Gottessegen colliery (Dortmund)

| Bill God's blessing | |||

|---|---|---|---|

| General information about the mine | |||

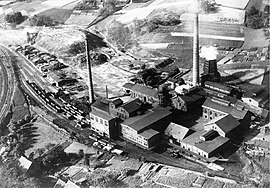

| The Gottessegen colliery 1914 | |||

| other names | Pay God's blessing | ||

| Mining technology | Underground mining | ||

| Information about the mining company | |||

| Operating company | Hörder mining and smelting association | ||

| Start of operation | 1743 | ||

| End of operation | 1963 | ||

| Funded raw materials | |||

| Degradation of | Hard coal / iron ore | ||

| Degradation of | Iron ore | ||

| Geographical location | |||

| Coordinates | 51 ° 26 '46 " N , 7 ° 27' 17" E | ||

|

|||

| Location | Kirchhörde | ||

| local community | Dortmund | ||

| Independent city ( NUTS3 ) | Dortmund | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Ruhr area | ||

The Gottessegen colliery in the Dortmund district of Löttringhausen and Kirchhörde is a former hard coal mine . The colliery was also known as the colliery God's blessing . In the beginning, both hard coal and iron ore were mined at the mine. The Julius Philipp colliery union was one of the founding members of the Rhenish-Westphalian coal syndicate .

history

The beginnings

A length field was awarded on May 3, 1743 and October 8, 1744 , after which tunnel construction was carried out. In the following year, the pit field Gottessegen was measured . In the years 1754 and 1755, the mine was given time limits due to a lack of sales . The mine was in operation in 1758 and 1759, 1761 and 1762, after which it was initially no longer mentioned. On October 16, 1877, the Hörder Bergwerks- und Hütten-Verein acquired numerous mine fields and tunnels, a.o. a. also God's blessings, some of which have existed since the beginning of the 17th century. In addition, there were the pit fields of the Caspar Friedrich, Benjamin, Carlsbank, Argus and Heinrichsfeld collieries . The mining took place in the Caspar Friedrich seam. First, coal was the tonnlägigen shaft supported Reinsbach the colliery Argus. The shaft had a deeper depth of 305 meters and had a wooden shaft lining . In 1877 the Reinbach shaft was renamed the Gottessegen 1 shaft.

19th century

On January 4 of 1879 it came to the consolidation of Berechtsamen Caspar Friedrich, Benjamin, Carl Bank, Argus , God's blessing and Heinrich field for colliery God's blessing. On August 31 of the same year, the mining of iron stone in the Argus mine field was stopped. In 1882 there was a fire in the Reinbach shaft, in which the wooden shaft lining was destroyed. As a result of the fire, production was temporarily suspended . The following year was up to second in the shaft Reinsbach again sole promoted are. In 1884 the mining of iron stone was completely stopped. In 1885, the well was Reinsbach gesümpft and deeper geteuft . In 1886 the 4th level was set in the Reinbach shaft at a shallower depth of 383 meters and the mining of coal iron stone was resumed. On October 6, 1888, a contract was signed to mine the Joshua field. In 1890 a weather forecast was created in Flöz Dickebank up to the surface. In 1891 a new shaft was sunk. The shaft of today Hagener road was north of the old shaft Reinsbach west scheduled . The ore mining was stopped and the daytime facilities were completely rebuilt, and on July 17th of the same year the consolidation with Argus Beilehn and Trau auf Gott took place. In 1892, shaft 2 reached the Joester Erbstollen sole at a depth of eight meters (+137 meters above sea level ). The first level was set at a depth of 76 meters (+70 meters above sea level). The 2nd level was at a depth of 191 meters (−45 meters above sea level) and the 3rd level was at a depth of 291 meters (−145 meters above sea level). In addition, this year to the south of shaft 2, a broken weather shaft was reworked up to the first level. The shaft had a cross-section of four square meters. A total of five shafts were now in operation. In 1893, mining began in shaft 2, shaft 1 was used for dewatering . In addition, a weather shaft was thrown down in the same year and a briquette factory was built to utilize the fine coal.

A year later, in 1894, the Reinbach shaft burned again and then had to be abandoned and filled . The Argus open-air facilities were completely destroyed by this fire, and the fire also caused difficulties with drainage. The entire southern field with two shafts was abandoned. In 1896 more shafts were abandoned, so only one weather shaft and shaft 2 were in operation. The pit grew through the acquisition of further surrounding pit fields. The owners of the closed Venus colliery and the pit fields of the Frischauf, Rosina & Rosina II collieries with a weather shaft were acquired. The rightful now covered an area of ten square kilometers. This year, the bill was the first time in yield , this continued until the year 1920. In 1897, the main cross-cut was further on the third sole means of mechanized drilling ascended . This year, the cross passage was driven to a length of 900 meters. The dismantling and the installation were limited this year to the Caspar Friedrich seam (main seam). Above ground , a hydraulically operated dewatering machine , system Kaselowasky installed. The machine was able to pump out up to 4½ cubic meters of mine water per minute. In addition, the Venus field was divided into Venus I and Venus II this year, and Venus I field was transferred to the Glückauf Tiefbau colliery. At that time, the mine was part of the southern Dortmund mining area . On April 13, 1899, the legitimate Venus II was consolidated with Rosina and Frischauf. In 1900 the 4th level was aligned and a die was made next to shaft 2. The bottom was at a depth of 366 meters (−220 meters above sea level).

The 20th century

In 1902 35 party shifts were carried out at the mine . In 1903 the closed mines Glücksanfang I-III, Güldene Sonne and Wiendahlsnebenbank were acquired. The right now covered 6.8 square kilometers and five length fields. In 1904 work began on aligning the newly acquired fields on the 2nd and 3rd level. In 1907 a blind shaft was sunk from the 4th level and in the following year the 5th level was set in the blind shaft at a depth of −323 meters above sea level. In 1921 and 1922, the mine changed hands. In 1923, a field swap was made with the Wiendahlsbank colliery, the Rosina length field was exchanged for several pieces of seam from the Wiendahlsbank colliery. In the same year operations were stopped because of the occupation of the Ruhr. In the following year, operations were resumed, with a production shaft and a weather shaft in operation. In 1925 the mine was taken over by the Vereinigte Elektrizitätswerke Westfalen AG . In 1927 the southern field was swamped. In 1929, shaft 2 was renamed to shaft 1, and in addition to shaft 1 (formerly shaft 2), work began on digging a new shaft called shaft 2. In 1930, mining began in shaft 2 from the 3rd level, the 3rd level was also the final depth for shaft 2. Shaft 1 was converted into a weather shaft and the pits below the 4th level were swamped. Then the dismantling was carried out below the 4th level in the substation construction . This year there were 41 party shifts. The following year there were again party shifts, this time there were 31 party shifts. In 1932 a blind shaft was sunk from the 5th level to the 6th level in the north field. In addition, the closed “ Kleine Windmühle” colliery was acquired this year . In 1933 there were party shifts on 33 days. In 1935 iron ore mining was resumed.

In 1937 a blind shaft was sunk from the 3rd level to the 6th level in the north field and mining then started. The Joshua field was also acquired that year. In 1938 part of the field of the Admiral colliery was acquired. On October 1st, the briquette production was stopped, the reason for this was that from now on all fine coal should be used to generate electricity in the company's own power plants. In 1939 the Zufall and Hermann fields were acquired. In 1940 ore mining was abandoned. At this point in time, the deepest level in the north main department with location 1 was below the 6th level. From 1934 to 1941 a total of 531,641 tons of coal iron stone were mined. In 1942 the rights of the closed Admiral colliery as well as the Clarenberg field and the United Bickefeld civil engineering colliery were taken over. In 1946, the beneficiary comprised a total of nine square kilometers and the Eisensteinfeld Gottessegen, which was created through a real division of the consolidated Eisensteinfeld Argus I, Argus II and Gottessegen I. The shafts weather shaft 1 and conveyor shaft 2 were in operation. The extraction level was the 3rd level, which was at a depth of 289 meters (−144 meters above sea level). The weather floor was the second floor, which was 191 meters deep (−44 meters above sea level). In 1948 a blind shaft up to the 7th level was built in the main department. The 7th level was at a depth of 836 meters (−690 meters above sea level). Below the 7th level there was an auxiliary level at a depth of 906 meters (−760 meters above sea level). In December of the same year, an excavation was made for shaft 3 from the 2nd level. On March 9 of the following year, work began on digging shaft 3 from above ground. The location of the shaft was Am Franzosensiepen in Großholthausen. On December 12th of the same year the breakthrough came with the departure. On July 1, 1950, shaft 3 up to the second level was put into operation. In 1954, the Christian shaft of the former Glücksanfang colliery was used for ventilation . In 1955, the Auguste field was acquired, and the rights now covered an area of 9.9 square kilometers. In 1957, the “Auf dem Blick” outer shaft went into operation. The shaft was located in Kirchhörde and had a depth of 287 meters. The mine was shut down in 1963.

Promotion and workforce

The first workforce and sponsorship figures are named for the year 1878. With 132 miners 9,792 tons of hard coal and 9,698 tons of ore were mined. In 1880, around 58,000 tons of hard coal were extracted with 228 miners. In 1887, 271 miners extracted 40,248 tons of hard coal and 13,199 tons of ore. In 1890, hard coal production rose to 71,009 tons, while ore production fell to 2077 tons. This production was carried out by 319 miners. In 1895, hard coal production increased again to around 90,000 tonnes; the production was carried out by 416 miners. In 1900, 591 miners extracted 166,821 tons of hard coal. In 1905 the production sank slightly to 150,542 tons, the workforce increased to 672 miners. In 1910 production increased to 168,283 tons of hard coal, the workforce was 769 miners. In 1913 production rose again to 203,568 tons, and the workforce also rose to 779 miners. In 1915 the production sank to 149,939 tons, and the workforce also fell to 651 miners.

In 1920, despite an increase in the workforce to 730 miners, production fell to around 113,000 tons. In 1925 the production rose to 162,307 tons, and the workforce rose to 798 miners. In 1930, 1,100 miners extracted 284,252 tons of hard coal and 600 tons of ore. The colliery's maximum production was achieved in 1932 with 968 miners; 326,441 tons of hard coal were produced. In 1935, production fell slightly to 286,943 tons of hard coal, and the workforce also fell slightly to 955 miners. In 1938, 262,048 tons of hard coal and 120,949 tons of ore were mined; 1165 miners were responsible for the mines. The ore production in 1938 was the maximum ore production of the mine. In 1940, 1137 miners extracted 250,117 tons of hard coal and 115,098 tons of ore. In 1945, 1,083 miners extracted 149,882 tons of hard coal. In 1950, 1191 miners produced 249,853 tons of hard coal. In 1955 the production sank sharply to 179,877 tons of hard coal, the production was provided by 1,067 miners. In 1960 production increased again to 210,952 tonnes; in that year 922 miners were employed at the mine. The last known production and workforce figures for the mine are from 1962; in that year, 806 miners produced 234,415 tons of hard coal.

What is left

Today there are workshops for the disabled on the grounds of the Gottessegen mine.

In January 2012 the Gottessegen colliery came into the media again: the A 45 had to be closed in both directions for about two weeks to fill cavities and break the colliery between the crosses Witten and Dortmund Süd. Further cavities under the road surface were discovered during investigations. The state of North Rhine-Westphalia or the taxpayer will remain responsible for the costs because the mine has no legal successor who could be made liable for damages.

Individual evidence

- ↑ a b c d e f g h i j k l m n o p q r s t u Joachim Huske : The coal mines in the Ruhr area. Data and facts from the beginning to 2005 (= publications from the German Mining Museum Bochum 144). 3rd revised and expanded edition. Self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- ^ Gerhard Gebhardt: Ruhr mining. History, structure and interdependence of its societies and organizations. Verlag Glückauf GmbH, Essen 1957.

- ↑ a b c d e f g h i j k l m Wilhelm Hermann, Gertrude Hermann: The old collieries on the Ruhr. Past and future of a key technology. With a catalog of the "life stories" of 477 mines. 6th edition, expanded to include a digression according to p. 216 and updated in parts relating to energy policy. The 5th, completely revised and expanded edition 2003, updated by Christiane Syré and Hans-Curt Köster. Langewiesche Köster, Königstein im Taunus 2008, ISBN 978-3-7845-6994-9 .

- ↑ a b Tilo Cramm: Dortmund mines in the picture . 1st edition, Regio-Verlag, Werne 2004, ISBN 3-929158-17-5 , pp. 5–10.

- ↑ a b Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Volume 46, published by Wilhelm Ernst & Sohn, Berlin 1898.

- ^ Werkstätten Gottessegen (last accessed on October 18, 2012).

- ↑ WAZ of January 18, 2012: "45-Alte Zeche Gottessegen is to blame for the break of day in Dortmund on the A45" online (accessed on January 20, 2012).

- ^ Mining damage - A 45 closed (last accessed on October 18, 2012).

Web links

- Early mining on the Ruhr: Zeche Gottessegen (last accessed on June 5, 2015)

- Early mining on the Ruhr: historical map around 1840 (last accessed on June 5, 2015)

- Early mining on the Ruhr: Map of the situation around 2000 (last accessed on June 5, 2015)

Remarks

- ↑ A weather overburden is a mine that is built in the seam from bottom to top and is used for ventilation . (Source: Tilo Cramm, Joachim Huske: Bergman language in the Ruhr area. )

- ↑ As Beilehn or Beilehen is called an additionally imparted pit box, which is connected with another holding moderately pit pitch. (Source: Tilo Cramm, Joachim Huske: Miners' language in the Ruhr area. )