power adapter

A power supply unit converts the voltage from the power grid for a consumer . It can be designed as a stand-alone device or assembly . Output voltage and maximum output current can be fixed or variable.

Power consumption

In the past, power supplies were responsible for a not inconsiderable power consumption due to their large number in the household, so the legislature took on this problem in the 2000s. The EU and USA pioneered the introduction of binding limit values. According to the EPA , this can reduce electricity consumption by 1% per year in relation to the USA, which is 32 billion kilowatt hours (kWh).

No-load power loss

The no-load power loss that contributes to standby consumption has been limited by law:

External power packs under 50 watts may only consume 0.3 watts in the EU , larger power packs 0.5 watts. In the USA they were similarly limited to 0.1 and 0.21 watts. Canada and Australia have similar, albeit less stringent, requirements. Since device manufacturers sell their products worldwide, power supplies with the highest required efficiency level are often included, regardless of the country of purchase. The level is printed on the power supply unit, see example on the right.

In the EU, devices with a built-in power supply unit are switched off to 0.5 watts, in standby mode with additional functions, e.g. B. Time display, limited to 1 watt. According to a study, this reduced idling losses in the EU from 51 billion kilowatt hours (kWh) to 16 billion kilowatt hours per year.

Efficiency

The efficiency is specified with a formula depending on the output power. In the EU, for example, a smartphone power supply with 5 V and 1 A must achieve at least 68 percent efficiency and devices from 50 watts at least 87 percent efficiency; in the USA, values of 74 percent and 88 percent apply analogously. The power supply units must maintain the respective efficiency at a load of 25%, 50%, 75% and 100% on average.

species

Power supplies are divided into switched-mode power supplies and those with mains transformers (so-called "transformer power supplies "); there are also transformerless power supplies, e.g. B. Capacitor power supplies. Switching power supplies are increasingly being used today. There are different versions for different purposes.

Types of switching power supplies:

- with regulated DC voltage at the output and safe mains isolation. These are very common.

- with a step-down converter directly on the network without disconnection from the network.

- with unregulated AC voltage, e.g. B. "Electronic transformers" for low-voltage halogen lamps.

- with constant current output, for example to operate light emitting diodes, semiconductor lasers or as a charger .

Types of transformer power supplies:

- unregulated, with alternating or (filtered) direct voltage.

- regulated with a linear regulator

- regulated with a secondary-side buck converter .

Mains adapters with autotransformer for adapting the mains voltage 230 V / 127 V are not referred to as power packs.

Classic transformerless power supplies work with a capacitor as a lossless series resistor in order to lower the AC mains voltage.

Laboratory power supplies with adjustable DC voltage and adjustable current limitation work on the principle of linearly regulated transformer power supplies or they are designed as switched-mode power supplies.

Switching power supply

In switched-mode power supplies, the energy is transmitted at a frequency of typically a few 10 kHz to a few 100 kHz, which is thus significantly higher than the mains frequencies of 50 or 60 Hz. This allows the use of smaller transformers with the same power . Therefore, switched-mode power supplies are not only significantly lighter and smaller than transformer power supplies, but also have lower power consumption when idling and are more efficient in operation. Although they have a higher component cost, they largely replaced transformer lines due to the increased raw material costs and energy prices. In addition, in most countries no-load power loss and efficiency are regulated by law and can only be achieved with switched-mode power supplies.

Practically all switched-mode power supplies supply a regulated direct voltage or a regulated direct current. They are usually short-circuit-proof and can often be operated at all common mains voltages in the world from 85 V to 250 V thanks to a wide-range input. However, due to the high switching frequencies occurring in their interior, they generate more interference despite interference suppression measures . Switching power supplies are more sensitive to short-term mains overvoltage than mains transformers.

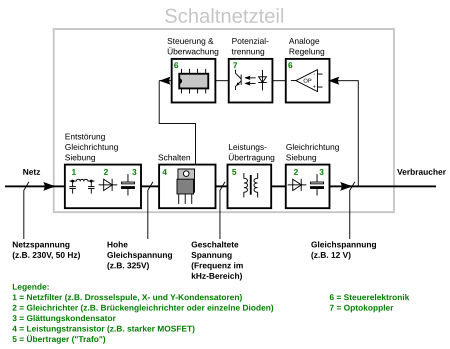

The schematic structure of a switched-mode power supply can be seen in the illustration opposite. It is an isolated switching power supply with a regulated output voltage. The safety barrier between the mains voltage and the output voltage is formed by the transformer and the optocoupler.

Switching power supplies can also be built without output voltage fed back for the purpose of regulation (i.e. without optocouplers) at the expense of voltage stability. Here, a is fly back -Transformator used and the output voltage is determined at the primary winding or an auxiliary winding. When a single monolithic integrated circuit is used, such power supplies can have a greatly reduced component outlay compared to the solution described above.

Switching power supplies with monolithic IC that are not isolated

Also called Off-Line Switcher IC in English .

A switched-mode power supply variant, which is often used for low power, consists of only a few external components and a special monolithic integrated circuit (IC) that combines power MOSFET and control. Externally, only a choke or a transformer, two capacitors for output and input voltage, a diode and a few other passive components are required. The maximum output current is typically a few hundred milliamperes. Since mains separation is usually not required within a device, such power supplies are usually not electrically isolated .

Usually the mains voltage of 230 volts is rectified and smoothed, so that the effective value of the input voltage for the controller is 325 V. This is then reduced.

Such ICs early 90's, when you have a high-voltage MOSFET and the control logic on the same the first time made possible the could accommodate. Such power supplies are very economical due to the integration.

Manufacturers of such ICs for non-isolated low-power power supplies are z. B. ST with the VIPer, VIPerPlus and Altair series, Power Integrations with the LinkSwitch TN2, LNK304, TNY and TOP series, NXP with the STARplug series (TEA), ONsemi with the NCP and FS series.

Manufacturers of monolithic ICs for isolated switching power supplies are z. B. Power integrations with the TinySwitch LT series (up to 30 watts). The company also manufactures circuits with built-in potential barriers for the feedback of the output voltage (InnoSwitch3-EP series, up to 100 watts).

Low-power switched-mode power supplies with only one IC can be found e.g. B. in white goods, in plug-in power supplies, LED lamps or plug-in chargers. They are tightly dimensioned or do not have a suitable input filter to ward off mains overvoltage and are therefore particularly susceptible to surge voltages (surge according to EN 61000-4-5).

Buck converters with a constant current output are also predominantly installed in LED lamps . You don't have a transformer, just a storage reactor.

Transformer power supply

So-called conventional power supplies, often referred to as transformer power supplies, have a power transformer that is larger than that in switched-mode power supplies due to the low operating frequency of 50 or 60 Hz.

Their structure can be seen in the adjacent figure. They consist of the following components:

- Mains transformer , the primary winding of which is fed directly with the alternating voltage of the mains with mains frequency . It reduces the voltage and ensures galvanic isolation from the mains . Autotransformers can be used for power supplies without galvanic isolation .

- Rectifier for rectifying the secondary AC voltage

- Smoothing capacitor for filtering the pulsating DC voltage obtained

- optional linear regulator for stabilized devices ; stabilizes the output voltage in the event of load and mains voltage fluctuations

- optionally a buffer capacitor / output capacitor to intercept load peaks

Such stabilized power supplies have an efficiency of less than 50% at full load. Some have a step-down controller instead of a linear controller to increase efficiency and reduce heat loss.

The small conventional power supply units with mains transformers are often designed for low weight and low costs: attempts were made to control the iron core to the maximum, which was also often of inferior quality. As a result, the no-load losses of such power supplies are often in the range of over 1 watt. That brought them into the focus of energy-saving measures. In 1998 the BUND calculated in a media campaign that the power of a medium-sized nuclear power plant could be saved by consistently switching off or pulling out all stand-by power supplies and plug-in power supplies in German-speaking countries.

Different output voltages can be achieved by switching the winding taps of the mains transformer. The open circuit voltages of unregulated devices are often much higher than the specified nominal voltage. The transformers contain a self-resetting or non-resettable thermal fuse for fire protection ; The latter become unusable after overload.

Transformer power supplies with an AC output only consist of a mains transformer .

Capacitor power supply

A traditional variant without potential separation for output currents up to about 100 mA is the capacitor power supply. This uses the reactance of a capacitor as a series resistor to reduce the mains voltage. The output voltage depends on the load; if this is not constant, there must be a voltage limitation.

Capacitor power supplies must have a resistor with high surge voltage resistance connected in series with the capacitor in order to protect the load from mains transients and inrush currents. The load must have a buffer capacitor for the protection to be effective.

Capacitor power supplies are built into some LED light sources , for example, as well as twilight switches and motion detectors for self- sufficiency. They are not electrically isolated, so the entire circuit is on the life-threatening mains voltage potential - these devices must be completely safe to touch.

Designs

Power supplies are offered in various designs, depending on the intended use and the output power to be provided:

Plug-in power supplies

Power packs are power packs that form a unit with the power plug . The plug for connection to the AC mains is integrated in the housing of the power supply unit. The extra-low voltage output is usually led to the supplying device via a line. But there are also types that have a socket on the low voltage side, e.g. B. USB chargers. Today, all plug-in power supplies are designed as switched-mode power supplies , as the legally required efficiency requirements can only be implemented cost-effectively with such a power supply unit . Until the beginning of the 2000s, transformer power supplies with a conventional design and above that, switched-mode power supplies were used for small outputs below 5 watts. Due to the mechanical stress on the socket, there are no plug-in power supplies with more than 50 watts.

Secondary connector

A wide variety of connectors and voltages are used when connecting to the device to be supplied. Often the inner contact has positive polarity , the outer ground. In many devices barrel plugs and jack plugs can be found, the former being preferable to jack plugs. Jack plugs cause a temporary short circuit when plugged in and should only be connected or disconnected when the power supply unit is de-energized. Usually the polarity is marked by two concentric circles with "+" and "-" signs on the power supply unit.

The figure shows a selection of plug connections (from left to right):

- EIAJ-01 barrel connector (yellow cap) 2.35 mm × 0.7 mm (outer diameter × inner diameter)

- Jack plug 2.5 mm

- Barrel connector 3.5 × 1.35 mm

- 3.5 mm jack plug

- EIAJ-02 barrel connector (yellow cap) 4 × 1.7 mm

- Barrel connector 5.0 × 2.1 mm

Hollow plugs measuring 5.5 × 2.1 mm and 5.5 × 2.5 mm can also be found. Mostly they are compatible with sockets for 5.0 × 2.1 mm.

In the case of mobile phone power packs, the micro-USB plug for smartphones is standardized across the EU ( EN 62684: 2010 , " Micro-USB standard "). The successor standard USB-C is not legally standardized, but de facto standard - except for the iPhone and iPad, where the Lightning connector has been used since 2012, two years before USB-C was specified. But even there, USB-A is used on the power pack .

A USB 2.0 plug connection comprises four cables plus a shield. The stabilized voltage of 5 V is fed in at the outer pins 1 and 4. Outputs of the USB 2.0 standard deliver a maximum of 500 mA, from USB 3.0 a maximum of 900 mA. USB devices with an integrated charging function, such as cell phones, “recognize” the USB charger by a resistor in the power supply that is connected between the data lines D + and D−, which are not normally used in USB chargers. Is the resistance value between the two data lines 200 Ω , the charge controller is in the USB device assumes on a dedicated USB charging port such as a USB charging cable ( English Dedicated charging port, DCP ) to be connected which is at least 500 mA or more can deliver.

Proprietary charging cables from Apple encode the output of a power supply unit via a voltage that is applied to the data lines D + and D−. If the data lines are not connected, devices from this manufacturer can be operated on the power supply unit, but the device battery does not charge. This coding is not standardized and has already been changed by Apple a number of times. The corresponding charging currents are assigned to the following voltages on the data lines.

| electricity | D− | D + |

|---|---|---|

| 500 mA | 2.0V | 2.0V |

| 1000 mA | 2.75V | 2.0V |

| 2000 mA | 2.0V | 2.75V |

The voltages of 2 V or 2.75 V are generated by voltage dividers on the 5 V supply line, for example by the pair of resistors 75 kOhm and 49.9 kOhm or 43.2 kOhm and 49.9 kOhm.

Markings

The following product labels are used:

- Polarity: DC power supply units have positive or negative polarity, which is marked with the symbols shown in the adjacent figure and corresponds to the polarity of the inner pole of the plug and socket. The polarity of the power supply unit must match that of the device operated with it in order to prevent damage (usually destruction of the entire device).

- “Stabilized” means that the output voltage retains its nominal value even when the system is idling. (Only found on transformer power supplies.)

- Output: xx volts ⎓ means rectified, filtered voltage; contains alternating voltage components, when idling the output voltage sometimes rises significantly above the nominal voltage.

- Output: xx volts AC or ~ means alternating voltage output (e.g. for fairy lights).

The voltage specification is followed by the specification of the maximum drawable current or the output power.

There are also symbols and pictograms:

- Crossed out garbage can: according to the Electronic Scrap Ordinance, disused devices do not belong to the residual waste

- Double square: protective insulation of live parts

- stylized house: to be used indoors only

- CE mark : A free trade mark for the European Union. By affixing the CE mark, the distributor confirms that the product complies with the product-specific European EU directives.

- Overlapping circles separated by a line: protective separation between mains and output voltage ( safety extra-low voltage )

- Dot or ring with a Roman number in it: indicates the energy efficiency . The larger the number, the more tightly the no-load power loss is limited. Sometimes it says "EFFICIENCY LEVEL" to the left. Power supplies that are currently (2017) new on sale are marked with the numbers 'IV' (according to CEC Tier 2), 'V' (according to CEC Tier 3) or 'VI' (according to DOE VI, to be complied with since February 2016 ) for the US and harmonized markets. In particular, older power supplies that meet less stringent criteria can have the number 'III'. 'I' denotes a power supply unit that does not meet any of the criteria of the other efficiency classes; criteria have never been specified for the 'II' label.

Standalone devices

Fixed voltage power supplies

For medium power (10–200 W) there is a wide range of power supplies with common output voltages (one or more DC or AC voltages) in the form of external units that are fed via a power cord that is partially plugged into the device and the consumer via an outgoing line supply with device plug.

The use of external power supplies as opposed to power supplies integrated in the device offers device manufacturers some important advantages:

- By using purchased, standardized, external power supplies, development costs and risks are avoided. In addition to the purely functional aspects, this primarily affects the aspects of safety and electromagnetic compatibility, which contribute significantly to the development effort of a power supply unit.

- External power supplies are standardized mass-produced items that are manufactured and offered very cheaply, which has a positive effect on the overall costs of the device.

- The adaptation of the device to country-specific power grids is reduced to a suitable selection of the external power supply.

- The evaluation and checking of devices that work with external power supplies with regard to their conformity with applicable legal regulations, e.g. B. in the context of a product approval , is usually significantly less expensive than for devices with integrated power supply units, because the dangerous mains voltage is not introduced into the device itself.

- An approved power supply unit can be used for several extra-low voltage devices.

This design (e.g. for printers or laptops) also rarely has a power switch, so that some energy can be saved by using switchable socket strips. However, inkjet printers in particular often carry out a complex self-test after a complete network disconnection, in which a great deal of ink is unnecessarily wasted.

Laboratory power supplies

So-called laboratory power supplies, also called laboratory power supplies, are devices that can be used in a variety of ways. They usually have an infinitely adjustable voltage limitation and an adjustable current limitation, as well as a current and voltage display.

Built-in power supply

With higher outputs (over 100 W), power supply units within devices or switch cabinets are often designed as assemblies or built-in devices. The requirements for contact protection are then lower. On the other hand, however, the integration of the power supply increases the security requirements for the overall device, as this is now e.g. B. with regard to contact protection, creepage distance and surge voltage resistance or protective earthing must meet the requirements that were previously only placed on the separate power supply.

Built-in devices or built-in power supplies are also often used when multiple voltages are required, such as in computers , televisions, video recorders, fax machines or laser printers.

DC switching converter

Power supply units are also used in DC voltage networks (motor vehicles, solar systems, small aircraft) when voltages have to be transformed or alternating voltage is required. However, they are usually not referred to as a power supply unit.

One example are power supplies built into powerful audio amplifiers for operation on the vehicle's on-board voltage network, which often generate voltages of more than ± 40 V for the output stages from 12 V (on-board network). DC / DC switched-mode power supplies are used there, which contain an inverter and a transformer with subsequent rectification.

DC voltage converters are used in the low-power range (below 5 W) as encapsulated hybrid modules for the galvanically isolated supply of components.

Typical applications are line interfaces of telephone modems or network cards , modern PC mainboards and powerful graphics cards that generate their operating voltages as close as possible to the consumer from the voltages supplied by the PC power supply ( point-of-load converter ).

Inverters generate AC line voltage from DC voltage networks, e.g. B. as a plug-in power adapter in motor vehicles or permanently installed in direct voltage networks of solar systems.

Web links

Individual evidence

- ^ Andrew Fanara: APEC Session. ( PPT ) EPA, February 20, 2004, p. 9 , accessed December 30, 2019 (English): “Active Mode accounts for nearly ¾ of all power supply energy use; focus to date has been on standby […] Estimated savings of 32 billion kWh / year […] Cut national energy bill by $ 2.5 billion / year "

- ↑ a b Christof Windeck: One watt regulation. heise online , January 2009, accessed on May 19, 2014 .

- ↑ a b c Efficiency Standards for External Power Supplies. (PDF) CUI Inc., February 2019, accessed December 18, 2019 .

- ^ Sophie Jankowski: Idle losses. Federal Environment Agency , September 30, 2015, accessed December 30, 2019 .

- ↑ Universal chargers for cell phones should really come now. heise online , February 7, 2011, accessed on August 3, 2011 .

- ↑ Florian Müssig: USB developer about Apple's Lightning connector: "We were too sluggish". In: heise online . January 24, 2020, accessed January 27, 2020 .

- ↑ Florian Müssig: Uniform USB-C chargers in the EU should come. heise online , accessed on December 18, 2019 .

- ↑ Christof Windeck: Uniform (cell phone) chargers: The EU does not come in the socks. In: heise online . January 14, 2020, accessed January 14, 2020 .

- ↑ Battery Charging Specification Rev. 1.1. (ZIP) (No longer available online.) USB Implementers Forum, June 24, 2009, archived from the original on March 29, 2014 ; accessed on March 4, 2014 (English).

- ↑ Lady Ada: iCharging - The mysteries of Apple device charging. November 20, 2015, accessed May 6, 2018 .

- ↑ Efficiency Standards for External Power Supplies | DigiKey. Retrieved August 19, 2017 (American English).