Springfield Armory (Massachusetts)

The Springfield Armory in Massachusetts (official name National Armory, Springfield ) was the most important state arms factory in the USA , the later created Harpers Ferry Armory was smaller. It was built on the site of the Springfield Arsenal , where ammunition and other war materials were manufactured from 1777 onwards . From 1795 to 1968, where most of the US Army conducted rifles , from flintlock to the self-loading rifle manufactured. In addition, it was an important arsenal ( armory ) of the USA for light weapons . In 1968 the then Secretary of Defense of the United States' Defense Department, Robert McNamara , decided to close the Springfield Armory. Today it is a museum.

history

War of Independence

Before the American War of Independence , the colonists in North America were armed with British and French weapons, less often with imports from the Netherlands and Spain. When the first unrest broke out, Great Britain stopped all deliveries to the settlers. Since there was no arms industry in North America and the gunsmiths could not manufacture firearms in large numbers, one had to rely on contraband from France.

Colonel Henry Knox , an officer subordinate to George Washington , took the view that arsenals with workshops for the storage and maintenance of weapons should be set up in suitable locations , and that ammunition, artillery pieces and other war material should also be manufactured there. After George Washington endorsed this proposal and Congress approved it, a study was conducted to examine possible locations.

A first depot was set up in Carlisle, Pennsylvania, near the theater of war at the time, but far enough away from the British troops that they were not endangered.

Shortly thereafter, it was decided to build another arsenal in the states of New England . Brookfield and, preferred by George Washington, Hartford (Connecticut) were proposed . Colonel Knox dissuaded him from this idea because, in his opinion, British ships from Long Island Sound could easily sail up the Connecticut River and attack Hartford. Knox suggested Springfield (Massachusetts) , located further up the Connecticut River , because the river there was no longer navigable for larger ships. The region had a large amount of forest and three large sawmills necessary for the construction of buildings , and the river's hydropower could also be used.

From the end of 1777 the construction of barracks, warehouses, workshops and powder magazines began on a hill near Springfield. Almost at the same time the manufacture of ammunition, the repair of muskets and, a little later, the manufacture of artillery pieces began.

Because of the rapid expansion of the Revolutionary War, all surplus war material was moved off the Atlantic coast for safekeeping in Springfield. The arsenal thus became an important logistics center; in addition to weapons and ammunition, clothing, food and other materials were also stored, manufactured and handled here. The village of Feeding Hills near the arsenal got its name because of the herds of cattle raised there for the army.

According to Robert WD Ball , supplies from the Springfield Arsenal were essential to the success of the campaigns against Howe and St. Leger and the assault on opponents stationed in Canada in 1779.

With the end of the war in 1781, most of the workers were laid off, only a few workers remained in the arsenal.

1782-1795

In 1782, Congress decided to continue operating and expanding the Springfield Arsenal. In the same year the construction of a new powder magazine for 4,000 barrels of gunpowder was started; this was used until 1842.

In 1786, farmers attacked the arsenal to steal weapons. The aim of the farmers was to occupy local courts in order to prevent them from expropriating their over-indebted lands. The plan was quickly thwarted by the local militia . In order to prevent unrest and to legitimize its position, the government of the United States presented an amended constitution, which, with its ratification in 1788, replaced the previously existing articles of confederation . It is still in force today as the United States Constitution .

In 1794 the government decided to manufacture army weapons in their own country in the future. The decision was taken because of the inconsistent armament problems arose during the War of Independence. In the future, enough standardized weapons should be produced to equip a standing army. In addition to the National Armory, Springfield , President Washington determined that a second state arms factory, the Harpers Ferry Armory, should be established in Virginia.

1795 Arms production begins

After controls of the weapons inventory had shown in 1793 that the reserves of muskets were insufficient, President Washington commissioned the production of 7,000 muskets of the type of the French model 1768 "Charleville". Since both Springfield and Harpers Ferry had not yet been upgraded, the Springfield Armory had only produced 220 of these Model 1795 US Flintlock Muskets in 1795 ; Harpers Ferry did not start production until 1800. Between 1795 and 1814, Springfield produced a little over 80,000 of these weapons in various variants, while Harpers Ferry produced around 70,000 between 1800 and 1815.

In addition to the two state manufacturers, various third-party suppliers also received production orders, which meant that the weapons did not meet the specifications and showed defects. Due to the lack of marking and manufacturer designation, it was not possible to investigate the cause of these defects. It was therefore decided that from 1799 all weapons would have to bear the name of the manufacturer, a serial number, the designation "US" and the image of the US eagle. The first dies with the eagle were purchased according to the Armory books on June 11, 1799 at a price of $ 7.41.

Based on the bad experience, the Ordnance Department and Congress demanded in a law of February 8, 1815, that in future all weapons must be manufactured according to specified standards and that their components must be interchangeable. Weapons that did not meet these requirements were rejected by the state inspectors. The Model 1816 US Flintlock Musket thus became the army's first standard weapon.

The Springfield Armory did not limit itself to the manufacture of weapons, it was also concerned with their further development and the development of machine tools for the serial production of their products. For example, Thomas Blanchard (June 24, 1788 to April 16, 1864), as an employee of the Springfield Armory, patented a copy milling machine on September 6, 1819, which allowed the serial production of rifle stocks and other irregularly shaped wooden parts and which was introduced in the arms industry worldwide. Further developments were a lathe completed in 1822 for the external machining of gun barrels and machine tools for the series production of small parts.

In 1833 a commission demanded the introduction of a new weapon based on the French model 1822. Production ran from 1839 to 1844, the musket was produced in Springfield as the Model 1840 US Flintlock Musket in a number of more than 30,000.

After the decision in 1842 to convert the weapons stored in the arsenals from year of manufacture 1831 to percussion ignition , they were modernized in this sense from 1849. However, this meant that the Americans were still primarily dependent on flintlock muskets in the war with Mexico in 1846.

275,000 Model 1842 US Percussion Muskets were manufactured in Springfield and Harpers Ferry between 1844 and 1855 . As requested by the Ordnance Department, all parts of these weapons were standardized and therefore interchangeable. The 1842 model was the last state-made musket with a smooth barrel and the first with percussion ignition .

The first rifled rifles were the 47,100 Model 1855 US Percussion Rifle muskets manufactured between January 1857 and December 1861 . Later these were used in a slightly different form as the main weapon in the civil war.

Manufactured from 1855 to 1857, the Springfield Model 1855 pistol carbine was an attachable butt pistol made on the system of the 1855 rifle musket . It was intended to arm the US Cavalry and Dragoon regiments .

1861–1865 (Civil War)

Throughout the war, the Springfield Armory kept large quantities of firearms ready, and production was so high that a daily newspaper wrote:

"So many rifles and bayonets are now being turned out of the Springfield Armory, that if our armies lost theirs in every battle they could be replaced in a very short time."

"There are so many rifles and bayonets shipped from the Springfield Armory that if our armies lost theirs in every battle they could be replaced in a very short time."

With the Model 1861 and Model 1863, the last muzzle loading rifle made by the Springfield Armory was introduced. During the Civil War, the period of muzzle-loading rifles and ended Hinterlader as the Sharps rifle or bolt action rifles for metallic cartridges, the schüssige 16- Henry rifle and the Spencer repeating rifle made their entry into the world of the military.

After the destruction of the Harpers Ferry Armory by the troops of the southern states , Springfield was the only remaining state arms manufacturer, which led the US government to award various large orders to third-party manufacturers such as Colt , Hartford and Remington & Sons , Ilion, NY and others. At the end of the war, the Springfield Armory was storing several hundred thousand muzzle loading rifles.

Since there was no money for the production of modern breech loading rifles, they looked for ways to convert muzzle loading rifles cheaply. Erskine S. Allin , master armorer in the Springfield Armory devised such a conversion and in 1865 a first order for the modification of over 5,000 muskets in .58 caliber was awarded to the Springfield Armory. In 1866, an additional 25,000 guns were changed to rear loading and a smaller .50 caliber, as a result, 65,000 such rifles and carbines, now known as trapdoor , were manufactured again up to 1873 .

From 1872 the called Trapdoor rifle in caliber .45-70 Government was introduced after a recommendation by the Terry Board led by General Alfred Terry . It should be noted that General Terry in the campaign of 1876 against the Indians was the direct superior of George Armstrong Custer , who was massacred at the Battle of Little Bighorn with his 7th US Cavalry, also because of reloading problems with the trapdoor carbine .

The weapon became the standard weapon of cavalry and infantry for 30 years. It was used in the Indian Wars and later by secondary troops in the Spanish-American War .

1890-1918

As the first infantry rifle of the US Army in a modern small caliber, the Krag-Jørgensen repeater in the .30-40 Krag caliber was introduced in 1892. The weapons were built as a rifle and carbine. After 1905 they were still used for military training and later retired.

The five-shot Model 1903 Rifle Caliber 30-06 repeating rifle was handed over to the American armed forces from 1905 and was used in the First World War . Before the First World War, 110 rifles were built in Springfield every day, which were delivered not only to the US Army but also to the National Guard and stored in depots. In April 1917, with the entry into the First World War, production in the Springfield Armory was greatly increased.

In addition, a total of 25,767 Colt M1911 pistols (number series 72 751-133 168) were produced in the Armory during the First World War .

It was manufactured around the clock, new buildings were erected and studies should help reduce production times and increase efficiency. In November 1918, the workforce reduction began.

1919-1968

World War I had also introduced the US armed forces to the need for self-loading rifles. From 1921 tests began in the Springfield Armory, in which inventors could submit their weapon developments. This lasted until 1928.

At the end of all tests, the commission decided on the John Garand self-loading rifle, later introduced as the M1 . The M1 was introduced as a standard weapon in the US Army in 1936 and was also used as a replacement for the Johnson Cal during World War II . 30 M41 semi-automatic machines delivered to the Marine Corps. Series production started in 1937 and was steadily increased to equip the entire armed forces with this weapon, as the government feared a new world war. Around 3.5 million M1 rifles were produced in Springfield by the end of World War II. At that time, about 14,000 people were employed in the Springfield Arsenal.

When the war ended, the number of employees was very quickly reduced to around 1,700 people, who also returned to a normal 40-hour week.

Due to the tensions that occurred after the Second World War, the number of employees was increased again to 6,000 by July 1951 and in the Korean War up to 7,700 people were employed in the Springfield Armory.

After the Korean War, the number of employees decreased again and remained constant at 2,500 until the weapons factory was closed.

The main tasks now changed to the areas of research and development, repair and prototype production. This is how the M14 rifle and other experimental weapons were developed.

During the Vietnam War , machine guns, grenade launchers and other military equipment were developed in Springfield in addition to rifles. However, only prototypes and pre-series were produced, the drafts were prepared for production and made available to other suppliers to the US Army.

On November 19, 1964, Secretary of Defense Robert S. McNamara decided that the United States no longer had any need for its own arms manufacturer. The closure was announced for April 1968.

Todays use

After the closure, the most important buildings were renovated between 1987 and 1991 and prepared for new uses. Today the Springfield Armory is a registered museum in the National Register of Historic Places , which is administered by the Ministry of the Interior, or by the National Park Service subordinate to it. On December 19, 1960, the place was registered as a National Historic Landmark .

Listed as a Springfield Armory National Historic Site , the museum houses a comprehensive collection of weapons and other witnesses from American industrial history. Another part of the building houses a technical college, the Springfield Technical Community College (STCC).

Just six years after the Armory was closed, Robert Reese , an American industrialist, took over the no longer protected name for his gun business, which he founded in 1974. This Springfield Armory, Inc. , based in Geneseo, Illinois, manufactures and imports weapons and can benefit from one of the traditionally most important names in the US arms industry without a relationship between the two.

Production and development of weapons

Flintlock rifles

Weapons production in Springfield began in 1795 with the completion of 220 Model 1795 US Flintlock Muskets in .69 ″ caliber , corresponding to (17.5 mm), of which between 80,000 and 85,000 were produced in various variants until 1814.

In 1807 the Model 1807 US Flintlock Carbine in caliber .54 "was produced and later followed by the Model 1816 US Flintlock Musket in caliber .69". Of the last 30,000 flintlock muskets model 1840 US Flintlock Muskets manufactured at Springfield, a large part were adapted to percussion ignition in 1849–1851, from 1841 onwards only percussion rifles were manufactured in Springfield.

Model 1842 US percussion musket

This musket, also manufactured in the Harpers Ferry Armory, is the last smooth-barreled weapon in .69 ″ caliber. It had a barrel length of 42 ", equivalent to 1060 mm, and a total of 275,000 units were produced, 172,000 of them in Springfield. Some of these weapons were later fitted with trains. They were called Model 1842 US Rifled Musket .

If the production of the 450 weapons had not been delayed until 1844, the Cadet Rifle Model 1841 US Percussion Cadet Musket would have become the first percussion weapon . A similar cadet rifle was then produced again in 1851.

Model 1847 US Artillery Musketoon

For the artillery and cavalry with the Model 1847 US Cavalry Musketoon , a series of short- barreled , smooth-barreled weapons in .69 "caliber were made for close-range defense, and in 1851 the lighter cadet rifle in .57" caliber, (14.5 mm) Model 1851 followed US Percussion Cadet Musket .

Model 1855 US percussion rifle musket

The Model 1855 was .58 "(14.7 mm) caliber, which would become the standard caliber for muzzle loading rifles in the American Civil War. The weapon was the first rifled muzzle-loading rifle of the American army to be introduced in large numbers. A total of 59,273 pieces of this weapon were manufactured from 1857 to 1861, of which 47,115 were in Springfield and 12,158 in Harpers Ferry.

It fired the Minié projectile designed by Claude Minié and further developed in the Harpers Ferry Armory , which was expanded by the gas pressure acting in the rear cavity and pressed into the trains. The advantage of this projectile was that, because it was under-caliber, it could easily be loaded from the front and adapted to the trains when fired.

The ignition was carried out by the Maynard Primer System, in which the individual primers were replaced by a tape with inserted detonators. These were automatically pushed onto the piston when the cock was cocked. The system was quickly abandoned because the feeder did not guarantee the correct position of the squib, and functionality in wet weather was not guaranteed. Conventional detonators were therefore used again during the civil war.

Model 1861 US percussion rifle musket

One of the most produced military rifles of the US was the Model 1861 and Model 1863 US Percussion Rifle Musket Type I . Between 1861 and 1863, the Springfield Armory alone produced 538,394 weapons, with private suppliers producing over 800,000 of these weapons. With this weapon, described as excellent in the literature, a good marksman could place ten bullets in a four-inch circle at 100 yards.

In 1864 and 1865 another 255,040, somewhat modified weapons were manufactured in Springfield under the designation Model 1863 US Percussion Rifle-Musket Type II . All of these weapons had caliber .58 ", the barrel of the infantry rifles measured 40", corresponding to 1026 mm and the artillery model had a barrel of 33 "(840 mm).

The weapons consisted of 47 parts, which were created and assembled in 396 steps. According to a newspaper report to the government, the workers had to bear full responsibility for errors during manufacture. For example, since every sixtieth run exploded during an inspection, these incidents were investigated in detail and the responsible employee had to pay the damage.

The bayonets were no longer made by hand, but machine milled. Here, too, tests were carried out on the breaking strength and, in the event of errors, the workers were burdened financially.

Allin Conversion Model 1865 Rifle

Towards the end of the American Civil War , Erskine S. Allin, master gunsmith in the Springfield Armory developed a breech-loading rifle with a hinge lock, the Allin Conversion Model 1865 Rifle, from the Model 1861 US Percussion Rifle-Musket .

Between 1865 and 1870 some of the old percussion rifles were converted to rear loading. While the Allin Conversion Model 1865 Rifle was set up for the .58 rimfire cartridge, other Model 1861 percussion rifles were modified to Springfield Model 1866 rear loaders, officially designated US Springfield Allin Conversion Model 1866 for the .50-70 Government centerfire cartridge . In total there were around 95,000 weapons. They were the forerunners of the Springfield Model 1873 with the same locking system in the caliber reduced to .45.

Between 1870 and 1871 Springfield produced 22,000 rolling-block rifles in .50-70 caliber under license from Remington Arms , Ilion, NY, using barrels from the Model 1868 US Springfield Rifle . For the army and for test purposes, 10,000 such rifles and carbines were added in 1871–1872.

The "trapdoor" of Springfields

In the early 1870s, General Alfred H. Terry was the president of the Terry Board, a commission that recommended the adoption of a .45 caliber single-shot with the breech developed by Erskine Allin, the Armory's chief gunsmith. On June 6, 1872, Congress passed a $ 150,000 loan for the manufacture of the Terry Board-recommended rifle in the National Armory, Springfield.

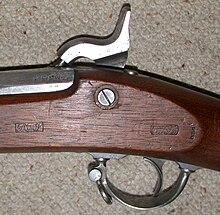

The Springfield Model 1873 and its later variants was the last single loader used by the American Army. It was used as an infantry rifle in the .45-70 Government caliber . The carbine fired a slightly less loaded cartridge, the .45-55. In addition, a shotgun for the meat supply of the troops and a cadet rifle were made.

A total of just over 568,000 of these weapons in various designs were manufactured in Springfield between 1873 and 1893. They were used in the Indian Wars and were given to secondary troops after the repeating rifle appeared. In the Philippines, Filipino militias still carried trapdoor carbines.

Hotchkiss repeating rifle Model 1879

Benjamin Berkeley Hotchkiss (1826-14 February 1885) was a versatile inventor in the field of weapons. In addition to guns, a revolver cannon and machine guns, he developed a repeating rifle in .45-70 caliber for Winchester with a cylinder lock and a tubular magazine in the piston. Several thousand of these weapons were made as muskets and carbines for the US Army and the US Navy. US Ordnance documents show that all of these weapons were produced by the Springfield Armory, according to other sources they were assembled at Winchester with barrels made in Springfield.

US Krag-Jørgensen M1892 Rifle

From 1892 the Springfield single-shot was replaced by the five-shot Krag Model 1892 repeating rifle and the Krag carbine with a cylinder lock in .30-40 Krag . The weapon was a variant of the infantry rifle developed in Norway by Ole Krag and Erik Jørgensen, adapted to American requirements. It was the weapon of the US troops in the Spanish-American War and subsequently in the Filipino-American War . In total, a little over 485,000 of these rifles and carbines in various variants were manufactured in Springfield between 1892 and 1899.

US Springfield Cal. .30-06 M1903 Rifle

Shortly after the introduction of the Krag rifle, the US Army Ordnance Department began to take an interest in the Mauser system, and in 1901 the Springfield Armory ordered 5,000 weapons of this system with 30 "(760 mm) barrels. Even before these were completed, the authorities decided on shorter barrels of 24 "(610 mm) so that the weapon could be used by infantry and cavalry. These Springfield M1903 rifles and the new .30-03 cartridges were tested in 1905 and recommended for introduction. That same year, the US government paid Mauser $ 200,000 in royalties for rights to the latch and magazine system and other design details.

After switching to the new .30-06 pointed bullet, the Springfield Arsenal and Rock Island Arsenal , Illinois, produced 843,239 of these weapons by the end of World War I. By the beginning of World War II, the Springfield Arsenal had produced a total of 1,028,634 Model 03 Springfield rifles in various variants.

US Rifle Cal. .30 M1 (Garand)

After John C. Garand had presented a locking system for self-loading rifles to the US Ordnance Department, the function of which was triggered by the recoil energy of the primer, he was commissioned by the Springfield Armory in 1921 as the engineer in charge to advance the development of a self-loading rifle. This gas pressure loader, developed by him, prevailed in the tests carried out by the US Ordnance Department in 1929 against all other designs, most recently against the .276 Pedersen rifle proposed by John D. Pedersen, with a mass lock delayed by a knee joint. The decisive factor for the decision was the too weak .276 cartridge, which still had to be greased to ensure functionality.

Developed for series production, the .30-06 caliber was adopted by the authorities in 1936 as an orderly weapon of the US Army. Between 1936 and 1940, the Springfield Armory produced the first 50,000 of these US Rifle .30 M1 rifles. From 1940 until the end of the war, 4.2 million of these weapons were manufactured with a slightly modified gas extraction system. The main supplier was the Springfield Armory; 513,582 guns were produced by the Winchester Repeating Arms , New Haven, Connecticut.

7.62 Rifle M14

The last development of the Springfield Armory was the adaptation of the US Rifle .30 M1 rifle to the requirements of NATO . The first prototype Rifle, caliber .30, T20 , presented in November 1944 , looked like the Garand and could be switched to single and series fire. The cartridge was fed via a magazine that could be inserted below. The M 14 rifle developed from this fires the 7.62 × 51 mm NATO cartridge and also exists in a variant called M15 that can be switched to series fire. In contrast to the Garand M1, it has a 20-round box magazine that can be inserted below and a short forend. It was only made in small quantities at the Springfield Armory. The main suppliers were private third-party manufacturers.

Pistol production

Although most of the handguns from third-party suppliers such as Simeon North, Berlin, Connecticut , AH Waters & R.Johnson, Millbury, Connecticut , NPAmes, Springfield, Mass. and Henry Aston and Ira Johnson, Middletown, Connecticut , also produced the Springfield Armory pistols.

The first pistols made in Springfield for the Army were 2,000 Model 1817 Flintlock Pistols in .69 "caliber. They corresponded to the Model 1807 made in Harpers Ferry and were later modified to percussion ignition.

The Model 1855 Percussion Pistol-Carbine , manufactured in Springfield, is a rifled barrel in .58 "caliber, barrel length 12" (30 cm) and sights up to 400 yards . Total production 4021. The pistol had a removable wooden butt and was intended to be used by the cavalry on horseback as a pistol and dismounted as a carbine. Since a large part of the US cavalry was armed with Colt revolvers from 1847/48 , this pistol had no future. Even later in Springfield, with the exception of the 25,767 army pistols made in 1914/15, corresponding to the Colt M1911 , no more handguns were mass-produced.

Maintenance, acceptance and modification of weapons

The National Armory, Springfield, had a dual function; it was also the main army arsenal in the United States. One of the functions of the Springfield Arsenal, along with other arsenals, was the storage and maintenance of peacetime weapons for the US armed forces.

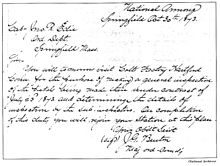

Another task was the control and acceptance of weapons from third-party suppliers. For logistics reasons , these checks were carried out by inspectors appointed by the Springfield Armory at the respective manufacturers. In a letter dated Oct. 30, 1873 , the then commander of the National Armory, James G. Benton , instructed Captain John R. Edie to organize the inspection of the Colt Single Action Army revolvers to be delivered by Colt .

As the central arsenal, the takeover and distribution to the various arsenals in the United States was also the task of the Springfield Arsenal.

The maintenance and modification of weapons were at least partly the responsibility of the factory; in 1842, for example, the Ordnance Department commissioned the Springfield Armory to change all flintlock muskets that were never used and stored in the arsenals after 1831 to percussion ignition. This conversion did not really start until 1849 after the renewal of the production facilities; from 1849 to 1851, over 26,800 model 1840 Flintlock muskets were converted to percussion ignition in the Springfield Armory .

Another documented example of weapon modification is the 1894-1898 modification of Colt Single Action Army revolvers by shortening the barrel from 7½ "to 5½" and upgrading these weapons. Much of this work was done in Springfield. While the manufacturer Colt modified a little over 6600 revolvers, Springfield brought it to over 16,500 pieces.

Cultural reception

In 1843 Henry Wadsworth Longfellow visited the Armory and wrote his poem " The Arsenal at Springfield ". The anti-war poem describes the rows of finished weapons of which a million were hoarded there at the time. They lay vertically in open cupboards: " Like a huge organ, rise the burnished arms " ( Eng . "Like a huge organ that lifts its polished arms").

See also

- List of entries on the National Register of Historic Places in Springfield

- List of National Historic Landmarks in Massachusetts

literature

- Norm Flayderman: Flayderman's Guide to Antique American Firearms . Krause Publications, Iola, WI 1971, ISBN 0-87349-313-3 .

- Marfe F. Delano, Barbara C. Mallen: Echoes of Glory, Arms and Equipment of the Union . Time Inc. Book Co., New York, NY 1991, ISBN 0-8094-8855-8 .

- C. Kenneth More: Single Action Army Revolvers US Alterations . Andrew Mowbray Publishers, Lincoln, RI 1999, ISBN 0-917218-85-X .

- WHB Smith, Joseph E. Smith: The Book of Rifles . The Stackpole Company, Harrisburg, PA 1963, OCLC 381757 .

- THE GUNS AT SPRINGFIELD im Videoarchiv - Internet Archive (1971, the story of the development of the US Army's small arms from the French and Indian War through the Vietnam)

- Jacob Abbott: Marco Paul's voyages & travels: Springfield armory. Publisher: Harper & Brothers New York, 1852 ( archive.org ).

Web links

- Springfield Armory , the official website of today's museum

- The Trapdoor Springfield , Fact Sheet of the Springfield Armory Museum

Individual evidence

- ^ A b c d Robert WD Ball: Springfield Armory - Shoulder Weapons 1795–1968. Antique Trader Books, Dubuque, Iowa 1997, ISBN 0-930625-74-9 , p. 6.

- ^ Springfield Armory - The National Armory. National Park Service, US Department of the Interior

- ^ Robert WD Ball: Springfield Armory - Shoulder Weapons 1795–1968. Antique Trader Books, Dubuque, Iowa 1997, ISBN 0-930625-74-9 , p. 13.

- ↑ Listing of National Historic Landmarks by State: Massachusetts. National Park Service , accessed August 13, 2019.

- ^ The Springfield Armory. from: Harper's Weekly. September 21, 1861, In: Springfield Armory: Technology in Transition. Springfield Armory National Historic Site, National Park Service, p. 16.

Coordinates: 42 ° 6 '26 " N , 72 ° 34' 54" W.