Rail interoperability

Under interoperability is understood in the rail , that rail vehicles and throughout a certain possible security between different rail networks may communicate, especially between the railway networks of different states. The definition of interoperability in the Trans-European Rail Interoperability Regulation (TEIV): the suitability of the trans-European rail system for safe and continuous train traffic.

In Europe in particular, there are many national rail systems that have evolved over time. Different technical standards hinder cross-border rail traffic. That is why it is usually necessary to change locomotives at the border station on international trains . In particularly difficult cases, passengers have to change trains or goods have to be reloaded. Complex national approval procedures make it difficult to use multi-system vehicles that can run on different rail networks. In order to counteract this, the EU and other organizations are promoting the introduction of internationally standardized systems ( ERTMS ), which are intended to standardize rail operations in Europe.

Further technical harmonization is intended to develop transport services in the EU and with third countries. Interoperability in rail traffic is intended to ensure the integration of the market for equipment and services for the construction, renewal and functionality of the railway system from a technical point of view, but also to increase the safety of railway operations and promote deregulated competition between railway companies.

background

The reason for the lack of interoperability in European rail transport lies in history. The technical progress led to ever improved systems that were superior to the older ones. Each railway company introduced the most modern, most economical technology - unless it was already using an older system, with which compatibility was required. The governments hardly intervened to regulate, least of all to harmonize rail systems with other countries.

One example is the rail power system in Denmark . The neighboring countries Germany , Sweden and Norway as well as Austria and Switzerland agreed on 15 kV 16⅔ Hz alternating current at the beginning of the 20th century. Denmark continued to run its trains on steam and diesel. When electrification began later, the industrial standard 25 kV 50 Hz was chosen for technical reasons. Because of the island location, interoperability with the mainland was not really an issue. That changed with the construction of the Öresund connection and the electrification of the Neumünster – Flensburg – Padborg railway line on the German side, which required system separation points on the Swedish side of the Öresund and on the German-Danish border in Padborg.

On the other hand, the couplings of freight wagons are compatible across Europe, but technically outdated and uneconomical. Technical innovations such as the central buffer coupling could not prevail because freight wagons always had to travel across borders and it had to be possible to couple them with the vehicles there. The costs for a comprehensive conversion are so great that the uneconomical operation is still accepted.

Legal framework

In the EC Directive 2008/57 / EC of June 17, 2008 on the interoperability of the rail system in the Community, the directives 2001/16 / EC on the conventional trans-European rail system and 96/48 / EC on the trans-European high-speed rail system were combined and updated Adapted to developments. Their requirements were to be implemented by the member states of the Union by July 19, 2010.

The directive regulates the conditions for promoting the interoperability of the trans-European rail system with regard to the construction, commissioning, renewal, operation and maintenance of the system. Operational aspects are covered by Directive 2004/49 / EC on railway safety, and the safety and health of workers at work.

The gradual implementation of the interoperability of the rail system is achieved through the harmonization of technical standards. Therefore, this policy addresses:

- the essential requirements with regard to safety, reliability, health, environmental protection, technical compatibility and functionality of the system (regulated in Annex III of the Directive);

- the technical specifications for interoperability (TSIs), which are formulated in accordance with this directive for each subsystem or part of a subsystem and, when published in the Official Journal of the EU, supersede conflicting national regulations in their validity, and

- the corresponding European specifications.

The railway network is subdivided into subsystems of a structural (energy, train control, train protection and signaling, vehicles) or functional type (traffic operation and traffic control, maintenance, telematics applications).

In justified exceptional cases (e.g. in the case of advanced construction projects, technical incompatibility with the existing structure, economic unreasonableness, in the event of a catastrophe, etc .; see Art The scope of the directive is decisive.

TSI drafts are prepared by the European Railway Agency on the basis of the examination of the subsystems in cooperation with the associations and social partners . The drafts are then submitted to the European Commission , which changes them and accepts them, while maintaining Parliament's supervisory powers.

The interoperability components are subject to European specifications (such as the European standards) and the process of the EC declaration of conformity or the EC declaration of suitability for use.

Technical obstacles

Gauge

A uniform track gauge is the most important prerequisite for rail vehicles to run on different rail networks. Solutions to overcome this obstacle are, for example, gauge change systems , multi-rail tracks and trolleys . After all new lines on the Iberian Peninsula (Spain, Portugal, keyword Alta Velocidad Española ) are being built in standard gauge, and there are still considerations to convert the existing ones in the long term, there is a clear trend towards standard gauge in Europe.

Clearance profile and vehicle gauge

A clearance gauge that is too small prevents vehicles with a larger gauge from being able to drive on a route. The situation is similar with the width of the pantographs , except that pantographs that are too wide and too narrow must be excluded because of the zigzag line of the overhead contact line . While equipment with several pantographs is technically relatively problem-free and inexpensive, harmonization itself is only very expensive to achieve in the event of deviations from the clearance profile (widening of the tunnel, enlargement of the center-to-center distance of the tracks). Great Britain in particular has a small clearance profile compared to the rest of Europe; modern locomotives, freight cars and multiple units can be exchanged between most Central European countries without any problems. However, there are certain restrictions (boundary lines, KLV traffic ) e.g. B. even within Germany.

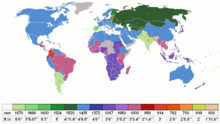

Power system

Direct and alternating currents with different voltages are common in railways. The transition from one power system to another is called a system separation point . Multi-system vehicles can run in different power systems and are becoming increasingly standard in cross-border freight traffic, as well as in high-speed traffic (ICE 3M, TGV POS). Due to the energy requirements for high-speed traffic, there is a clear trend towards 25 kV / 50 Hz for new lines (except in countries with an existing 15 kV / 16.7 Hz network such as Germany), especially in countries with relatively low DC voltage (the Netherlands , South of France) a conversion of the existing network is discussed again and again, but would be correspondingly expensive.

Train control

The train control systems show the greatest differences between the national railway networks. Since more than one system is already in use in most countries, multi-system locomotives have up to ten different train control systems installed. Due to incompatibilities, the external train control systems must be switched off. In Europe, the existing national train control systems are to be replaced by the new ETCS standard .

automation

Each operator also has his own system for train number reporting systems and train routing. In the future, ERTMS will also standardize traffic management.

Overview

| country | Gauge | Clearance profile | Power system | Rocker width | Train control |

|---|---|---|---|---|---|

| Germany | 1435 mm | G2 EBO | 15 kV 16.7 Hz ~ **) | 1950 mm | Indusi , PZB , LZB |

| Austria | 1435 mm | G2 EBO | 15 kV 16.7 Hz ~ **) | 1950 mm | Indusi , PZB , LZB |

| Switzerland | 1435 mm | <G2 EBO > UIC 505-1 |

15 kV 16.7 Hz ~ **) | 1450 mm | ETCS , Euro-ZUB |

| Netherlands | 1435 mm | ≥ G2 EBO | 1500 V DC 25 kV 50 Hz ~ |

1950 mm | ATB , ATB VV, ATB NG |

| Belgium | 1435 mm | ≥ G2 EBO | 3000 V DC 25 kV 50 Hz ~ |

1950 mm | TBL , crocodile |

| Luxembourg | 1435 mm | ≥ G2 EBO | 3000 V DC | 1950 mm | Crocodile , TBL |

| 25 kV 50 Hz ~ | 1450 mm | ||||

| France | 1435 mm | UIC 505-1 | 1500 V DC | 1950 mm | Crocodile , TVM , KVB |

| 25 kV 50 Hz ~ | 1450 mm | ||||

| Italy | 1435 mm | UIC 505-1 | 3000 V DC 25 kV 50 Hz ~ |

1450 mm | RS4 Codici , SCMT |

| Spain | 1668 mm 1435 mm (NBS) |

3000 V DC 25 kV 50 Hz ~ |

ASFA , ZUB 121 , LZB | ||

| Portugal | 1668 mm | 25 kV 50 Hz ~ | EBICAB 700 | ||

| Great Britain | 1435 mm | <UIC 505-1 | 750 V DC | Busbar | AWS , TPWS |

| 25 kV 50 Hz ~ | |||||

| Ireland | 1600 mm | 1500 V DC | |||

| Denmark | 1435 mm | ≥ G2 EBO | 25 kV 50 Hz ~ | 1800 mm | ATC |

| Norway | 1435 mm | ≥ G2 EBO | 15 kV 16 Hz ~ | 1800 mm | EBICAB |

| Sweden | 1435 mm | ≥ G2 EBO | 15 kV 16 Hz ~ | 1800 mm | ATC , EBICAB |

| Finland | 1520 mm *) | 25 kV 50 Hz ~ | EBICAB 900 | ||

| Estonia | 1520 mm *) | 3000 V DC | |||

| Latvia | 1520 mm *) | 3000 V DC | |||

| Lithuania | 1520 mm *) | 25 kV 50 Hz ~ | |||

| Poland | 1435 mm | ≥ G2 EBO | 3000 V DC | 1950 mm | SHP |

| Czech Republic | 1435 mm | ≥ G2 EBO | 3000 V DC 25 kV 50 Hz ~ |

1950 mm | LS90 |

| Slovakia | 1435 mm | ≥ G2 EBO | 3000 V DC 25 kV 50 Hz ~ |

1950 mm | LS90 |

| Hungary | 1435 mm | ≥ G2 EBO | 25 kV 50 Hz ~ | 2050 mm | EVM 120 |

| Slovenia | 1435 mm | 3000 V DC 25 KV 50 Hz ~ |

|||

| Romania | 1435 mm | 25 kV 50 Hz ~ | |||

| Bulgaria | 1435 mm | 25 kV 50 Hz ~ | |||

| Greece | 1435 mm | 25 kV 50 Hz ~ |

identification

The UIC and the International Container Office have standardized various numbering schemes for uniform identification of vehicles, containers and trains . International trains have a unique train number across Europe . The rail wagons have a uniformly coded UIC wagon number across Europe . The containers have an internationally uniform and standardized container number ( BIC code according to ISO 6346). So far, the swap bodies have only had a size coding, but no uniform identification. The same applies to trailers, but as road vehicles they have a vehicle registration number.

Automatic reading process

The national railway administrations and the employees of private railway companies trained in these companies do not yet use modern transport management methods, for example for the automatic identification of rail wagons and containers in freight traffic. It is questionable whether there will be a change without a generation change.

Since the beginning of the numbering (numbering) the car number is read visually. This is still the method of choice today (2008). No railway company is able to read the wagon numbers automatically and with a sufficiently low error rate (1 in 10,000).

The lettering (DB AG: straight standard font DIN 16 variant DB) is read with an error rate of less than 5% (1 out of 20) using the OCR process.

Barcode identification

An established system of identification with barcodes, which simply reproduce the UIC number, is not known. The low level of support for error identification through only check digits would not be sufficient for a robust operating concept.

With a horizontal orientation, automatic reading by scanning when driving by would be possible. With a vertical orientation, automatic reading by scanning would only be possible with camera arrays when driving past.

Matrix code identification

There is no known system of identification with matrix codes which simply reproduce the UIC number. For example, a data matrix code according to ISO / IEC 16022 ECC 200 would be well suited. With a camera chip and flash lighting, these codes could be easily recognized at any time, regardless of weather conditions.

By correcting errors using the inherent redundancy of 25%, it would be possible to safely and reliably reconstruct code that is only partially readable. The good support for error detection and correction through redundancy is the only approach that makes coding superior to visual recognition from the start. Visual-manual post-processing would be unnecessary if the data from train runs were linked accordingly.

With a suitable choice of color (pigments, paint, carrier, application process), this marking can be designed to be forgery-proof and permanent.

RFID identification

RFID coding has been introduced for train systems in some cases and for individual types of wagon . As a rule, however, this does not support the driving operation, but only the management of the train units in maintenance and repairs.

With a horizontal orientation, the automatic reading of RFID tags attached to the side would be possible by scanning when driving past. The concept must contain a label that is either affixed on both sides (good concept because of inherent redundancy of the labels) or recorded with reading from both sides (more expensive concept because double antenna equipment is required everywhere). In the case of double labeling, standardization of the allocation of numbers must ensure that RFID tags have unique identification numbers and also include unique wagon numbers.

RTLS localization

The search for a cost-effective and robust instrumentation of railway wagons for automatic localization including identification, which has been pursued by subsidiaries of DB AG for years, is nowhere . The operator is neither willing to deviate from his specifications, nor is the industry able to meet the operator's price expectations.

TAF TSI

The provisions of the European Commission in the Technical Specification for Interoperability (TSI) for Telematics Applications for Freight (TAF) put the railway undertakings (RU) under pressure to sustainably improve interoperability on the basis of uniform procedures by the mandatory date of general introduction.

The Commission adopted Regulation (EC) No. 62/2006 of December 23, 2005 on the technical specification for interoperability (TSI) for the telematics applications subsystem for freight transport of the conventional trans-European rail system, published in Official Journal L13 of 18 January 2006, p. 1.

- Appendix 1: Data definition and messages

- Appendix 2: Infrastructure data and vehicle data

- Appendix 3: The consignment note data and description

- Appendix 4: The train path data and description

- Annex 5: Figures and flow charts of the TAF-TSI messages

- Appendix 6: TAF configuration management, concept and general requirements

Safe transport chains

When labeling containers on rail wagons on the door side in six packs (3 × 2 TEU ), read rates of 60% were found in the USA in 2005.

Organizational and legal difficulties

Approvals

Vehicles - especially multi-system locomotives - require national approval in every country. This is expensive and time-consuming in terms of administration.

Operating rules

Every country has different operating regulations and signaling systems . The differences in railway signaling are sometimes considerable and cannot be compared with the differences in road signaling. Personnel who are to be deployed internationally need additional training and appropriate examinations.

business

Operational differences make it difficult to hand over a train to a third-party railway company and traffic in the network access .