Discovery of the Staßfurt potash deposit

This article deals with the potash shafts in Staßfurt in the Salzlandkreis in Saxony-Anhalt .

Preliminary remarks

In this article the shafts “vd Heydt” and “v. Manteuffel ”. They are considered to be the first potash shafts in the world. The Achenbach shaft, which was sunk later and connected to the pit field of these first two potash shafts, is described in the article Salt extraction on the Staßfurter Sattel .

The "success story" of potash extraction on the Staßfurt-Egelner-Rogensteinsattel is preceded by salt extraction in salt pans in the Staßfurt area - documented since the beginning of the 9th century.

The exploration work on the Salinehof

As is well known, the Staßfurt saltworks had been in Prussian ownership since 1797. In the endeavor of the saltworks administration to avoid the costly grading of the only about 17 percent natural brine , as well as in the firm, expert-supported conviction that here, as before with Jagstfeld , where a large rock salt deposit was proven by a deep drilling, rock salt would be stored in the subsurface, one step of drilling a deep hole directly on the Kokturhof of saline.

On April 23, 1839, a hole was drilled in the bottom of a 62 foot (about 19.5 m) deep well.

“[...] The drilling progressed very slowly with the imperfect means of the drilling technology at that time. As the depth progressed to 244 m, the brine content gradually rose to 21.9 pCt. NaCl increased; then suddenly, without any other changes being noticed during drilling, it showed a special. Weight of 1.205, which corresponds to a saturated saline solution. The first traces of rock salt were found in the drilling mud at 249.5 m ; from 259 m to 581 m one drilled in rock salt. "

After a total of 12 years, drilling was stopped on May 31, 1851 at a final depth of 581 m. To the general disappointment, the brine obtained contained "Epsom salts" and was therefore unsuitable for boiling operation. The chemical analysis of a deep sample showed the following composition:

4.01% sulphate of magnesia ( magnesium sulfate , MgSO 4 ), 19.43% magnesium chloride , 2.24% potassium chloride , 5.61% sodium chloride and 68.71% water at a density of the brine of 1.3 g / ml.

Considerations of damaging the area of the perforated Epsom salt layers in order to then brine only in pure rock salt had to be discarded due to the small diameter of the borehole.

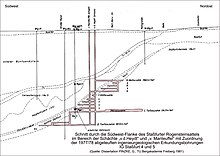

“[…] The final decision in a conference on November 20 and 21, 1851 in accordance with the memorandum of the secret Bergrath v. Carnall decided on the sinking company was placed under the overall direction of the mining authority in Halberstadt, in particular its director Küper, to which the Berggeschworne Oemler and the building inspector Redtel were referred to special management. The salt works administration, however, had to take care of the cash and billing matters. It was decided to go straight down with two shafts, of which one, which would serve as an art shaft , should always be driven a little ahead of the other so that the dead water could be fed to the former. For this purpose, a more frequent cross-cutting connection of the two shafts was planned, which were created by four cross-cuts at 40 m, 123 m, 182 m and 257 m according to the water outcrops. "

Sinking the shafts

The actual sinking of the vd Heydt shaft did not begin until December 15, 1851, due to a lack of suitable crews; Shaft v. Manteuffel was started on February 9, 1852.

"[...] St. Barbara is once our patron saint, and although under the circumstances I have been informed of, I will be back from you on the 4th of d. M. [= 4th of the month] could not receive a message, so on the occasion of a small celebration I asked our Minister to give the first shaft in Staßfurt his name . M. brought luck, after which he should be regarded as having started that day and given the name "Von der Heydt". "

The vd Heydt shaft was square ( clear width 11⅔ feet long and 8 feet; ergo approx. 3.7 m × 2.5 m), the v. Manteuffel shaft in a round cross-sectional shape ( clear width 8 feet and 8 inches; ergo approx. 2.70 m diameter).

First the vd Heydtschacht penetrated :

"[...] 4 laughs 28 inches [= approx. 9.10 m] heaped mountains and diluvial gravel [Diluvial gravel are Pleistocene sands / gravels from Ice Age ( Diluvium ) deposits], but from then on the various layers of the colorful sandstone group, under which a red, more or less solid slate of slate predominates, with individual sandy ones Layers, including banks of fine-grain sandstone, as well as rye stone or very solid gray limestone ( chert ). At these deposits, although not always clearly, the stratification of the mountains could be diminished, while in the slate mostly only an irregular bank division can be noticed, which is also darkened by the colorful (green, yellow and gray) stripes . Depending on the position of those intermediate layers, the dip varied between 33 and 42 degrees, with a westerly direction. "

Since it was planned to brick the shaft head, it was initially only boarded. From a depth of 8 laughs (= around 16.7 m), strong bolt-shot timber was used. The inflow of water was initially low and was lifted with the bucket. Later, when these rose to around 4.2 cubic feet per minute (= around 130 l / min), a

The natural ventilation of the shaft bottom extended to a depth of about 40 m. Thereafter, the supply of fresh weather over weather was required.

"[...] On April 22nd, 1854, the simple and direct acting above-ground water retention machine of 200 HP, built by FA Egells in Berlin, came . in operation, which since then has effected the dewatering for the entire old Staßfurt plant from the excavation level until it was stopped in autumn 1900 after 46 years of operation after the plant had become inevitable to drink. "

At a depth of 255.8 m, the first rock salt layers were reached under the previously drilled salt clay. This was [nothing other than the = later named after the Lord of Carnall of "mostly red Epsom salts" carnallite ] manually ausgeklaubt . The drilling of this layer lasted the whole of the 1st quarter of 1856 until "water-white pure rock salt" was finally reached.

The sinking of the v. Manteuffel-shaft - as a future " steam Göpel shaft be had in August 1852 initially set because, leaving salty waters from the deep well on which the shaft was so attached too much -" bulk exhibited. At a depth of 40.8 m, the first cross passage was driven from the vd Heydt shaft to the v. Manteuffel shaft to control the inflows from the pre-borehole from here. After quite extensive water lifting work, the shaft finally reached its preliminary final depth of 334 m in mid-February 1857 and was connected to the vd Heydt shaft by means of a cross passage. The rock salt store (here the “older rock salt”, interspersed with many anhydrite deposits, stood) was accessed through a cross passage facing east into the lying wall and a cross passage facing west into the hanging wall. This finally reached a length of 550 m in 1869.

The further sale of the shafts in 1880/81

From the years 1880 and 1881 it is reported: “In the mine field of the“ vd Heydt-Schacht ”, to expand the kainite mining - from the braking shaft between the X. and VII Kainite has already been won. "

Carnallite was mined on soles V and VI.

"[...] Due to the fact that both floors were soon to be broken down, the two shafts vd Heydt and v. Manteuffel tackled by 52 m. In the rock salt storage of the vd Heydt shaft, equipment and extraction work have been carried out. The production amounted to 40,950 tons of rock salt and 178,522 tons of potash salts (including 36,300 tons of kainite). The workforce of the salt works consisted of an average of 353 men, including 10 men for supervision; they fed 1313 relatives. "

The demonization work in both shafts was completed in 1881 without major problems. From this new 387 m level (II. Underground level, see section above), the main cross passage with counter-site operation was deflected by a simultaneously brought down die and driven into the lying area of the carnallite camp. The workforce was now 868 plus 10 supervisors. 56,821 tons of rock salt and 267,308 tons of potash (including 80,624 tons of kainite) were extracted.

The following is a summary of the depths reached when the von der Heydt / von Manteuffel shafts were brought down , divided into annual disks:

| end of the year | Shaft vd Heydt | Shaft v. Manteuffel " |

|---|---|---|

| Manhole profiles | Shaft cross-section 3.66 × 2.51 m, corresponds to 9.19 m 2 | Shaft cross-section 2.72 × 2.72 m, corresponds to 7.40 m 2 |

| Late 1852 | 31 laughers = 64.86 m | 16 laughs 15 inches = 33.87 m |

| Late 1853 | 57 laughers = 119.27 m | 19 laughs 25 inches = 40.41 m |

| Late 1854 | 96 ⅜ laughers = 201.66 m | 36 laughers = 75.33 m |

| Late 1855 | 122 ⅜ laughers = 256.06 m | 102 ⅝ laughers = 214.73 m |

| Late 1856 | 162 laughs = 338.97 m | 151 ⅝ laughers = 317.26 m |

| Late 1880 | Further sold by 52 m | Further sold by 52 m |

| Remarks: Both shafts were placed at a distance of 10 lights (= approx. 21 m) from one another and connected to one another by 5 cross passages. So in the depths 19½ Lr., 58⅞ Lr., 87⅞ Lr., 122½ Lr. and 160 Lr. (= Laughing). | Explanations: At that time, the following applied in Prussia: 1 Lachter = 2.0924 m and 1 inch = 2.6155 cm of today's dimensions. |

The start of salt production in 1857

In mid-February 1857, the sinking team of the future Manteuffel mine shaft also had the depth of 160 puddles planned for the extraction of rock salt to enrich the brine of the Staßfurt saltworks , which was previously planned for the so-called von der Heydt art shaft (primarily used for driving , material transport, water management, etc.) (1st level, 334 m level) reached. The construction and installation of the salt deposit began quickly .

About this is noted in the official report of the Prussian mining administration for the year 1857:

"[...] 1. West of the Manteuffel Schacht you directly in the footwall of Epsom salts [that are later to be extremely valuable estimated, but for the time being to stockpile dumped potash] highly contaminated waste salts on the overhanging rock salt Bank Underlining deflected to the north and south namely in the former a 23 ½ ltr. [= laughing], in the latter 22 ¼ ltr .; However, towards the end of the year, these routes were closed again due to the heavy contamination of the rock salt with bitter salts.

2. In order to establish a second connection between the eastern mines and the Manteuffel shaft for the purpose of facilitating extraction, the ad. 1st listed northern trending distance from at 10 Ltrn. Length of the same one queer stroke to the east, set in the lying position and in the month of December up to 3 ¾ liters. Length carried away.

3. The queer strike into the lying east of the Vonderheydtschachte, which began in 1856, was used for further investigation of the deposit and for closer exploration of the former with the borehole at 202 liters. Depth of pure rock salt layers drilled up to 38 ⅞ liters. Length continued. The same will have a length of approx. 60 liters up to the same. reach and is in the crystalline rock salt more or less permeated by thin gypsum strings.

4. In 20 Ltrn. to the east of the Vonderheydtschachte there are 2 striking mining sites of 3 liters to the south and north. Width and height and from the same 4 queer spaces set in such a way that 4 liter strong rock salt pillars remain between them and a chessboard-like dismantling is initiated. "

Employees and things

The Prussian mining administration published annually, among other things, the minerals extracted in their mines, the number of employees there and their earnings. Here are some selected works:

The workforce at the plant vd Heydt / v. At the end of 1852 Manteuffel had 38 workers, 12 sinkers and 26 miners and day laborers . At the time of the increased water inflow (in June 1852) 63 men were also employed to operate the hand pumps. The shift time was 8 hours; 2 risers were used to supervise the work . The following is noted for the remuneration of the miners when they sink the vd Heydt shaft :

"[...] The first 4 ½ Lachter were drilled in layer Lohne, but then verdungen work. The Gedinge für das Lachter [= 2.0924 m] came from an initial 56 thalers. [= Thalers ] to 92, lastly to 95 thalers , including carpentry and pumping work, the average for the laughing at wages is 122 thalers. and for materials 63 thalers. 8 Sgr. [= Silver groschen ], altogether 185 thalers. 8 Sgr. issued. "

For the remuneration of the miners when sinking the shaft v. Manteuffel is noted:

"[...] The Lachter Abteufen averaged 79 Thlr in wages. 8 Sgr. 2 Pf. [= Pfennig] and materials (mainly room wood) to 76 thalers. 10 Sgr. 5 Pf., Together to 155 thalers. 18 Sgr. 7 Pf. "

The following is a summary of the manpower and resources required to bring down the von der Heydt / von Manteuffel shafts , divided into annual disks:

| End of year | Shaft vd Heydt | Shaft v. Manteuffel " | Total workers |

|---|---|---|---|

| Late 1852 | Wages: 122 thalers. (= Thaler). Material: 63 thalers. 8 Sgr. (= Silver groschen), altogether 185 thalers. 8 Sgr. | Wages: 79 thalers. 8 Sgr. 2 pfennigs (= pfennig), together 155 thalers. 18 Sgr. 7 Pf. Material: 76 Thlr. 10 Sgr. 5 Pf., All together 155 thalers. 18 Sgr. 7 Pf. | 76 men + 2 climbers; in addition up to 63 water pumps in June. |

| Late 1853 | Wages or goods : 140 thalers, additional Abteuf bonuses. Material: 238 thalers. | Wages or goods: 163 thalers. Material: 163 thalers. | I.a. 12 tusks; total shifts a. 8 hours: 4739. |

| Late 1854 | Wages or things: 55–85 thalers, additional Abteuf bonuses. Material: no information. | Wages or goods: 40–50 thalers. Material: no information. | Initially 52 men + 2 climbers; Up to 85 men were lining the shaft. |

| Late 1855 | Wages or things: 165–310 thalers, additional Abteuf bonuses. Material: no information. | Wages or goods: 40–265 thalers. Material: no information. | Initially 80 men + 2 climbers + 2 machine operators, later a total of 106 employees. |

| Late 1856 | Wages or things: 125–300 thalers, additional Abteuf bonuses. Material: no information. | Wages or goods: 120–250 thalers. Material: no information. | A total of 144 men, including 30 tusks, 2 foremen, 1 foreman, 7 machine operators. |

| 1880/81 | Further sold by 52 m | Further sold by 52 m |

|

| Remarks: wages, things, materials etc .: all information related to 1 laughing abyss progress. |

The closure of both shafts

In the neighboring ducal Anhalt salt mine Leopoldshall - the safety pillar between these two mines was only 28 m in the depth range 260–270 m - the first supporting pillars broke in 1879; later followed in 1881. This initially resulted in increased water inflows into the Leopoldshaller mine works. Despite various measures taken by the Prussian mine administration to prevent these water and salt solutions from entering their mine buildings, they broke through the separating anhydrite complex. The Prussian mine building also began to drown. Ultimately, on October 9, 1900, the dewatering was finally stopped here.

Today these shafts are filled and in 1994 they were covered with concrete covers. The administration of the city of Staßfurt has redesigned the area into a "potash garden" and keeps the memory of the first two potash shafts in the world alive through a variety of signs.

| Brief chronology of the von der Heydt / von Manteuffel mine . |

|---|

| 1839: Start of drilling work on the Salinehof in Staßfurt to sink a borehole to extract brine. |

| 1851: Cessation of drilling work at a depth of 581 m in rock salt. |

| 1851: On December 4th: naming of the vd Heydt art shaft on the salt works; Start of sinking: December 15, 1851. |

| 1852: On January 31: naming of the v. Manteuffel production shaft on the above-mentioned borehole; Start of sinking: February 9, 1852. |

| 1856: During the sinking work in the vd Heydt shaft, carnallite (then still overburden salt) of the Staßfurt potash seam is approached at a depth of approx. 256 m . Application of the first excavation level at 334 m depth. |

| 1857: Start of the extraction of Staßfurt rock salt from 334 m depth from both shafts. |

| 1859: Beginning of sinking the Bodelschwingh shaft (Calbesche Strasse) to expand the mining area of the von der Heydt and von Manteuffel mine . The work had to be stopped due to technical difficulties at a depth of approx. 10–12 m. |

| 1860: In March of the year mining exploitation of the Staßfurt potash seam and the first beginnings of carnallite extraction and extraction. |

| 1861: Carnallite production starts at the Royal Prussian Salt Mine in Staßfurt. |

| 1866: Beginning of sinking the Emmerson shaft (Häuerstraße) to expand the excavation area of the mine. The project had to be abandoned in 1867 due to strong tributaries at a depth of 16 m. |

| 1872: Beginning of sinking the Köppen shaft (on the Löderburger Bahn) also to expand the mining area. For the first time, a shaft tube is to be sunk in a circular shape. Due to strong water inflows, the work had to be stopped at a depth of 46 m. |

| 1877: In this year the Achenbach shaft broke through at a depth of 338 m with the vd Heydt shaft driven cross passage. |

| 1880: Surface subsidence above the mine field of the Royal Prussian Salt Mine in the center of the city of Staßfurt. |

| 1880/1881: Extension of both shafts by 52 m. |

| 1893: End of funding in the v. Manteuffel shaft. The vd Heydt shaft is used as a weather and water drainage shaft. |

| 1895: Start of sinking the Brefeld mine near Tarthun to cover the kainite requirement of the Royal Prussian Salt Mine in Staßfurt ( vd Heydt / v. Manteuffel / Achenbach supplies exhausted. Newly built Berlepsch-Maybach mine so far without kainite find). |

| 1900: In May, the first lye transfers into the vdHeydt / v mine field . Manteuffel from the neighboring Leopoldshall mine. |

Individual evidence

- ↑ Kokturhof: old name for a Salinenhof; from Latin coctura : cooking

- ↑ Johannes Westphal: History of the Royal Salt Works in Staßfurt, taking into account the general development of the potash industry . Memorandum on the occasion of the 50th anniversary of the Staßfurt salt mining (= journal for mining, metallurgy and saltworks in the Prussian state . No. 50 ). 1902, B. Treatises, p. 11 .

- ^ Sulfuric acid magnesia. In: zeno.org. Retrieved July 1, 2016 .

- ^ A b Johannes Westphal: History of the Royal Salt Works in Staßfurt, taking into account the general development of the potash industry . Memorandum on the occasion of the 50th anniversary of the Staßfurt salt mining (= journal for the mining , metallurgy and saltworks in the Prussian state . No. 50 ). 1902, B. Treatises, p. 13 .

- ↑ From a letter from Mr. von Carnalls of December 8, 1851 to the Berggeschworen Oemler In: Johannes Westphal: History of the Royal Salt Works in Staßfurt, taking into account the general development of the potash industry. Memorandum on the occasion of the 50th anniversary of the Staßfurt salt mining industry. In: Journal for the mountain, - iron and salt works in the Prussian state. 50, 1902, B. Treatises., P. 13.

- ↑ de.academic.ru

- ↑ a b c d The sinking of the rock salt shafts at Staßfurt in 1852. In: R. von Carnall (Hrsg.): Journal for the mining, metallurgy and saltworks in the Prussian state. First volume. Verlag von Wilhelm Hertz, Berlin 1854, p. 200.

- ↑ zeno.org

- ^ Journal of mining, metallurgy and saltworks in the Prussian state. Twenty-ninth volume. Verlag von Ernst and Korn, Berlin 1881, p. 202.

- ↑ a b Journal for the mining, metallurgy and saltworks in the Prussian state. Thirtieth volume. Verlag von Ernst and Korn, Berlin 1882, p. 199.

- ↑ Rock salt mining . In: Rudolf von Carnall (Hrsg.): Journal for the mining, metallurgy and saltworks in the Prussian state . Sixth volume. Wilhelm Hertz, Berlin 1858, p. 255 ( Google Books [accessed February 12, 2016]).

literature

- E. Baumecker: Leopoldshall 1901 . Its origin, development and meaning; Report of the Chamber of Commerce in Dessau. In: Germany's potash industry . Verlag der Fachzeitung-Industrie, Berlin, p. W 9 .

- Bruno Baumert: About caustic and water inflows in German potash mining . Ed .: Technical University of Aachen. Printed by Gebr. Gerstenberg, Hildesheim 1927 (dissertation).

- E. Beichardt: The salt mine in Staßfurt near Magdeburg (= Nova Acta of the Kaiserlich Leopoldinisch-Carolischen German Academy of Natural Scientists . No. 27 ). Hall 1860.

- Bergmannsverein Staßfurt, cradle of potash mining eV (Ed.): History of the Staßfurt salt mining and the Staßfurt potash industry in the period from 1952 to 2002 . Staßfurt 2002.

- F. Bischof: The rock salt works near Staßfurt . 2nd Edition. Pfeffer, Halle 1875 ( gbv.de [PDF; accessed on October 27, 2015]).

- Staßfurt 2010 - Recognize, analyze, evaluate and forecast the future development of post-mining damage . In: Johannes Gerardi (Hrsg.): Final conference of the joint research project dynamics of flooded or flooded salt mines and their overburden levels (= EDDG excursion guide and publications of the German Society for Geosciences ). No. 244 ( gbv.de [PDF; accessed October 27, 2015] proceedings).

- Dietrich Hoffmann: Eleven decades of German potash mining . Essen 1972.

- Ernst Loock: Disused shafts - a problem of the potash industry (= Freiberg research books . A 136). Academy, Berlin 1960.

- Maenicke: Water ingress in potash mining (= Potash . 12th year, no. 6 ).

- Günter Pinzke: Hydrogeochemical interpretation of mineral stratified water from engineering geological exploratory boreholes in the urban area of Staßfurt . Expert opinion, Council of the District of Schwerin, Geology Department, 1979. Archives of the State Office for Geology and Mining (LAGB) of the State of Saxony-Anhalt.

- Günter Pinzke: A contribution to the assessment of mining damage of disused potash and rock salt mines . Freiberg 1981 (dissertation, Bergakademie Freiberg, Geotechnical and Mining Section).

- Johannes Westphal: History of the royal salt works to Staßfurt taking into account the general development of the potash industry . Memorandum on the occasion of the 50th anniversary of the Staßfurt salt mining (= journal for the mining , metallurgy and saltworks in the Prussian state . No. 50 ). 1902, B. Treatises.

Coordinates: 51 ° 51 ′ 10.3 " N , 11 ° 34 ′ 58.3" E