Pulp (processing technology)

Pulp (from Latin pulpa 'meat' ), sometimes also (the) pulp or (the) pulp , is a technical term for various masses that usually contain fibers , sometimes also coarser particles and often have a pulpy consistency. Pulps are created during processing, mostly as an intermediate product or by-product .

Cellulose pulp

Made paper

In the manufacture of paper , the mixture of water and fibers is referred to as pulp , especially as a technical term in the context of the historical or traditional manufacture of handmade paper . The terms fiber pulp , paper pulp or paper fiber pulp are also used as a description or synonym .

In Europe, pulp was made almost exclusively from rag until the middle of the 19th century . The old clothes and rags were first shredded in the pounding mills of the paper mills , later in the Dutch . Due to the design, the addition of a great deal of water was necessary in the Stampfwerke and Holländer to ensure constant movement of the rags. The suspension produced during the defibration was therefore thin. In the bucket it was further diluted with water in order to finally achieve a water content of up to 99 percent.

Industrial manufacture of paper and pulp

In modern paper production, a fiber material or a mixture of different fiber materials is mixed with water. Different names are used for the mixture of water and fibers, including: fiber-water suspension , the pulp suspension or fiber suspension or suspended pulp system . The mixture is usually, but not always, in the form of a suspension. Occasionally, more general terms are used, such as a mixture of fibers and water or a mixture of substances and water .

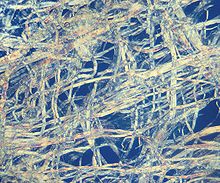

During the production of the pulp, a fibrous material - usually wood - is shredded and frayed in water to release the cellulose fibers. This process is called wood disruption or general fiber disruption . Important fiber materials in modern industrial paper production are cellulose and wood pulp , which consist of different proportions of cellulose , hemicellulose and lignin , and waste paper stock .

Wood pulp

Processes for pulping wood, with which wood pulp are produced, are grinding with grinding stones (SGW process, from stone ground wood ), grinding with preceding steam digestion (PGW, from pressure ground wood ), grinding with steam digestion (TMP, from thermomechanical pulp ) , Grinding with metal disks (RMP, from refiner mechanical pulp ) and grinding with prior treatment with hot solutions of sodium carbonate , sodium hydroxide or sodium sulfite (CTMP, from chemithermomechanical pulp ).

cellulose

Using chemical pulping processes without grinding, pulp is produced which consists largely of cellulose. These procedures are more costly. The most important chemical digestion processes are the sulphate process (synonymous with Kraft digestion , produces around 96% cellulose), the sulphite process (produces around 92% cellulose) and the rather historical soda process. Pulp is also mainly made from wood, and to a lesser extent from bamboo , bagasse and other paper raw materials.

Not only paper is made from cellulose, but also, for example, hygiene products such as diapers . Chemical pulp is chemically processed, including viscose and lyocell .

Waste paper

Waste paper is the most important paper raw material in terms of quantity. The waste paper is broken down into its individual fibers in a pulper filled with water . This in turn creates a pulp (fiber suspension). The secondary pulp ( waste paper ) obtained in this way is then available for the production of paper ( paper recycling ). In the past, waste paper was ground in a pan mill .

Bleaching and deinking

In the manufacture of white paper from cellulose and wood pulp, the fibers are subjected to bleaching . The corresponding process in the processing of waste paper is the removal of printing inks , also known as deinking .

Consistencies

In a paper or pulp mill, the fibrous materials are mainly transported by pumps in pipelines and must therefore be in suspension. The consistencies primarily depend on the water content or the consistency of the material. The consistency of a pulp suspension is the proportion of the oven-dry pulp in the total mass of the fiber-water mixture, which can also contain fillers and auxiliaries. To simplify matters, three consistency areas can be distinguished based on the consistency of the material:

- LC range (LC = English low consistency ): low consistency (<8%). In the LC area, the suspension can be conveyed with normal centrifugal pumps .

- MC area (MC = English medium consistency ): medium consistency (8–15%). In this area, the suspension can still be conveyed with special centrifugal pumps that are equipped with vacuum suction, among other things.

- HC area (HC = English high consistency ): high consistency (> 15%). In the HC area, transport with centrifugal pumps is no longer possible; instead, the pulp is transported with a screw conveyor , for example . In the HC range, the moist fibrous material is present without any dripping water, which is also known as “crumbs”.

Immediately before dewatering in the paper machine, the paper pulp is a highly diluted suspension of water and fibers with a consistency of 0.5 to 2%, that is, the water content is around 98 to 99.5%. Sometimes an even higher value is given for the water content of the maximally diluted pulp, for example 99.7% in a report on the manufacture of toilet paper.

Many paper mills process pulp that they do not make themselves. Pulp is therefore traded in large quantities on the world market and also regionally. For this purpose, pulp is dewatered during production on a Fourdrinier machine, then dried to a residual moisture content of approx. 6–8% (“air dry”, “lutro” in industry jargon) and then pressed into bales or blocks for transport. The air-dry market pulp is not called pulp.

Paper mache

Also papier-mâché made from a pulp. For example, newspaper that has been torn into shreds is soaked in warm water and further crushed with a hand blender . The warmer the water and the longer it acts on the paper fibers, the more the individual fibers separate from each other and the finer the pulp becomes. As much water as possible is then removed by pressing out the pulp. Paper mache is made by kneading wallpaper paste or another binding agent into the pressed mass.

Fiberboard and fiber-reinforced panels

In the production of wood fiber boards , pulp is first made by defibrating wood or woody plants. It not only contains individual fibers (long and short intact fibers as well as broken individual fibers), but also small fiber fragments (which appear as dust when dried) and fiber bundles (at least two, but mostly many, accumulated, unseparated individual fibers). The proportions of these fractions vary considerably, depending on the type of wood used. In contrast to the treatment of wood pulp for paper production, the fiber bundles are not sorted out, their volume percentage of the total fiber material is sometimes well over 50 percent. Depending on the type of board, a binding agent may be added. Dewatering and drying, compacting and pressing are further essential process steps. Fiberboard is one of the wood-based materials .

Gypsum fiber boards are made from a mixture of gypsum and cellulose fibers. The fibers are often obtained from waste paper, the pulp is then mixed with plaster of paris and additives. Gypsum fiber boards are fiber-reinforced mineral boards. In contrast to fibreboard, they are not flammable.

Plaster mixture with a high water content

In a patent from 2015, a plaster mixture mixed with an unusually large amount of water and containing a high proportion of cellulose fibers was referred to as “cohesive pulp”. Otherwise, plaster mixtures mixed with water are usually not referred to as pulp.

Processing of food crops

Fruit pulp

Fruit pulp (also called fruit pulp , pulp or pulp ) is a semi-finished product in the food industry with a pulpy consistency, a mixture of pulp in pulpy form and pieces of fruit or peeled whole fruits. Fruit pulp is used, among other things, to make jams or jams . When the pulp through fine crushing and passing is processed into a homogeneous dispersion, one speaks against it of Mark .

Crushed pulp

When orange juice and other juices are made from citrus fruits, the raw juice initially contains crushed pulp. This is also referred to as pulp . The pulp consists of coarser and finer particles that are separated from the juice in several steps (sieving, centrifuging, decanting ). When making “orange juice with pulp”, a little pulp is added again before filling.

Unprocessed pulp is also referred to as pulp for some fruits, for example coffee beans and cocoa beans .

Byproducts

Potato pulp is a fibrous by-product in the manufacture of potato starch that is used as animal feed. The term “washed-out pulp” was used as a term for the pure fiber substance in connection with quality control.

Some similar by-products from processing other food crops are also called pulp and can be used as animal feed, for example:

- Field bean pulp - by-product of the extraction of starch from field beans

- Pea pulp - by-product of the extraction of starch from peas

- Grain pulp - by-product of the extraction of starch from grains or flour

- Chicory pulp - by-product of the extraction of inulin from the roots of chicory

When sugar is extracted from sugar beet, the by-product is sugar beet pulp from which the sugar has been removed. These are sometimes called pulp or pulp and are also used as animal feed (see next section).

Sugar beet

According to the Association of German Sugar Technicians , the word Pülpe is used in the production of sugar from sugar beets in three more precise technical terms, which are cited here in the order of the work steps:

- Alluvial water pulp - fine beet or other plant particles contained in the alluvial water (the alluvial water is used to transport the beets)

- Raw juice pulp - beet particles contained in the raw juice (the raw juice is created by extracting the sugar from the sugar beet pulp )

- Pressed water pulp - particles of the extracted sugar beet pulp contained in the press water (the press water runs off when the extracted pulp is pressed)

In some texts the extracted sugar beet pulp is referred to as pulp or pulp , possibly influenced by the English name beet pulp and the French name pulpe de betterave for beet pulp. The Association of German Sugar Technicians advises against naming the extracted schnitzel pulp , and refers to the competing meaning of the word in the field of fruit processing as a justification.

Deviating from this, Römpp states that pulp is a name for raw beet sugar juice with remaining schnitzel particles.

manioc

The crushed, peeled cassava root is called pulp .

Slurries without fibers

Ore pulp

In metallurgy , a slurry of finely ground ore is called ore pulp , and more rarely ore pulp or ore pulp . The properties of the suspension are mainly determined by the concentration and size distribution of the solid particles. Using the flotation process , the ore is concentrated and separated from the waste rock. After the ore has been extracted, muddy residues remain, the so-called tailings , which are usually stored in large settling basins .

Clay pulp

Clay pulp, a muddy mixture of clay and water, was used in mining to prevent and contain fires and as a backfill . The pulp used earlier as backfill, i.e. to fill excavation cavities, was described as " clayey sludge".

Individual evidence

- ↑ a b Entry on pulp. In: Römpp Online . Georg Thieme Verlag, accessed on June 4, 2020.

- ↑ a b Paper production in a paper mill sankt-albanteich.ch, with historical graphics

- ↑ a b c Anita Brockmann: Everything about paper, part 2 - The history of paper in Europe boesner.com. In this text, the terms pulp, paper pulp, fiber-water mixture and hand-made pulp are used interchangeably .

- ^ A b Carla Meyer, Rebecca Sauer (2015): Paper . Contribution to the Collaborative Research Center 933 “Material Text Cultures” of the German Research Foundation, 2015.

- ↑ a b Paper made from asparagus shells moz.de, June 13, 2012

- ↑ papermaking with children familie.de

- ↑ a b c make paper yourself crafting instructions at geo.de (Geolino)

- ↑ Paper scooping awb-landkreis-rastatt.de

- ↑ See video paper mill Alte Dombach (2:30 min.). In this short film, from 0:37, the older technology can be seen: a rag mill with hammers and a pounding trough. Then (0:54 to 1:10) the newer technique: a Dutchman with a clearly recognizable knife roller.

- ↑ Joachim Engl: Büttenpapier and its production englverlag.de

- ↑ pulper papierundtechnik.de, September 2 of 2010.

- ↑ Hans G. Hirschberg: Handbuch Verfahrenstechnik und Anlagenbau , Springer, Berlin 2013, pp. 442 ff., ISBN 978-3-642-58357-5 . Here the terms pulp, fiber suspension, suspension and fiber suspension are used interchangeably .

- ↑ a b Jürgen Blechschmidt (Ed.): Taschenbuch der Papiertechnik , Fachbuchverlag Leipzig im Carl Hanser Verlag, 2nd, updated edition 2013, p. 254.

- ↑ Paper technologist job description at Zukunftberuf.de

- ^ The paper machine: Constant part of papier-machen.de

- ^ House Martfeld - Kollergang medienwerkstatt-online.de

- ↑ Georg Thieme Verlag: RÖMPP lexicon Environment, 2nd Edition, 2000. Georg Thieme Verlag, 2014, ISBN 978-3-13-179582-3 ( limited preview in Google Book Search).

- ↑ Kollergang medienwerkstatt-online.de

- ↑ Too oven dry see otro in the paper dictionary on papyrus.com.

- ↑ Jürgen Blechschmidt (Ed.): Taschenbuch der Papiertechnik , Fachbuchverlag Leipzig in Carl Hanser Verlag, 2nd, updated edition 2013, p. 576.

- ↑ Jürgen Blechschmidt (Ed.): Taschenbuch der Papiertechnik , Fachbuchverlag Leipzig in Carl Hanser Verlag, 2nd, updated edition 2013, p. 255.

- ↑ Jürgen Blechschmidt (Ed.): Taschenbuch der Papiertechnik , Fachbuchverlag Leipzig in Carl Hanser Verlag, 2nd, updated edition 2013, p. 259.

- ↑ Jürgen Blechschmidt (Ed.): Papierverarbeitungstechnik , Fachbuchverlag Leipzig im Carl Hanser Verlag, 2013, ISBN 978-3-446-43071-6 , p. 39.

- ↑ Off the roll - this is how toilet paper is made geo.de/geolino, explanation of picture 2 of the photo series.

- ↑ lutro in the paper dictionary on papyrus.com

- ↑ Jürgen Blechschmidt (Ed.): Taschenbuch der Papiertechnik , Fachbuchverlag Leipzig in Carl Hanser Verlag, 2nd, updated edition 2013, p. 253.

- ↑ Institute for Wood Technology Dresden and Institute for Plant and Wood Chemistry at the TU Dresden: Investigation of the fiber-binder interaction for the production of MDF from hardwood. Final report 2015. Dresden, May 23, 2016, p. 11 f., 25–31. See project description (PDF).

- ↑ Example: fiber-reinforced calcium sulfate board baubiologie-ibr.de

- ↑ Gypsum fiber boards oekologische-bauen.info

- ↑ Patent plastering of interior walls of a residential building with a three-dimensional surface structure , DE102014113314, April 16, 2015. This plaster mixture is used because of the very high content of cellulose fibers (28% to 52% in the dry mixture) and starch (2% to 10% in the dry mixture) mixed with a lot of water, quote: "The weight of the water in the pulp is preferably 2.4 times the weight of the dry mixture." This means that the proportion of water in the ready-to-use plaster mixture is many times higher than in conventional plaster mixtures.

- ^ A b Claus Schünemann: Technology of the bakery production. Gildebuchverlag, 2002, ISBN 978-3-7734-0150-2 , p. 245 ( limited preview in the Google book search).

- ^ Rudolf Heiss: Food technology. Springer-Verlag, 2013, ISBN 978-3-662-08285-0 , p. 222 ( limited preview in the Google book search).

- ↑ Background: Apple and orange juice , in: Schrot & Korn , January 2007.

- ↑ Dieter Osteroth: Pocket book for food chemists and technologists. Springer-Verlag, 2013, ISBN 978-3-642-58220-2 , p. 344 ( limited preview in the Google book search).

- ↑ Gerald Rimbach: Food product knowledge for beginners. Springer-Verlag, 2010, ISBN 978-3-642-04486-1 , p. 305 ( limited preview in the Google book search).

- ↑ Ernst Berl: Chemical-technical investigation methods , Springer, Berlin 1924, Vol. 4, p. 143.

- ↑ Standards commission for straight feed in the Central Committee of German Agriculture: Positive list for straight feed , 12th edition, 2017 (PDF).

- ↑ Sugar-technical terms zuckertechniker.de

- ↑ Patent DE3782884T2 of April 8, 1993 on patent-de.com; see. the newspaper article Der Rübenkönig von Anklam on neue-deutschland.de, October 25, 2003. According to these texts, pulp remains after extraction of the sugar beet pulp , which is used as fodder.

- ↑ Customized EnviThan gas feed-in in France Press release from EnviTec Biogas, December 10, 2018. This text mentions sugar beet pulp as a substrate for biogas plants.

- ↑ Zuckertechnische technical terms zuckertechniker.de, see the note under the keyword Schnitzel, extracted . The imprecise term “fruit pulp” probably means fruit pulp .

- ^ Rudolf Heiss: Food technology. Springer-Verlag, 2013, ISBN 978-3-662-08285-0 , pp. 279, 280 ( limited preview in the Google book search).

- ↑ Vladimir Morkun, Natalia Morkun: Estimation of the Crushed Ore Particles Density in the Pulp Flow Based on the Dynamic Effects of High-Energy Ultrasound (PDF), in: Archives of Acoustics 2018 (Vol. 43), No. 1, p. 61-67.

- ^ The former Schmirchau mining company bergbauverein-ronneburg.de. Quotes: “Production of clay pulp for backfilling mining cavities and fighting fires”. "Measures involving the introduction of a clay-water turbidity (pulp) and silting up did not lead to the containment of the fires until 1964."

- ↑ Günter Leonhardt: Uranium mining of the bismuth - technical-scientific achievement and environmental problem . In: Meeting reports of the Leibniz-Sozietät, Volume 26, 1998 (PDF), pp. 63–78, here pp. 77 f.