Ammeter

An ammeter , also known as an ammeter , colloquially as an ammeter and in English for short as an ammeter , is a measuring device for measuring the strength of the electrical current . It belongs to the field of electrical measurement technology .

During the measurement, the measured variable is converted into a display of its multiple of the unit amperes . For laboratory, service and field use, there are switchable multiple measuring devices with several measuring ranges , called multimeters . There are displayless measuring devices for industrial applications .

use

To measure the current, the current to be measured must flow through the measuring device. It is therefore connected in series with the consumer . To do this, it must be permanently installed. To install or remove the ammeter, the circuit must be switched off and disconnected: The measurement requires an intervention in the circuit to be examined and an interruption of the current flow during this time. If necessary, a “bypass” can be set up to divert the current around the point to be separated.

There are several ways to avoid this disconnection of the circuit:

- If there is a known ohmic resistance in the circuit, you can measure the voltage across the resistance with a voltmeter and calculate the current accordingly .

- If a single current-carrying line (no cable with forward and return conductors) is accessible, a measuring device is used that records the magnetic field caused by the current flow ( clip-on ammeter , Rogowski coil ).

- To measure direct current (e.g. in measuring transducers with a standard signal ) it is allowed to flow continuously through a diode. An ammeter can be clamped parallel to the diode for testing purposes. If the terminal voltage of the ammeter remains below about 200 mV (i.e. safely below the forward voltage of the silicon diode), the current will only flow through the measuring device.

Embodiments

Digital devices

Digital current measuring devices are the usual measuring devices in practical operation and belong to the field of digital measuring technology . In principle, they are voltage measuring devices that measure the voltage drop across a built-in or external measuring resistor , also known as a shunt , in accordance with Ohm's law . The functions of the digital current measuring device, voltage measuring device and resistance measuring device are often combined into a digital multimeter . The specific function is usually selected by the user using a rotary switch attached to the device .

In addition, there are designs for use in control centers and equipment rooms, which are permanently installed in switchboards (panels) and serve as displays for the control and operating personnel. These so-called built-in ammeters are configured once during assembly with a shunt suitable for the measurement task.

Analog devices

Moving coil measuring mechanism

Because of its low internal consumption, its reliability and its low susceptibility to interference, the moving-coil measuring mechanism is still widely used for current measurement. It measures the (positive or negative) direct current and must be supplemented by connecting a shunt in parallel for higher currents.

AC current can be measured with a moving- coil measuring mechanism using a rectifier , with 1.11 times the rectified value displayed; However, this is only the rms value when the alternating current is sinusoidal . Due to the forward voltage of the diodes of the measuring rectifier, this method requires a greater voltage drop (internal consumption) than with direct current. The voltage drop, which is also non-linear, must be countered by a non-linear scale division in the lower range. Analog multimeters with built-in amplifiers circumvent this problem.

Moving iron measuring mechanism

The moving iron measuring mechanism is suitable for measuring the effective value . However, the devices are primarily designed for 50 Hertz, are also suitable for Harmonic Rich AC power and DC power. Moving iron measuring mechanisms can be manufactured for very large currents without having to use a shunt.

Hot wire measuring mechanism

A hot wire measuring mechanism uses a wire through which current flows, which heats up due to Joule heat and increases its length according to its temperature expansion coefficient and drives a pointer via a lever mechanism. Hot wire measuring units measure the effective value and are suitable for direct and alternating current, also for high frequency . These devices have not been manufactured for decades.

Transmitter

In industrial metrology or automation technology is used not indicating measuring devices, but transducers such as current transformers that provide a standardized electric signal to the central processing. This can be a standard analog signal , e.g. B. 4… 20 mA. It can also be a digital output signal for transmission via a data bus , which is called a fieldbus in this context . These measuring devices with a digital measuring signal at the output are also called measuring converters .

Current measurement via the magnetic field

A clip-on ammeter evaluates the magnetic field around the conductor to measure the current .

- Designed as a transformer

A hinged ferrite or sheet iron core frame forms the transformer core, the current-carrying conductor, when the pliers are closed, encompasses the primary winding and the coil around the core forms the secondary winding. The conductor passed through has the number of turns . The current of the secondary winding, which is inversely proportional to the ratio of the number of turns, is displayed via a moving iron or moving coil measuring mechanism with rectifier or via digital electronics. This meter is only suitable for measuring alternating current.

- Version with current sensor

Devices that are equally suitable for direct current and alternating current measurements also have a hinged core, but are equipped with current sensors . They work according to the compensation principle ( compensation current transformer ) or the Hall effect ( Hall sensors ) or with magnetic field-dependent resistors together with an electronic measuring transducer .

Clip-on ammeters are manufactured as indicating devices for measurements in the power supply network; They are also available as accessories for multimeters to expand the range or as accessories for oscilloscopes for potential-free measurement of rapidly changing current curves. They are then also called current clamps or current probe .

Sometimes clip-on ammeters are also provided with a voltage input and can measure electrical power and power factor in addition to voltage .

Measurement of very large currents

Current measurement with current transformer

Alternating currents can be measured using current transformers (special measuring transformers); the ammeter measures its secondary current (which is smaller according to the nominal ratio). Alternatively, a resistor is connected to the secondary winding and the voltage is measured on it. In addition to measuring high currents (from approx. 10 A upwards), converters are used for potential-free measurements on high-voltage lines.

Current transformers can only feed a maximum external resistance (the burden), otherwise the measurement result is incorrect or they are overloaded. If nothing is connected to the secondary winding, they generate dangerous voltages due to the nature of the power source . Unused current transformers must therefore always be short-circuited on the secondary side.

Current measurement with shunt

With large direct currents or currents with a direct component, a measuring resistor is often used to which a voltmeter is connected. The shunts are often designed with four-wire connections in order to avoid measurement errors due to the contact resistance of the connections. Versions that generate a voltage drop of 60 mV at the specified maximum current are common. With a measuring resistance of 1 mΩ, an associated voltage measuring device is practically not labeled with a measuring range end value of 60 mV, but with 60 A.

Measurement of very small currents

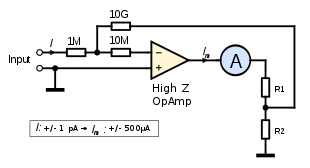

Very small electrical currents in the range of a few pico amperes (pA) can no longer be recorded directly and are converted into larger, proportional currents for measurement. This can be done by means of an operational amplifier , as shown in the simplified circuit shown here . In order to keep the measurement deviation due to the input current of the operational amplifier low, a MOS structure is required in its input.

With the appropriate selection of the resistor pair R1 / R2, which defines the measuring range, the circuit converts, for example, a current at the input from −1 pA to +1 pA into a proportional current at the output of the operational amplifier from −500 µA to +500 µA which is displayed by a corresponding ammeter A with a scale adapted to the selected input range. The following applies to the simplification shown .

Current measuring devices for recording very small currents, also known as picoammeters in English , are usually designed as independent precision measuring devices and have measuring ranges of below 1 fA (Femtoampere).

Measuring range adjustment, errors due to internal consumption

Devices with moving coil measuring mechanism

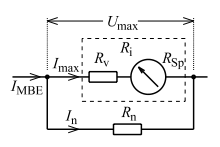

The measuring mechanism has a full scale value (mostly full scale on the associated scale ) with a design- related maximum permissible current . At the same time it has an internal resistance . This means that when the maximum current flows, a maximum fall voltage from that according to the Ohm's law to

calculated. If the maximum current strength is exceeded, the measuring mechanism can be overloaded. For measuring devices with a class symbol , a permissible overload capacity is specified by standardization.

In order to adapt to the desired measuring range, a shunt resistor is connected in parallel to the measuring unit , which absorbs that part of the current that is not supposed to flow through the measuring unit. It is calculated in such a way that at the desired end value of the measuring range, the portion flows through the measuring mechanism and the rest through the shunt.

can not only be formed by the coil resistance , as the copper used for this changes its resistance with the temperature by 3.9 ... 4.5% / 10 K, which also changes the display depending on the temperature. To reduce this measurement deviation , a temperature-independent resistor must be connected in series with the measuring mechanism: With , the temperature influence is reduced by a third, i.e. around 1.5% / 10 K; This value represents the maximum permissible limit for measuring devices of accuracy class 1.5.

- Example of measuring range adjustment

- The measuring device has an internal resistance and its full scale at . It should be used for a measuring range of 10 mA. Then at the end of the measuring range, 200 µA must flow through the measuring mechanism and = 10 mA - 0.2 mA = 9.8 mA through the shunt resistance. The maximum voltage is = 750 Ω ⋅ 0.2 mA = 150 mV. So that a = 9.8 mA flows at 150 mV , its resistance value must be = 150 mV / 9.8 mA = 15.31 Ω. The total resistance of the parallel connection is then 15.00 Ω. At the end of the measuring range 10 mA, you come back to 150 mV.

For ammeters that can be switched to several measuring ranges , see under analog multimeters .

The fact that the ammeter builds up the voltage required for the measurement leads to the fact that every measurement falsifies the original conditions on the measurement object, since the voltage required for the measurement is missing elsewhere. Therefore this should be kept as small as possible, i. H. the resistance of the ammeter should also be as small as possible. Examples of this type of measurement deviation are described under feedback deviation .

Devices with moving iron measuring mechanism

The coil of a moving iron measuring mechanism has a considerable inductive component of the internal resistance, so that the use of a shunt for alternating current measurements is not possible. The use of a shunt also causes problems when measuring direct current, since the copper winding of the measuring mechanism has a different temperature coefficient than the shunt.

Moving-iron measuring mechanisms are therefore manufactured for different measuring ranges up to about 100 A by using different numbers of turns and wire cross-sections for the coil for the measuring ranges.

However, current transformers can also be used to adapt the measuring range for alternating current . Moving-iron measuring mechanisms intended for this purpose usually have a full deflection of 5 A, which corresponds to the rated output current of the current transformer. The scale is labeled according to the transformation ratio of the current transformer to be connected, so it has, for example, the final value 300 A for a current transformer 300 A: 5 A (number of turns ratio 1: 60).

Digital electricity meters

The measuring resistor in digital multimeters and panel meters is usually designed in such a way that its voltage drop at the end of the respective current measuring range corresponds to the smallest voltage measuring range. For most measuring devices, this is 200 mV. To switch over the current measuring range, there is an uninterrupted switch to one or more measuring resistors along several shunts connected in series.

Digital measuring devices often have a lower internal consumption than moving-coil measuring devices, and this means that the feedback deviation (circuit influence error) is lower. However, this does not apply to direct current measurement , since with moving coil devices (the voltage required for full deflection) is almost always less than 200 mV.

- Example of the feedback deviation

- The current from a flashlight battery with 1.2 V is measured at the full scale value. Because 0.2 V is dropped on the digital ammeter, there is only 1.0 V on the consumer. In the ratio of the voltages 1.0 / 1.2 = 83%, the current decreases with an ohmic consumer ; it is measured with a relative measurement deviation of −17%.

Web links

Individual references, footnotes

- ↑ The term ammeter has been replaced in the standardization, since the ampere denotes the unit and not the physical quantity that is actually measured.

- ↑ Low Input Current BiMOS Operational Amplifier CA3420 - data sheet. Retrieved June 11, 2016 .

- ↑ Keithley Series 6400 Picoammeters. Retrieved June 11, 2016 .

- ↑ Series Femto / Picoammeters and electrometer, Keysight. Retrieved June 11, 2016 .