Thaletec

| Thaletec GmbH

|

|

|---|---|

| legal form | GmbH |

| founding | 2007 (1835) |

| Seat |

Thale , Germany |

| management |

|

| Number of employees | 199 |

| sales | 25 million euros |

| Branch | Mechanical engineering , apparatus engineering |

| Website | www.thaletec.com |

The Thaletec GmbH (spelling: THALETEC GmbH ) in Thale am Harz is a successor company of the former VEB Eisenhüttenwerk Thale, in which more than 7,500 employees worked until the fall of the GDR . Thaletec is today one of the two manufacturers of enamelled process engineering equipment in Germany that is coated with technical enamel .

history

In 1835, an enamelling factory was founded in Thale on the initiative of JCW Bennighaus . A part of the company was created whose products were to establish the globally recognized good reputation of the enamelled products manufactured in Eisenhüttenwerk Thale under the brand name Löwen-Email and from which the oldest and largest enamelling plant in Europe developed. The shell of the pot was prefabricated from forged sheet metal and then riveted to the pot frame. The fittings , such as handles and handles, were also riveted to the pot frame and lid. The connection between the frame and the base was folded and the inside of the pot was only enamelled. The outside of the pot was given a black protective coating.

In 1900, through the early application of autogenous welding from barrel construction, Eisenhüttenwerke Thale AG created a large-scale welding plant in which mainly sheet metal from its own rolling mill was processed. At this point in time, Eisenhüttenwerke Thale AG already owned a Siemens-Martin steelworks, several rolling mills, the stamping and enamelling plant and a foundry.

In 1907 an enamelling plant was attached to the large welding plant. Until well into the 1920s, the focus was on the production of large enamelled containers, primarily for the beverage industry. Ring or screw tanks , fermentation vats , bottle filling devices and storage tanks for use in breweries were manufactured. The large container construction of the EHW Thale had achieved a leading position on the world market with its products under the Löwen-Email trademark .

In 1932 Otto Krüger developed the acid-resistant enamel “Trisorit” in Thale and introduced it into production. Higher quality demands required further development of the construction systems and an improvement in welding technology.

In 1940 the use of electric welding and X-raying of weld seams in tank construction began. Arms contracts dominated during the Second World War . Large parts of the technical potential were converted to the manufacture of aviation tanks up to 50 m³, torpedo tubes , sea mines and buoys .

The Thale ironworks and the city of Thale remained completely undestroyed in World War II and were therefore of great importance for the reconstruction in the Soviet zone of occupation. The plant was under Soviet administration ( SAG ) from 1946 to 1953 . In 1946 buckets, barrels and the first enamelled polymerisation kettles (12 m³) were manufactured in the container and apparatus construction. From the 1950s, the tank and apparatus construction was again represented with its products at trade fairs in Germany and abroad.

From 1954 to 1990 the Thale ironworks was a state- owned company . From 1960 onwards, production began after typing and standardizing , planning and developing a cycle line based on the latest scientific and technical knowledge, a modern sandblasting blower, new special automatic cutting machines and a universal SA welding system. The new technologies resulted in an extensive delivery program with sales in Germany, Germany , Western and Southern Europe and the Asian region. The quality mark Q and fair gold could be achieved at Leipzig trade fairs . In 1968, under the direction of Günter Kozlowski, the blue, highly acid and alkali-resistant chemical ceiling enamel ACIBAS was developed.

In the 1970s a new hall for small parts production, the commissioning of electric chamber and shaft furnaces, a new flow line for frame production and the commissioning of the central floor production took place. In 1971, the production of enamelled cast iron equipment for the chemical industry in the old tank enamel factory was taken over by VEB Emailleguss Radebeul and continued until 1990. Enamelling of agitators up to 4 m³ in the hot powder process. The type of enamelling was unique in post-war Germany. In 1972 new halls for small parts production were completed. The electric chamber and shaft kilns went into operation in the new hall of the tank enamelling plant. In 1975 a new flow line made work much easier and improved the production flow in the frame production.

The central floor production was put into operation in 1977. The prepared floors could be processed on welding manipulators. The 1980s were characterized by the use of microelectronics , robotics , research and development of more effective stirring and sealing systems on mixing machines and the introduction of new operating standards .

After the fall of the Berlin Wall , the VEB Eisen- und Hüttenwerke Thale was facing the end. On May 28, 1990 VEB Eisenhüttenwerke Thale became Eisenhüttenwerk Thale AG with the container, apparatus and plant construction division. Production fell sharply because the majority of customers in the Comecon area could not pay in free currency . The investment backlog that lasted for decades and the inadequate productivity meant that the Treuhandanstalt , under whose administration the EHW was, could not find an investor for the plant. In order to save the company, Ernst Albrecht , who was then Chairman of the Supervisory Board of EHW Thale AG, and the Bremen businessman Hans Henry Lamotte bought the company. The company was privatized on January 1, 1993 for the symbolic purchase price of one DM . Both buyers undertook not to derive their own income from the company and not to benefit from a future sale price.

In the course of the 1990s, there was a major change in container and apparatus construction . The production was converted to DIN . In April 1997 Ernst Albrecht sold the shares of the remaining divisions of EHW Thale AG (EHW Thale Email GmbH and EHW Thale Sintermetall GmbH) to the Schunk Group (Schunk GmbH, Heuchelheim, and Schunk GmbH, Oberhausen). Following the acquisition, this increased the share capital of EHW Thale AG from 2.5 to 14.5 million DM.

After the sale to Schunk GmbH, a 4-strand enamelling system was built for the external coating of pipes for heat exchangers for use in power plants and in the chemical industry. Further investments such as the construction of a new enamel laboratory concentrated on products for the chemical and pharmaceutical industries. From 2006 to 2007, the no longer needed buildings of the old stamping and enamelling plant, the old switching house and Hall 7 were demolished and these areas were given up. When the corporate division was no longer in the red in 2007, Schunk GmbH sold it to three private investors who founded the THALETEC company.

A comprehensive documentation of the history of the Thale ironworks can be viewed in the Thale Hüttenmuseum .

Current situation

Thaletec GmbH has been continuing the tradition of enamelling devices and components for the chemical and pharmaceutical industry at the Thale site since October 2007. Among other things, enamelled agitators and storage containers, stirrers and stirring systems, columns and pressure filters as well as heat exchangers and heat exchanger tubes are manufactured. Two large low-mass kilns enable the enamelling of devices with a volume of up to 110,000 l.

Today Thaletec is a legally independent company which continues the tradition of enamelling apparatus and components for the chemical and pharmaceutical industry at the Thale site. The processes and technologies used today are essentially based on a (modernized) continuation of the technologies for the manufacture of glass-lined apparatus that were developed, introduced and successfully used since the 1970s to 1990s.

The focus of the company today is the manufacture of containers and process engineering equipment specifically according to customer requirements in accordance with all currently applicable standards and guidelines as well as an extensive range of services relating to glass-lined equipment. Today the company supplies its products to a large number of customers in the chemical and pharmaceutical industries around the world. Since THALETEC GmbH was founded, a number of innovations have been introduced on the market, for example the particularly wear-resistant ABRISIST enamel, a particularly fast-responding temperature measuring probe and special stirring systems for highly complex chemical processes and gassing tasks. In addition, additive manufacturing processes (3D printing) for enamelled components are playing an increasing role in the product range of THALETEC GmbH.

The corporate philosophy clearly puts the catchphrase Made in Germany in the foreground - most of the added value in the development and manufacture of enamelled equipment takes place at the company's location in Thale. The majority of deliveries come from Germany and to a lesser extent from other European countries.

Comprehensive investment measures in production technology as well as in research and development, also in close cooperation with universities (e.g. Anhalt University ), for example on the subject of hydroabrasion and the optimization of baffles in enamelled stirring vessels, are intended to ensure the company's competitiveness.

Trade fair participations

The leading trade fair of Thaletec is Achema , which takes place every 3 years in Frankfurt am Main and where the company exhibited in 2009. The company was also represented with a booth at Achema 2012, 2015 and 2018.

Products

The company's main products are today

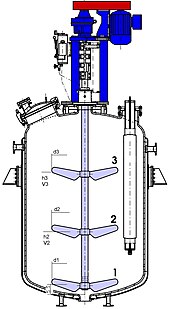

- Enamelled stirred tank similar to DIN 28136 with double jacket or half-pipe coil .

- Special enamelled apparatus for customer-specific applications

- Enamelled apparatus for the manufacture of active pharmaceutical ingredients

- Enamelled storage tanks

- Columns

- Heat exchangers for installation in agitator vessels , as top condensers in columns or as condensers in distillation systems

- Components for glass-lined apparatus, such as stirrers , baffles , valves

- Enamelled pipes

- Pipes for energy and environmental technology, e.g. B. for the construction of economizers

- Metrological components for recording process parameters such as temperature and pH value

An essential characteristic of the products is that they are enamelled with technical enamel .

Web links

- Website of Thaletec GmbH

- Early documents and newspaper articles on Eisenhüttenwerk Thale AG in the 20th century press kit of the ZBW - Leibniz Information Center for Economics .

Coordinates: 51 ° 44 '52.4 " N , 11 ° 1' 57.6" E