emulsion

An emulsion ( Latin ex and mulgēre `` milked out '') is a finely divided mixture of two normally immiscible liquids without any visible separation. Examples of emulsions are numerous cosmetics , milk or mayonnaise .

Structure of the emulsion

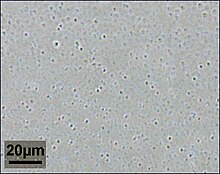

An emulsion is a finely divided mixture of two liquids, such as oil and water. One liquid ( phase ) forms small droplets, distributed in the other liquid. The phase that forms droplets is called the inner phase or disperse phase . The phase in which the droplets float is called the outer phase or continuous phase . Emulsions belong to the disperse systems and differ from mixtures of miscible liquids, such as ethanol and water. Emulsions are usually cloudy, milky liquids.

Emulsions made of water and oil are divided into water-in-oil emulsions (W / O emulsions) and oil-in-water emulsions (O / W emulsions). Another important component of emulsions is the emulsifier ( surfactant ), which facilitates the formation of droplets and counteracts segregation (phase separation).

Chemical consideration of an emulsion

Many liquids can either be well miscible with water (they are hydrophilic ) or can be well miscible with oil (they are lipophilic ). Hydrophilic liquids mainly develop intermolecular forces in the form of hydrogen bonds . In the case of lipophilic liquids , on the other hand, mainly intermolecular van der Waals forces develop . If you put some oil in water, the oil will float up. The abovementioned forces cannot develop properly between the two phases. In contrast, an interfacial tension develops at the interface . The interfacial tension is the drive to form the smallest possible interface and thus prevents the existence of an emulsion.

Surface-active substances , the surfactants ( emulsifiers ), are necessary to produce and stabilize an emulsion . The surface tension at the oil-water phase interface is significantly reduced by the surfactant. They mediate between the two phases and have a polar ( hydrophilic ) and a non-polar ( lipophilic ) part. The polar part can form hydrogen bonds and bond with hydrophilic substances, while the non-polar part of the molecule develops van der Waals forces and bonds with lipophilic substances.

Nevertheless, emulsions are unstable systems and have a limited lifespan. The so-called breaking of the emulsion occurs because the size of the interfaces is reduced by the confluence of droplets to form larger droplets (see stability of emulsions ). Butter , a water-in- milk-fat emulsion, is made from cream , a milk-fat-in-water emulsion, by breaking the emulsion.

Hydrocolloids can be used as stabilizers for additional stabilization of an emulsion . These substances increase the viscosity of the continuous phase, delay the creaming and thereby the breaking of the emulsion.

Although an emulsion is made up of liquids, it can also be solid and is then referred to as a solid emulsion . If a suspension is emulsified, it is called a suspo-emulsion .

Physical consideration

The most important parameters when considering emulsions are the phase volume ratio (the quotient of the volume of the inner phase to that of the outer phase), the mean particle size (Dm) and the particle size distribution.

Phase volume ratio

Up to a phase volume ratio of 0.3 / 0.7 (30% inner phase, 70% outer phase), the properties of the emulsion essentially depend on the properties of the outer phase. The droplets can move almost independently of one another in the outer phase and the viscosity also roughly corresponds to that of the outer phase.

As the phase volume ratio increases, the properties of the inner phase become significantly more important. If the volume fraction of the inner phase becomes too high, the phase position can change. An O / W emulsion becomes a W / O emulsion and vice versa. One speaks of a so-called phase inversion . Inversion of an O / W emulsion can also result from an increase in temperature, since higher temperatures weaken the hydrophilic interactions of the emulsifier with the water, so that the lipophilic interactions are relatively strengthened. Thus, an energetically more favorable situation can be found in the system in that the oil phase forms the continuous phase in which the water phase is present in emulsified form. The (effective) phase volume ratio can also be increased by controlled aggregation of the dispersed phase. This goes hand in hand with a sharp increase in viscosity and the occurrence of shear-thinning flow behavior.

Droplet size

Emulsions that are produced by shearing (e.g. rotor-stator system) and high-pressure emulsifying machines are not monodisperse . The droplet sizes are distributed within a certain range (see also dispersity analysis ). The production of monodisperse emulsions is possible by dispersing them using micropores (microporous solids, membranes or microchannels).

Polydisperse emulsions allow more space to be filled than would be possible in a monodisperse, hexagonal close packing . Gaps between the larger droplets are filled with smaller droplets.

The mean particle diameter (Dm) in emulsions is normally between 100 nanometers and 1 millimeter. The larger the mean particle diameter and the broader the particle size distribution, the greater the milky-white turbidity of the emulsion. Emulsions such as milk have a bluish tinge in incident light and sometimes clearly red in transmitted light. The cause of this is the dependence of the scattering on the particle diameter (see Mie scattering , electromagnetic scattering on objects in the order of magnitude of the wavelength and Rayleigh scattering ).

Emulsions with a droplet diameter

- larger than 1 micrometer are called macroemulsions ,

- in the range of 1 micrometer or smaller is called miniemulsion or submicron emulsion (the latter are thermodynamically more stable),

- below 100 nanometers is called nanoemulsion

Stability of emulsions

Most emulsions are thermodynamically unstable: The disperse phase tries to unite to form larger areas through coalescence - the interfacial energy between the two phases is reduced.

Emulsions should usually be retained for a certain period of time (between a few hours and a few years) and under certain conditions ( temperature range , pH range ). If an emulsion breaks down, this happens in individual phases, which however often run simultaneously.

- Phase: Short-term stable emulsion

For example, fat droplets are dispersed in the outer phase (water). - Phase: creaming or sedimentation (reversible)

Due to the force of gravity , the mixed phases are separated into the specifically lighter and the specifically heavier. - Phase: Ostwald ripening (ripening)

- Phase: aggregation (reversible)

The fat droplets form aggregates , the particle diameter is increased and, according to Stokes' law , the sedimentation speed of the dispersed fat droplets increases. - Phase: Coalescence

The fat droplets combine; in extreme cases this can lead to the breaking of the emulsion.

Manufacture of emulsions

By reducing the size of the droplets when producing an emulsion, the interface between the two phases increases. The interfacial tension must be overcome and a new interface created. This requires work that must be mechanically introduced into the system. The resulting shear forces make the droplets smaller and smaller.

Surfactants (low and high molecular weight) and high molecular weight emulsifiers

By surfactants or emulsifiers, which are often referred to as surfactants (surface active agents), the leaves interfacial tension en drastically reduced. The surfactant should also prevent the newly created droplets from coalescing ( flowing together) again. To do this, the surfactant must diffuse as quickly as possible to the new interface of the droplets formed and form an interface film. Synthetic surfactants do this in a few milliseconds.

High molecular surface-active substances are also referred to as emulsifiers (e.g. proteins, polyvinyl alcohols with a high degree of polymerization) due to their amphiphilic and mostly slight molecular rearrangement or flexibility at the interface (ionic molecular residues facing the water phase). These adsorb somewhat more slowly (but also in milliseconds) and form more stable and highly viscous interfaces compared to the surfactants (see following figure). As a result, these emulsions have a higher coalescence stability than the low molecular weight emulsifiers.

Another property to be considered when choosing a suitable low molecular weight surfactant is its spreading speed (spreading speed). The interface of a new drop is initially only partially covered by surfactant. This now spreads to that part of the interface that was initially unoccupied. This initially creates a surfactant concentration gradient at the interface, which, depending on the spreading speed, is balanced out more or less quickly to form a uniform surfactant distribution.

With increasing droplet size reduction and an increasing interface, the surfactant concentration in the continuous phase decreases. If there is not enough surfactant to cover the interface, a smaller, stable drop size cannot be achieved.

From the volume of the phase to be dispersed and the desired droplet diameter, the necessary amount of emulsifier can be calculated for the interface to be covered. To do this, it must be known which area can be covered by 1 g of emulsifier (low molecular weight emulsifiers about 10 mg per ml of oil, proteins about 15 mg per ml of oil). As the particle size decreases, the interface per ml of oil increases, which leads to a higher need for emulsifier.

In the case of higher molecular weight emulsifiers, about double the amount is used to ensure the formation of the emulsion.

When using low-molecular surfactants, the necessary concentration is generally well above the required or the micelle formation point cmc (critical micelle concentration). The necessary emulsifier molecules are supplied from the micelles as the interface increases.

Usually, the phase in which the emulsifier dissolves better is the outer or continuous phase. With an HLB value of 3 to 6 the emulsion becomes a W / O emulsion, from 8 to 18 an O / W emulsion (Bancroft's rule).

High molecular emulsifiers at interfaces

While polyglycerol-polyricinoleate (PGPR, M 1200-2000 g / mol), an emulsifier for water-in-oil emulsions, has a higher molar mass, the polymeric emulsifiers with about M <10,000 g / mol are counted among the high molecular weight ones . Due to the different content of non-charged and charged amino acids and a pH-dependent charge state, the unfolded amphiphilic protein molecules adsorb with different activity at the interfaces (air / water, water / oil). With an increase in charge and solubility, the affinity to the aqueous phase also increases at the interface (high hydrophilicity), at the same time the uncharged lipophilic amino acid residues attach to the air or oil phase and support the formation of air bubbles or oil droplets when shear energy is introduced.

Since proteins are mostly negatively charged above the isoelectric point (IP) and positively charged below the IP (in the more acidic pH range), adjusting the pH value of the aqueous phase changes the charge state at the interface. So the protein interface can e.g. B. at a pH below 4.0 with a positive charge complex with negatively charged polymers (polyelectrolytes). This can be used to cover interfaces with negatively charged polysaccharides (ionic bond). This changes the transport of substances between the aqueous and hydrophobic phase (e.g. lower oxygen transfer with reduced oxidation of the oil phase, lower release of hydrophobic aromatic substances, slower lipid release in the digestive tract).

A further coating is possible by introducing the oil droplets additionally coated with a polysaccharide into a neutral protein phase. After lowering the pH again, another negatively charged polysaccharide layer can accumulate. Variants of the interface coverage are shown in the following figure for possible interface stabilization.

In addition to the second protein layer, smaller oil droplets stabilized with protein can also be deposited. Such oil droplets, which are coated with very small oil droplets, are called colloidosomes. Heavily denatured proteins, which are present as very small aggregates or gel particles (nano or microparticles), also adsorb at interfaces and lead to stabilization. Such droplet stabilization is called “Pickering stabilization”, the emulsions are called “Pickering emulsions” (also “Pickering-type emulsions”) (see solids stabilization). Possible variants of the interface stabilization of oil-in-water droplets are:

- Pickering or particle stabilization,

- Use of low-molecular or high-molecular emulsifiers (proteins),

- Use of protein-polysaccharide complexes (soluble or insoluble complexes),

- Formation of multilayers from protein and ionic polysaccharides,

- Accumulation of coated nano-drops (colloidosomes).

Solid stabilizers

An emulsion can e.g. B. be stabilized by means of particles of various types. These include a. rigid and non-swellable, but differently wettable, swellable, synthesized, uncharged or charged amphiphilic rigid or deformable particles (Janus particles). This is commonly referred to as particle stabilization or the emulsion according to the discoverer as Pickering emulsion.

Pickering showed in 1907 that small solid particles (salts), which are wetted better by water than oil, can stabilize O / W emulsions. It is important for adequate stabilization that a mechanically stable interface is formed.

Particle properties

The particles should have the following properties for interface stabilization (air / water, oil / water):

- Nano- or microparticles, amphiphilic or differently wettable with the hydrophilic phase

- Insoluble in the hydrophilic or hydrophobic phase or swellable in the hydrophilic phase

- Formation of a contact angle θ <90 ° at the interface to form oil-in-water emulsions, θ> 90 ° to form a water-in-oil emulsion

Advantages of a solid stabilized emulsion

- Mostly more resistant to changes in the chemical environment (pH value, salt concentration, etc.)

- Increased long-term stability (high coalescence stability of emulsions with larger oil droplets, e.g. 10 to 100 µm)

- Coalescence stabilization of double emulsions

- Adjustable digestibility in the gastrointestinal tract through particles with adjusted enzyme resistance

- Increase in freeze-thaw stability

- Influence of the rheological properties (increase in viscosity, yield point and consistency)

equipment

There are a number of possible methods of introducing the work required for emulsification into the medium. In general, however, four different main groups can be distinguished.

Rotor-stator systems

With these, a component is moved (or rotated) and a component is at rest. Examples are:

- Fanta bowl and pestle

- Agitators

- Shaker

- Vibratory mixer

- Emulsifying centrifuges

- Colloid mills

- Gear ring dispersing machines

Fluid mechanics means

- Baffles

- Vortex chambers

- High pressure homogenizers , these consist of a pump and orifices or valves. For this, z. B. atomizers can be used.

Ultrasonic generators

Here the drops are crushed by means of an ultrasound transducer and a sonotrode. The principle of ultrasonic emulsification is based on cavitation, which is generated when high-intensity ultrasonic waves are introduced into a liquid. The ultrasonic cavitation generates high shear forces as well as microturbulence in the liquid, so that the droplets of the two phases (water and oil phase) are crushed and mixed into one phase.

Microstructured systems

Using micropores in membranes or using microchannels, polydisperse or monodisperse oil droplets particles with an adjustable size range can be generated. The architecture of the micropores (undefined or defined pore shape, round or slit-shaped outlet opening) is important here.

Important parameters for the droplet size of the emulsions are summarized in the following figure. These parameters also predominantly apply to the formation of monodisperse emulsions generated by means of defined microchannels.

Rotating membranes enable very small drops to be generated, in particular by increasing the wall shear stress. The wall shear stress can be increased significantly via the rotation speed and the viscosity of the continuous phase.

Plastics, special glass, ceramics and various metals (e.g. nickel, iron, aluminum) are used to manufacture membranes with undefined and defined pore geometry. The surfaces are hydrophilized or hydrophobized depending on the dispersion phase. To form monodisperse droplets, silicon micro-platelets or 3-D printing membranes made of plastic are also used.

For the droplet size and the droplet size distribution, the following parameters are mainly of importance:

- Composition of the continuous phase (emulsifier type, density, viscosity)

- Interfacial tension between the phases

- Volume flow of the continuous phase or wall shear stress

- Membrane material (pore diameter, hydrophilicity, pore shape)

- Density, viscosity and flux of the oil phase

Microemulsions

Microemulsions are water-oil-surfactant mixtures which, unlike other emulsions, are thermodynamically stable. They are optically transparent and form without the high energy input otherwise necessary for the production of emulsions. Usually cosolvents or cosolvents are used to produce a microemulsion. Microemulsions only form in certain areas of the phase diagrams of the ternary or also quaternary material systems.

Multiple emulsion

Multiple emulsions are made up of drops within drops. While under multiple emulsions z. B. W1 / O1 / W2 / O2 / W3 or O1 / W1 / O2 / W2 systems are understood, W1 / O / W2 and O1 / W / O2 systems are also referred to as double emulsions.

When producing such emulsions, it is important that, for double emulsions, the inner W1 or O1 phase is produced with droplet sizes <1 µm and high coalescence stability. The resulting W1 / O or O1 / W emulsion is dispersed in a new outer phase under conditions that allow the inner W1 or O1 phase to be maintained. Therefore, W / O and O / W emulsifiers should be selected in such a way that there are no negative interactions during the emulsification process that lead to instability of the inner emulsion. Furthermore, the osmolality of the inner and outer water phase is to be adjusted so that the drops of the inner W1 phase do not swell or shrink due to high osmotic differences.

Double emulsions are suitable for the inclusion of ingredients in the inner phase. This can be used to encapsulate substances that are sensitive to oxidation, for sensory or other reasons, are slowly released during storage or quickly under the action of shear forces or osmotic shock. It can e.g. B. volatile aromas, flavors (desirable or undesirable), micronutrients, probiotics, therapeutics, enzymes and biologically active substances. Furthermore, W1 / O / W2 systems are suitable for the production of low-fat food emulsions by increasing the proportion of W1 phase in O.

In the technical field, multiple or double emulsions u. a. can be used for liquid membrane permeation (a special form of extraction ), in which the middle phase (membrane phase) serves as a filter between the inner and outer phases. Liquid membrane permeation is also used to extract traces of heavy metals from wastewater, for example sulfuric acid is emulsified in an oil phase that contains chelating agents in dissolved form and this emulsion is in turn emulsified in the wastewater, the heavy metals are dissolved in the oil phase by liquid-liquid extraction and from this, also converted into sulfuric acid by liquid-liquid extraction. After the oil phase has been separated off, the acid-in-oil emulsion is split in a high-frequency alternating current field.

Photo emulsion

In analog photography , the photosensitive layer applied to a substrate is commonly referred to as a photo emulsion . In the sense described above, however, this is not an emulsion, but a solidified suspension .

Classification in the scheme of chemical substances

| Schematic classification of the substances | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

See also

literature

- NI Kosin: food emulsions. translated from Russian by Karlwilhelm Horn. Fachbuchverlag Leipzig, 1954, DNB 574438777 .

- H. Schubert (Hrsg.): Emulsification technology basics, processes and applications . Behr's Verlag, Hamburg 2005, ISBN 3-89947-086-9 .

- G. Lagaly, O. Schulz, R. Zimehl: Dispersions and emulsions . Steinkopff Verlag, Darmstadt 1997, ISBN 3-7985-1087-3 .

- B. Dobiáš: emulsions. Part 1. In: Tenside detergents. Vol. 15, No. 5, 1978, pp. 225-238; Part 2. In: Tenside Detergents. Volume 16, No. 6, 1979, pp. 289-297.

- H. Asche (Ed.): Technology of ointments, suspensions and emulsions . An APV seminar from 20. – 22. September 1982 in Darmstadt. Wissenschaftliche Verlagsgesellschaft, Stuttgart 1984, ISBN 3-8047-0748-3 .

- G. Muschiolik, H. Bunjes (Ed.): Multiple emulsions - production and properties . Behr's Verlag, 2007, ISBN 978-3-89947-339-1 .

Individual evidence

- ↑ Gerhard Lagaly, Oliver Schulz, Ralf Zimehl: Dispersions and Emulsions - An introduction to the colloidics of finely divided substances including clay minerals. Steinkopf-Verlag, Darmstadt, ISBN 3-7985-1087-3 , p. 253 (partly available from Google Books) .

- ↑ H. Schubert (Ed.): Emulsification technology. Basics of procedures and applications. ISBN 3-89947-086-9 , p. 531.

- ↑ Philipp L. Fuhrmann, Guido Sala, Markus Stieger, Elke Scholten: Clustering of oil droplets in o / w emulsions: Controlling cluster size and interaction strength . In: Food Research International . tape 122 , August 1, 2019, ISSN 0963-9969 , p. 537-547 , doi : 10.1016 / j.foodres.2019.04.027 ( sciencedirect.com [accessed June 25, 2019]).

- ↑ a b H. Schubert (Ed.): Emulsification technology. Basics of procedures and applications. Behr's Verlag, ISBN 3-89947-086-9 , p. 1 (excerpts available online at Google Books) , last accessed in July 2012.

- ^ GE Petrowski: Emulsion Stability and its Relation to Foods. In: Advances in Food Research. Volume 22, 1976, pp. 309-359.

- ↑ YS Gu, EA Decker, DJ McClements: Formation of colloidosomes adsorption of small charged oil droplets onto the surfaces of large oppositely charged oil droplets. In: Food Hydrocolloids. Volume 21, 2007, pp. 516-526. doi: 10.1016 / j.foodhyd.2006.05.011

- ↑ YS Gu, EA Decker, DJ McClements: Formation of colloidosomes adsorption of small charged oil droplets onto the surfaces of large oppositely charged oil droplets. In: Food Hydrocolloids. Volume 21, 2007, pp. 516-526. doi: 10.1016 / j.foodhyd.2006.05.011

- ^ E. Dickinson: Use of nanoparticles and microparticles in the formation and stabilization of food emulsions. In: Trends in Food Science & Technology. Volume 24, 2012, pp. 4–12. doi: 10.1016 / j.tifs.2011.09.006

- ↑ G. Muschiolik: Surface-active biopolymers - emulsifiers as green ingredients. In: Deutsche Lebensmittel-Rundschau. Volume 114, 2018, pp. 434-444.

- ↑ G. Muschiolik: Development of new emulsion systems. In: Behr's yearbook 2013. Behr's Verlag, Hamburg 2013, ISBN 978-3-95468-006-1 , pp. 117-134.

- ^ SU Pickering: Emulsions. In: Journal of the Chemical Society. Volume 91, 1907, pp. 2001-2021. doi: 10.1039 / CT9079102001

- ↑ Patent specification device for forming an oil-water emulsion

- ↑ Generation of Emulsions by Ultrasonic Cavitation. Retrieved February 22, 2017 .

- ↑ GT Vladisavljević, I. Kobayashi, M. Nakajima: Production of uniform droplets using membrane, microchannel and microfluidic emulsification devices. In: Microfluid Nanofluid. Volume 13, 2012, pp. 151-178. doi: 10.1007 / s10404-012-0948-0

- ↑ G. Muschiolik, H. Bunjes (Ed.): Multiple emulsions - production and properties. Behr's Verlag, 2007, ISBN 978-3-89947-339-1 .

- ↑ G. Muschiolik, H. Bunjes (Ed.): Multiple emulsions - production and properties. Behr's Verlag, 2007, ISBN 978-3-89947-339-1 .

- ^ G. Muschiolik: Multiple emulsions - status and progress. In: Behr's yearbook 2018 food industry. Behr's GmbH, Hamburg 2018, ISBN 978-3-95468-526-4 , pp. 85-93.

- ^ G. Muschiolik, E. Dickinson: Double Emulsions Relevant to Food Systems: Preparation, Stability, and Applications. In: Comprehensive Reviews in Food Science and Food Safety. Volume 16, 2017, pp. 532-555. doi: 10.1111 / 1541-4337.12261

- ↑ Rolf Marr, Manfred Prötsch, Alexander Bouvier, Josef Draxler, Alois Kriechbaumer: Continuous Attempts to liquid membrane permeation in a pilot plant. In: Chemical Engineer Technology. Volume 55, Issue 4, 1983, pp. 328-329.