N - tert -butylacrylamide

| Structural formula | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

| General | ||||||||||||||||

| Surname | N - tert -butylacrylamide | |||||||||||||||

| other names |

|

|||||||||||||||

| Molecular formula | C 7 H 13 NO | |||||||||||||||

| Brief description |

white crystals |

|||||||||||||||

| External identifiers / databases | ||||||||||||||||

|

||||||||||||||||

| properties | ||||||||||||||||

| Molar mass | 127.18 g mol −1 | |||||||||||||||

| Physical state |

firmly |

|||||||||||||||

| density | ||||||||||||||||

| Melting point | ||||||||||||||||

| solubility |

slightly soluble in water (7 g · l −1 at 25 ° C ), soluble in methanol , ethanol , chloroform and acetone , insoluble in petroleum ether |

|||||||||||||||

| Refractive index |

1.4830 (25 ° C, 589 nm) |

|||||||||||||||

| safety instructions | ||||||||||||||||

|

||||||||||||||||

| Toxicological data | ||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . Refractive index: Na-D line , 20 ° C | ||||||||||||||||

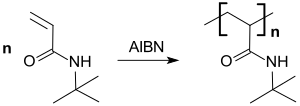

N - tert -Butyl acrylamide is an N-substituted acrylamide , the nitrogen atom of whichbearsa tert-butyl group . The substance is used as a comonomer , usually with other acrylamides, such as. B. N-isopropylacrylamide , for thermoresponsive polymers or temperature- and pH-sensitive smart hydrogels as intelligent materials from textile to medical applications.

Occurrence and representation

The synthesis of N - tert -butylacrylamide was first reported in 1951 by John J. Ritter and co-workers.

In this case, the added from tert-butanol with concentrated sulfuric acid formed tert -butyl carbonium ion to the nitrile group of acrylonitrile , and the thus formed Nitrilion hydrolyzed to N - tert -butylacrylamide (yield ca. 85%). The Ritter reaction with intermediate formation of the tert -butyl cation from isobutene or tert -butyl acetate gives TBAAm in yields of 85 to 92%.

Instead of sulfuric acid (usually together with acetic acid), a large number of liquid and solid Bronsted acids can be used as catalysts in the Ritter reaction .

Addition of catalytic amounts of the pentafluorophenylammonium triflate PFPAT, which is described as efficient, stable and easily separable, to a mixture of tert- butanol or tert-butyl acetate and acrylonitrile gives TBAAm in 92% yield.

The reaction to form N - tert-butyl acrylamide can also be carried out continuously. Acylation of tert-butylamine with acrylic acid chloride produces 96% TBAAm on neutral aluminum oxide surfaces with complete conversion within 5 minutes.

Because of the relatively expensive starting materials, this synthesis route is more suitable for laboratory quantities of N - tert -butylacrylamide.

properties

N - tert -Butyl acrylamide is an odorless white crystal powder that dissolves only slightly in water (8 g l −1 at 25 ° C, 15 g l −1 at 70 ° C), but dissolves well in alcohols, chloroform and acetone .

Applications

Due to its low solubility in water, N - tert -butylacrylamide can cause radical effects in aqueous dispersion, e.g. B. with potassium peroxodisulfate K 2 S 2 O 8 , homopolymerized to form monodisperse latices .

While the water-insoluble homopolymeric poly- N - tert-butyl acrylamide has so far found little interest, copolymers of N - tert-butyl acrylamide with hydrophilic comonomers, such as. B. acrylamide or acrylic acid , e.g. B. more common as a hair setting agent.

Copolymers with the closely related N -isopropylacrylamide NIPAM are, because of their thermoresponsive behavior, in an aqueous medium, i.e. H. the temperature-dependent change in their solubility and the transition from the open coil to the dense spherical structure (English 'coil-to-globuli transition'), as possible chromatography materials or as drug carriers for the controlled release of pharmaceuticals or proteins Research objects.

Individual evidence

- ↑ a b c Data sheet N-tert-Butylacrylamide from Sigma-Aldrich , accessed on June 22, 2019 ( PDF ).

- ^ A b Carl L. Yaws: Thermophysical Properties of Chemicals and Hydrocarbons, 2nd Edition . Elsevier Inc., Oxford, UK 2015, ISBN 978-0-323-28659-6 , pp. 164 .

- ↑ Entry on N-tert-butylacrylamide at TCI Europe, accessed on May 22, 2019.

- ↑ Patent US3806543 : Method for alkali-cleavage of N-tert-alkylamides. Filed December 29, 1971 , published April 23, 1974 , Applicants: Toho Belson KK, Inventors: T. Takata, T. Yamada, H. Fukuizumi.

- ↑ Michael D. Larrañaga, Richard J. Lewis, Sr., Robert A. Lewis: Hawley's Condensed Chemical Dictionary, 16th Edition . John Wiley & Sons, Hoboken, NJ, USA 2016, ISBN 978-1-118-13515-0 , pp. 219 .

- ↑ a b Entry on N-tert-butyl acrylamide in the GESTIS substance database of the IFA , accessed on June 26, 2019(JavaScript required) .

- ↑ Y.-J. Kim, YT Matsunaga: Thermo-responsive polymers and their applications as smart biomaterials . In: J. Mater. Chem. B . tape 5 , no. 23 , 2017, p. 4307-4321 , doi : 10.1039 / C7TB00157F .

- ^ H. Plaut, JJ Ritter: New reaction of nitriles. VI. Unsaturated amides . In: J. Am. Chem. Soc. tape 73 , no. 9 , 1951, pp. 4076-4077 , doi : 10.1021 / ja01153a005 .

- ↑ Patent EP99752A1 : Production of Nt-alkylamides from t-olefins or t-alcohols. Applied July 19, 1983 , published February 1, 1984 , Applicant: Eastman Kodak Co., Inventor: S. Wake, M. Beppu, T. Mizuno.

- ↑ JE Milne, JC Baum: An efficient and scalable Ritter reaction for the synthesis of t-butyl amides In: Organic Syntheses . 89, 2012, pp. 519-526, doi : 10.15227 / orgsyn.089.0519 ( PDF ).

- ↑ JC Baum, JE Milne, JA Murry, OR Thiel: An efficient and scalable Ritter reaction for the synthesis of tert-butylamides . In: J. Org. Chem. Band 74 , no. 5 , 2009, p. 2207-2209 , doi : 10.1021 / jo8024797 .

- ↑ a b S. Khaksar, E. Fattahi, E. Fattahi: Organocatalytic synthesis of amides from nitriles via the Ritter reaction . In: Tetrahedron Lett. tape 52 , no. 45 , 2011, p. 5943-5346 , doi : 10.1016 / j.tetlet.2011.08.121 .

- ↑ Patent US2719176 : Continuous method of making N-substituted amides. Filed on Feb. 5, 1953 , published on Sept. 27, 1955 , applicant: Eastman Kodak Co., Inventor: HW Coover, Jr., NH Shearer, Jr

- ^ VK Yadav, KG Babu: Reactions on a solid surface. A simple, economical, and efficient acylation of alcohols and amines over Al 2 O 3 . In: J. Org. Chem. Band 69 , no. 2 , 2004, p. 577-580 , doi : 10.1021 / jo03541f .

- ↑ a b A. Narumi, Y. Kimura, S. Kawaguchi: Precipitation polymerization of N - tert -butylacrylamide . In: Coll. Polym. Sci. tape 290 , no. 4 , 2012, p. 379-384 , doi : 10.1007 / s00396-011-2571-0 .

- ↑ VP Gilcreest, WM Carroll, YA Rochev, J. Blute, KA Dawson, AV Gorelov: Thermoresponsive poly (N-isopropylacrylamide) copolymers: Contact angles and surface energies of polymer films . In: Langmuir (magazine) . tape 20 , no. 23 , 2004, pp. 10138-10145 , doi : 10.1021 / la0487996 .

- ↑ NS Save, M. Jassal, AK Agarwal: stimuli sensitive copolymer poly (N-tert-butylacrylamide-ran-acrylamides): Synthesis and characterization . In: J. Appl. Polym. Sci. tape 95 , no. 3 , 2005, p. 672-680 , doi : 10.1002 / appl.21216 .

- ↑ Patent WO2016091464A1 : Means and method for the temporary deformation of keratin-containing fibers. Registered on November 2, 2015 , published on June 16, 2016 , applicant: Henkel AG & Co. KGAA, inventors: T. Förster, R. Bayersdörfer, T. Knappe.

- ↑ O. Gibbons, WM Carroll, F. Aldabbagh, B. Yamada: Nitroxide-mediated controlled statistical copolymerizations of N -isopropylacrylamide with N - tert -butylacrylamide . In: J. Polym. Sci. Pole. Chem. Band 44 , no. 21 , 2006, p. 6410-6418 , doi : 10.1002 / pola.21751 .

- ↑ K. Yoshimatsu, BK Lesel, Y. Yonamine, JM Beierle, Y. Hoshino, KJ Shea: Temperature-responsive “catch and release” of proteins by using multifunctional polymer-based nanoparticles . In: Angew. Chem. Int. Ed. tape 51 , no. 10 , 2012, p. 2405–2408 , doi : 10.1002 / anie.201107797 .