Colliery

The term Zeche (Middle High German: order, row) originally referred to the union of several people, u. a. for operating a mine . With their contribution to the mining union , those involved paid the bill, which is still used today as a slang expression for paying a bill . The term "Zeche" is used synonymously with "Bergwerk", especially for the hard coal mines in the Ruhr area , where the word "Zeche" is placed in front of the name of the mine. In the Freiberg district , where ores were mined, the teaching and research mines “Reiche Zeche” and “Alte Elisabeth” exist in the above sense .

A distinction must be made between the mine in the former Saxon - Thuringian uranium mining of the SAG Wismut , where it describes a plant in which ores were crushed, radiologically sampled, sorted and packed ready for delivery.

Operating procedure (as an example in hard coal mining)

Underground

The mine property entitled to reduction of coal in a particular area. The mining area is (also underground stretch studs ) on different soles developed (levels) connected by shafts and blind shafts are connected. The deposit is mostly mined using longwall mining , with the longwall supported by shields following the seam . In the past, the stone was extracted with a mallet and iron , later with a jackhammer ; Today's mining methods are fully mechanized, common machines are stepping shields , coal planers that “peel off” thin layers of rock and shearers that remove thicker layers by cutting. The mountains recovered in the mining operations are transported on conveyor belts or rail- mounted trolleys to the filling point on the conveyor shaft. The coal is there in a bucket transferred (Skip) and this at a haul rope brought to light.

Over days

The parts of the mine that are visible above ground are the daytime facilities : Above the shaft there is a headframe that carries a sheave that deflects the hoisting rope leading out of the shaft to the hoisting machine in the machine house. The energy required comes from steam generators in the boiler house , which are heated with low-quality coal. The extracted raw coal is transferred to freight carts on the hanging bank and separated (washed) from the deaf rock in special systems , processed and refined. The overburden is again filled in part as backfill underground and sold as building material, but today for the most part on heaps permanently unloaded while charcoal on Halden is stored. The coal is loaded and shipped in freight carts for the railroad, barges and, rarely, trucks; in some cases, a complete coal-fired power plant or a coking plant with systems for the extraction of by- products is also directly connected , and in the past it was often a briquette factory for the production of house fuel . Usually several shafts belong to a colliery, which take on single or multiple tasks such as extraction, cable travel , ventilation and dewatering . They are then often named according to their function ("weather shaft", "main extraction shaft"), but often in ascending order according to their construction numbered (shaft 1, shaft 2) or, more rarely, named after people. The day-care facilities also include workshops, storage areas for the excavation , sewage treatment plants and fining ponds for the pumped pit water , buildings for the administration, a kaue and other social buildings for the miners.

Colliery death

→ Main article: Colliery dieback

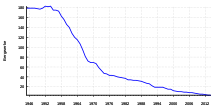

After the Second World War, new energy sources such as crude oil and natural gas as well as cheaper imported coal forced their way onto the German market, so that the coal crisis began in 1957/58 : around half of the mines had to be closed in the following ten years (“colliery die”). In order to mitigate the ongoing coal crisis, the coal and steel companies brought their mines into Ruhrkohle AG (RAG) in 1968 . The RAG was able to organize the reduction of the production capacity with composite mines, early retirement and transfer of employees from closed mines to other companies without further mass layoffs. Gradually, the remaining independent hard coal mines were also transferred to RAG by the end of the 1990s.

Most recently, the RAG subsidiary Deutsche Steinkohle AG (DSK) operated the last coal- producing mines in Germany:

North Rhine-Westphalia

- Ibbenbueren mine (Anthracite mine) in Ibbenbueren, closed on December 4, 2018

- Prosper-Haniel mine in Bottrop, closed on December 31, 2018

literature

- Joachim Huske : The coal mines in the Ruhr area. Data and facts from the beginning to 2005 . German Mining Museum, Bochum, 3rd, revised edition 2006, ISBN 3-937203-24-9 .

- Wilhelm Hermann, Gertrude Hermann: The old mines on the Ruhr. Past and future of a key technology. With a catalog of the "life stories" of 477 mines (series Die Blauen Bücher ). Verlag Langewiesche Successor, Königstein im Taunus, 6th, 2008 edition expanded to include an excursus from p. 216 and updated in energy policy parts, ISBN 978-3-7845-6994-9 (with “Section through a hard coal mine” and a “Site plan of the Pit fields and shaft systems ”from 1922 and a map of the location of the 128 mines that mined in 1958).

Individual evidence

- ↑ Zeche, f. . In: Jacob Grimm , Wilhelm Grimm : German Dictionary . Hirzel, Leipzig 1854–1961 ( woerterbuchnetz.de , University of Trier).

- ^ Otfried Wagenbreth , Eberhard Wächtler : Der Freiberg mining. Technical monuments and history. Verlag für Grundstofftindustrie, Leipzig 1986