Refrigerated shipping

As reefer sea transport of perishable goods is by means of cooling vessels and refrigerated container ships , respectively.

Pioneering phase, banana and meat transport

It started with the transportation of bananas and meat. In retrospect, the years after 1876 are both the beginning and the pioneering phase of refrigerated shipping. After several setbacks, the principle of silent cooling had become established on board meat refrigerated ships. In high cargo holds lined with pipes, the air was cooled by the flowing refrigerant - in many cases ammonia was used at the beginning - and kept at temperature. No fans were necessary for this. Engineers named Charles Tellier (1828–1913, cold steam engines), Ferdinand Philippe Carré (1824–1900, absorption machines ) and the Scottish doctor John Gorrie (1802–1855, cold air machines) were the inventors and pioneers of the use of refrigeration processes in shipping . Carl von Linde (1842–1934) created the essential theoretical foundations of refrigeration technology. In 1871 he developed a refrigeration machine that worked with methyl ether , which he had manufactured in the Augsburg machine works (now MAN AG ). The second generation of Linde's refrigeration machines , following in 1876 , worked with ammonia. With the silent cooling, meat could be frozen deep for the first time and transported over long distances. From this a new branch of shipping developed - and in the following years England in particular was supplied with meat from Australia and America .

It was in 1803 when the sailing ship Reyward came into New York from Cuba . In addition to the normal cargo, there were 30 stalks of red bananas from Cuba on board. Although this did not establish a regular banana transport, this is considered to be the beginning of the banana shipping. The regular transport of bananas with refrigerated ships, after many failures, did not begin until 80 years later, around 1896/97, with the use of the first specialized banana steamers with ventilation cooling between Jamaica and England . The previous numerous failures illustrate the complexity of this business, since fruits as a breathing load - and especially the banana as a climacteric fruit - place much higher demands on temperature, air circulation and fresh air supply compared to meat. The silent cooling, as it is also used in household refrigerators, turned out to be unsuitable for such demanding loads. It was not until the introduction of ventilation cooling in 1897 that the results were satisfactory. For this purpose, cold air was driven through the banana charge with steam-driven fans and then cooled again in air coolers. Next to meat, bananas are the most important branch of refrigerated shipping today.

Development of refrigerated shipping

In the decades that followed, the refrigerated ships and especially the cargo cooling systems - consisting of the actual refrigeration system and the transfer of cold into the cargo - were improved and optimized step by step in parallel to technical progress. For this purpose, the tried and tested procedures on land were adapted to the peculiarities of the harsh ship operation and finally adopted - with a time delay, of course - for reefer shipping. In the case of refrigeration machines, for example, the so-called cold steam process has established itself in exactly the same process that is also used in our household refrigerators and freezers . There were several changes to the refrigerants. The tried and tested refrigerants ammonia and carbon dioxide (CO 2 ), which were tried and tested in the pioneering phase, were replaced by CFC- containing “safety refrigerants ” developed in the USA in the 1930s due to their risk to humans from leaks . Much later it was recognized that they endangered the ozone layer due to their CFC content and they were banned. In the meantime, the industry is currently returning to the tried and tested - and already mentioned - refrigerants CO 2 and ammonia. A good example of how useful it can be not to neglect historical knowledge.

As refrigeration advanced into the world of ships, so did shipping as such. Until 1870, all goods and passengers were still transported on universal freighters (mainly on sailing ships , but occasionally also on steamers), but in the decades that followed, with the growth of world trade and the invention of refrigeration technology, a specialization of ship types began. The first refrigerated ships were followed by other specialists in the course of time - for passengers, of course, but also for liquid and solid bulk goods ( tankers , bulkers ) and later also for trucks and cars ( car transporters , ferries ) and general cargo ( container ships ).

Due to the high demands of the banana, the class of refrigerated ships was divided into “banana steamers”, which specialized almost exclusively in the transport of this climacteric fruit, and reefers for frozen goods such as meat and fish until the middle of the 20th century. It was not until the following decades that the refrigerated ships were designed for universal use, so that today around three quarters of all refrigerated ships are suitable for transporting all kinds of fruit as well as for deep-frozen cargo. However, until the 1980s, sea transport of refrigerated cargo was by no means reserved for refrigerated ships: many cargo liner ships also had refrigerated cargo holds ready. The Hamburg museum ship Cap San Diego is an ideal example of this. In the meantime, however, container ships have largely replaced these liner carriers. Since their introduction around 50 years ago, the refrigerated containers have replaced the refrigerated rooms of the liner cargo carriers. Some voices even claim that container shipping will also displace refrigerated ships.

Reefer ships

Among the around 35,000 registered merchant ships over 500 GRT / GT in 2005 there were around 1,250 refrigerated vessels with around 336 million cbft . Compared to most other types of ships, they are relatively small and can also call at small ports of discharge and loading directly. This is also due to the special cargo and the drafts in many loading ports are limited. The size of the room is important for the refrigerated ships, as bananas, the most important refrigerated cargo, are light and require a lot of space. The load-bearing capacity only became important since reefer ships also loaded reefer containers on deck. With these refrigerated containers, the previous transport space below deck is increased by 40 to 100 percent, the load-bearing capacity is used and journeys in ballast are reduced. According to the external appearance of some modern reefer ships, only an expert can tell whether it is a reefer or a container ship.

Refrigerated ships are equipped with central refrigeration systems and ship-mounted cargo refrigeration systems, which at least consist of the refrigeration system for generating cold and the air system for removing heat from the hold. The superstructures and machinery on the younger reefer vessels are located aft, which creates as much contiguous space as possible for the refrigerated cargo and ensures uninterrupted cargo handling. Larger refrigerated ships have four hatches on the weather deck, each of which leads vertically down to the four decks in the ship's belly that form the refrigerated rooms. These isolated special cargo compartments stretch across the entire width of the ship and are at least 2.20 meters high, which enables undisturbed forklift operation. About steerage hatches the cargo arrives at the lower loading deck.

Two of the four loading decks represent a separate cooling zone in which the temperature can be set independently of that in the other cooling zones. In addition to excellent insulation, this is made possible by a whole series of fans and heat exchangers that are installed in a small space at the front of the cargo space. The fans arranged above the heat exchangers suck in the air from the top of the cargo space horizontally above the cargo and push it vertically down through the heat exchanger and then cooled horizontally under the cargo. The load - such as bananas, packed in perforated film and air-permeable cardboard boxes - stands on perforated or slotted grating made of wood or aluminum, the grating. The cold air is distributed under the Grätingen and looks for a way through the cargo vertically upwards. It transports heat, moisture and other metabolic products of the bananas out of the boxes and into the air space above the cargo. This closes the air cycle, because here the fans suck in the heated air again in order to send it back into the cycle after cooling down in the heat exchanger. A small part of this circulating air, around 2 to 3 percent, is constantly replaced by fresh air when the fruit is loaded in order to flush out the metabolic products, especially the undesired ethylene .

With this division, up to eight different loads can be transported in up to eight different temperature environments with a total of 16 refrigerated holds - provided, of course, that the decks are closed off from one another and all the boundary walls, floors and ceilings are completely isolated from one another. This arrangement is particularly recommended for the transport of sensitive fruits such as bananas or pineapples that are not pre-cooled on land. On the one hand, small holds can be cooled down more quickly than large ones - and on the other hand, the range of exotic fruits such as pineapple is often not large enough for large refrigeration spaces.

As a rule, only packaged refrigerated goods are transported in the cold room of a reefer. The packaging helps to prevent transport damage and prevents the load from drying out - after all, air speeds in a cold store are like those of a small storm. Which packaging is used depends on the type of cargo: If plastic film and simple cardboard are sufficient for frozen goods, breathing cargo such as bananas or vegetables makes significantly higher demands on their transport. The extremely stable fruit cartons made of corrugated cardboard with air holes have proven their worth here: They can be stacked up to two meters high in the hold and then withstand even the extreme loads generated by the rough seas and the pressure of the upper cartons. The sensitive fruits are protected from drying out with perforated foil and from pressure points with kraft paper . Even the high humidity in the cold room - 90 to 100 percent relative humidity - cannot affect the stability of the boxes.

Innovations in refrigerated ships

The innovation steps of the last 10 years were often only noticed by experts:

- The introduction of the controlled atmosphere (CA) results in fewer cargo losses during the transport of fruit and a reduction in the loss of quality due to the transport.

- The CA leads to a very rapid reduction in metabolism with the advantage of a faster cooling phase.

- The improvement of the ship lines, the use of efficient engines and propellers led to the reduced fuel consumption of the ships.

- The optimization of the construction and the enlargement of the ballast tanks resulted in a higher stability and thus more refrigerated containers can be transported on deck.

- The output of the auxiliary diesel was increased to provide the power supply for the refrigerated containers .

- In many cases, additional facilities were created to connect the refrigerated containers to the central CA supply.

- On-board handling has been optimized using side loading equipment , container and special pallet cranes.

The winter class with large loading space openings for pallet handling

Controlled atmosphere

“Controlled atmosphere” (CA) means that the oxygen (O 2 ) and carbon dioxide (CO 2 ) levels in the atmosphere can be regulated. This is usually the case in land storage technology for long-term apple storage with the use of nitrogen generators and CO 2 scrubbers.

"Modified atmosphere" (MA) means that at least one of the variables oxygen or carbon dioxide can be controlled. This technology is used on ships or in refrigerated containers, sometimes in conjunction with controlled relative humidity. For oxygen scavenging, nitrogen is used, which is seldom produced from pressure bottles or pressure tanks, but mainly with the use of nitrogen generators on the ship or in the refrigerated container. Nitrogen is generated from the ambient air mainly according to the principles of PSA (Pressure Swing Absorption) or membrane technology; the nitrogen concentration is adjustable and amounts to 95–98 percent. The carbon dioxide concentration can be adjusted to 5–6 percent depending on the tightness of the holds.

The self-breathing of the fruit can also be understood as MA if the oxygen content is measured and the oxygen content is not fallen below a lower limit value by adding air. The resulting high carbon dioxide content is then reduced by a CO 2 scrubber, in the simplest case with quick lime.

Around the world, around 5–7 percent of all refrigerated ships are prepared for CA and regularly carry out CA transports. When transporting bananas, the oxygen content is reduced to values of 2 - 5 percent and the carbon dioxide content is increased to values of 2 to over 5 percent, depending on the fruit.

New refrigerated ships for the transport of fruit are predominantly built in a CA-compatible manner, ie the cargo holds are better sealed and the additional pipelines, measurement technology and electrical connections required for CA operation are already in place. The active elements (nitrogen generator, oxygen and carbon dioxide measurement technology and the control) are only given on board for CA transports.

The major refrigerated container manufacturers offer the CA as an option for a surcharge, a total of 1–3 percent of the refrigerated containers are CA refrigerated containers that are equipped with their own refrigeration and CA components. The number of refrigerated containers that can be connected to central CA systems (Dole, Chiquita) or that contain a unique gas mixture as a modified atmosphere (MA) (Transfresh) is significantly higher.

Container ships and reefer containers

Porthole container with clip-on unit on a truck

The development of container and refrigerated container transport began in North America in the 1950s. In addition to the advantage of transporting and handling the goods with little manual labor and therefore with less personnel, the refrigerated container had another important advantage of uninterrupted refrigerated goods transport, ie the cold chain was closed. Small loads of particularly sensitive refrigerated goods such as exotic fruits, vegetables and shrimp could only be transported economically by ship with the introduction of the refrigerated container, which opened up new market segments. The term refrigerated container ship is not clearly defined and initially only applied to container ships with fixed cooling rods (CON-AIR ships) that transported insulating containers (also known as porthole containers ).

The refrigerated containers have meanwhile replaced the refrigerated rooms of the liner freighters and since the banana war between the EU and the USA in 1993 the competition with the refrigerated ships has also been noticed more and more clearly. Since 1966, several innovation steps have been completed in refrigeration and automation technology, which have led from the insulated container (porthole container) without its own refrigeration unit to today's automatic integral container with its own refrigeration and cold air system. This made the transition of the north-south shipping areas from porthole to integral container, completed in 2005, possible, although this was bought at the expense of increased energy consumption and extensive monitoring. However, the refrigerated container has the advantage of a closed cold chain and enables the inexpensive transport and distribution of small quantities of refrigerated cargo in intermodal transport.

The 5500 TEU ships of the Monte class , specially constructed for the South American service , have the world's largest refrigerated container capacity with 1365 refrigerated container spaces, that is around 2,700 TEU. With an average power requirement of 2 - 4 kW per R-TEU z. B. 5400 - 10800 kW of electrical power is required on the Monte ships for the operation of all refrigerated containers. The changeover was also completed in the South Africa service and the new flagship of the German Africa Lines (DAL), the DAL Kalahari , started service in March 2005. The 4500 TEU refrigerated container ship was built at the Lindö shipyard in Denmark, which is part of the AP Møller group, and is used with other ships of the same construction in the SAECS consortium.

In mid-2005 there were 3480 container ships with container spaces for 7.7 million standard containers (TEU) and refrigerated container spaces for around 0.85 million TEU (approx. 850 million cbft). Container shipping shows a steep increase, in 2004 around 91 million TEU were transported (2003 = 83 million TEU), and container handling in the ports was around 320 million TEU lifts (2003 = 290 million TEU lifts). This results in an average of three to four transshipment processes per container transported. Many of the containers are distributed via small feeder ships to (from) ports with little cargo and shallow drafts.

Reefer container

Considerable research and development work has been carried out to ensure that the durability, the empty weight, the insulation and the tightness meet the high requirements of sea transport, port handling and road and rail transport. The ISO 1496 standard requires e.g. B. the max. Stack weight of 96 t, the heat transfer rate of 51 W / K and the max. Individual weight per container of 30.4 t. For refrigeration have piston compressor proven, but they are increasingly from lower-cost scroll compressor displaced (Scroll). The advantages of the innovative scroll compressors are particularly the lower weight and the lower noise level. However, further optimizations and adjustments are necessary in order to reduce the E-consumption of the refrigerated containers and the cargo space ventilation.

Worldwide there were around 1.4 million TEU refrigerated containers in 2005, and the trend is rising. Around 75,000–150,000 TEU are manufactured each year, and 50–60,000 TEU are scrapped annually. A new 40-foot reefer container costs about $ 18,000. Today's global production of reefer containers takes place almost exclusively in China and the company China International Marine Containers (CIMC) is the most important manufacturer of reefer containers with 30 subsidiaries and 14,000 employees. From 1994 to 1996, with the technical support of Graaff in Elze (Germany), CIMC prepared refrigerated container production in China. Production actually began in 1996, and in 2005 around 50 percent of all refrigerated containers were manufactured by CIMC.

Depending on the ambient temperature and mode, modern 40-foot refrigerated containers (2 TEU) have an electrical consumption of 4 to 6 kilowatts for deep freezing or 6 to 10 kilowatts for fruit cooling in normal operation. When transporting in the hold, a further 1 to 3 kilowatts of fan power per FEU are required to dissipate heat if no water cooling is provided. Around 3,000 to 4,500 cubic meters of fresh air per hour are required for this per TEU.

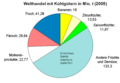

Cooling charge

The most economical and environmentally friendly method of transporting perishable food and other refrigerated goods intercontinental is to use refrigerated vessels and refrigerated container ships. On the other hand, it is a logistical masterpiece, as a closed cold chain from the producer via the sea to the trade in the consumer country is essential. The refrigerated cargo consists of bulk cargo such as meat, fish, bananas and citrus fruits, as well as seasonal fruits, vegetables, exotic species, plants, cut greenery and cut flowers. For 2005, the global export of refrigerated goods was estimated at around 270 million tons, including around 180 million tons of fruit and vegetables and 90 million tons of meat, fish and dairy products. In 2005, around 80 million tonnes of these goods were transported by sea in reefer and reefer container ships, around 50 percent each in reefer vessels and 50 percent in reefer containers.

Typical examples of the group of frozen goods are fish (almost 14 million tons), meat (around 13 million tons) and dairy products (2.3 million tons), which are transported by ship every year. Meat and dairy products are mainly transported in refrigerated containers, fish less so. A special fleet of refrigerated ships takes over the deep-frozen fish partly directly at sea, partly from the fishing vessels in the port or from deep-freeze warehouses.

The other group are fruits and vegetables, with the banana coming first. It is considered to be the most important cargo for the reefer ships, because most of the bananas traded around the world are transported by sea. Bananas are very sensitive refrigerated goods that are transported by refrigerated ships over long distances to Europe and the Far East. Since around 1970, bananas have also been transported in refrigerated containers over shorter journeys such as Central America - USA. For 2005 around 14 million t were estimated that were transported by ship. Around a third of the refrigerated ship fleet is busy transporting bananas.

The citrus fruits, the second most important group in fruits, are harvested in both the southern and northern hemisphere. In 2005, around 8 million t of this was transported by ship across the sea. The seasonal fruits include apples, pears, kiwi, peach, nectarines and grapes, which are also harvested in the southern and northern hemisphere. Most of the export and transport is from south to north, in 2005 almost 8 million tons were transported by ship. The vegetables such as B. tomatoes, cucumbers, pumpkin are among the other refrigerated goods. The berries, stone fruits, exotics and flowers, which were previously mainly transported by plane, are now also transported by ship in special refrigerated containers.

In contrast to frozen goods, fruits and vegetables have their own metabolism. After the harvest, they consume oxygen and in turn give off heat, carbon dioxide and water, as well as aromatic substances and ripening gases. Depending on the temperature and the ambient atmosphere, this metabolic and maturing process takes place at different speeds. The colder the ambient temperature and the lower the oxygen content of the air, the slower the fruits ripen.

In the more than 130-year history of refrigerated shipping, the crews have gradually found the optimal temperatures for storing and transporting the most diverse types of fruit, partly through accidental observations, partly through targeted trial and error, and partly also through painful and lossy experiences. To transport the bananas, a 60 to 80-fold air circulation and a double fresh air supply per hour are absolutely necessary for normal transport. Today, however, almost half of all bananas to Western Europe are transported under a modified atmosphere (MA).

Examples and notable reefer vessels

The first such refrigerated container ships that were used to transport bananas were the Bayano and Barranca , which transported bananas for the Chiquita fruit company . This was followed by the Puritan of the F. Laeisz shipping company . She also drove bananas, initially for Chiquita and later for Dole from South and Central America to the USA.

The fruit company Dole Food Company had four such ships for around 840 TEU refrigerated containers built at Fincantieri in Italy from 1988 to 1991 . They were measured at a length of 179 m, width of 27 m with 16,500 GRT and with a draft of 8.7 m had a load capacity of 11,800 dwt. They were driven by a slow-running two-stroke diesel engine and the rated speed was with the drive power of 15,200 kW 20 knots.

Barranca

The Barranca was the first of two ships of a special design that were only built for the transport of banana containers by the United Fruit Company between the Honduran port of Puerto Cortés and Galveston (Texas) in the United States . The sister ship was the identical Bayano .

Carmel Ecofresh

The Carmel Ecofresh was the first of two ships of a special design that were built for the combined transport of refrigerated cargo, containers and vehicles of the Agrexco between Haifa , Ashdod , Valencia , Genoa and Marseille . The sister ship was the structurally identical Carmel Bio-Top .

literature

- JT Critchel, J. Raymond: A History of the Frozen Meat Trade. Constable & Co., London 1912.

- HG Prager: F. Laeisz, from freighter to bulk carrier. Köhler Verlag, Herford 1971.

- H. Linde: For transporting refrigerated cargo in containers on board ships. In: Hansa. No. 24, 1971.

- A. Kludas, R. Witthohn: The German refrigerated ships. Köhler Verlag, Herford 1991.

- K.-H. High-rise: technical developments for reefer container ships. In: Ship & Harbor. No. 10, 1993.

- K.-H. High-rise: German refrigerated shipping. Hausschild Verlag, Bremen 1996.

- B. Renk: refrigerated container principle, operation and onshore service. Lecture on the STG consultation day.

- K.-H. High-rise: sea transport of refrigerated goods. Conference proceedings, published by TUHH 1997.

- K.-H. High-rise: cooling applications on ships. In: Textbook of refrigeration technology. Volume 2, CF Müller, Heidelberg 1997.

- NN: Reefer Shipping, Drewry Shipping Consultants 1999. London.

- K.-H. High-rise: MA / CA technology in transport. In: Fruit World International. No. 3, 2005.

- K.-H. Hochhaus, H. Glandien: Cool - Reefer technology with a future. Seehafen Verlag, Hamburg 2007, ISBN 978-3-87743-818-3 .

- Peter Dittrich: Working on reefer ships in the 1960s. About the change in cargo shipping . In: Men from Morgenstern , Heimatbund an Elbe and Weser estuary e. V. (Ed.): Niederdeutsches Heimatblatt . No. 818 . Nordsee-Zeitung GmbH, Bremerhaven February 2018, p. 1–2 ( digitized version [PDF; 8.7 MB ; accessed on July 5, 2019]).

Individual evidence

- ^ A. Keith Thompson: Fruit and Vegetables Harvesting, Handling and Storage. Blackwell Publishing, Oxford 2003, ISBN 1-4051-0619-0 , pp. 61-70.