Torsion bar

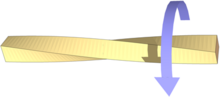

A torsion bar spring (also torsion bar or torsion bar ) is a rod-shaped spring . When the rod is rotated around its longitudinal axis, torsional stresses , called shear stresses , arise in its cross-sections , which are in equilibrium with the torsional moment applied from the outside .

Torsion bar springs can have a cylindrical or other cross-section, rectangular ones can be used in bundles, e.g. B. on light car trailers or the F series from Hanomag-Henschel . Bundling cylindrical torsion bar springs is more complex.

A coil spring is also a torsion spring . It is a helically wound rod that, like the straight torsion rod, is elastically stressed over its entire length by a torsional moment.

Examples of torsion bars used are, in addition to torsion bar springs and stabilizers in automobiles, the torsion pendulum in mechanical watches , the torsion band in moving coil measuring instruments (for generating the reaction torque and as a bearing element for the moving coil).

calculation

The angle of twist is proportional to the length of the rod and the torsional moment loading it:

The shear modulus is a material constant. The shape and size of the cross-sectional area are taken into account with the polar area moment of inertia .

So that no permanent deformation occurs, the flow limit must not be exceeded. The torsional stress must be less than its permissible value :

The torsional stress is greatest at the cross-section edge. This is expressed in the polar section modulus with the maximum vertical distance between the edge fiber and the neutral (tension-free) fiber .

Car

Well-known vehicles with torsion bar suspension - mostly the torsion bars are arranged transversely to the direction of travel - are the Audi 60 (front axle: torsion bars in the direction of travel, rear axle: transversely), BMW 501/502 (torsion bars in the direction of travel), DAF 55 (torsion bars in the direction of travel), Simca 1100 (Rear axle), VW Beetle , VW Bus T1 , T2 and T4 , VW Type 82 (Kübelwagen), Porsche 356 , Porsche 911 (until 1989) and Barkas B 1000 ; Torsion bar suspension can also be found on the rear axles of many Peugeot and Renault car models - on Renault 4 , 5 , 6 and 16 with slightly different wheelbases for the left and right sides of the vehicle, because the two parallel torsion bars protrude over the center of the vehicle. With some torsion bar spring axles, for example the Peugeot 205, Porsche 356 and BMW 501/502, the preload and thus the ground clearance of the vehicle can be adjusted by adjusting elements on the firmly clamped side of the spring .

US automakers' special ways

In 1955 and 1956, Packard used a composite system called Torsion-Level Ride for most models , which essentially consisted of two main torsion bars lengthways and two auxiliary bars acting on the rear axle. With an interposed, relay-controlled electric motor , the system functioned as an automatic level control: It kept the car level at all times and automatically compensated for the load in the trunk within 7 seconds. It could also support a wheel change. The time delay was necessary so that the electrical system did not intervene whenever the floor was uneven, but only when there was a permanent change in weight, for example when passengers got on or off or the trunk was loaded.

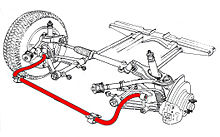

From 1957 to 1970 Chrysler had a torsion bar suspension for the front axle called Torsion-Aire . It should also reduce excessive roll in corners. For a long time, leaf springs were used to suspend the rear axle. The system was further developed into Torsion Quiet in 1971 (until 1992).

General Motors went with its 1966 resp. Introduced in 1967, the luxury coupes Oldsmobile Toronado and Cadillac Eldorado (until 1978) followed a similar path, but probably for reasons of space. At the rear, coil springs were always used.

truck

The Czech Tatra 813 and Tatra 815 are up to four-axle extremely off-road utility vehicles with central tubular frames and wheels individually suspended on semi-axles. The 4x4 variants are on all axles and the 6x6 variants are sprung on the rear axle with longitudinally installed torsion bars. The front axles of the 6x6 and all axles of the 8x8 variant are sprung with semi-elliptic leaf springs ( bogie axles ). The semitrailer variant is equipped with torsion bar suspension on the front axles and air springs on the rear axles.

motorcycle

Torsion bars are occasionally found on rear swing arms.

military

Another area of application for torsion bars are battle tanks : since the Second World War, the suspension of medium ( PzKw III - from Ausf. E, Panther ) and heavy tanks ( Tiger and King Tiger ) as well as modern battle tanks such as the Leopard 2 or the M1 Abrams has been based on torsion bars .

railroad

In rail vehicles torsion springs are used as rolling support; they cushion the rolling movement of the vehicle body around the longitudinal axis. Anti-roll supports are a crucial part of the suspension, especially in vehicles with air suspension. The torsion bar of the anti-roll support can be installed in the chassis or in the vehicle frame, depending on the space available.

additional

The detachable cable car clamp "DT", short for "Doppelmayr Torsion", also works on the torsion bar principle. It has been manufactured by Doppelmayr Garaventa since 1993.

literature

- Wolfgang Merhof: Driving mechanics of tracked vehicles . Ed .: Ernst-Michael Hackbarth. 2015, ISBN 978-3-943207-13-2 , pp. 445 ff . ( Link to the PDF document [accessed February 29, 2020]).

Web links

Individual evidence

- ^ Packard, a history of the motor car and the company - General Edition - Beverly Rae Kimes, Editor - 1978 Automobile Quarterly, ISBN 0-915038-11-0

- ↑ Chrysler Torsion Bar Car Suspensions, 1957–1992: Torsion-Aire, Torsion-Quiet at Allpar.com (in English)

- ^ Gunnell, John (editor): The Standard Catalog of American Cars 1946-1975 , Krause Publications (1987), ISBN 0-87341-096-3