Salt mine

A salt mine is a mine for the purpose of obtaining of stone and / or potash .

Overburden salt

The term overburden salt is misleading because it is not about overburden , but mountains . However, the overburden salt does not accumulate separately during underground mining, but is first separated from the extracted brine (in wet mining ) or the set (in dry mining ) brine in various fractions as sodium salt from the potassium salt and magnesium salt by physical separation processes and then recrystallized. According to today's definition, the unusable salt residues from mining are industrial waste and must either be pressed or discharged as brine or stored in crystal form as wet salt above or below ground.

A salt deposit usually consists of a mixture of chlorides and sulfates of potassium , magnesium and sodium as well as calcium . There are crystals of the valuable minerals of easily soluble potassium chloride and magnesium sulphate (Epsom salt) as well as the accompanying salts magnesium chloride (hygroscopic), sodium chloride (table salt) and poorly soluble calcium sulphate ( gypsum ). Due to other optical properties, gypsum tones the spoil salt white even when it is wet; iron and clay turn it gray or reddish in color.

After potassium chloride (fertilizer) with a proportion of 10 to 20 percent and magnesium sulfate (fertilizer) and also magnesium chloride (technical use) have been separated from the raw material in a treatment process, the rest is mainly made up of table salt (proportion approx. 95%) and gypsum ( Share approx. 5%) as overburden salt in exploited mine workings ( offset ) or dumped for days on an overburden dump.

Dismantling process

Dry mining

The salt rock is mined by drilling, blasting and cutting work. Salt festivals remain, which secure the cavities, some of which are very large ( chamber construction ). The salt obtained is processed through mechanical crushing, flotation , sedimentation as well as dissolving and recrystallization processes ( graduation tower ).

Wet mining

Salt extraction is particularly economical by dissolving the salt with water, previously by means of sinking works , today in drilling and flushing works . From the thus obtained sols is in the saline salt generated (such as in Berchtesgaden salt mine ). In northern Germany, salt domes are being drilled and leached . If the brine is not simply drained into surface waters , as is the case in the Burglesum , for example , the salt is extracted in salt pans. The large cavities created in the salt can be used as gas or oil storage or for waste storage.

Mining

Compared to ore or coal mining , water represents an even greater danger for a salt mine. Penetrating groundwater or seepage water would dissolve the salt and thus destroy the mine workings. It is therefore dry in an intact salt mine.

If moisture occurs, it must be checked whether it is fresh water or salt water . With fresh water or unsaturated saline solution there is the greatest danger, since further signs of dissolution are to be expected and the water influx can increase. If a saturated saline solution is encountered, which originates from the time when the salt deposit was formed, there is no danger as it cannot dissolve any further salt.

Using the example of the flushing out of the salt dome at Wapno (1977) and Lake Peigneur (1980) it becomes clear what dangers can arise from uncontrolled penetration of large amounts of water into a salt mine (cf. drowning ).

The frequent use of salt mines is also worth mentioning. If mining is no longer worthwhile, some salt mines are used because of the specific properties of the salt as repositories for waste that must be reliably sealed off from the biosphere. It is also possible to store radioactive waste in salt, although not necessarily safe, as the salt solution access to the Asse research nuclear waste dump near Wolfenbüttel proves. They are also used more and more often as healing tunnels ,

The Halurgie ( Greek. , Also Halo technology, saltworks customer) is the historical name for the study of the extraction of salt.

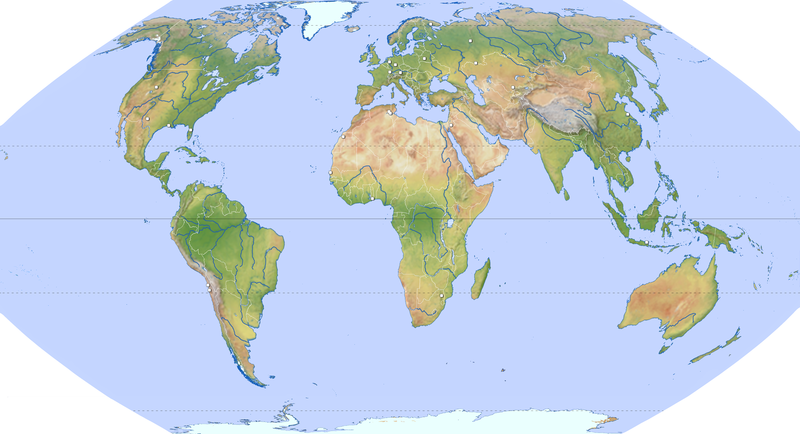

(The basic source for this map does not provide a more precise distinction between the salts)

If you would like to see a more detailed map of the world on mining "freely movable" in large format (5.6 MB), follow this link

history

One of the oldest salt mines is located in Wieliczka, Poland . There was a salt works there from around 3500 BC. BC, underground mining took place since the 13th century. There are extensive finds from the Bronze Age on the Hallstatt Salt Mountain near Hallstatt in the Salzkammergut (type locality from the Hallstatt Age ). In the early Iron Age (up to around 400 BC), underground salt mining began on the Dürrnberg ( Halleiner Salzberg near Salzburg) . In the younger Iron Age, this salt mining on the Dürrnberg already showed industrial features, the mine was largely in operation until 1989 (i.e. 2½ thousand years) and is now a show mine.

Germany

In Berchtesgaden salt mine is mined for over 500 years, rock salt, the salt mine Heilbronn / Bad Friedrichshall and Haigerloch -Stetten ( Zollernalbkreis ) since the 19th century. In Germany, rock salt is still mined on a large scale in Bernburg .

The potash mining areas of the southern and eastern Harz Mountains are known in Germany, but production has ceased there. In the Werra region , Hattorf, Wintershall, Unterbreizbach and Merkers , the Werra composite mine is the world's most modern and largest potash salt mine. The potash district of Zielitz (near Magdeburg ) is also of great importance . A potash mine is still running in the Hanover area, Sigmundshall plant. Parts of the Werra potash plant, Merkers site, can be visited underground as a visitor and adventure mine.

Large quantities of potash salts were also mined near Mulhouse in Alsace . Since underground mining in the potash district in Alsace was no longer profitable from 1992, the conveyor systems were shut down.

The outdated term for the share of a pan in a salt works is a droppings , it could be about the length of 35 shoes , a height of 20.5 shoes and a width of 49 shoes.

See also

- State Mining Museum Baden-Württemberg with a focus on salt mining

- Lye inflows into the salt mines of southwest Mecklenburg

Individual evidence

- ^ Mining and industry of the individual continents in the Alexander World Atlas 2000, Klett-Perthes, Gotha 2000

- ↑ Konrad Duden: Complete Orthographic Dictionary . Bibliographisches Institut, Leipzig - Vienna, ISBN 978-5-87566-651-3 ( google.de [accessed on January 31, 2018]).

- ^ Journal of the Association for Hessian History and Regional Studies . Neumeister printing works, 1908, p. 24 ( archive.org [accessed January 31, 2018]).

literature

- Silvio Zeibig, Olaf Hartmann: Recording the shafts of potash and rock salt mining in Germany. In: Potash and Rock Salt. No. 1, 2006, pp. 38-43.