Peat extraction in West Mecklenburg

| Breesen raised bog deposit | |||

|---|---|---|---|

| General information about the mine | |||

| White peat heaps in Drispether Moor | |||

| Mining technology | different extraction methods | ||

| Information about the mining company | |||

| Start of operation | 1945 | ||

| End of operation | 1990 (as a state-owned company ) | ||

| Funded raw materials | |||

| Degradation of | Extraction of white and black peat | ||

| Geographical location | |||

| Coordinates | 53 ° 43 '15 " N , 10 ° 59' 20" E | ||

|

|||

| District ( NUTS3 ) | Northwest Mecklenburg | ||

| country | State of Mecklenburg-Western Pomerania | ||

| Country | Germany | ||

Since time immemorial there has been peat extraction in West Mecklenburg for heating purposes. Especially after the Second World War , burning peat extraction was an alternative to supplying the population with fuel. This began here in the summer of 1945, under the command of the Soviet Military Administration in Germany (SMAD).

After the greatest need was alleviated, a more effective use of the peat ingredients was considered. In addition, these peat storage sites, the responsible professional institutions and the social framework conditions at the time up to the political change in 1989-90 are documented.

The raised bog deposits

The raised bog peat deposits of this mining era in West Mecklenburg were (are) the raised bogs Grambow I, also called Stralendorfer Moor, Drispeth , Breesen I and Woitendorf , also known as Breesen II.

The geological conditions of the deposits

The Grambower and the Lutzow Horster Moor (the latter only partially) the hydrological Moor type " bog over siltation Moor attributed". These are rain bogs that emerged from the siltation of late glacial and early holocene lakes. The raised bog peat is mostly stored here over silting or broken forest peat. Partly the Grambower Moor as well as the Lützowhorster Hochmoor also arose from swamping as a result of the Holocene groundwater level fluctuations, as beisen, reed and sedge peat can be found in the lying areas. This type of bog is subdivided into rain bogs, which developed via silting bogs - supplied by groundwater and surface water or interflow - and rain bogs, which developed via silting bogs, which were fed exclusively by surface water and interflow.

Also the Breesener, Woitendorfer and Dripether Moore are hydrological genesis after rain moors over silting moors. The water supply of the lakes, from whose silting stages these raised bogs developed, came exclusively from tributaries in the area. This typology of the raised bogs is ultimately the basis for the planning and implementation of the renaturation measures within the framework of the rain bog protection program of the state of Mecklenburg-Western Pomerania.

Geochronologically, according to the last C-14 dating, the sedimentation of the mineral deposits (clays, silts, limestone and muddone formation) began in the late glacial (around 11,000 years ago) and ended in the preboreal (around 10,000 years ago). Then the deposition of organic sediments began. It usually ends in the boreal region (around 9,000 years ago), in some moors even in the sub-Atlantic (around 2,500 years ago), if one neglects the sedimentation that still takes place in the existing moor lakes.

In the following, the individual raised bogs of West Mecklenburg, which at the time were under mining protection, and their qualitative and quantitative parameters will be considered.

The high moors Grambow I and II

The high moor Grambow I is located in the Ludwigslust-Parchim district between the villages of Grambow, Wodenhof, Stralendorf and Groß Rogahn. Its size is 370 hectares, of which 200 hectares have been geologically studied. The Grambow II raised bog deposit is immediately north of Deposit I and covers an area of around 100 hectares.

The strata profile of the high moor Grambow I is shown in this table:

Geological layer

Degree of decomposition (nvPOST)Substrate medium thickness Younger moss peat (strongly grounded) Bunker soil 3 dm Younger moss peat 2 - 5 White peat approx. 11 dm Older moss peat 2 - 5 Black peat approx. 8 dm Transitional peat 4 - 8 Lower peat Seggentorf 4 - 8 Lower peat Reed peat 2 - 8 Lower peat Beisentorf 2 - 3 Lower peat Σ approx. 20 dm

Below this are peat, liver, lime and clay sludge with an average thickness of 15 dm over clay, silt, sand, loam and marl boulder.

The Grambow I peat deposit was the subject of extensive geological research work in 1986/87. As a result, inventory class C2 (according to the inventory classification order of August 28, 1979, Sdr. No. 1019 of the Law Gazette) was confirmed by the State Inventory Commission of the GDR. Although this meant the lowest storage class of recorded deposits, because only examined in a rough grid, the possibility of economic mining and processing was proven.

The Drispeth high moor

This peat deposit is located in the north-west Mecklenburg district between the villages of Drispeth and Zickhusen and covers an area of 90 hectares.

The layer profile of the Drispeth raised bog is shown in this table:

Geological layer

Degree of decomposition (nvPOST)Substrate medium thickness Heather forest peat - Bunker soil 2 dm Younger moss peat 2 - 5 White peat 17 dm Older moss peat 5 - 8 Black peat 10 dm Reed-sedge peat 5 - 8 Transitional Lower peat

11 dm

This sequence is subordinated to an average of 3 dm thick Lebermudde, which is followed by gray till. The depth of the lying area varies greatly, which made the extraction of milled peat considerably more difficult. The geological exploration status was economically sufficient.

The high moor Woitendorf (Breesen II)

This deposit (Fig. 5) is located about 10 kilometers west of Gadebusch in the north -west Mecklenburg district, in the immediate vicinity of the town of Breesen. The moor covers an area of about 75 hectares.

The sequence of layers of the Woitendorf raised bog is shown in the table below:

Geological layer

Degree of decomposition (nvPOST)Substrate medium thickness Forest meadow peat - Bunker soil 2 dm Younger moss peat 2 - 5 White peat 9 dm Older moss peat 6 - 8 Black peat 17 dm Reed-sedge peat 5 - 6 Transitional peat 3

Below this there is an average of 10 dm (up to max. 18 dm thick) Mudde (Gyttja) over 1-8 dm of sand.

The high moor Breesen I

This moor adjoins the Woitendorfer moor immediately to the east and has a similar substrate sequence. In the past, extensive black peat extraction through pütten (water-filled trenches) has broken it up on around 70 hectares. It was therefore of subordinate importance from an economic point of view.

The hydrogeological reservoir conditions

For all raised bogs that are used for mining, a groundwater level close to the surface is characteristic, the height of which depends on the seasonal fluctuations in precipitation . While the peat and liver muds are considered to be difficult or impossible to drain, the water permeability ( kf value ) of the peat in the area is between 1 × 10 4 to 1 × 10 8 cm / s, directly dependent on the humus factor.

The high moor Grambow I has its natural drainage over the Otterngraben to the Sude . An existing electric pump, which was necessary due to the small difference in level between the excavation level and the receiving water , also conveyed into the Otterngraben . These hydrogeological conditions made the mining of white peat difficult and made a close-knit network of drainage ditches necessary.

The extraction of balneological or veterinary peat, on the other hand, even required stationary groundwater levels.

The natural drainage of the Drispether Moors takes place via the excavation into the Great Dambeck Lake . Here, too, pumps had to be used to improve peat extraction. Problems in the peatland drainage occurred during periods of increased rainfall, as the bridge passages of the Aubach caused a backlog of the natural water runoff.

Around the moors Breesen I and Woitendorf existed more or less intact ditch systems, which drained via receiving waters flowing southwards . The Woitendorfer Moor drains over the Thurower Bach to Goldensee with drainage towards Schaalsee .

The Breesener Moor is also connected to the catchment area of the Schaalsee via the Aubach or Roggendorf-Kneezer-Beek. To improve the drainage, further main drainage ditches were dug in the Woitendorf field (Breesen II) in 1982/83.

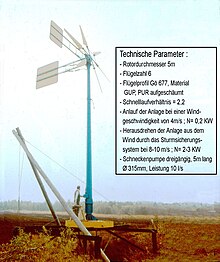

As a replacement for stationary pump systems with kilometers of electric cables or diesel engines, an innovator collective developed and built a wind-powered pumping station. This was an absolute novelty in the GDR in 1984: nowhere was a comparable, let alone finished and tested system to be acquired. Even the three-speed, five-meter-long screw pump was an in-house development.

The hydrogeological conditions of the former reserve deposits Grambow II and Lützowhorst will not be discussed further here, as no peat has been extracted there to date. It should be noted, however, that the latter raised bog has relatively favorable natural conditions.

Peat extraction after the Second World War

The relevant orders of the occupying power

After the occupation of Mecklenburg-Western Pomerania by the Red Army , the Soviet Military Administration in Germany (SMAD) established a state administration on July 9, 1945. This was under the supervision and control of the SMAD and had to implement its orders.

With command no. 103 of 10 October 1945 was the commander of the Soviet occupation forces in Germany, Marshal Zhukov, already instructed the country's president and local governments, "by all means ... exploitation to promote any kind local heating material." This command was by the head of administration of the SMAD in Mecklenburg-Western Pomerania, major general of the Guard Skossyroff, with his order No. 13 of January 26, 1946:

" §1. In order to use the peat deposits in the country, an overall plan for the extraction of 160,000 tons of air-dried peat for the summer season 1946 must be drawn up ... "

A total of 19 districts and cities were charged. The district administrators and mayors were made responsible for the implementation and planning . The charge for the city of Schwerin alone was 35,000 tons. This command also specified, among other things:

“ B) that the company 'Sander', Schwerin, will produce 7 machines of the excavator type on April 1st, each with 12,000 tons of air-dry peat production capacity per season; "

“ C) that the machine factory 'Meinke', Rostock, is producing 48 hand-held machines at the beginning of the season (April 1st, 1946) and another 50 such machines by May 20, which are to be used immediately after their production; "

“ D) that the construction company 'Meske', Rostock, in cooperation with the machine factory 'Eikelbart' is producing 6 small elevator machines with a capacity of 2,000 tons of peat per season according to the plans of the company 'Meske' at the beginning of the season. "

This order also stated that the Schwerin company "Sander" had to carry out the planning by February 20, 1946 and the production of a system "... for artificial peat dehumidification and extraction of 10,000 tons of peat coke" by August 1, 1946 . And "... in order to accelerate the construction of this system, the Boizenburg shipbuilding yard has to produce 1 drying unit for the 'Sander' company based on their drawings on July 1st, 1946."

Further SMAD orders relating to peat extraction were:

- Order no. 128 of July 20, 1946 (regarding the fulfillment of the peat extraction plan 1946, the distribution of the extracted peat, among other things, also for hospitals and schools for the substitution of coal and briquettes)

- Order no. 38 of March 18, 1947 (regarding the drawing up of a plan for the “yield of 300,000 tons of air-dried peat for the 1947 year”, for the production of various peat machines and “... to supply the peat companies with workers on April 1, ac : Men 7,500, women 9,000 ")

- Order no. 111 of August 1, 1947 (regarding "On the course of the planned execution of the peat harvest during the 1947 season") and

- Order no. 173 of October 24, 1947 (concerning the obligation of the "Sander" company to complete a peat press by November 15, 1947. Otherwise "... for late and late fulfillment of the demands of this order, the strictest against him Executive measures are taken " )

The work of the planning company for peat extraction mbH Schwerin

The “Planungsgesellschaft für Torfgewinnung mbH” Schwerin (hereinafter referred to as “Planungsgesellschaft” for short) was founded on December 28, 1945. According to Section 2, the object of the company was: “a) recording of peat deposits, b) planning peat extraction, c) funding the production of peat equipment, d) the brokerage of peat extraction options, d) the monitoring of peat production. "

On the same day, a contract with the following content was concluded between the state administration of Mecklenburg-Western Pomerania and the planning company:

" §1) The planning company for peat extraction carries out its activities in Mecklenburg-Western Pomerania and undertakes: a) to record the peat deposits, b) to plan and carry out peat extraction, c) to promote the production of peat equipment, d) to convey peat extraction options, e) to carry out a production control. The state administration authorizes the planning company to conclude contracts with all peat-extracting companies and institutions, according to which the planning company is allowed to influence pricing and levy an expense contribution of RM 0.05 per hundredweight to cover organizational, planning and research costs. The contract comes into force on January 1, 1946. "

The company employed until its liquidation i. In 1950 in her main office in Schwerin three employees in addition to the managing director, and four in 1948 and 1949.

In their Rostock technical office there was one, in 1948 and 1949 two engineers and a secretary.

This branch was also the connection base for the moor science institute of the University of Rostock , which was also commissioned to search for and explore peat deposits.

The activities of the planning company as well as the peat extraction were put on an exact legal basis with the Mecklenburg Peat Act of October 29, 1947 and its implementing provisions of March 10, 1948.

It is interesting that in the ministerial vote on the draft of the peat law the question of its incompatibility with the moor protection law in force since April 21, 1920 arose. Certainly owed to the economic hardship at the time, these justified concerns were dispelled with Section 15 of the Peat Act: "All previous moor protection law provisions expire when this Act comes into force."

The company was put into liquidation on September 29, 1950 without justification, but presumably due to the financial difficulties of the planning company and the large number of distressed peat operations as a result of the new loan granting regulations. The various responsibilities for the peat producers, which developed up to 1950, also made the further existence of the planning company unnecessary.

In 1950, for example, the state-owned companies were subordinate to the Vereinigung Volkseigener Betriebe (VVB) Chemie, the municipal companies to the peat department of the Ministry of Economic Affairs and the private peat companies to the State Contract Office in cooperation with peat planning. This tripartite division of the peat industry naturally made it more difficult for the planning company to monitor and control the peat-producing companies under the Peat Act (Section 1, Paragraph 2).

The creation of the technical prerequisites for peat extraction

Until the middle of 1948 there was a great demand for peat machines, such as hand diggers, peat mixing presses, excavators, elevators, etc. Due to the decline in war reparation services , the peat machine manufacturers were able to deliver the machines they had ordered in the shortest possible time. However, as a result of the currency reform that took place in the Eastern Zone on June 23, 1948 and the restrictions on the granting of loans, many private companies gave up or became distressed for financial reasons.

The ordinance on the reorganization of the currency stipulated: "The state and municipal budgets, the state-owned enterprises, the democratic parties and the free trade unions should be given preferential treatment in the exchange." While the municipal and state-owned enterprises as well as the nationalized banks 1 : 1 exchanged, private companies received the same rate only up to the amount of a weekly turnover and the wage arrears. Otherwise the exchange rate was 10: 1. Ultimately, the planning company was left with unapproved machines worth DM 216,000.

Overall, the machinery of all peat operations in Mecklenburg in 1950 had the following:

- approx. 760 grooving machines, mostly as 4 to 5 meter machines,

- 210 mixing presses, some of which were driven electrically, some with diesel engines or steam locomotives,

- 10 excavators, including three of the latest design with an output of around 380 m³ wet peat per shift,

- 13 elevator systems,

- 2 power engravers, electrically driven,

- 4 large systems, ie elevators with presses and cable conveyors.

The beginnings of refining the raw material peat; the moor science institute Rostock

In the archives of the State Main Archives Schwerin , the first reference in this regard is the correspondence of Dr. Gerhard Luckow from Schwerin with the President of the State of Mecklenburg-Western Pomerania, Department of Economics, from August 11, 1945. Luckow suggested founding the "Society for Wood and Peat Utilization " in Schwerin with the corporate purpose of "... building a coal lighter factory in connection with a chemical factory in the field of distillation and processing of wood and peat ..." And He goes on to say, "... to make the state of Mecklenburg-Western Pomerania at least partially independent by extracting wood and peat tar and other products for the production of antiseptics, wood tar, wagon grease, pitch, wood vinegar and spirit ... " .

The state government gave the company a state loan of RM 75,000. Start of production should be at the beginning of April 1946; but the establishment of the company ultimately failed due to equipment that could not be procured.

The Chamber of Technology (KdT) founded in 1946 had the task of bringing engineers, technicians and scientists together in certain activities. So on September 8, 1949, the zonal working group “peat utilization” was founded with its sub-committees “peat extraction”, “peat chemistry” and “peat refinement”. The latter was subdivided into the working groups “Basic Research”, “Chemical-Technical Peat Refinement” and “Plant Physiological Studies”. The head of the "Peat Utilization" working committee was Prof. Dr. Möller from Rostock University. Employees of this committee came from state governments, VVBs, universities and institutes, among others. The Rostock Moor Science Institute and the planning company were also represented. The range of topics of the KdT work even included detailed work standards for manual and machine peat extraction.

On October 1, 1947, the Dean of the Faculty of Agriculture and Director of the Institute for Soil Science and Cultural Technology at the University of Rostock, Prof. Dr. Janert, after consultation with the planning company and in agreement with the state government, the Ministry of Economics, the moor science institute . Dipl.-Ing. Kadner instructed; the workforce was about 10 employees. The institute was initially financed by the planning company and, since May 1950, directly from the state government's budget; for special larger research tasks from 1949 also from funds of the GDR government. The institute's tasks were, in particular, peatland research, the conception of an effective peat extraction technique and the development of proposals for the control and rationalization of peat production.

In the year-end report for 1949, the work carried out to date is listed as follows:

I. General theoretical studies (literature studies, basic research) ,

II. Research and advice on issues relating to the preparation and exploitation of peatlands, rationalization measures in the peat industry, etc. Study on work preparation ,

III. Attempts to further develop technical methods for the production of building elements from peat (hard, insulating, building boards, building blocks, other building elements) ,

IV. Attempts to manufacture other materials or materials from peat (insulating and molding compounds, etc.) ,

V. Investigations and studies on the suitability of different types of peat as generator fuel ,

VI. Investigations of the chemical and physical processes in the charring and high-temperature charring of peat and experiments on the chemical refinement of peat ,

VII. Testing and further development of a fast electric moisture meter for peat ,

VIII. Studies on occupational diseases in the peat industry.

From 1947 to 1950, employees of the Moor Science Institute examined around 400 moors and carried out around 5,000 test boreholes. They worked out moor maps of the country and all districts.

The peat science institute published important information for peat-producing companies in leaflets, e.g. B .:

- Leaflet No. 1 from October 1948 on the sales regulation for peat in the state of Mecklenburg-Western Pomerania of May 22, 1946 and

- Leaflet No. 2 of December 1948 on the guidelines for the production of coke peat (mixture of coke breeze with peat).

In the latter, the optimal mixing ratio of coke breeze (mostly waste from the local gas works) and peat of various compositions to finished coke peat was specified in detail. Other work dealt with e.g. B. with the change of the sod shape for the purpose of faster drying, the improvement of raw peat processing, the use of younger raised bog peat for drawing and embossing cardboard, the production of paper glue from strongly humified peat types through alkaline digestion and dispersion to substitute natural and synthetic resins as well the briquetting of peat. Investigations of different types of peat for their content of bitumen, humic and fulvic acids served the search for possibilities of chemical peat processing. Studies were also carried out on the re-use of peat bogs for fish farming and other possibilities for reclamation.

Peat extraction and processing in the VEB Norddeutsche Torfwerke Schwerin

The last peat mining operation in West Mecklenburg was VEB Norddeutsche Torfwerke Schwerin with the operating parts Stralendorf, Drispeth and Breesen until it was privatized in 1990.

Raised moor, transition and fens peat were mined; in recent years exclusively for the production of fertilizer peat, peat for the production of activated carbon (in the former VEB Kunstseidenwerk Premnitz using the zinc chloride process) as well as peat preparations for use in human (balneology) and veterinary medicine. The extraction took place in the high moors Grambow I (also called Stralendorfer Moor), Drispeth, Breesen I and Woitendorf, also known as Breesen II.

The technology for the direct extraction of the peat is primarily determined by the degree of decomposition of the peat and its further processing. The top layer of a peat seam with a degree of decomposition of H2 – H5 (according to v. POST) is called white peat in practice. This peat was mainly extracted using the milled peat method. A layer of peat approx. 3 cm deep is milled off in the horizontal drive and at the same time loosened so that the peat dries better.

After the field surface has dried off, the milled layer is turned over and, after further drying, pushed together to form a swath. The peat is picked up from the swath in collecting bunkers and conveyed from the excavation field. The white peat subsidized in this way or stored in rents - for production in the winter months - was processed into "loose peat", "peat balls" and "peat substrate" (with added fertilizers). He found buyers in the cultivation of ornamental plants, seed farms, horticulture, agriculture and forestry as well as in allotment gardening. Peat waste was also used for the industrial production of germination pots using the fiber flow method. The finished products filled in PE bags were called "Biosal", "Vegebil" and "Humisal".

Pieces of peat with a degree of decomposition of H5 – H8 (na POST), known as black peat, were extracted for the production of activated carbon (according to TGL 6886). The promotion was carried out by a special peat excavator (type "Liliput") or by means of disc milling machines. After the extraction, with simultaneous formation of the peat mass and depositing of the formed peat on the field surface, the peat had to dry out from originally 86-92% to below 40% moisture content under the natural weather conditions. In the chemical industry, activated carbon was used for separating mixtures, separating gases and vapors, clarifying solutions and the like. a. m. used.

Peat with a degree of decomposition of H3 – H5 was extracted from the Grambower Moor using traditional excavators under in-situ conditions for applications in medicine and animal rearing. The “moor paste” (sold in loose form or processed into compresses) was a highly hydrated colloid-disperse paste-like substance after preparation, which, thanks to its high proportion of humic and fulvic acids, was very well suited for applications in physiotherapy and balneotherapy . The products were sold under the names "Moorpa", "Manupack", "Pedopack" and "Moorko".

Because of the astringent, antibacterial, antiviral and antimycotic effects of its humic substances, peat paste was added to the milk for the prophylaxis or therapeutic treatment of diarrheal diseases in animals.

The peaceful revolution in 1989/90 and German reunification as well as the subsequent privatization of the former state-owned companies also meant the end of VEB Norddeutsche Torfwerke Schwerin.

In 2011 only a limited amount of peat for medical purposes will be extracted from the Grambow I peat deposit. The Drispeth deposit is almost completely exhausted. The peat extraction for activated carbon production in Breesen has been discontinued. Only peat substrate is produced there for horticultural purposes.

Geological and economic evaluation of the peat deposits

In addition to the aforementioned qualitative properties of the moors or their peat, the deposits are of particular importance for an economic assessment.

The following premises apply: minimum thickness 1 m of peat; Density wet = 0.44-0.45 g / cm 3 . In mid-1990 the following inventories were found (insufficient knowledge is available about the Grambow II deposit):

| Grambow I Deposit (Confirmed Supplies) | Wet peat in Tm³ |

| White peat | 1,170.4 |

| Black peat | 131.1 |

| Transitional and low bog peat | 2,754.8 |

| Breesen I and II deposits (estimated reserves) | |

| White peat | 172.0 |

| Black peat | 532.0 |

| Transitional and low bog peat | 200.0 |

| Drispeth Deposit (Estimated Inventories) | |

| White peat | 65.0 |

| Black, transition and low peat peat | 460.0 |

| Lützowhorst deposit (estimated stocks) | |

| White peat | 425.0 |

| Black peat | 300.0 |

| Transitional and low bog peat | 300.0 |

The mining and land law conditions in the GDR

The GDR Mining Act of May 12, 1969 (Journal of Laws of I No. 5, p. 29) stipulated in § 3 that “mineral raw materials, the use of which is of economic importance, natural resources and - regardless of the property - owned by the people stand " . This also included peat in accordance with the 3rd Implementing Ordinance to the Mining Act of August 12, 1976 (Journal of Laws of I No. 32).

At the request of the VEB Norddeutsche Torfwerke Schwerin, the Schwerin District Assembly had already at its 6th meeting on December 20, 1972 with resolution No. 28 on the basis of the "Order on the establishment, public announcement and registration of mining protection areas of July 10, 1969" (GBl . II, p. 405) for the peat deposits Drispeth, Grambow I and II, Breesen I and II and Lützowhorst mining protection areas. In 1986 the Grambower Moor was placed under special protection by the Schwerin District Council.

The mining work was carried out on the basis of a technical operating plan, which had to be reported to the competent mining authority in Staßfurt and had to be approved by them.

According to Section 5 of the Mining Act, it was not possible to grant extraction rights to semi-public or private companies until the political change. It was only with the 4th implementing regulation for the regulation on the establishment and activities of companies with foreign participation in the GDR - "Authorization to Extract Mineral Raw Materials" of March 14, 1990 (Journal of Laws I No. 21) - that it was for companies with foreign participation (and this also included companies from the Federal Republic of Germany) according to Section 2, it is possible to cooperatively bring in the required storage stocks as a contribution in kind for the share capital via the participating company from the GDR.

Through the intervention of the North German peat works and the two other peat-extracting companies in the GDR in 1971/72, the otherwise customary payment of land use fees in accordance with the ordinance on the introduction of a land use fee to protect the agricultural and forestry land fund - "Ordinance on land use fee from June 15 .1967 (Journal of Laws of II No. 71) “- to be averted until 1990 for the extraction of peat.

The legal framework for the restoration or recultivation of the land required for peat extraction was set out in the following GDR laws:

- Order on the restoration of land used for mining purposes - Restoration Order - of April 10, 1970 (Journal of Laws of II No. 38),

- Order on the recultivation of land used for mining - recultivation order - of February 23, 1971 (Journal of Laws of II No. 30).

The reclamation or recultivation of the eroded areas (in the sense of a renaturation ) should have been carried out for years on the basis of an opinion from the Academy of Agricultural Sciences of the GDR on January 23, 1974. The funds required for this were not granted to the necessary extent due to the dire economic situation in the GDR.

The efforts to preserve or renaturate these unique biotopes, in particular the Grambower Moor , which began after the political change , are set out in the “Concept for the Protection and Use of Moors” in Mecklenburg-Western Pomerania (short Moors Protection Concept 2000).

Explanations

Lennart von Post (born June 16, 1884 - January 11, 1951), Swedish geologist, from 1929 to 1950, professor of geology in Stockholm.

Mudde is the generic term for sediments deposited in stagnant waters with organic and mineral substances primarily formed from aquatic organisms. Lime, clay and sand muds as mineral muds arose at the beginning of the Holocene, in the Preboreal (about 10,000 years ago). Peat and liver muds, on the other hand, are organic muds, whose origin can be dated in the boreal region (around 8,800 years ago).

Gyttja , Swedish name for Mudde, introduced into science by the Swedish geologist Hampus Adolf von Post (* December 15, 1822, † August 16, 1911).

Humidity number : von Lennart v. Post-introduced 10-step field method (from H1 = of still recognizable plant residues in the squeeze residue and pressed colorless clear water, to H10 = no squeeze residue: the entire sludge mass slides between the fingers).

Interflow : underground near-surface water runoff that has not yet reached the groundwater.

TGL = technical standards, quality regulations and delivery conditions in the GDR

- TGL 42808: "Peat for use in horticulture and agriculture"

- TGL 37125/02: "Organic fertilizers for agriculture"

- TGL 6886: "Black peat for the production of activated carbon"

literature

- G. Bailleul, W. Bratzler, W. Herbert, W. Vollmer: Activated carbon and its industrial use. 4th edition. Stuttgart 1962.

- J. Chmieleski: Between fen and soil: pedogenetic studies and classification of Central European muds. Dissertation . HU Berlin, 2006.

- KF Engmann: Investigation of the vegetation and structure of the Drispether high moor and the course of the post-glacial forest history on the young diluvial soil areas in northwest Mecklenburg. In: Archives of the Association of Friends of Natural History in Mecklenburg. NF 14, 1939, pp. 109-122.

- O. Gehl: Mecklenburg's high moors. Berlin 1952.

- K. Göttlich: Bog and peat science. Stuttgart 1976.

- R. Kadner, W. Fischer: Elemental composition and inorganic components of peat. FFH A 204. Freiberg 1961.

- R. Kadner, W. Fischer: For the knowledge of the chemical composition of peat from deposits of the German Democratic Republic. FFH A 263 Freiberg 1962.

- R. Kadner: The development of peat use in the GDR and its future possibilities. Dissertation. BA Freiberg 1963.

- G. Pinzke: Peat extraction and processing in the former Schwerin district. TELMA, Volume 40. Hanover 2010.

- G. Pinzke: The raised bog deposits of West Mecklenburg - exploration, mining and exploitation 1945–1990 . In: Martin Guntau et al. (Hrsg.): On the history of the geosciences in the GDR (= series of publications for geosciences . Issue 18). Part 2. Manfred Störr, 2011, ISBN 3-937040-26-9 , p. 473-482 .

- A. Precker, M. Krbetschek: The rain bogs of Mecklenburg-Western Pomerania - First evaluations of the investigations into the rain bog protection program of the state of Mecklenburg-Western Pomerania. In: TELMA. Volume 26, Hannover 1996, pp. 205-221.

- A. Precker: The Mecklenburg-Western Pomerania rain bogs - preliminary final evaluation of the investigations into the rain bog protection program of the state of Mecklenburg-Western Pomerania. In: TELMA. Volume 29, Hannover 1999, pp. 131-145.

- A. Precker: Hydrogeological aspects of the formation and the possibility of restitution of north German moors. In: TELMA. Volume 31, Hannover 2001, pp. 53-64.

- G. Schlungbaum, W. Fischer: On the knowledge of the chemical composition of peat from occurrences in the GDR. FFH A 254, Freiberg 1962.

- H. Schmidt, G. Pinzke: Raw material peat - current use in the GDR and aspects of future use. Freiberg, BHT 1983, lecture.

- R. Stahl: Structure, origin and history of Mecklenburg peat bogs . in communications from the State Geological Institute. 23rd 1913.

- Holdings of the State Main Archives Schwerin, Ministry of Economics, Main Industry Department, 6.11-14; Economic Council Schwerin, 7.11-1; Prime Minister, 6.11-2.

Individual evidence

- ^ O. Gehl: Mecklenburg's high moors. Berlin 1952.

- ↑ a b Concept for the protection and use of moors.

- ↑ A. Precker: The rainy Moore Mecklenburg-Western Pomerania - preliminary final evaluation of studies on the bog protection program for Mecklenburg-Vorpommern. In: TELMA. Volume 29, Hanover 1999.

- ↑ A. Precker, M. Krbetschek: The rainy Moore Mecklenburg-Western Pomerania - First results of the investigations into the bog protection program of the Land Mecklenburg-Vorpommern. In: TELMA. Volume 26, Hanover 1996.

- ↑ A. Precker: Hydrogeological aspects of the formation and the possibility of restitution of north German moors. In: TELMA. Volume 31, Hanover 2001.

Web links

- More photos on peat cutting guenter.pinzke.de