are four-cylinder gasoline engines with two overhead camshafts (DOHC) and four valves per cylinder. The engines are built in Ulsan and Hwaseong , South Korea . They were developed in Hyundai's research and development center in Yongin (South Korea).

Starting in 1995, the Beta series supplemented the first engine series developed in Korea, Alpha, which appeared in 1990 with larger displacements . Previously, Hyundai only installed Mitsubishi engines manufactured under license .

The engine block is made of gray cast iron , the cylinder head of light metal . The smallest version is the 1.6 liter model with a 77.4 mm cylinder bore and 85 mm cylinder stroke with a dry weight of 136 kg. For the 1.8 liter version (135.6 kg) the cylinders were bored out to 82 mm and in the 2.0 liter version (144 kg) the stroke was also extended to 93.5 mm. The latter was submitted in 1997. The idle speed is given below .

The inlet and outlet camshafts are connected by a timing chain , and the power is transmitted between the crankshaft and cylinder head with a toothed belt . Its inspection is planned every 45,000 / 95,000 km or 48 months, its replacement every 100,000 / 135,000 km or 60/72 months (models with premiere before / from 2006). The motors are not free runners .

The auxiliary units are driven by three V-belts . The inspection interval for models presented from 2006 onwards has been shortened from 48,000 km / 24 months to 15,000 km / 12 months. They must be replaced when the tension drops or wear is evident.

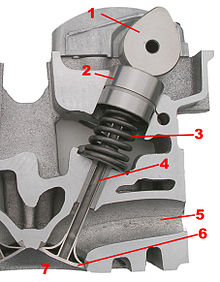

The valve actuation changed from the Beta to the Beta II series. The valve clearance inspection is planned every 95,000 km or 48 months, and the tappets are replaced as required. The Beta II CVVT sometimes makes a ticking noise after a little over 100,000 km due to worn bucket tappets. The adjustment of the valve clearance (see Beta II , third to last paragraph) can therefore be combined with the timing belt change at 100,000 km as a precaution, as both tasks require similar work steps.

Differences to the Sirius series

Before the start of the Beta series in 1995, Hyundai had been using Mitsubishi Sirius series engines in this displacement class since 1987 . This was further developed into the Sirius II series in 1994 and offered in parallel with Beta engines - in particular the 2.0, which was only released in the Beta series in 1997, and the 2.4 liter version that was not included there. Hyundai models before 2005 with 1.8, 2.0 and 2.4 liter displacement, which cannot be found in the list below , therefore contain a Sirius engine. At KIA, this only applies to the Joice (which, like the Hyundai Santamo, was based on the Mitsubishi Space Wagon ), as well as the Magentis and Sorento . The Hyundai engine codes are for the 1.8 G4CM (Sirius), the 2.0 G4CP, G4JP (Sirius, Sirius II) and the 2.4 G4CS, G4JS (Sirius, Sirius II).

The Sirius motors are around 5 kg heavier, but also a little longer, wider and higher than the beta motors. In the Sirius series, the toothed belt drives both camshafts, in the Beta series only one, which moves the second via a horizontal timing chain on the cylinder head.

In contrast to Beta and Sirius motors, the toothed belt of the Sirius II series is automatically retensioned. The same applies to the two balancer shafts : they are also only part of the Sirius II series. Their cylinder head, in turn, prevented the installation of a camshaft adjustment, unlike the Beta II series, which is suitable for this .

beta

The development of the first beta series began in 1992 and cost 120 million US dollars . The use of plastic in many parts from cylinder head covers to air filters should on the one hand reduce weight and on the other hand increase the proportion of recyclable materials. The focus was on achieving the demanding California environmental laws of 1996.

The valves are operated via hydraulic valve lifters . This form of valve clearance compensation is maintenance-free until the hydraulic valve lifters wear out. This is created by removing the contact surface between the cam and hydraulic valve lifters. The distance is initially compensated for by a spring that presses the top of the plunger flush upwards. Continuous ticking indicates that this is no longer sufficient and that the cam no longer rests constantly on the hydraulic valve lifter, but only reaches it once per revolution - the occurrence generates the ticking noise. When replacing the tappets, they are replaced by slightly longer ones in order to compensate for the removed cam material. If the replacement is not carried out, the cams are also increasingly worn, which ultimately results in a "broken-in camshaft". Then this would have to be exchanged in addition to the tappets. A ticking can also be caused by unsuitable oil viscosity or failure to comply with the change intervals. If the oil channel in the hydraulic valve valve runs empty because the oil level is too low, the valve clearance will also be too large and the valve will no longer open completely. The result is a smaller amount of air and thus a little less performance. Even after a long standstill, the noise is possible if the oil ducts have run empty. This is not a sign of wear and tear and disappears after a few seconds.

Problems

Cracks appear in the exhaust manifold on some engines in this series . This can be recognized by features such as low draft, irregular running noise, increased consumption or unusual noises when accelerating. Due to the uncontrolled outflow of exhaust gases in front of the cleaning catalytic converter and the incorrect measurements that follow behind, the engine management adds too much or too little fuel, which means that emissions standards are usually no longer complied with ( cf. ). The exhaust manifold has to be replaced for repairs, which on some models and the catalytic converter form an expensive component. In the DA-CH region, the manufacturer took over the exchange free of charge for vehicles up to five years old. The goodwill regulation therefore expired in 2007 for the last affected vehicles. This affects Hyundai Lantra, Elantra and Coupé, which were manufactured from mid-1998 to January 31, 2002 (model years 1999 to 2002). The date of manufacture can be found on a sticker in the driver's door. With the Beta II series, the material became more resistant and the exhaust manifold problem disappeared.

Beta II

In 2001 the Beta series underwent a number of efficiency-enhancing and noise-reducing measures and thus became Beta II. The 1.6-liter version was discontinued.

After the debut in the Hyundai Coupé in 2002, the revised versions replaced the previous ones in the course of facelifts or new presentations. The last newly released model with a Beta II engine is the Kia Soul in non-European markets. Within Europe, it is only available with the 1.6-liter versions of the Gamma - Otto and U2 diesel series .

The changes to improve the running smoothness included a reinforced cylinder block, eight instead of four counterweights on the crankshaft and an oil pan now made of aluminum. The engine itself was better decoupled from the body with the change from rubberized to hydraulic bearings. In addition, the idle speed was reduced from 850 to 700 revolutions per minute and a larger engine cover was installed. The idling speed no longer increases by 100 when the air conditioning is active.

To increase performance, the air filter box was designed to be more aerodynamic and provided with a heat shield opposite the engine, which means that more air can flow in overall. This resulted in an increase in performance of 2 percent. The fuel supply has been converted to a non-return system with higher fuel pressure. This has been the standard for all new engine series since 1999.

In order to reduce emissions, the shape of the combustion chamber was changed, which was made possible by more precise production of the cylinder head. This only had to be sealed twice instead of three times. As a result, the valve lift and opening time could also be set more precisely. In the valve actuation, the hydraulic one has also been replaced by a rigid tappet. The valve clearance is adjusted with shims, which are replaced with new ones when they are worn out. Visually and functionally nothing changed in the description above .

For the air volume measurement, a MAF (Mass Air Flow) sensor was switched to a MAP sensor (Manifold Absolute Pressure).

Beta II CVVT

In 2003, the 2.0-liter version was the first result of the technical collaboration with Daimler-Chrysler as part of the Global Engine Manufacturing Alliance to receive a camshaft adjustment for the intake side called CVVT. The CVVT varies the opening time of the intake valves (by 40 ° of a crankshaft revolution), but not the valve lift and thus the opening duration . It thus influences the overlap between the inlet and outlet side and is comparable to BMW single VANOS technology .

This addition resulted in a 5 percent fuel saving and a better torque in the lower speed range. Like the maximum torque, the power increased by 4 percent (see also background ). The nitrogen oxide values in particular have also been reduced by using the exhaust gas recirculating effect of a large overlap - exhaust gas that has already been emitted is sucked back into the combustion chamber.

In some models ( e.g. KIA Cerato , Hyundai Elantra ) a mass air flow sensor (MAF) replaced the indirectly measuring MAP air flow meter introduced with Beta II . The latter can be recognized in the engine compartment of the pro_cee'd above the DOHC lettering by the black wired component on the silver intake pipe.

In the models that have been released since 2006, the hydraulic power steering has been replaced by an electrically assisted one.

Since 2006, the Theta family , which was created as part of GEMA , has gradually replaced the Beta series in new models. These were only used for cost-sensitive models or markets. In Europe, their use ended in the 2011 model year, as the Euro 5 standard became mandatory from 2011 . The beta series was no longer adapted to this.

Data

| series | Engine code | Displacement (cm³) | Stroke × bore (mm) | Power at (1 / min) | Torque at (1 / min) | cylinder | compression | Charging | injection |

|---|---|---|---|---|---|---|---|---|---|

| beta | G4GR | 1599 | 85 x 77.4 | 90/114 at 5800 1 | 143 at 3000 | 4th | 10.1 | - | MFI |

| beta | G4GM (R) 2 | 1795 | 85 × 82 | 128 at 6000 | 166 at 5000 | 4th | 10.1 | - | MFI |

| Beta II | G4GB | 1795 | 85 × 82 | 122/132 4 at 6000 | 162 at 4500 | 4th | 10.1 | - | MFI |

| beta | G4GF (S / -EG) 2 | 1975 | 93.5 × 82 | 135-139 1 at 6000 | 180-182 at 4800 | 4th | 10.1 | - | MFI |

| Beta II | G4GC (G-139 / G-141) 5 | 1975 | 93.5 × 82 | 136-141 1 at 6000 | 179-182 at 4500 | 4th | 10.1 | - | MFI |

| Beta II CVVT 3 | G4GC (X) 5 | 1975 | 93.5 × 82 | 141-143 4 at 6000 | 184-186 at 4500 | 4th | 10.1 | - | MFI |

commitment

All models with beta engines are listed; not all configurations listed were offered in every country.

Hyundai Coupe

- Coupé RD / J2

- G4GR, G4GMR: 1996–1998,

- G4GF: 1996-2000

- Coupe RD2

- G4GFS, G4GF-EG: 1999-2001

- G4GCG-141: 2001-2003

- Coupé GK

- G4GCX: 2003-2009

Hyundai Lantra

- Elantra J2 / RD

- G4GR, G4GM: 1996-2000

- G4GF: 1998-2000

Hyundai Elantra

- Elantra XD

- G4GM, G4GCG-139, G4GCG-141: 2001-2003

- G4GB, G4GCX: 2003-2006

- Elantra HD

- G4GCX: 2007-2011

Hyundai i30

- i30 FD (from Korea) / FDH (from Czech Republic)

- G4GCX: 2007-today (since 2010 only for the USA, sold there as Elantra Touring )

Hyundai Matrix

- Matrix FC

- G4GB: 2001-present

Hyundai Trajet

- Trajet FO

- G4GCG: 2004-2008

Hyundai Tucson

- Tucson JM

- G4GCX: 2004-2009

KIA Carens

- Carens FC

- G4GC1: 2003-2006

- G4GCX: 2004-2006

KIA cee'd

- cee'd ed

- G4GCX: 2006-2010

KIA Cerato

- Cerato LD

- G4GB: 2005-present (China)

- G4GC1: 2003-2006, G4GCX: 2003-2009

KIA Soul

- Soul AM

- G4GCX: 2009-2011

KIA Sportage

- Sportage JE

- G4GCX: 2004-2010

Individual evidence

- ↑ Production in Ulsan and Hwaseong ( Memento from December 27, 2010 in the Internet Archive ) (PDF; 145 kB)

- ↑ Development site of the beta series ( Memento from November 12, 2011 in the Internet Archive )

- ↑ Page no longer available , search in web archives: launch of alpha and beta engine series

- ↑ Change from motor license production to in-house development

- ↑ Weights of the beta engine series ( Memento from September 20, 2010 in the Internet Archive )

- ^ Inspection interval for the Hyundai Elantra XD timing belt

- ↑ a b Inspection interval of the toothed belt operating instructions Hyundai i30 chapter 7, page 9

- ↑ Instructions for the Elantra timing belt replacement: "Both engines are interference engines"

- ↑ Drive principle of the ancillary units Beta

- ↑ Drive principle of the ancillary units Beta II

- ↑ Inspection interval of the V-belts operating instructions Hyundai i30 chapter 7, page 9

- ↑ Inspection interval of the V-belts Operating Instructions Hyundai Elantra 2004 Chapter 5, page 5

- ↑ Inspection interval of the V-belts operating manual Hyundai Elantra 2007 chapter 7, page 9

- ↑ Typical problems of the Elantra XD ( Memento from August 9, 2011 in the Internet Archive )

- ↑ Hyundai Stellar with Mitsubishi 4G63 / Hyundai G4CP ( Memento from September 4, 2008 in the Internet Archive )

- ↑ Hyundai engine codes of the Sirius series ( Memento from July 19, 2011 in the Internet Archive ) (PDF; 271 kB)

- ↑ Dimensions and weights of the Sirius and Beta motors (PDF; 1.3 MB)

- ↑ Differences between Sirius and Beta

- ↑ Note on the timing belt for Sirius and Beta

- ↑ Quoted on page 42 of the Korea Daily Times March 7, 1995

- ↑ a b Type of valve actuation Beta and Beta II (CVVT)

- ↑ Hyundai Lantra 1.6 GLSI Engine Noise on YouTube

- ↑ Hydraulic valve lifters . Werdenweiss-was.de. Retrieved June 28, 2013.

- ↑ hydraulic tappets / hydraulic valves (or hydraulic lifters) on YouTube

- ↑ Noises in hydraulic valve lifters

- ↑ Beta exhaust manifold - picture of a defective 2.0L (only caused additional consumption)

- ↑ Beta exhaust manifold problem description

- ↑ Beta exhaust manifold welded to the catalytic converter

- ↑ Beta exhaust manifold Description of an inexpensive replacement

- ↑ Beta exhaust manifold replacement regulation

- ↑ Beta exhaust manifold manufacturing range

- ↑ Changes from Beta to Beta II

- ↑ Idle speed of the beta engine series ( Memento from September 20, 2010 in the Internet Archive )

- ↑ Identification of a MAF and MAP air flow meter from the Beta engine series

- ↑ Explanation of the Hyundai CVVT technology including images

- ↑ Page no longer available , search in web archives: engine codes

- ↑ engine power

- ↑ Page no longer available , search in web archives: compression

- ↑ Beta throttle