Potash works union Johannashall

| Potash works "Union Johannashall" | |||

|---|---|---|---|

| General information about the mine | |||

| other names | Kurt Schacht Schacht Johannashall |

||

| Information about the mining company | |||

| Start of operation | 1902 | ||

| End of operation | 1922 | ||

| Successor use | no | ||

| Funded raw materials | |||

| Degradation of | |||

| Mightiness | up to approx. 20 m | ||

| Greatest depth | 542 m | ||

| Geographical location | |||

| Coordinates | 51 ° 34 ′ 19 ″ N , 11 ° 46 ′ 15 ″ E | ||

|

|||

| Location | Trebitz b. Toilet sweat | ||

| local community | Salzatal | ||

| District ( NUTS3 ) | Saalekreis | ||

| country | State of Saxony-Anhalt | ||

| Country | Germany | ||

| District | Saale-Unstrut | ||

The Johannashall potash mine of the union of the same name was a mine for potash salts with an attached fertilizer factory approx. 700 m south of the village of Trebitz in Saxony-Anhalt ( Saalekreis ). This pit is located on the northeast edge of the Mansfeld Mulde. Due to the proximity of the edge of the basin, the effects of salt leaching near the edge became noticeable in the vicinity of the pit fields (e.g. locally missing saline from Zechstein 4 and 3). Due to the influence of the marginal disturbances of the Halle porphyry area , the storage conditions of the salinar on Johannashall are very complicated. The “Staßfurt” potash seam was mined mainly in carnallitic facies , and to a lesser extent also hard salt .

In connection with the end of the German potash monopoly after the First World War and the endeavor to fundamentally reorganize and rationalize the potash industry, which was reflected in the so-called decommissioning ordinance of July 18, 1919 , operations ceased in 1922 541.45 m); Shaft diameter 5.50 m; open pit cavities: approx. 100,000 m³.

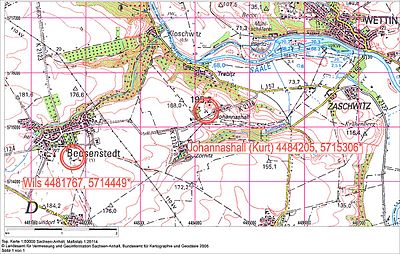

A breakthrough contract was signed with the neighboring Wils union to meet a second shaft required by the mining authorities . The "Wils Union" had built a shaft near the Beesenstedt train station, which was finished at the end of 1911. The breakthrough in both pit fields took place in February 1912.

Geological and hydrogeological deposit conditions of the Johannashall mine

Geological and reservoir economic situation

The Johannashall mine is located in the northeast part of the Mansfeld Mulde. Against the presalinary layers of the Hallesches Mulde (Rotliegende and Porphyre) in the east and the Halle-Hettstedter mountain bridge in the north, the Mansfeld Mulde stands out relatively steeply. The leaching of the Zechstein from the point of departure towards the interior of the hollow is quite advanced in this area - due to the steep incline of these layers. The salt level is on the northern edge of the Mansfeld Mulde at around −190 m above sea level; he was u. a. proven with the Zaschwitz borehole ( brine source ). In addition to leaching , tectonic processes led to severe disturbances in the Zechstein deposits in this area. The general stroke of the Salinar runs almost parallel to the axis of the Mansfeld Mulde (SE-NW), but the undulating course of the trough and saddle lines leads to the formation of irregular crests and depressions. In addition, rigid horizons (such as main anhydrite ) have been separated out due to flow tectonics and salt accumulation , so that the geological conditions in the area of the mine are relatively complicated. The intensity of the faults increases after the edge of the basin due to the porphyry abutment there, so that the Zechstein in the Johannashall mine to the north was more heavily influenced by tectonics than on the neighboring Wils mine to the west. In the vicinity of both shafts there are a large number of OT boreholes, the evaluation of which allows a very detailed picture of the local geological structures.

Geological conditions of the mine

Eight deep boreholes were drilled by the “Bohrgesellschaft Johanna” in the eastern field of the Mansfeld Mulde . Rock salt was drilled at depths of 415 m to 646 m, carnallite at depths of 427 m to 655 m and thicknesses of 5 m to 20 m. The Johannashall shaft itself is located within a distribution area of Sangerhauser Anhydrite , a facial representation of the potash deposit Flöz “Staßfurt”. There were outcrops in the mine field from Zechstein 4 (red salt clay) to Zechstein 2 (Staßfurt rock salt ). Apart from areas with local disturbances, in which in particular red and gray salt clays and main anhydrite with large fluctuations in thickness occur, the other horizons are in the thicknesses typical for the Mansfeld Mulde and in normal formation. The “Staßfurt” potash deposit is tectonically very badly disturbed. With a thickness that is worth building , it occurs primarily in areas of local compression and folds. A distinction must be made between the following occurrences:

a) Normal storage of the potash seam between gray salt clay and Staßfurt rock salt.

b) Storage of the potash seam within the Staßfurtstein salt.

c) Storage of the potash seam between flax rock salt and Staßfurt rock salt.

Petrographically, the potash store consists of anhydrite carnallite halite with little kieserite . It was mostly in the form of recrystallized, conglomerate, dirty-brown to brick-red carnallitite; stratified carnallitite was completely absent. K 2 O and kieserite content showed an increasing tendency towards the hanging wall; the kieserite content was lower than in the other outcrops of the Mansfeld Mulde. Occurrences of hard salt have been observed in the east and south-east field in the hanging wall of the camp. Petrographically, it was a clayey-anhydritic sylvine halite with a dirty red-brown color, which mainly appeared in the form of nests or lumps. The various authors have different information about the thickness and the K 2 O content of the deposit:

According to LÖFFLER, the carnallitite reached thicknesses of up to 17 m, the hard salt up to 2 m. The K 2 O content of the hard salt is said to have averaged 8.8%. In a later reassessment of the potash plant, a potash store of varying thickness with a K 2 O content of 7 to 12% was mentioned.

Due to the influence of the tectonics, the Johannashall mine has very "tangled / undulating" storage conditions. Particularly noteworthy is the eastern field, in which larger overthrusts in the salt deposit were exposed. Initially, blocks of rock salt appeared above the potash store, which then joined together to form a blanket up to 20 m thick. The shaft itself stood in the north wing of a wide salt saddle. Further to the north there is a wide basin, the axis of which gradually rises to the east of the shaft. The potash store disappears to the north. It was found in small hollows and special saddles up to around 200 m from the shaft. In a westerly direction, only a flat section was driven to the northern fault in the potash store. To the east of the shaft, the potash deposit only reached minable thicknesses in the depths of the trough. The saddle rises very high towards the south and reaches its greatest height in the south-east cross passage.

According to MÜLLER, the potash store on the saddle ridge has probably been removed. In general, the southern leg of the saddle is flatter than the northern, and the saddle flattens out more and more towards the southeast. The potash store is almost at the bottom here. MÜLLER characterizes this deposit as a potash deposit that gradually lifts out from south to north, which has been intensively folded in the northern and western parts and rolled out by three large folds, but is dammed again in another place.

Hydrogeological conditions of the mine

The hydrogeological conditions of the area are influenced to a certain extent by the leaching around the northeast edge of the Mansfeld Mulde in the area of the outflow of the Zechstein. This applies in particular to the area north and west of the Johannashall mine. In the areas where salt leaching occurs, there are only seldom usable water resources. Most of the time the hanging wall is largely drained, while the lying wall is more or less salty, or depending on the level of leaching, only water with a high degree of hardness occurs. The middle red sandstone appears as the main aquifer. The main part of the Johannashall mine field is in its area of distribution. The Upper Buntsandstein shows only little water flow, mainly bound to the Lower Röt. The waters are characterized by high carbonate hardness . It is also worth mentioning water resources in Quaternary fluvial formations, for example northwest of the Wils mine or southeast of the Johannashall mine. However, due to the small spatial extent of these deposits and their small catchment areas, they are only of local importance. Detailed hydrogeological documents are not available from the areas of the Johannashall mine or the neighboring Wils mine, so that information on the depth and course of water-bearing horizons, as well as information on the chemistry of the water, cannot be given.

Shaft sinking / shaft lining

After purchasing an area of 67 acres in the municipality of Trebitz, on the left bank of the Saale , opposite the town of Wettin, on October 25, 1899, the sinking of the Johannashall shaft, also known as the Kurt shaft, began. In mid-March 1900, a depth of 82 m had been reached without any particular difficulties. In July 1900 the depth of 91.55 m was reached with great effort as a result of the strongly increasing water inflows from the sandstone.

The shaft project already planned to use the short distance from the shaft to the Saale waterway to create a tunnel connection - the “Trebitzer tunnel” (also known as the “Henrietten tunnel” ). On this, both the considerable water inflows from the red sandstone should be drained to the Saale without the use of pumps and this route should also be used for transport purposes (material and shipping). So they waited until the tunnel that was set up from the hall level would reach the Kurt shaft. This tunnel also ended at the shaft after about 720 m at the end of 1900 ( tunnel bottom at shaft depth 91 m). The further sinking began on January 7, 1901. Despite inflows of up to 7 m 3 / min, the depth of 110.25 m was almost effortlessly reached in order to set the foot of the wall here. At the beginning of March, the shaft area was covered with masonry up to the surface. The further promotion by handicraft was normal. A second foot of the wall was set at a depth of 155.20 m; a third at depth 417.5 m. The sinking to the final depth of 541.45 m (in rock salt) also proceeded without any special incidents. This part was also lined with masonry (shaft diameter 5.50 m clear width). At the end of September 1903, that is, after less than three years, the Johannashall shaft was ready for the further development of the deposit to begin.

The last visit to the Trebitzer tunnel took place in August 1942. At that time it was still passable up to a length of approx. 250 m, after which it was broken . There are no precise documents about the exact course of the tunnel. According to recent research, it can be assumed that the tunnel runs almost in a straight line between the Johannashall shaft and the exit of the tunnel near the hall (see upper left figure).

A communication from the Technical Inspection Mining Hall from June 18, 1957 shows that the studs to about 150 to 200 m (middle part) in masonry stands and is still well preserved. The mentioned collapse of the tunnel (350 m from the mouth hole) is said to be in a section with a door frame. This break in the tunnel is stated in the mine book at about 250 m from the mouth hole (August 28, 1942). However, the inflowing water continued to flow into the Saale through the pile. In 1970 the tunnel mouth hole was bricked up and provided with drainage pipes. The discharge volumes were not recorded. Since the plumbing of the shaft water level in 1955 was significantly above the tunnel level, it can be assumed that the tunnel has since broken down completely.

These are the last current photos from 1999 [KLUGE, JOHANNES]:

Removal and installation, dismantling and relocation processes

The mining field of the "Johannashall" shaft

The mining field can be divided into three closed assemblies, which are connected to each other by routes for driving , conveying and weather management . A z. The route system, some of which has branched out, served to explore the very complicated conditions of the deposits. The shaft had a rectangular shaft safety pillar that was cut through by several stretches in a radial pattern. Only a small number of mining chambers have been created in the route system. The longitudinal axes of the chambers run roughly north-south. One assembly, northeast of the shaft, consists of four mines with an area of approx. 60 × 100 m; Another assembly is located about north of the shaft, the size of which is about 120 × 150 m. The breakthrough with the route system of the Wils mine took place in February 1912. The very complicated conditions of the deposits affected the way both pits were dismantled . Different methods of raw salt extraction were probably used - due to the fluctuations in thickness.

In November 1940, Wintershall AG / Kassel informed the former Halle Oberbergamt in an overview of the type of mining at the Johannashall mine:

- Type of salt: Carnallite and hard salt, K 2 O content: 7–9%.

- Thickness of the potash deposit: up to 20 m.

Construction field depths:

- Ostfeld: −375 m to −412 m above sea level.

- Southeast field: −365 m to −385 m above sea level.

- Southwest field: −373 m to −412 m above sea level.

- Mined thickness: full deposit height or maximum construction height 9 m.

- Type of extraction: Chamber construction .

Dimensions of the chambers:

- Ostfeld: 30–50 m long, 10 m wide.

- South-east field: 60–70 m long, 10 m wide.

- Southwest field: 100 m long, 10 m wide.

Remnants were isolated up to a width of 20 m.

- Pillar thickness between the chambers = 7 m, to the sections = 7 m (at least).

- Number of cuts between the chambers: 3 m wide cuts at a distance of 30–50 m.

- Breakdown losses : 40 to 45%.

Information on the offset

Offset type: dry offset , complete or incomplete offset. Backfill material: rock salt from the alignment and fixture lines and small amounts of residues from the potash factory.

Due to the special permit granted by the Halle Oberbergamt on April 11, 1922, the excavation cavities that were still open in the Johannashall shaft could not be offset.

Unmoved cavities:

- I. West field: 13 chambers (width: 10 m; height: 2–6 m), cavity 23,900 m 3 .

- II. Ostfeld: 15 chambers (width: 10 m; height: 3–9 m, max. Height = 11 m (1 ×)), cavity 33,205 m 3 .

- III. South field: 16 chambers (width: 10 m; height: 2–8 m), cavity 27,100 m 3 .

Total : 84,205 m 3

The financial and business situation

Founding: As Kalibohrgesellschaft Johanna 1897, as union Johannashall on August 18, 1899, entered in the commercial register of the Halle / Saale district court on November 6, 1903. Number of Kuxe : 1000.

Legal : 14 fields = 30,505,814 m 2 . Consolidation under the name " Potash Mine Johannashall" in the districts of Beesenstedt, Naundorf, Schwittersdorf, Dederstedt, Zörnitz, Fienstedt, Wils, Gödewitz, Pfütztal, Gorslegen, Schochwitz, Trebitz, Rumpin, Kloschwitz and Zaschwitz, with the fields of the "Wils Union" , the fields of the "Schutzbohrgemeinschaft", the "Kaliwerke Krügershall", the Prussian treasury and the Mansfeld trade union. Seven of the fields, namely "Johanna I and II", "Else I and II" and "Johannashall I, XIII and XIV" with a total of 15,189,490 m 2 were already one on October 27, 1934 under the name "Johannashall" unified mine has been consolidated (see figure above right). In addition to the potash fields , the Johannashall union owned three ore fields (copper slate).

Potash Syndicate : Since November 1st, 1903, the Johannashall union has belonged to the syndicate. Initially, she was only allowed to participate in Groups I, II and IV. Later, after encountering the hard salt deposit, but also for group III. The investments: initially together with the Wils mine 16.34 thousandths, from January 1, 1925 3.3447, then on December 31, 1926 3.2433, on December 31, 1927 3.2083 and finally from October 1, 1932 3, 1438 thousandths.

The chronology of the company's development (excerpts from the years 1907–1914)

For 1907: Board of Directors: Privy Councilor A. Thoene, Halle / Saale (chairman). Kommerzienrat A. Lucas, Berlin. Management: Director Hugo Honigmann and Dr. H. Stauch, Johannashall. Production: in 1905: 76,303 dz K 2 O. Quay near Wettin with “1,000 horse hydroelectric power plant (turbines) for generating electrical operating power”. Operator : Obersteiger Gerhard Kloster, Johannashall. Average number of workers: approx. 250 men.

- For 1908: Management: as before. Production: in 1906: 77,385 dz K 2 O.

- For 1909: Management: as before. Production: not specified.

- For 1910: Management: as before. Production: in 1908: 73,087 dz K 2 O. Average number of workers: approx. 320 men.

- For 1911: Management: as before. Production: in 1909: 66,813 dz K 2 O. Average number of workers: approx. 120 men.

- For 1912: Management: as before. Production: not specified. Average number of workers: approx. 120 men.

- For 1913: Management: as before. Production: not specified. Average number of workers: approx. 210 men.

- For 1914: Management: as before. Production: not specified. Average number of workers: approx. 235 men.

The Johannashall potash factory

The construction of a chlorinated potassium factory began on July 15, 1903 and ended in April 1904. It was designed for a processing capacity of 5,000 quintals of potash salt. It was followed by a kieserite extraction and sulphate plant. The archive material transmitted on the manufacturing processes is very sparse. Here are some sales figures:

Paragraph K 2 O: 1911: 70.359 dec. 1912: 70.350 dec. 1913: 55.762 dec. 1914: 46.464 dec. 1915: 30.427 dec. 1916 : 32.246 dec . 1917: 25.278 dec. 1918: 31.532 dec. 1919: 30.662 dec. The later sales figures were included in the overall sales of the Wintershall Group.

Closure of the Johannashall mine

After the First World War and the "loss" of the Alsatian potash mines, the German potash monopoly was broken. In order to curb the overproduction of potash salts, on October 22, 1921, the Reichstag issued the “ Ordinance on the Amendment of the Regulations of the Law on the Regulation of the Potash Industry ” of July 18, 1919, briefly referred to as the “ Decommissioning Ordinance ”. With this ordinance, the potash plant operators were offered to voluntarily shut down less profitable plants by the end of December 31, 1953. The participation number previously granted to such works, the so-called sales quota, could be transferred (read: sold) to other works. At the request of the “Johannashall union”, the potash testing office granted the union a participation rate of 70% of the average participation of all plants in 1922. A later union meeting on September 20, 1926 decided to liquidate the union itself and to sell its entire assets to "Kali-Industrie A.-G." (later Wintershall AG). In exchange, Kali-Industrie A.-G. the trades per Kux nom. 600 RM Potash Industry Shares (effective December 13, 1927).

Further information / data on decommissioning: October 10, 1922: Equipment in the old and new south field and in the north and east field expanded. October 8, 1923: The sump pump was removed, the wall was pulled to secure the shaft, a flipper installed to divert the water from the eaves into the eastern field. November 5, 1923: Two men fatally injured while removing the shaft cable. March 3, 1924: Removal of the pit rails and the final caustic line from the Trebitz tunnel. April 7, 1924: underground dismantling work finished. November 12, 1924: Drinking water supply from the Trebitz tunnel abandoned, instead a new borehole was sunk between the porter's building and the laboratory building (91 m deep). October 23, 1924: Dismantling of the hoisting machine, demolition of the shaft building and the boiler house. Shaft wall bricked up to 1.30 m above the soil level. September 5, 1925: The shaft is covered, all the company buildings are demolished. Johannashall shaft was built over with a pump house for the purpose of water extraction.

Current condition (status 2004)

After the transfer of the entire assets to Wintershall AG, shaft maintenance and controls were also carried out by Wintershall AG from this point in time. From 1945 and with the exception of the period from January 1, 1952 to August 1, 1953 - during this time the "Geological Commission in Berlin" was responsible for the shafts - VEB Kaliwerk "Deutschland", KSB "Saale", was responsible for maintenance and control of the manhole cover / overbuilding. Since the issue of the " safekeeping order of the GDR " of October 10, 1971 (GDR-GBl. II No. 73), the council of the Halle district has been responsible for a large number of old potash pits , so-called " pits of old mining without legal successors ".

With the accession of the GDR to the area of application of the Basic Law , the Johannashall mine was considered to be a "decommissioned facility of a mining operation for which a legal successor does not exist or can no longer be determined" . In place of the councils of the districts, the respective state governments acted until the relevant regulatory authority regulations were issued (for the state of Saxony-Anhalt : Law on Public Safety and Order of the State of Saxony-Anhalt (SOG LSA) in the version published on 23 September 2003 ( GVBl. LSA p. 214), last amended on May 18, 2010 (GVBl. LSA p. 340)). Thus, up to now, this shaft system is the responsibility of the municipality with regard to the duty of care for the purpose of averting danger.

These and many other potash and rock salt mines that were closed at the time require continuous monitoring.

swell

- FUCHS, GÖTZE, BAUER and KIESEWETTER: Analysis of mining damage for the shafts "Johannashall" near Kloschwitz, Saalkreis, "Wils" near Beesenstedt, Saalkreis, in the district of Halle, Teutschenthal, in September 1971, archive of the LAGB Saxony-Anhalt.

- KLUGE, JOHANNES: Mining historical documents and photos, private collection.

- O.V .: Yearbooks of the German lignite, hard coal and potash industry, Wilhelm Knapp's publishing house in Halle / Saale.

- MOSSNER, J. (editor): Handbook of the potash mines, salt pans and deep drilling companies, Finanz-Verlag Berlin, 1936.

- MÜLLER, E .: The salt deposit on the northeastern edge of the Mansfelder Mulde in the outcrops of the Johannashall, Wils and Salzmünde potash works. "Kali" magazine 23 (1929).

- PINZKE, G .: Expertise on the assessment of the mining and public safety of selected potash pits without legal successors on the territory of the Halle district. Expert opinion, Council of the District of Schwerin, Department of Geology 1979, archive of the LAGB Saxony-Anhalt.

literature

- BLEI, JUNG: About the anomalous Zechstein profiles in the area of the Mansfeld Mulde. Freiberg Research Booklet C 133, Bergakademie Freiberg, 1962.

- LÖFFLER: The potash and rock salt deposits of the Zechstein in the GDR, Part III Saxony-Anhalt. Freiberg research booklet C 97 / III, Bergakademie Freiberg, 1962.

- v. HOYNINGEN: Salt tectonics and leaching in the area of the Mansfeld Lakes. Freiberg research booklet C 56, Bergakademie Freiberg, 1959.