Inkjet printer

Inkjet printers are matrix printers in which a print image is generated by specifically shooting or deflecting small ink droplets . They belong to the group of non-impact printers .

Two groups of devices can be distinguished.

- CIJ: Continuous Ink Jet, i.e. devices with a continuous ink jet

- DOD: Drop On Demand, i.e. H. single drop shooting devices

History of the inkjet printer

The history of the inkjet printer began in the 1960s. The Teletype Inktronic was developed between 1963 and 1970 by the US company Teletype Corporation . It is considered to be the world's first inkjet printer. However, it was not a printer in the traditional sense, but a teleprinter with an integrated keyboard that served as an input / output device for mainframes. The printing performance was still low according to the time. The developers did not succeed in conveying the ink precisely onto the paper. This led to various problems, such as the printer becoming dirty far too quickly. This resulted in poor print quality. The device was too big to foresee private use.

The first functional inkjet printing devices were launched by IBM in the early 1970s . They printed in continuous operation (continuous drop) and could only be used in industry. However, the continuous ink jet process has been used in some ink jet printers to date in an improved form. Ultimately, it was the world-famous companies HP and Canon who succeeded in the technical implementation. In 1979, both filed the patent almost simultaneously.

One of the first inkjet printers for the end customer market was the HP ThinkJet from 1984. In the same year the first piezo printer came onto the market, the Epson SQ 2000. In 1987 the HP PaintJet brought color into the office. In 1988 the first inkjet printer for the mass market appeared, the HP Deskjet with a printing speed of up to 2 pages / min and a graphic resolution of 300 dots / inch .

After the first printers appeared around the year 2000 that enabled photo-realistic prints in better quality than conventional photo paper with additional colors such as red, blue, green and orange, the era of photo printers for the paper formats A4 and later A3 began. Numerous paper manufacturers developed products for the inkjet photo paper market. The market had stabilized and established itself by the end of the 2000s. On the one hand, there are now simple devices for A4 formats , which at most have light cyan and light magenta as photo-specific inks. Additional functions such as direct printing from cell phones and memory cards, scanners, copiers and fax machines can be added to these basic devices. On the other hand, large format printers and plotters with maximum formats larger than A3 have been developed, which are offered with additional ink combinations and compositions for professional photographers and printing companies. Since then, high-quality photo printing by amateur and occasional photographers has hardly taken place.

CIJ printer (Continuous Ink Jet, inkjet printer)

CIJ printers are used exclusively in industry, where they are used in various areas such as scratch cards , best before dates, EAN codes, addressing and personalization. Technological advances open up further areas of application in digital printing , for example, in mid-2009, Kodak offered a CIJ-based printing machine for black and white (Prosper S10) with spot colors and in mid-2010, four-color printing (Prosper 5000 XL).

Procedure

In both cases (single and multiple jets) the ink jet emerges from the printhead through a nozzle . This jet is modulated by a piezoelectric transducer located behind the nozzle, so that a uniform disintegration ( Rayleigh's drop disintegration ) into individual drops is achieved. The drops formed in this way are then charged electrostatically via a charging electrode . The drops with a speed of 10 to 40 m / s then fly through a larger deflection electrode. Depending on the strength of the electric field, they are deflected laterally between the two deflection electrodes. Depending on the device type, the charged or the uncharged drops get onto the substrate. Drops that are not required are collected again at the print head and fed back into the ink circuit. A further distinction is made between binary deflecting and multi-deflecting methods. In the former, the drop either hits the substrate or is deflected into a drop catcher. With the multi-deflecting process, the drops can be deflected differently by different charge states. In this way it is possible to print a wider line via a nozzle. The height of the line depends on the deflection voltage and the distance between the nozzle and the substrate, whereby a higher distance reduces the print quality.

DOD printer (drop on demand, ink printer)

left: integrated into the cartridge ( HP Deskjet 600), right: print head of an HP Business Inkjet 1100D, middle: cartridge of the BIJ1100D

This type of printer can be found in industry as well as in the office and home. In contrast to CIJ printers, only the ink drop that is actually needed leaves the nozzle . The devices are also differentiated according to the technology with which the ink drops are ejected. The area of application is very large and ranges from personalization orders to the home / office area to the printing of passport photos.

Depending on the ink, electrical circuits are also printed or three-dimensional models can be created in 3D printers , which was originally used for rapid prototyping . Instead of conventional ink, you can also use wax , long-chain polymers or hot, liquid solders .

Procedure

Depending on the type of DOD, the ink is driven out of the nozzle in different ways.

-

BubbleJet printers create tiny drops of ink using a heating element that heats the water or solvent in the ink. A tiny vapor bubble forms explosively, which presses a drop of ink out of the nozzle due to its pressure. Manufacturers are Canon , Lexmark and Hewlett-Packard in the DeskJet series. Again, two systems are used.

- Canon operates at its printers having a bubble-jet technique, in which the nozzle in a right angle to the heating elements are (edgeshooter). The process is very similar to the piezo process, except that the ejection pressure is not generated by a piezoelectric element, but by a vapor bubble. The individual heating element works with a frequency of up to 10 k Hz . The print head of the Kodak inkjet printer works at up to 24 kHz.

- Lexmark and HP for the Deskjet series rely on flat nozzle elements, which essentially consist of two plates. The one facing the paper contains a tiny nozzle hole and the vapor bubble forms opposite this hole (side shooter). Devices that work with this method are very easy to manufacture and are therefore inexpensive, but the method has the disadvantage of a limited service life of the print heads. It is used with all interchangeable print heads.

- Piezo printers use the inverse piezoelectric effect to press the printing ink through a fine nozzle, whereby ceramic elements are deformed under electrical voltage . The ink forms drops, the volume of which can be controlled by the size of the electrical impulse applied. The working frequency of a piezo crystal reaches up to 23 kHz. The manufacturer is Epson and was Siemens from 1977 with the Siemens PT80i .

- With pressure valve printers , individual valves are attached to the nozzles that open when a drop is to leave the nozzle. Due to the requirements, this technology is only used industrially or as an art object.

cleaning

What all DOD printheads have in common is that they dry out over time when they are not used. To prevent this, the inks are often slow drying and most printers run a cleaning cycle before the first print. The ink is usually injected into a sponge provided for this purpose only. Another measure is to park the print head airtight in a special place so that the ink cannot dry up in the nozzles. This is like putting a cap on the ink pen when it is not in use.

Many printer models automatically perform this cleaning at regular intervals (more often when the print head is disconnected from the cartridge). The cleaning can be started manually if necessary. Cleaning usually consumes a lot of ink, which at the current prices for printer cartridges makes up part of the printing costs, especially if there is only seldom and little printing and the ink dries up more often per printing process. Depending on the printer model and the size of the ink cartridge, the cartridge can be empty after 40 to 100 cleanings. Some printer models will perform cleaning when they have been unplugged, mainly Epson printers with separate cartridges. Such printer models should therefore not be connected to a switchable connector strip in order to avoid unnecessary cleaning and to save ink. If the power strip is turned on and off frequently, the cost of electricity saved will be less than the cost of cleaning the ink cartridges.

technology

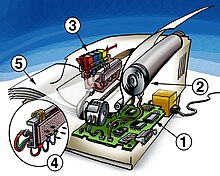

In order to print, a printer essentially has to perform two movements: the transverse movement of the print head and the vertical movement of the printing paper. The printhead is moved on rails by means of a toothed belt and a direct current or stepper motor . For the highly precise movement of the print carriage, which is synchronized with the data stream of the print head, the latter carries an optical incremental encoder that scans a stationary tape provided with lines. Stepper motors must work in microstep mode for this, since their step resolution or accuracy is by far not sufficient for the required resolution. The roller driving the paper sheet is driven by another motor. If this is a stepper motor, there is no need for a further incremental encoder.

The newer Memjet technology (MEM = microelectric mechanical) combines inkjet printing with a page printer by using an immovable print head in page width (DIN A5 to DIN A0) with a corresponding number of nozzles (74,400 for DIN A4) in high quality (1600 dpi) and speed (60 pages DIN A4 color prints per minute) without preheating.

Printers have their own character set that allows printing with a small amount of data to be transferred to the printer. With today's USB connection , however, large amounts of data transferred pixel by pixel as a bitmap are no problem, so that characters and graphics are converted into a bitmap in the printer driver of the controlling computer. This allows the much more extensive character sets of the software installed on the PC to be used.

A raster image processor is used to determine the positions at which the individual droplets are sprayed onto the paper , which uses dithering and color separation (for color printers) to convert the pixels of an image to be printed into print cells (dither cells or "halftone cells" for grayscale printing). that is, in groups of ink dots in the print image that reproduce the color and brightness of the image dots as precisely as possible by superimposing and combining the droplets in terms of number, color, possibly size and arrangement. The actual resolution of image points (determined as ppi , points per inch) that can be achieved by a printer therefore depends on the positioning resolution of the individual droplets (e.g. specified as dpi , dots per inch) and the size of the print cells. For example, a printer with a nominal resolution of 5000 dpi with a print cell size of 5 × 5 print pixels has a resolution of the pixels of 1000 ppi. In so-called dithering with error diffusion, no dither cells are formed, but the image is analyzed line by line and a quantization error is calculated in the software for each point, which is then distributed to the neighboring pixels. The processes used to convert images into ink droplet patterns on the medium contribute significantly to the quality of the print and are part of the know-how of printer manufacturers.

ink

Basically, the inks used in printing processes can be divided into two categories. On the one hand, dye inks are used which obtain their color from dye molecules dissolved in the ink liquid. On the other hand, pigment inks are used, the color of which is created by pigment particles floating in the ink liquid. Dye inks are easier to formulate because pigment precipitates cannot build up . In addition, they usually offer a larger color space and are less problematic with smooth papers. Pigment inks, on the other hand, have a longer shelf life (i.e. they fade more slowly on the paper), allow a stronger application of color and are more water and smudge-proof. Many developments by manufacturers aim to combine the advantages of the respective ink types with one another.

The ink used in ink (jet) printers is manufactured by most manufacturers on a water basis and contains additives that prevent it from drying out too quickly and, in particular, from drying out in the nozzle. This enables the printer to self-clean in order to restart blocked nozzles. On the other hand, these inks have a limited lifespan in the liquid state, since proteins are added to improve the durability of the printouts. Other additives to improve lightfastness and luminosity are added on a manufacturer-specific basis.

- Primary colors

- In order to be able to print in color, ink (jet) printers use inks in the colors cyan , magenta , yellow and black ( four -color printing , CMYK color model ). For pigment inks, the most common pigments are copper phthalocyanine (cyan, pigment blue 15: 3 or 15: 4), quinacridone (magenta, PR122, PV19 (more yellowish) or PR202 (even more yellowish)), and pigment yellow (yellow, PY74, PY180, PY120, PY175 or PY155) is used. By printing on top of each other and closely side by side, these three basic colors can be used to produce almost all colors that the eye can resolve (see the resolution of the eye ) and even black on the substrate. However, the exact complementary colors, i.e. red, green and blue, cannot be represented with such color purity as would be possible with the use of special dyes in these shades. With these colors, inkjet printers have problems producing the luminosity as in the RGB color space . Even black from cyan, magenta and yellow is usually just a dark brown. That is why almost all ink (jet) printers have an additional tank with black ink. Some models have additional colors to further increase the quality of photo printing .

- Contrast black

- These inks differ from Indian inks in that they are not pigmented . Some printers offer a second black cartridge with pigmented black, which allows blackening on plain paper that comes close to laser printers . However, since this black is not suitable for photo printing, a second black cartridge is used. There are also inkjet printers that work exclusively with pigmented ink. It was found that the reduction in size of the pigment particles leads to an increase in the reproducible color space.

- Photo cyan, photo magenta, gray

- Due to the nature of the principle, light cyan, magenta and gray tones produce an undesirable grizzling effect. The pixels are set further apart, so the droplets do not form a closed layer, but are too far apart. These problems are avoided with the two additional colors light cyan and light magenta. This form of improvement of the print result is known as the CcMmYK color model. The use of a gray ink also allows a finer gradation of gray tones when reproducing black and white images. An alternative approach to solving the problem of reproducing light colors is to provide nozzles that can eject different sized droplets, similar to what is done with a screen .

- Red, green, blue, orange

- Some printers also work with the basic colors of the additive color mixture , as these are on the edge and partly outside the CMYK color space. This approach comes from the field of offset printing, where Pantone developed a process called Hexachrome . The colors of the other inks may have to be adjusted accordingly in order to achieve the desired larger color space through the mixture on the paper. In addition to the above-mentioned PR 122 and PB 15: 4 pigments green (PG 36) and orange (PO 64) instead of yellow pigments (PY 213), the Epson patent US 787 1467, which avoids a mixture of different yellow pigments can.

- Clear ink

- Some printers also use a clear “ink” to create an extra top layer on the paper. This improves the gloss, especially with pigment inks (e.g. Kodak Easyshare or Epson R800).

- Ink for CIJ printers

- Inks for CIJ printers have special physical properties. For example, they have to be electrically conductive in order to be deflected in the ink tunnel. Mostly CIJ inks are separated into the components of a concentrate and the corresponding thinner and mixed in the device. Due to the use of different formulations and thinners (e.g. water, ethanol, methanol, MEK) these inks are very universal in terms of their drying times and adhesion properties. Special CIJ inks are UV-curing, thermochromatic (i.e. the color changes in a controlled manner when exposed to temperature), grease and oil penetrate or only become visible under special lighting.

- Displayable colors

- In a test, assuming that the human eye can distinguish 2.4 million colors, a comparison of different printers with additional inks was carried out. The results showed that the Canon imagePROGRAF iPF 5100 and Hewlett-Packard Designjet Z3100 printing with CMYK as well as light magenta, light cyan, light gray, red, green and blue , and the Epson Stylus Pro printing with CMYK, light magenta, light cyan, light gray, orange and green 7900 each could print about 800,000 different colors. In contrast, pure CMYK offset printing according to ISO 2846 or ISO 12647 achieves 400,000 different colors (for comparison: Adobe RGB 1,300,000, newer wide-gamut LCD monitors with LED backlighting 1,500,000)

Overview of ink systems and brand names

In the following, common ink systems are briefly described and the manufacturer's product names are given. Abbreviations used: C: cyan; c: light or photocyan; M: magenta; m: light or photo magenta; Y: yellow; K: black or photo black; k: other or matt black; L: gray (light); l: light gray; R: red; G: green; B: blue; O: orange; P: protective varnish / gloss optimizer.

Epson

The following types are used in Epson models.

- Claria :

Dye-based ink; CcMmYK color system with single ink tanks, introduced in 2006.

- DURABrite :

CMYK pigment ink with single tanks; first pigment-based color ink from a printer manufacturer, introduced in 2001.

- DURABrite Ultra :

CMYK pigment ink with individual tanks, like DURABrite, but with polymer-coated pigment particles as an adhesion promoter on the paper. Introduced in 2005.

- Ultrachrome Hi-Gloss :

Pigment-based ink from Epson, introduced in 2002, initially with CMYKLlk in the R2100.

- Ultrachome Hi-Gloss 2 :

In 2004 in the R800 to CMYKkRBP (i.e. with R, B and P) modified variant of Ultrachrome. Also available as CMYKkROP.

- Ultrachrome K3:

CcMmYKLlk. Pigment ink with resin-coated pigment particles. With three photo black levels (therefore “K3”) differentiated gray and brightness reproduction. Single ink tanks, introduced in 2006.

- Ultrachrome K3 "Vivid Magenta":

Like K3, but with other magenta pigments with more saturation.

- Ultrachrome K3 HDR :

like K3 "Vivid Magenta", but additionally G and O.

Canon

The following types are used in Canon models. BCI-6 ink system (still without a specific brand name, type designation of the ink cartridges). First dye-based ink system from Canon especially for photo printing, initially CcMmYK, later supplemented with R and then R + G.

- Chromalife100 :

dye-based, introduced in 2005, describes a combination of printhead, ink and paper. Extended lifespan; available with 4, 5, and 8 ink printers.

- Chromalife100 + :

compared to Chromalife100 improved red rendering, special black ink, available for printers with single tanks as well as combination print heads. Introduced in 2008.

- Pixma 4-ink system :

unofficial name for a CMYk color system for simpler printers; only CMY is used for photo printing; Single and combination cartridges (CMY + k) variants exist.

- Lucia :

Pigment-based inks.

- Lucia EX :

Further development of Lucia II, with CcMmYKLlRGBk 12 color system; according to information from Canon with 20% extended color space, which is very similar to Adobe RGB .

Hewlett-Packard

Hewlett-Packard uses the following combinations in its photo printers.

- Vivera :

Since around 2004 the name of all HP inks, both dye and pigment inks. The pigment inks (introduced in 2006) are polymer encapsulated and contain a particularly dark black, which allows gray tones to be displayed without mixed in color inks. The color system is CcMmYKLk. For dye inks, HP often uses combination cartridges (e.g. type 110) for CMY, which are supplemented with photo and gray cartridges. Other printers use single inks, mostly CcMmYK (e.g. series 02).

Kodak

Various technologies are summarized by Kodak as Kodacolor technology . The ink is pigment-based (“nanopigmented” through finer grinding of the pigment particles), CMYKkP color system, with two tanks (k and CMYKP, row 10); introduced in 2007. In 2010 a simplified system with K + CMY tanks (row 30) was introduced.

Lexmark

Like Kodak, Lexmark uses Vizix, a name for all inkjet technology, with printheads that remain in the printer; CMYK single ink tanks with dye ink; introduced in 2009.

Special papers

Inkjet printers only develop their true capabilities on special papers, which differ particularly in the absorbency of the surface. With normal paper, the ink penetrates the paper and spreads there to form a spot that is considerably larger than the actual ink droplet and, depending on the texture of the paper fibers, deviates significantly from the desired circular shape. This leads to blurred boundaries, blurring of the different colors into one another and generally to a "muddy" print image. Special papers, on the other hand, usually consist of a carrier material, which can consist of paper or, in the case of higher quality “papers”, also of plastic, and a special adhesive layer. This layer primarily prevents the ink droplets from running apart and thus guarantees a significantly higher level of detail resolution and color separation. In addition, the layer ensures stronger colors, depending on the type, a matt or gloss effect and sometimes even longer color stability of the inks.

With special papers in connection with high-quality inkjet printers and inks, photo-like "prints" can be made, which in many aspects (resolution of detail, color space) are on a par with classic, chemical photo prints. Photo- like prints can be made at home so that, for example, images from a digital camera are available on paper, similar to a classic color photo.

Disadvantages of this technology are the higher price compared to exposed photos, the inadequate lightfastness depending on the ink (especially under daylight with a high proportion of blue, violet and ultraviolet) and the artefact formation due to the printing screen .

For the production of overhead projector films, specially coated films are available that can also be processed with inkjet printers.

advantages

The greatest advantage of the inkjet printer is the comparatively simple design of the devices and the associated low manufacturing costs. In the last few years the results - at least on special papers - have reached a quality that other processes only rarely achieve or at high cost. For most applications, conventional paper is sufficient and the printing costs are then at a similar level for black and white and lower for color than for color laser printing. The high-quality output of digital data by means of exposure is very cheap in terms of material costs, but the devices are only profitable for larger companies due to the high purchase price.

Some inkjet printers achieve considerable color spaces - only full-color systems and thermal sublimation printers offer larger color spaces, the former are unaffordable to purchase for private use, the latter are higher in consumption costs.

disadvantage

- Inkjet printers are sensitive to the medium to be printed, many inks are not indelible and not of archive (water-soluble, long-term chemical changes) and bleach especially in influencing short-wave light components (light) significantly stronger than other methods, that are not fading . In contrast, lightfast color pigments can be used in laser printers.

- The highest quality is only achieved on relatively expensive special papers and leads to page prices of more than one euro per A4 page in individual cases. Significantly lower printing costs can be achieved with black and white laser printers.

- The inks tend to dry out unless you print regularly. The result is expensive replacement of ink and / or print heads.

- Inkjet printers are not suitable for mass printing because they are typically slower. Depending on the number of copies, the laser , offset or gravure printing process is more suitable.

Refilling ink cartridges

A significant part of the cost of printing comes from consumables (ink / toner). Therefore, there are suppliers of compatible consumables for all common printer manufacturers. Despite the measures taken by the printer manufacturers, such as encrypted identification chips on the cartridges, almost all types of ink are available from third parties. The quality of compatible consumables can vary widely. Compatible printer cartridges often have more capacity and a significantly lower price and the savings exceed the money for a new printer within a short time. Tests by independent magazines and laboratories show that there are many acceptable alternative printer consumables. Printer cartridges with a print head or drum cannot destroy the printer because the print head and, in laser printers, the drum is not in the printer, but on the cartridge. In the case of printer cartridges without a print head or drum, they can stick or dirty the printer due to poorly suited ink or toner, but the savings even allow frequent replacement with several new printers.

It is also economical to refill the ink cartridges yourself or to seek help from specialists who have tried and tested the market. A loss of the guarantee or warranty for the printer through the use of printer inks from third-party suppliers does not arise, at least under German law. Neither the statutory warranty nor the manufacturer's guarantee depend on the ink used. Only if the dealer or the printer provider can prove that the damage is due to the foreign ink, they can reject repairs under warranty. However, color shifts can occur in third-party inks and it makes sense to obtain or create an ICC profile for each alternative ink / paper combination used for the photo printout .

Aside from the use of foreign inks, refillable cartridges also offer the option of using original ink from larger containers such as those offered for plotters. For example, for Epson Ultrachrome ink, the list price per milliliter changes by a factor of almost three if the ink is purchased in 11 ml or 700 ml cartridges.

Storage of ink cartridges

So that printer cartridges can be used for as long as possible, they must be specially stored. A temperature that is as constant as possible is particularly important for the storage of cartridges. Too strong and constantly changing temperature has a negative influence due to thermal expansion. Ink cartridges can be stored at room temperature (20 ° C). Temperatures of −15 to +35 degrees Celsius were not a problem, however. To prevent open ink cartridges from drying out, regular printouts should be made or the cartridges should be stored in airtight boxes.

Niche products with ink printing

The last Brother models of the 700 and 800 series with an ink printer and an integrated text system were a type of typewriter that was only briefly represented on the market with moderate success . They already used the high-resolution possibilities of ink printing for fonts (several fonts with scaling) and graphics with black and, depending on the model, colored ink. However, their performance lagged behind that of modern PCs, and as fully configured systems they could not be expanded. They were only available for a few years in the early to mid-1990s.

Inkjet printing units are included in some cash registers, order picking devices or niche segments in industry and commerce. They are mainly in direct competition with the robust and colorfast dot matrix printers or the cheaper and compact thermal printing for special paper.

Emissions

During their operation, inkjet printers release volatile organic compounds (VOC and VVOC) from the inks used . Particles are released to a small extent. However, the emissions are far below the requirements of the Blue Angel eco- label .

Typical VVOCs measured on particularly fast inkjet printers were after acetone, alcohol and isopropanol. The emissions of hazardous substances would be far below those of low-emission laser printers.

Others

In 2015, the University of Linz succeeded in printing circuit boards for very low currents on paper. Nanoparticles were added to the ink to make the paper electrically conductive.

Individual evidence

- ↑ finanzen.net: Kodak Introduces Availability of Stream Technology as KODAK PROSPER S10 Imprinting System. June 16, 2009, accessed September 19, 2011 .

- ↑ Packaging & Converting Essentials: Kodak to Unveil KODAK PROSPER 5000XL Press at Ipex 2010. (No longer available online.) March 9, 2010, archived from the original on August 24, 2010 ; Retrieved September 19, 2011 (English).

- ↑ Discovery Channel: Bit.Fall - Discovery Channel Short Film. Youtube, November 27, 2006, accessed on September 19, 2011 .

- ↑ How much ink goes on cleaning , website of Stiftung Warentest , accessed on March 27, 2015.

- ↑ Tips - Product Finder Printer , website of Stiftung Warentest , accessed on April 26, 2012.

- ↑ Memjet developer Silverbrook ( Memento from September 4, 2009 in the Internet Archive )

- ↑ Torsten Schaßan: seminar script basic information technology. (No longer available online.) 2004, archived from the original on November 14, 2012 ; Retrieved September 19, 2011 .

- ↑ EASTMAN KODAK CO: Combining error diffusion, dithering and over-modulation for smooth multilevel printing. August 7, 2001, accessed September 19, 2011 .

- ↑ EASTMAN KODAK CO: MULTILEVEL HALFTONING METHOD OF DIGITAL IMAGE. April 11, 2003, accessed September 19, 2011 .

- ↑ SEIKO EPSON CORP: DITHER MATRIX GENERATION DEVICE, PRINTED MATTER, DITHER MATRIX GENERATION METHOD, PROGRAM, AND IMAGE PROCESSING DEVICE. April 30, 2008, accessed September 19, 2011 .

- ↑ CABOT: Pigments for Inkjet Applications. (PDF; 104 kB) July 30, 2009, accessed on September 19, 2011 (English).

- ↑ a b Jim Reczek: Image Quality with Kodak Pigmented Ink. (No longer available online.) August 11, 2010, formerly in the original ; Retrieved September 19, 2011 (English). ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Cathie Burke: The Inkjet Print Head for KODAK EASYSHARE AIO Printers. (No longer available online.) February 20, 2007, archived from the original ; Retrieved September 19, 2011 (English).

- ↑ Paul Lindstrom: Wide gamut approaching full gamut. (PDF; 253 kB) (No longer available online.) December 23, 2008, archived from the original on February 1, 2012 ; Retrieved September 19, 2011 (English).

- ↑ SEIKO EPSON CORP: Epson Claria Photographic Ink. Retrieved September 19, 2011 (English).

- ↑ a b SEIKO EPSON CORP: Epson DURABriteTM Ultra Pigment Ink Technology. (PDF; 235 kB) September 2010, accessed on September 19, 2011 (English).

- ↑ imaging resource: Epson: 13-inch R2000 photo printer unveiled. May 3, 2011, accessed September 19, 2011 .

- ↑ Nic Rossmüller: Epson UltraChrome K3 inks. April 24, 2006, accessed September 19, 2011 .

- ↑ SEIKO EPSON CORP: Ink Technology Rules. (PDF; 384 kB) Epson's World Leading UltraChrome ™ HDR Inkset. October 11, 2008, accessed September 19, 2011 .

- ↑ LexJet: Learn More about the LUCIA EX Inks in Canon's Newest imagePROGRAF Printer. (No longer available online.) Archived from the original on May 31, 2011 ; Retrieved September 19, 2011 (English).

- ↑ Hewlett Packard: The new HP Vivera pigment inks for professional photo printing. (PDF) 2006, accessed on September 19, 2011 .

- ↑ New Dye-based HP Vivera Inks for HP Compact Photo Printers. (PDF; 1.3 MB) May 2006, accessed on September 19, 2011 (English).

- ^ Hewlett Packard: HP six-ink photo printing technology. (No longer available online.) Archived from the original on August 9, 2012 ; Retrieved September 19, 2011 (English).

- ↑ Printing with cheap ink - without guarantee? . Website of the Stiftung Warentest . Retrieved April 26, 2012.

- ↑ Store printer cartridges correctly. hd-toner.de, May 14, 2014, accessed on September 12, 2014 .

- ↑ Hartmut Georg, Arno Goebel, Rachid Ngazi: Inkjet printer - emission measurements on the toner test bench. In: Hazardous substances - cleanliness. Air . 75, No. 6, 2015, ISSN 0949-8036 , pp. 231-234.

- ↑ https://www.dguv.de/ifa/forschung/projektverzeichnis/ifa3133.jsp DGUV : Emissions from inkjet printers with printing speeds of more than 30 pages / minute ; IFA project no. IFA 3133 (2015), accessed January 21, 2020

- ↑ http://ooe.orf.at/news/stories/2711531/ Innovative printer produces printed circuit boards, ORF.at, May 19, 2015. Accessed May 19, 2015.

Web links

- Ink (jet) printing ( Memento from January 25, 2011 in the Internet Archive ) (PDF file; 501 kB)