VEB development construction Pirna

The VEB development building Prina was in 1955 for the development and testing of engines and gas turbines within the GDR responsible. Until the end of aircraft development in the GDR in the summer of 1961, the company was assigned to VVB Flugzeugbau in Dresden as Plant 802 . Thereafter, the operation was transferred to the VEB gas turbines and energy machine development in Pirna, and from 1970 to the VEB flow machines. After the fall of the Wall, Strömmaschinen Pirna GmbH went bankrupt in 1995.

prehistory

At the end of the Second World War , more than half of the German aircraft industry was in the Soviet occupation zone . In addition to the cell production of Junkers Flugzeug- und Motorenwerke AG , Ernst Heinkel Flugzeugwerke or Arado Flugzeugwerke , in the area of drives it was primarily Junkers Flugzeug- und Motorenwerke AG with its main plant in Dessau and BMW with engine development and production in Neu Staßfurt . While other branches of industry were being dismantled through reparations , the Soviet Union wanted to use the knowledge of German engineers and technicians in this area and prevent their further migration to the other zones of occupation. Towards the end of 1945 several special design offices were set up, of which the OKB-1 in Dessau with Group 1 (aircraft) around Brunolf Baade and Group 2 (engines) around Dr. Scheibe and the OKB-2 in Neu Staßfurt around Dr. Prestel mattered. Even though many documents, test engines and systems had been transported to the USA or the USSR or destroyed and skilled workers had fled, development work on the Junkers Jumo 004C , Jumo 012 and Jumo 022 engines and the BMW 003 and BMW 018 engines were resumed under Soviet supervision . The projects were in different stages of development. With tight deadlines, the Soviet Union's backlog in this area was to be remedied and powerful engines were to be provided for its own aircraft.

Abduction as part of the Ossawakim campaign

However, this work contradicted the Allied Control Council Law No. 25 of April 29, 1946, which banned applied research in the field of military aircraft construction. Since the other victorious powers were technically more advanced and a continuation of the German developments was not necessary for them or they had already got the necessary German material and personnel out of the country, the Soviet Union was mainly affected, which is also in their interests lay. The Soviet Union was aware of this situation. With the directive 874-366 of the Soviet Council of Ministers of April 17, 1946 and the order 228 of the Ministry of Aviation Industry of April 19, 1946, the resettlement of selected engineers and technicians as well as their families and all of the material in the Soviet Union for the autumn Arranged in 1946. For the OKB-1, it was also planned that by then the project planning work on the Jumo 012 had to be completed and test samples had to be completed and the first run had to take place. This took place on June 24, 1946. A total of three test vehicles were built, one of which was destroyed by an accident and the other two were initially unable to safely achieve the required performance. On October 22, 1946, the selected specialists and their families were brought to Uprawlentscheski Gorodok , a district of today's Samara, as part of the Ossawakim campaign from Dessau and Neu Staßfurt . The test facilities and offices were dismantled and transported there by the end of 1946. In exile in the Soviet Union, the specialists worked in the specially established State Experimental Plant No. 2, from which the OKB 276 emerged in August 1953 and today's Russian manufacturer Kuznetsov in 2009 . First, however, the Germans set up the test facilities and offices again. Soviet engineers, who were supposed to quickly take over the wealth of experience of the Germans, as well as German prisoners of war from the field of flight tests were assigned to the plant.

Further development of Jumo 012 and 022

The BMW engines and the Jumo 012 were further developed in exile, the latter being fundamentally revised under the new head of development, Ferdinand Brandner . For the version designated as Jumo 012B, production of five prototypes began in late 1947 and tests began in June 1948. Success was achieved, even though at the end of the year a 100-hour approval test had to be canceled after 94 hours as a result of a broken blade. The engine type was not used in flight. Independently of the development, the Soviet Union procured the British Nene engine from the manufacturer Rolls-Royce and developed it first into the Klimow RD-45 and later the Klimow WK-1 . The RD-45 was more compact and 1.5 times lighter with a comparable thrust. That was the decisive factor in ending the development of the Jumo 012 at the end of 1948.

There were further setbacks, so that from the end of 1948 the plant was restructured. The two working groups were merged and the Soviet leadership was reorganized under the new head Kuznetsov . From then on, work was to concentrate on the development of a 6000 hp turbo -prop engine based on the Jumo 022. This project was started at Junkers as early as 1943 with a request from the Technical Office located in the Reich Aviation Ministry (RLM) for a turboprop version of the Jumo 012, but was discontinued in 1944. The development work in the Soviet Union was successful and the engine was able to successfully complete the acceptance runs under the new designation TW-022 in 1950. The then known as TW-2 (according to other sources also NK-2) engine was further developed by a Soviet company to the serial version TW-4 or NK-4 and then in the aircraft Antonov An-8 and An-10 as well as the Ilyushin Il -18 used. However, after incidents it was quickly replaced by other engines.

Development of the Kuznetsov NK-12

From then on, the work concentrated on the development of a 10,000 hp, later 12,000 hp turboprop engine, which was successfully completed in 1953. The 2TW-2F variant, which has meanwhile been tried and tested, in which two TW-2s act on a gear unit and the propeller, turned out to be unsuitable. The drive, designated as the Kuznetsov NK-12 in the later production version , was tested and used in the Soviet Tupolev Tu-95 bomber from 1954 . In 1955 the Tupolev Tu-114 was also equipped with this engine. Like the TW-2, the NK-12 was started by a small gas turbine developed by the German specialists. Later variants of the NK-12 developed up to 15,000 hp and were used in the Antonov An-22 , Tupolev Tu-142 and Tu-126 and the Ekranoplan A-90 Orljonok .

Return to the GDR

As early as August 1950, the gradual reduction of specialists began. After the uprising of June 17, 1953 in the GDR, the SED Politburo set the course for the establishment of an independent, civil aviation industry. The aim was to meet the GDR's domestic demand for aircraft and also to generate export revenues. Initially, the Office for Technology was responsible for the construction. The management staff of the German engine specialists in the Soviet Union as well as those of aircraft construction were also involved in the preparations. The rest of the staff was able to return home after the acceptance runs of the NK-12 at the end of 1953.

The GDR government's plan was revealed to the management staff at a special meeting in Sawjelowo on November 18, 1953. The minister responsible also came later. The task was that a passenger aircraft should be built on the basis of the bomber project 150 , which was discontinued in 1953 , and that the engines should also come from the GDR. A group of German specialists led by Brunolf Baade were previously involved in Project 150. In addition to technical drafts, the organizational and personnel structure of the future aviation industry was also discussed. The projects were named " Airplane 152 " and "Engine 014". In July 1954, the last German specialists were able to return. Head of engine development was Prof. Dr.-Ing. Rudolf Scheinost after the previous director Ferdinand Brandner returned to his home country Austria.

History of VEB Entwicklungsbau Pirna

The choice of a suitable location for the planned engine development was guided by safety issues and should therefore be a location in the Dresden , Chemnitz and Leipzig area far away from the allied flight corridors to Berlin . The highest level of secrecy was applied, as the Allied Control Council Act No. 25 still prohibited aircraft construction. The Sonnenstein Castle in Pirna with an adjacent area east of the castle park seemed suitable. The material office of the main administration 18 collected the documents there from 1950 and offered the returnees from the USSR suitable jobs.

After the arrival of the management staff from Sawjelowo on July 5, 1954, the previously planned organizational structure was implemented and the company was officially presented on May 1, 1955 as VEB Entwicklungsbau Pirna. As factory 802 it was a branch of the VVB Flugzeugbau and was managed by the factory director and chief designer Prof. Dr.-Ing. Rudolf Scheinost headed. At peak times, over 2000 workers and engineers were employed. All operating facilities such as workshops, production and manufacturing facilities, blacksmiths, prototypes and test stands were built on the area east of the castle park along Struppener Straße. Since there was no suitable supplier industry, special machines were also purchased from abroad.

In July 1954, work began on the project he had brought with him, which was referred to as "Pirna 014". The construction documents had to be re-created because the USSR did not release them until 1957, despite repeated requests. The project fell behind schedule. In addition, the lack of availability of highly heat-resistant materials, the lack of a supplier industry and the shortage of skilled workers prevented work. Nevertheless, the engine was further developed, flight tests began and a pilot series was produced in the VEB Industriewerk Ludwigsfelde production plant. Other projects, such as the Pirna 015 to 020 engines, reached other project stages, but were never produced as pilot series.

From 1958, the State Planning Commission took over responsibility and drastically reduced the funds. A market analysis carried out at this point in time and the delay in project 152 did not justify further financial support in this amount. In March 1961 the decision was made to discontinue aircraft construction and with it the development of aircraft engines.

In the summer of 1961 the company was renamed VEB Gasturbinen und Energiemaschinenentwicklung Pirna and switched to the development of ship propulsion systems and gas generators. The small gas turbines were sold under the brand name TURBOLEKT . It belonged to the VEB Kombinat Kraftwerkanlagenbau, which from 1969 was subordinate to the VVB Kraftwerkanlagenbau. In 1970 the company was merged with other companies to form VEB Turbo Machines and the product range was expanded to include hydrodynamic power transmitters for locomotives and fluid couplings. It was the second largest industrial company in Pirna. After the fall of the Berlin Wall, the company was run as Strömmaschinen Pirna GmbH, which had to file for bankruptcy in 1995.

Starting in 2010, various buildings on the site were demolished with money from the European Regional Development Fund (ERDF) and other contaminated sites were removed.

Products

Engines

The aircraft engines of VEB Entwicklungsbau Pirna were intended exclusively to drive the aircraft of VVB Flugzeugbau and thus closely linked to the course of the project. The following engines were planned and achieved different stages of implementation:

| Overview of engines | |||||||

|---|---|---|---|---|---|---|---|

| Data | Pirna 014 | Pirna 015 | Pirna 016 | Pirna 018 | Pirna 019 | Pirna 020 | |

| Type | Turbojet | Turbofan engine | Turbojet | Turboprop | Turbojet | Turbofan engine | |

| Start thrust | 3150 kp (30.9 kN) | 4500 kp (44.1 kN) | 3500 kp (34.3 kN) | - | 600 kp (5.9 kN) | 3700 kp (36.3 kN) | |

| Shaft power | - | - | - | 3680 kW (5000 PS) plus 670 kp (6.57 kN) residual thrust |

- | - | |

| Air flow | 52 kg / s | 100 kg / s | 60.4 kg / s | 31.3 kg / s | - | 96 kg / s | |

| Weight | 1060 kg | 1800 kg | 1050 kg | 1300 kg (without propeller) | 950 kg | ||

| propeller | - | - | - | Four-blade variable pitch propeller AW-68A | - | - | |

| fan | - | 4 levels | - | - | - | 3 steps | |

| Low pressure seal | - | - | - | - | - | 3 steps | |

| High pressure compressor | 12 levels | 8 levels | 12 levels | 13 levels | 3 steps | 8 levels | |

| High pressure turbine | 2 steps | 2 steps | 3 steps | 4 levels | 3 steps | 1st stage | |

| Low pressure turbine | - | 2 steps | - | - | - | 2 steps | |

| plane | 152 with 4 × Prina 014 155 with 2 × Pirna 020 |

152 with 4 × Pirna 015 | 152 with 4 × Prina 016 154 with 4 × Pirna 016 |

153 with 2 × Pirna 018 154 with 4 × Pirna 018 |

Training aircraft | 154 with 4 × Pirna 020 155 with 2 × Pirna 020 |

|

| annotation | Data refer to variant Pirna 014 A-0 |

configured data | configured data | Data refer to the latest development status |

configured data | configured data | |

Although designed for different areas of application and performance, all engines have a similar basic design. The combustion chambers, for example, with their combination of single and ring combustion chambers, are based on a concept that Brandner has already successfully implemented on the NK-12.

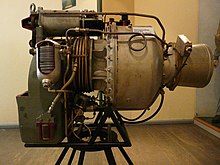

Pirna 014

The first project studies for this engine were made in the Soviet Union as early as 1953. A 3000 kp turbojet engine was designed under the designation "Dwigatel 014", which should power the aircraft 152, which was also planned. Technically, it is similar to the Junkers Jumo 012 , which the engineers involved had dealt with only a few years earlier. From July 1954, after returning from exile, the work in Pirna continued.

The engine was a single-shaft turbojet engine with a twelve-stage compressor and a two-stage turbine. The fuel was introduced via a combined annular combustion chamber with 12 individual combustion heads. Compared to the first draft "Dwigatel 014", the starter and generator were combined in one device at an early stage and installed in the inlet housing instead of on the outer housing. The oil tank and the control of the compressor via a blow-off system were also changed. The then known as Pirna 014 engine had its first run in version 014 A-0 on October 12, 1956. Further test engines were built for various test and measurement campaigns. In 1959, the 150-hour certification test with the 014 A-0 variant was successfully completed and the engine was approved for flight testing on an IL-28R . A more powerful version of the Pirna 014 A-0 was commissioned in 1959 and projected as the Pirna 014 C. Two test engines with a static thrust of 3300 kp were built and tested on test stands.

In the improved version 014 A-1, the compressor has been redesigned and its working range expanded. The de-icing system was changed. The air flow increased by 5.5 kg / s and the thrust was increased to 3300 kp. This version was able to successfully complete the certification runs in August 1960 and then also went into flight tests. A total of 10 engines of both variants were tested in flight. On August 26, 1960, the first test flight of a 152 / II took place, which was exclusively equipped with the Pirna 014 A-0. Previous flights were carried out with Soviet engines.

The series production of the engines was to take place in VEB Industriewerke Ludwigsfelde, part of the former Daimler-Benz engine works and today's MTU Maintenance Ludwigsfelde . Between 1959 and March 1961, 29 engines of both variants were produced. With the decision to discontinue aircraft construction, the development of the engine was essentially ended and series production stopped. The existing engines were converted for further use as gas generators.

Pirna 015

The Pirna 015 was a draft project from the company's early stages. The aim in 1955 was to replace the Pirna 014 with a more economical engine in the later course of Project 152. It was designed as a turbofan engine with two shafts.

The compressor was divided into a four-stage low-pressure and an eight-stage high-pressure compressor. Since the air mass flow was only divided into core and secondary flow after the low-pressure compressor, the first stages can be viewed as a fan. The combustion chamber was a combination of an annular combustion chamber with ten individual combustion heads. The turbine was divided into a two-stage high-pressure and a two-stage low-pressure turbine, which conducted their power to the compressor via two shafts. Due to a projected turbine inlet temperature of 1200 ° C, the availability of highly heat-resistant materials was a prerequisite for the implementation. Since these materials were not available to the GDR in 1955 and the development capacities were initially to be concentrated on the Pirna 014, the project was not pursued any further.

Pirna 016

Another project for the further development of the Pirna 014 was the Pirna 016. Even though the work on it did not begin until 1957 and it is therefore classified after the Pirna 015, it pursues the same goal. In the later course of the project 152 it was supposed to replace the Pirna 014 with an engine with lower fuel consumption. From 1957, before the flight tests of the Pirna 014 A-0, the advance development of an improved compressor and turbine was started. On the compressor, the work area should be expanded by using a guide wheel adjustment for the first time in the first three stages and a blow-off in the eighth stage. The expectations were confirmed in test runs on a compressor test bench. However, no further tests were undertaken since the project was halted in 1958. From then on, all resources should be concentrated on the delayed final development of the Pirna 014.

Pirna 018

The Pirna 018 was a single-shaft turboprop engine that was initially intended to drive the twin-engine 153/0 and the four-engine 154/0 . The latter was soon fundamentally revised and initially projected with the Pirna 014 and then later with the Pirna 020, as the development of the competing IL-18 with the NK-4 engine derived from the Jumo 022 was already too far advanced. In the new development of the Pirna 018, parallel to that of the Pirna 014, experience from the development of the NK-12 was incorporated.

The first draft at the end of 1955 with the designation Pirna 018/0 and an equivalent shaft power of 6000 hp was discarded only a little later because the USSR refused to supply highly heat-resistant material for the turbine. In order to still achieve the necessary performance with less highly heat-resistant material, the engine was redesigned and draft 018/1 was presented in the spring of 1956. Compared to the NK-12, the turbine inlet temperature fell by 100 ° C. Thanks to better calculations, the number of compressor stages fell by one to 13, and that of the turbine from five to four. The compression increased to 10: 1. Since the aircraft was revised in autumn 1956 to version 153/1 with a low takeoff weight (34 t instead of 36 t before), the Pirna 018/1 was now equipped with a four-blade single screw with a diameter of 5 m instead of the previously projected counter-rotating propeller.

In the course of 1958 the 153 was revised twice and after the 153/2 the version 153A was planned. The engine, which had also been revised, was supposed to produce an output of only 5000 hp under the new name Pirna 018B. Tests began in the same year. On November 28, 1958, the first test engine, still version 018A, was run for the first time. The second test engine crashed on February 7, 1959. The third was no longer installed.

In the second quarter of 1958, on the instructions of the VVB's scientific advisory board, all work on the engine was canceled. The development capacities should only be concentrated on the Pirna 014. Only the compressor revised in the 018B with a stator adjustment in the first stage was still tested until the beginning of 1960, as this development was also planned for the 014.

Pirna 019

The Pirna 019 was supposed to power a jet-powered training aircraft. The project did not get beyond the study phase and was not pursued any further.

Pirna 020

The Pirna 020 was designed as a turbofan engine with two shafts and was intended to drive the four-engine 154 and twin-engine 155 . Projected from 1959, it did not get beyond this stage. Only one compressor test item was built and, according to the sources, was still tested in 1962 at the TU Dresden .

The engine had a six-stage low-pressure and an eight-stage high-pressure compressor. After the third stage of the low-pressure compressor, the air mass flow was divided into core and secondary flow, so that these stages could be viewed as a fan. The bypass ratio was 1.5. As with the other engines, the combustion chamber was a combination of an annular combustion chamber with eight individual combustion heads. The turbine was divided into a single-stage high-pressure turbine and a two-stage low-pressure turbine, which conducted their power to the compressors via two shafts.

Gas generators

SAG Pirna 051/1

The Pirna 051/1 is a marine drive based on the Pirna 014 and used in the Hai II class of the People's Navy . It was planned in 1958 and developed by the successor company VEB Gas Turbines and Energy Machine Development from 1961. The sea tests took place from 1962, a 200-hour prototype run test in 1964 on a test bench in Pirna. A total of 12 drive systems and two replacement systems were built.

The gas flow generated by the gas generator was divided between two power turbines, each of which drove a ship's shaft via a reduction gear. There was no mechanical connection between the power turbines and the gas generator. The output was 7355 kW (10,000 hp). The gas generators were existing Pirna 014 engines of the versions A-0 and A-1, which were converted to the operation of marine fuel and designated as Pirna A-2 and A-3. The control system was adapted and the starter redesigned.

Peak load power plant E-1

The Pirna E-1 was a peak load power plant on the factory premises and served as a model system for the VEB Wissenschaftlich-Technische Zentrum (WTZ) Kraftwerkanlagenbau Pirna. It was planned in 1958 and put into operation in 1962. Two Pirna 014 Cs, which were originally intended to serve as test engines V-01 and V-02 for flight tests, were converted into gas generators ( aeroderivatives ). The gas flow generated by them was fed tangentially to a power turbine that drove a 12.5 MW generator. The control of the system was similar to that of the SAG Pirna 051/1. The power plant initially covered 2–4 hours of peak load per day, from 1964 up to 10 hours per day. In 1975 it was shut down due to high operating costs.

Small gas turbines

VEB Entwicklungsbau Prina and its successors have developed and sold the following small gas turbines for different areas of application since 1955:

| Overview small gastropubines | |||||||

|---|---|---|---|---|---|---|---|

| Data | Pirna 017 | Pirna 027 | Pirna 028 | Pirna 029 | Pirna 030 | ||

| Maximum power | 96 kW (130 PS) | 173 kW (235 hp) | 205 kW (278 hp) | 213 kW (290 hp) | 290 kW (394 hp) | ||

| Continuous output | 77 kW (105 PS) | 162 kW (220 PS) | 195 kW (265 hp) | 200 kW (272 hp) | 280 kW (380 hp) | ||

| annotation | Data refer to version 017A |

Data refer to version 028-2 |

|||||

The first small gas turbine, the Pirna 017, was intended to power the V101 turbine car. This vehicle was based on an initiative by Walter Ulbricht, but at the end of the sixties it was in keeping with the spirit of the times. The engine was designed by a group of engineers who had already developed the TS1 starter turbine for the NK-12 while in exile in the Soviet Union.

In the original version, the Pirna 017A, it was a single-shaft gas turbine with a radial compressor and a two-stage axial turbine. The maximum output of 96 kW (130 PS) was transferred to a reduction gear. To reduce fuel consumption, a heat exchanger was used in the Pirna 017D version. Installed between the compressor and the combustion chamber, the compressed air should transfer thermal energy from the exhaust gas there. The total mass of the small gas turbine increased to 250 kg, but fuel consumption fell by 40% with the same output. However, due to problems in the start-up phase, this version was not pursued. The car was also discontinued due to technical difficulties.

The small gas turbine was developed step by step and the area of application enlarged. The Pirna 017E version was installed on a trial basis in a hydrofoil of the border police. The Pirna 017E-2 version with 110 kW (150 PS) continuous output was installed in the WFG 32 water pumping device , a single-axle trailer for the fire brigade, and there it powered the PAT 322 centrifugal fire pump . When used as a fire extinguisher pump , up to 3200 l / min of extinguishing water could be delivered, as a bilge pump up to 4500 l / min. The WFG 32 was mainly used to deliver water when fighting forest fires, fires in the chemical industry and for draining pits. A total of 19 units were built, some of which were still in use until 2010. The small gas turbine Pirna 027 was installed in some of the units during their service life. The WFG 32 was also shown on matchboxes for fire prevention education and training.

With the Pirna 017E-2 version, the small gas turbine was coupled with a generator for the first time and marketed under the name TURBOLEKT as a stationary or mobile emergency power or energy unit. Customers were the NVA, airfields, companies and hospitals.

Over time, the performance range of the TURBOLEKT series was expanded and new small gas turbines were introduced. Even if the basic concept has always remained the same, technical innovations have been incorporated. In the Pirna 027 the combustion chamber has been revised, in the Pirna 029 the exhaust gas values have been improved and fuel consumption has been reduced again. Both small gas turbines were produced in the TURBOLEKT versions TE 330, TE 440, TE 550 as stationary or, as TE 333 and TE 443, as mobile emergency power generators until 1991. A total of 3900 units were sold worldwide by 1992.

swell

- Klaus-Hermann Mewes: Pirna 014 . Aero engines of the GDR. 1st edition. AVIATIC Verlag, Oberhaching 1997, ISBN 3-925505-39-3 .

Individual evidence

- ^ Constanze Werner: War economy and forced labor at BMW . On behalf of MTU AeroEngines and the BMW Group. Oldenbourg Wissenschaftsverlag, Munich 2006, ISBN 978-3-486-57792-1 .

- ^ A b c d e Rainer Appelt: Fast end of the GDR aviation industry . In: Aviation Classics . No. 3 , 2014, ISSN 1860-0654 ( klassiker-der-luftfahrt.de [accessed February 20, 2018]).

- ↑ a b c d e f g h i j k l m n o Klaus-Hermann Mewes: Pirna 014 . Aero engines of the GDR. 1st edition. AVIATIC Verlag, Oberhaching 1997, ISBN 3-925505-39-3 (159 pages).

- ↑ a b c d e f Reinhard Müller: Brunolf Baade and the aviation industry of the GDR: the true story of the jet airliner 152 . Sutton, 2013, ISBN 978-3-95400-192-7 ( google.de [accessed September 1, 2018]).

- ↑ a b c d e Holger Lorenz: The turbine aircraft Dresden-153A from 1959 . Erzdruck GmbH, Marienberg 2015, ISBN 978-3-9816919-6-2 .

- ^ Rainer Appelt: German specialists in the USSR from 1946–1956 - kidnapping or immaterial reparation? In: www.freundeskreis-luftwaffe.de. Retrieved October 21, 2018 (presentation by Konrad Eulitz).

- ↑ Mario Beck: Exciting journey through time into aviation history . In: Leipziger Volkszeitung . February 16, 2016 ( pressreader.com [accessed October 21, 2018]).

- ^ The Historical Chronicles of Kuznetsov (JSC). In: kuznetsov-motors.ru. Retrieved on March 4, 2018 (eng, history of the Russian engine manufacturer Kuznetsov).

- ↑ a b c d Dmitrii Alekseevich Sobolev, Dmitrii Borisovic Chazanov: The German imprint on the history of Russian aviation . Rusavia, Moscow 2001, ISBN 5-900078-08-6 (English, airpages.ru [accessed on August 26, 2018] Internet site based on the work mentioned).

- ↑ Antony Kay: German Jet Engine and Gas Turbine Development 1930–1945 . Airlife Publishing Ltd, Shrewsbury 2002, ISBN 1-84037-294-X (English).

- ↑ Ulrich Unger: German start for a Soviet engine era: PTL engine Kuznetsov TW-2 . In: Fliegerrevue Edition . No. 06 . FlugVerlag Berolina, Berlin 1996.

- ↑ a b c d e André Winternitz: VEB flow machines Pirna - administration. In: rottenplaces.de. October 30, 2015, accessed February 25, 2018 .

- ^ Rainer W. During: MTU Aero Engines 25 years of flight history. In: Der Tagesspiegel. July 1, 2016, accessed March 8, 2018 .

- ↑ a b VEB Kombinat Kraftwerkanlagenbau. In: Landesarchiv Berlin. Retrieved November 18, 2018 .

- ↑ Ferdinand Brandner : The propeller turbine development in the Soviet Union . In: Schweizerische Bauzeitung . tape 75 , no. 33 , 1957, pp. 520-524 , doi : 10.5169 / seals-63405 .

- ^ A b c Hans-Dieter Unkenstein: Water pumping devices 32 at professional fire departments in the former districts of the GDR Cottbus, Frankfurt / Oder and Potsdam . In: Contributions to the history of fire services . No. 7 . Landesfeuerwehrverband Brandenburg eV Technical Committee - Fireworks History ( lfv-bb.de [PDF; accessed on December 2, 2018]).

- ↑ Water pumping device WFG 32. In: www.feuerwehr-potsdam.de. Retrieved December 2, 2018 .

- ↑ Turbolekt emergency power generators. In: www.bunker5001.com. Retrieved December 2, 2018 .