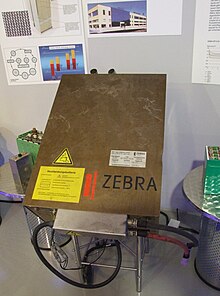

Zebra battery

A sodium-nickel-chloride cell , also known as ZEBRA battery ( English Zero Emission Battery Research Activities ), is a rechargeable battery , a so-called secondary cells . It is one of the thermal batteries . Instead of a liquid electrolyte , a solid electrolyte and a combination of liquid and solid electrodes are used. The accumulator has been installed in electric vehicles such as electric cars , hybrid buses, and electric buses . It is used in battery storage power plants and in the defense industry.

History and manufacturer

Thermally activated batteries ( thermal batteries ) were already used in Germany in the V2 rocket . They were developed by Georg Otto Erb on the basis of calcium chromate as early as World War II .

The Zebra cell was then expanded by the South African company Zebra Power Systems and Beta R&D Ltd towards the end of the 1970s , for which it received its first patent in 1978. The company Beta Research and Development continued to develop the technology before 1988 by the later AEG Anglo Batteries GmbH with the participation of Daimler AG was taken over. By AEG Anglo Batteries GmbH came and production since 1994 operational traction batteries for electric cars , so for the Mercedes-Benz A study as well as for the later serial production developed as an electric car A-class electric.

After the termination of this project and the merger of Daimler AG and Chrysler AG , technology and patents were sold to MES-DEA in Switzerland. MES-DEA produced Zebra batteries and equipped various vehicles with electric motors and Zebra batteries, among others. a. Renault Twingo , Smart and Fiat Panda . The batteries have been produced at the Stabio site in Switzerland since around 1998. In 2010, MES-DEA and the Italian battery manufacturer FIAMM founded FZ Sonick , which took over battery production in Stabio as well as all patents and intellectual property. After MES-DEA sold its shares in FIAMM on July 1, 2010, the company was renamed FIAMM SoNick SA . SoNick stands for sodium-nickel-chloride. The business segment vehicle conversion was developed by MES-DEA to the company Kamoo AG passed.

In 2010, FIAMM SoNick SA in Stabio (Switzerland) was a major manufacturer of Zebra batteries alongside Rolls-Royce in Great Britain . General Electric has also been manufacturing sodium-nickel chloride batteries since 2012 and sells them under the Durathon® name. They have an output of 50 kW and can store 100 kWh of energy. They can be combined into modules with an output of up to one megawatt and an energy of up to 6 MWh. Due to the low commercial success, production was greatly reduced in early 2015.

Structure and properties

The reactants are sodium chloride (common salt), sintered nickel impregnated with a liquid salt solution of nickel chloride and sodium chloride as a positive electrode , and liquid sodium as a negative electrode, separated by a separator . The separation in the separator is maintained by a semi-permeable ceramic wall that is only permeable to sodium ions , which separates the sodium electrode from the sodium chloride / nickel chloride / nickel electrode and at the same time serves as a solid electrolyte . An essential component of the ceramic is sodium β-aluminate (NaAl 11 O 17 ), in which from a temperature of 270 ° C the sodium ions become so mobile that there is sufficient conductivity. It is advantageous that the pure sodium metal is present in liquid form on the negative electrode, which prevents the build-up of inactive and destructive compounds ( dendrites ).

The operating temperature of the battery, which is thermally insulated by vacuum insulation, is typically 300 ° C (270 to 350 ° C). The battery does not show any electrochemical self-discharge, the efficiency is around 80%. However, the cell must be kept at a high operating temperature to maintain its function, which means that heating is necessary despite thermal insulation. While the thermal losses in the internal resistance of the cell are sufficient to maintain the temperature with a sufficiently high energy consumption, additional heating is necessary when not in use, which leads to a steady discharge when it draws its power from the cell.

With regard to the service life, a test battery was reported in 2004 that had been used in testing for eleven years and over 3000 cycles (which makes about one cycle per working day). Two types were presented: Both with 17.8 kWh energy content each , one at 278 V with 64 Ah and one at 557 V and 32 Ah. The blocks weigh 195 kg each with housing and battery management, the specific energy is 94 Wh / kg. According to the manufacturer, the maximum output is around 32 kW. Batteries that have cooled below the melting point of the salts can be reactivated by heating them up. When it has cooled down, it can be assumed that the shelf life is unlimited, as the chemical substances are then inactive. The manufacturer does not provide any official information on the number of cooling / heating cycles. It can be assumed that frequent cooling and heating lead to mechanical loads on the ceramic membrane. However, the occasional cooling down of the battery is not a problem in practical use.

The energy density is around 100–120 Wh / kg . In comparison, a lead accumulator has a density of around 30 Wh / kg. A Zebra battery requires 1.53 kg of nickel, 1.43 kg of iron, 0.31 kg of copper, 2.24 kg of NaCl and 1.43 kg of aluminum hydroxide ( boehmite ) per kWh of storage capacity .

Compared to other battery technologies, the starting materials are available in sufficient quantities at low cost. The production is also relatively straightforward. The currently high costs per kilowatt hour are explained by the low number of units produced and could be significantly reduced with automated mass production. In Switzerland, a study of the entire life cycle assessment was carried out using the example of a Twingo with a zebra battery. It was confirmed that only when operated with pure coal electricity or with a very unfavorable usage profile of the Zebra battery (long idle times) the environmental balance of the electric car can be worse than that of vehicles with combustion engines.

Electrochemistry

The overall reaction on discharge is:

When charging, the process is reversed. The cell voltage when idling with a charged cell is usually 2.58 V. In addition to the structure of the cell, this voltage also depends on the charging speed. There are also other variants, for example with electrodes made of sintered iron instead of nickel. These cells have an open circuit voltage of 2.35V.

Applications

Electromobility

The development of the Zebra battery was already closely linked to electromobility, triggered by the CARB legislation in California. MES-DEA then produced Zebra batteries until 2009 and also equipped vehicles with electric motors and Zebra batteries, among other things. a. Renault Twingo , Smart and Panda . These were distributed in Switzerland and Italy. In 1996, an 800 kg traction battery was also installed on the vehicle roof of the O 405 NÜH intercity hybrid bus, a duo bus .

The best known car with a zebra battery is the Think City and the Smart EV in a limited edition for London , GB. The world's largest manufacturer of electric vans and electric trucks, Smith Electric Vehicles, has also used Zebra battery packs. B. for the Smith Newton Range, a 7.5-tonner with a 120-kilowatt electric motor. ZEBRA batteries have also been fitted to hybrid buses in Italy and fully electric buses in California. Zebra batteries are also used in various electric vehicles in Germany. a. in a Daimler bus MB410E from BIMAQ, Bremen and in an Audi A2 converted to an electric drive by the company Krebs and Aulich. In France, in 2011/2012, the Post was equipped with electric vehicles of the Peugeot Partner and Citroën Berlingo type, which are equipped with Zebra batteries. The equipment took place at Venturi . The Iveco Daily Electric van is also equipped with a ZEBRA battery. B. used by Deutsche Post DHL since 2011 in small numbers on a test basis. Although the electric vehicles on the market are equipped with slow on-board chargers, a quick-charging option was mentioned in the Daimler AG brochure (page: 8). The German translation says: “Charging the batteries via the built-in charger takes seven hours when fully discharged. The charging process can be shortened to one hour with external chargers. "

Cellular base stations and storage power plants

Because of their long shelf life and unproblematic heating as stationary batteries at a power-supplied location, they are increasingly being installed in cell phone base stations as buffer batteries. The manufacturer is, for example, General Electric .

There are over a dozen electricity storage power plants that use sodium-nickel chloride batteries; about ten more were under construction in 2014. The currently strongest one is in use in Canada, comes from General Electric and can provide one megawatt for two hours.

Weapon systems

Because of their high energy density and reliability, ZEBRA batteries are also used in weapon systems such as submarines and missiles . European manufacturers are e.g. B. Rolls-Royce . Rolls-Royce offers ZEBRA batteries from 24 V to 1000 V and with a capacity of 2 kWh to 50 kWh.

literature

- RA Guidotti, P. Masset: Thermally activated ("thermal") battery technology Part I: An overview . In: Journal of Power Sources . tape 161 , no. 2 , 2006, p. 1443 to 1449 , doi : 10.1016 / j.jpowsour.2006.06.013 .

- Jeffrey W. Braithwaite, William L. Auxer: Sodium-Beta Batteries . In: David Linden (Ed.): Handbook of Batteries . 2nd Edition. McGraw-Hill, 2002, ISBN 0-07-135978-8 , chap. 40 .

Web links

- Homepage of Fiamm SoNick

- Varta battery dictionary: The development of the battery

- Electric versions of the Fiat Panda (PDF; 223 kB) and Renault Twingo (PDF; 325 kB) with zebras

- Driving report Renault Twingo elettrica with Zebra battery

- Smart gets an electric motor - An electric version of the Smart Fortwo is now celebrating its premiere in Great Britain. July 13, 2006. A large-scale test with 100 cars is to start in London in 2007

- Electromobility in Ticino , PDf article on MES-DEA / FZ Sonick and electromobility

- The Rolls-Royce ZEBRA concept

Individual evidence

- ↑ a b c d Jeffrey W. Braithwaite, William L. Auxer: Handbook of Batteries . 2nd Edition. McGraw-Hill, 2002, ISBN 0-07-135978-8 , chap. 40: Sodium-Beta Batteries , p. 40.1 to 40.31 .

- ↑ a b c Cord-H. Dustman, MES-DEA , Stabio, Switzerland 2004: Advances in ZEBRA batteries , historical and technical facts about ZEBRA batteries, PDF document, accessed on January 25, 2012.

- ↑ a b c Brochure of Daimler-Benz AG, 12/1997: The A-Class Electric Vehicle, Powered by the ZEBRA Battery System PDF brochure, accessed on January 18, 2012.

- ↑ Competences. Battery Consult, accessed January 6, 2016 .

- ↑ GE Launches Durathon Sodium Metal Halide Battery for UPS Market. Green Car Congress, May 18, 2010, accessed July 25, 2014 .

- ↑ Jeff St. John: GE Scales Back Production of Grid-Scale Durathon Batteries . Greentech Media. January 22, 2015. Accessed January 10, 2016.

- ^ AF Holleman , E. Wiberg , N. Wiberg : Textbook of Inorganic Chemistry . 101st edition. Walter de Gruyter, Berlin 1995, ISBN 3-11-012641-9 .

- ↑ Lecture by Dr. Cord-Henrich Dustmann (then head of Zebra activities at MES-DEA), June 2004.

- ↑ Galloway, Dustmann: ZEBRA Battery - Material Cost ( Memento from December 25, 2010 in the Internet Archive ) (PDF; 415 kB)

- ^ Paul Scherer Institute PSI, April 7, 2010: Life cycle assessment of electromobility (PDF; 361 kB), inserted on February 27, 2012.

- ↑ Omnibus Archive, December 23, 2008: Alternative drives in Daimler AG buses - Part I , Section O 405 GNTD: the renaissance of wheel hub motors , accessed October 11, 2013.

- ↑ Venturi, (01/09/2011): MANUFACTURE DE VÉHICULES ÉLECTRIQUES ( Memento of the original dated February 6, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Videolink production: "mve - Voir la video", inserted on March 12, 2012.

- ↑ Deutsche Post DHL relies on Iveco Electric Daily . Iveco press release of September 20, 2010. Online at web.iveco.com.

- ↑ Deutsche Post DHL makes Bonn a model city for CO2-free delivery vehicles ( memento of the original from June 13, 2013 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. . Deutsche Post DHL press release of May 21, 2013. Online at www.dp-dhl.com. See also the link “Factsheets alternative vehicles”.

- ^ DOE Global Energy Storage Database - Projects. Sandia Corporation, accessed November 7, 2014 .

- ^ DOE Global Energy Storage Database: Wind Energy Institute of Canada Durathon Battery. Sandia Corporation, November 7, 2014, accessed November 7, 2014 .