Glycerine 1,2-carbonate

| Structural formula | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

| Mixture of two isomers structural formula without specifying the stereochemistry |

||||||||||||||||

| General | ||||||||||||||||

| Surname | Glycerine 1,2-carbonate | |||||||||||||||

| other names |

|

|||||||||||||||

| Molecular formula | C 4 H 6 O | |||||||||||||||

| Brief description |

clear, colorless to light yellow liquid |

|||||||||||||||

| External identifiers / databases | ||||||||||||||||

|

||||||||||||||||

| properties | ||||||||||||||||

| Molar mass | 118.09 g mol −1 | |||||||||||||||

| Physical state |

liquid |

|||||||||||||||

| density |

|

|||||||||||||||

| Melting point |

|

|||||||||||||||

| boiling point |

|

|||||||||||||||

| Vapor pressure |

0.93 Pa at 25 ° C |

|||||||||||||||

| solubility |

with water and polar solvents such as alcohols and tetrahydrofuran miscible |

|||||||||||||||

| Refractive index |

|

|||||||||||||||

| safety instructions | ||||||||||||||||

|

||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . Refractive index: Na-D line , 20 ° C | ||||||||||||||||

Glycerine-1,2-carbonate is formally the cyclic ester of carbonic acid with glycerine and has met with great interest as a possible product from the “waste materials” carbon dioxide CO 2 and glycerine (especially from biodiesel production) with a wide range of applications.

The currently unsatisfactory yields and complex process conditions in direct synthesis prevent the further spread of glycerol carbonate as a solvent and building block made from renewable raw materials.

Manufacturing

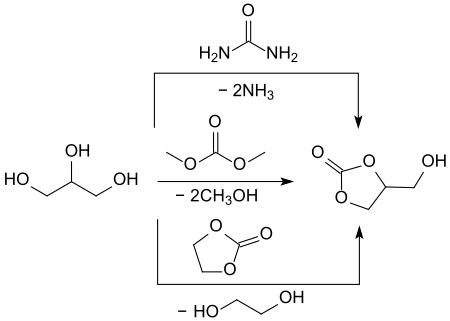

A large number of synthetic routes have been described for the production of glycerol-1,2-carbonate, many of which do not meet the criteria for modern chemical processes in terms of economy, environmental compatibility and safety.

Non-glycerol-based syntheses, especially if they are based on expensive preliminary products, such as B. glycidol or 3-chloro-1,2-propanediol or epichlorohydrin and expensive catalysts fall back, do not contribute to the economic solution of the huge oversupply of glycerin (estimate for 2024: about 6.3 million tons of global production volume).

Of the indirect glycerine-based syntheses, in which the cyclic carbonic acid ester glycerine carbonate is formally formed by the entry of a carbonyl group , reactions with particularly inexpensive urea and with dialkyl carbonates such as dimethyl carbonate DMC and ethylene carbonate have been worked on particularly intensively.

Transesterification results in methanol or, in the case of urea, ammonia as a by-product , which can easily be removed from the reaction and do not interfere with work-up.

Recently, a glycerol carbonate synthesis with urea under microwave irradiation with anhydrous zinc sulfate as heterogeneous catalyst was described, whereby under optimized conditions (150 ° C, 100 min reaction time) glycerol carbonate could be obtained in 93.7% yield.

Most common are transesterification of dialkyl carbonates, mainly of dimethyl carbonate, has been studied with acidic and basic catalysts in particular under homogeneous and heterogeneous catalysis. Practically quantitative yields of glycerol 1,2-carbonate are sometimes achieved. In homogeneous catalysis, however, often only mixtures that are difficult to separate are formed, while the solid bases used in heterogeneous catalysis are often quickly exhausted and only costly, e.g. B. by calcining at temperatures of 300 ° C, are recyclable. In addition, with high DMC excesses and long reaction times, by-products such as diglyceryl tricarbonate ( A ) and glycerol dicarbonate ( B ) are formed by reaction of DMC with the free hydroxyl group of the glycerol carbonate .

The enzymatically catalyzed conversion of glycerol with DMC in polar solvents is also described.

More recently, continuous processes have also been published. In this, very high space-time yields could be achieved at moderate temperatures (140 ° C.) and short residence times (<10 min) .

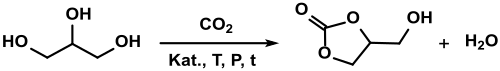

The efficient direct synthesis of glycerol 1,2-carbonate from glycerol and inert CO 2 remains a major challenge .

Reports of yields up to 35% in the reaction in methanol with dibutyltin oxide as a catalyst at 80 ° C could not be confirmed.

The results actually achieved are a maximum of 17% when using acetonitrile , which reacts in the basic ( potassium carbonate ) with the water formed to form acetamide . The reaction conditions required on a 5 millimolar scale (80 bar CO 2 pressure, 155 ° C. reaction temperature, 16 h reaction time) are not yet suitable for an economical industrial synthesis. When CO 2 is passed through to strip the water of reaction, a maximum yield of 13% is achieved under optimized conditions.

The direct carbonylation of glycerol with CO 2 over highly active cerium (IV) oxide CeO 2 catalysts in the presence of the water-binding reagent 2-cyanopyridine and the solvent dimethylformamide DMF at 150 ° C, 40 MPa CO 2 pressure and 5 h reaction time provides in 10 millimolar batches "... the incredibly high yield of glycerol carbonate ..." of up to 78.9%, with the cerium oxide catalyst being regenerated after 5 cycles by calcining at 400 ° C.

properties

Glycerin-1,2-carbonate is a clear, colorless, viscous liquid with a mild odor that dissolves completely with water and with polar organic solvents such as e.g. B. Mixes alcohols. The compound exists as a racemate and can be enzymatically separated into the enantiomers using lipase . The polymers cellulose acetate , nitrocellulose , polyamides and polyacrylonitrile are dissolved in glycerine carbonate. The compound is non-flammable, non-toxic and easily biodegradable, it has a low evaporation rate and high moisture retention capacity.

Applications

Potentially large-volume applications of glycerol 1,2-carbonate would be of enormous interest in view of the glycerol flood, which can only be managed by caloric utilization, and the suitability of glycerol carbonate for the chemical fixation of large amounts of CO 2 .

At high temperatures, glycerine carbonate almost exclusively breaks down into carbon dioxide and 3-hydroxypropanal HOCH 2 CH 2 CHO, a reactive aldehyde which is thought to have great potential as a fuel additive to reduce soot formation in internal combustion engines.

As a derivative of glycerol, 4-hydroxymethyl-1,3-dioxolan-2-one can be used, especially in cosmetics and personal care products, as a protic solvent with a high dielectric conductivity ε = 82.7 and a humectant .

Because of its similarity to propylene carbonate and because of its non-flammability and high dielectric constant, which allow significantly higher lithium ion concentrations, hydroxypropylene carbonate is being investigated as an electrolyte in lithium-ion batteries . However, protic solvents with reactive free hydroxyl groups are undesirable in battery systems.

The epoxy alcohol glycidol is formed during the decarboxylation of glycerol 1,2-carbonate at temperatures> 175 ° C, reduced pressure and in the presence of acidic or basic (such as potassium oxide ) catalysts in yields of 75 to 85%.

Inexpensive glycidol as a precursor to polyglycerols, glycerol esters and glycidyl ethers could find wider use in detergents, paints and paints and stabilizers for natural oils and for vinyl polymers.

Epichlorohydrin , which is important for the production of epoxy resins and adhesives, can be obtained from glycerol carbonate via 2-chloromethyl-1,3-dioxolan-2-one and its decarboxylation at 80 ° C. in yields of up to 90%.

Polyglycerol esters are formed by the reaction of long-chain carboxylic acids with glycerol carbonate (and other cyclic carbonates such as ethylene carbonate) in the presence of strong bases and can u. a. as emulsifiers, dispersants, flow improvers and lubricants use.

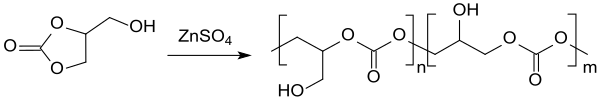

When glycerine 1,2-carbonate is heated to 140 ° C in the presence of zinc sulphate, biodegradable, water-soluble and non-flammable polycarbonate homopolymers are produced,

and copolymers with excess glycerine which could find use as lubricants, detergents, drilling aids, etc.

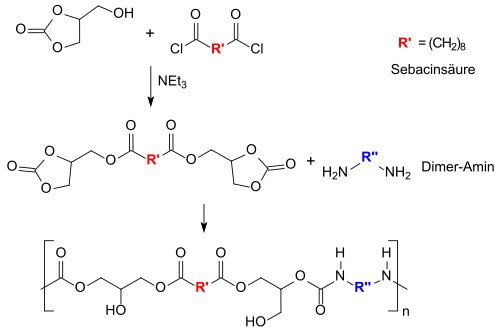

Of particular interest is the use of up-glycerol carbonates could in non-isocyanate-based polyurethanes (Engl. Non-isocyanate polyurethanes ) be NIPUs, the problematic fact diisocyanates such as toluene diisocyanate, 2,4- TDI and methylene diphenyl could replace MDI.

Even a partial substitution of diisocyanates in polyurethanes by bis-glycerine carbonates would be a significant outlet for byproducts of glycerine and a milestone in the use of monomers from renewable raw materials.

Individual evidence

- ↑ a b c d Data sheet 4- (Hydroxymethyl) -1,3-dioxolan-2-ones from Sigma-Aldrich , accessed on October 15, 2018 ( PDF ).

- ↑ a b c Entry on Glycerol-1,2-carbonate at TCI Europe, accessed on October 15, 2018.

- ↑ a b c d Product Safety Summary for Glycerol carbonate. UBE Chemical Europe, SA, January 25, 2016, accessed October 15, 2018 .

- ↑ a b c d Technical Bulletin JeffsolR Glycerin Carbonate. Huntsman Corp., 2008, accessed October 15, 2018 .

- ↑ a b K. Lanjekar, VR Rathod: Utilization of glycerol for the production of glycerol carbonate through greener route . In: J. Environ. Chem. Eng. tape 1 , 2013, p. 1231-1236 , doi : 10.1016 / j.jece.2013.09.015 .

- ↑ Entry on 4-hydroxymethyl-1,3-dioxolan-2-one in the GESTIS substance database of the IFA , accessed on October 30, 2018 (JavaScript required)

- ↑ a b c M.O. Sonnati S. Amigoni, EP Taffin de Givenchy, T. Darmanin, O. Chouletb, F. Guittard: Glycerol carbonate as a versatile building block for tomorrow: synthesis, reactivity, properties and applications . In: Green Chem. Band 15 , 2012, p. 283-306 , doi : 10.1039 / C2GC36525A .

- ↑ a b c J. Liu, Y. Li, J. Zhang, D. He: Glycerol carbonylation with CO 2 to glycerol carbonate over CeO2 catalyst and the influence of CeO 2 preparation methods and reaction parameters . In: Appl. Catal. A: General . tape 513 , 2016, p. 9-18 , doi : 10.1016 / j.apcata.2015.12.030 .

- ↑ JI Garcia, H. Garcia-Marin, E. Pires: Glycerol based solvents: synthesis, properties, and applications . In: Green Chem. Band 16 , no. 3 , 2014, p. 1007-1033 , doi : 10.1039 / C3GC41857J .

- ↑ a b J.R. Ochoa-Gómez, O. Gómez-Jiménez-Aberasturi, C. Ramiréz-López, M. Belsué: A brief review on industrial alternatives for the manufacturing of glycerol carbonate, a green chemical . In: Org. Process Res. Dev. Band 16 , 2012, p. 389-399 , doi : 10.1021 / op200369v .

- ↑ M. North, P. Villuendas, C. Young: Inter- and intramolecular phosphonium salt cocatalysis in cyclic carbonate synthesis catalysed by a bimetallic aluminum (salen) complex . In: Tetrahedron Lett. tape 53 , no. 22 , 2012, p. 2736-2740 , doi : 10.1016 / j.tetlet.2012.03.090 .

- ^ Glycerin Market And Industry Analysis, Retail Research, Survey, Global Forecast to 2018. Market Watch, March 20, 2018, accessed October 22, 2018 .

- ↑ L. Zhang, Z. Zhang, C. Wu, Q. Qian, J. Ma, L. Jiang, B. Han: Microwave assisted synthesis of glycerol carbonate from glycerol and urea . In: Pure Appl. Chem. Band 90 , no. 1 , 2018, p. 1-6 , doi : 10.1515 / pac-2017-0303 .

- ↑ JR Ochoa-Gómez et al .: Synthesis of glycerol carbonate from glycerol and dimethyl carbonate by transesterification: Catalyst screening and reaction optimization . In: Appl. Catal. A: General . tape 366 , no. 2 , 2009, p. 315-324 , doi : 10.1016 / j.apcata.2009.07.020 .

- ↑ FSH Simanjuntak et al .: CaO-catalyzed synthesis of glycerol carbonate from glycerol and dimethyl carbonate: Isolation and characterization of an active Ca species . In: Appl. Catal. A: General . tape 401 , no. 1–2 , 2011, pp. 220-225 , doi : 10.1016 / j.apcata.2011.05.024 .

- ↑ a b G. Rokicki, P. Rakoczy, P. Pazuchowski, M. Sobiecki: Hyperbranched aliphatic polyethers obtained from environmentally benign monomer: glycerol carbonate . In: Green Chem. Band 7 , 2005, p. 529-539 , doi : 10.1039 / B501597A .

- ↑ JR Ochoa-Gómez, O. Gómez-Jiménez-Aberasturi, C. Ramirez-López, B. Maestro-Madurga: Synthesis of glycerol-1,2-carbonate by transesterification of glycerol with dimethyl carbonate using triethylamine as a facile separable homogeneous catalyst . In: Green Chem. Band 14 , no. 12 , 2012, p. 3368-3376 , doi : 10.1039 / C2GC35992H .

- ↑ S. van Mileghem, WM de Graeve Borg, IR Baxendale: A robust and scalable continuous flow process for glycerol carbonate . In: Chem. Eng. Technol. tape 41 , no. 10 , 2018, p. 2014–2023 , doi : 10.1002 / ceat.201800012 .

- ↑ J. George, Y. Patel, SM Pillai, P. Munshi: Methanol assisted selective formation of 1,2-glycerol carbonate from glycerol and carbon dioxide using nBu2SnO as a catalyst . In: J. Mol. Catal. A: Chemical . tape 304 , no. 1–2 , 2009, pp. 1-7 , doi : 10.1016 / j.molcata.2009.01.010 .

- ↑ a b A. Dibenedetto, A. Angelini, M. Aresta, J. Ethiraj, C. Fragale, F. Nocito: Converting wastes into added value products: from glycerol to glycerol carbonate, glycidol and epichlorohydrin using environmentally friendly synthetic routes . In: Tetrahedron . tape 67 , no. 6 , 2011, p. 1308-1313 , doi : 10.1016 / j.tet.2010.11.070 .

- ↑ Karolin Schenk: Direct Synthesis of Glycerol Carbonate from Glycerol and Carbon Dioxide by Brønsted Base Catalysis (dissertation) . Ed .: RWTH Aachen . Aachen 2018 ( online ).

- ↑ Product Safety Summary for Glycerine carbonate. UBE Corp. Europe, December 14, 2017, accessed October 15, 2018 .

- ↑ M. Pallavicini, E. Valoti, L. Villa, O. Piccolo: Lipase-catalyzed resolution of glycerol-2,3-carbonate . In: J. Org. Chem. Band 59 , no. 7 , 1994, pp. 1751-1754 , doi : 10.1021 / jo00086a026j .

- ^ Mario Pagliaro, Michele Rossi: The Future of Glycerol: New Usages for a Versatile Raw Material, 2nd Edition . RSC Publishing, Cambridge, UK 2010, ISBN 978-1-84973-046-4 , pp. 107 .

- ↑ M. Szöri, BR Biri, Z. Wang, AE Dawood, B. Viskolcz, A. Farooq: Glycerol carbonate as a fuel additive for sustainable future . In: Sustainable Energy Fuels . tape 2 , no. 10 , 2018, p. 2171-2178 , doi : 10.1039 / c8se00207j .

- ↑ Patent US9199950B2 : Method for producing glycidol by successive catalytic reactions. Filed June 24, 2014 , published January 12, 2015 , Applicant: Korean Institute of Science and Technology, Inventors: HJ Lee, BS Ahn, SD Lee, J. Jae, JS Choi.

- ↑ Patent EP3330261A1 : Glycidol synthesis method. Registered on July 28, 2016 , published on June 6, 2018 , applicant: Fundación Tecnalia Research & Innovation, inventors: JR Ochoa-Goméz, O. Goméz de Miranda Jiménez de Aberastur, N. Blaco Pérez, B. Maestro Madurga, S. Prieto Fernández.

- ↑ Patent WO2008142374A1 : Method of making polyglycerol esters. Registered on May 15, 2008 , published on November 27, 2008 , applicant: Croda International Plc, inventor: HS Bevinakatti, AG Waite, J. Frank.

- ↑ Patent US7928182B2 : Glycerol polycarbonate, organic compositions containing same and method for obtaining said compositions. Filed August 10, 2005 , published April 19, 2011 , Applicant: Condat SA, INRA, INPT, Inventors: TD Nguyen, Z. Mouloungui, P. Marechal.

- ^ J. Guan et al .: Progress in study of non-isocyanate polyurethane . In: Ind. Eng. Chem. Res. Volume 50 , no. 11 , 2011, p. 6517-6527 , doi : 10.1021 / ie101995j .

- ↑ C. Carré, L. Boet, L. Avérous: Original biobased nonisocyanate polyurethanes: Solvent- and catalyst-free synthesis, thermal properties and rheological behavior . In: RSC Advances . tape 4 , no. 96 , 2014, p. 54016-54025 , doi : 10.1039 / C4RA09794G .

- ↑ C. Duval, N. Kébir, R. Jauseau, F. Burel: Organocatalytic synthesis of novel renewable non-isocyanate polyhydroxy urethanes . In: Polym. Chem. Band 54 , no. 6 , 2016, p. 758-764 , doi : 10.1002 / pola.27908 .

- ↑ A. Cornille, R. Auvergne, O. Figovsky, B. Boutevin, S. Caillol: A perspective approach to sustainable routes for non-isocyanate polyurethanes . In: Eur. Polym. J. Band 87 , 2017, p. 535–552 , doi : 10.1016 / j.eurpolymj.2016.11.027 .