Zollverein colliery

| Industrial complex Zeche Zollverein in Essen |

|

|---|---|

|

UNESCO world heritage |

|

|

|

| Aerial view of shaft 12 |

|

| Contracting State (s): |

|

| Type: | Culture |

| Criteria : | ii, iii |

| Surface: | 100 ha |

| Reference No .: | 975 |

| UNESCO region : | Europe and North America |

| History of enrollment | |

| Enrollment: | 2001 (session 25) |

| Zollverein colliery | |||

|---|---|---|---|

| General information about the mine | |||

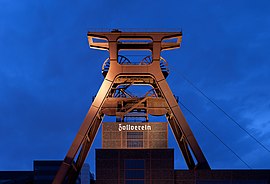

| Zeche Zollverein: The double block of shaft 12 | |||

| Mining technology | Underground mining | ||

| Information about the mining company | |||

| Operating company | The Haniel family - Phönix AG for mining and smelting operations - Gelsenkirchener Bergwerks-AG |

||

| Start of operation | 1851 | ||

| End of operation | 1986 | ||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

| Coordinates | 51 ° 29 '11.5 " N , 7 ° 2' 38.7" E | ||

|

|||

| location | Katernberg, Schonnebeck, Stoppenberg | ||

| local community | meal | ||

| Independent city ( NUTS3 ) | meal | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Ruhr area | ||

The Zeche Zollverein, also known as the "Eiffel Tower of the Ruhr Area", was an active hard coal mine in Essen from 1851 to 1986 . It was named after the German Customs Union founded in 1834 . Today it is an architectural and industrial monument . Together with the directly neighboring Zollverein coking plant , pits 12 and 1/2/8 of the colliery have been part of the UNESCO World Heritage since 2001 . Zollverein is the anchor point of the European Route of Industrial Culture and the location of various cultural institutions as well as the Folkwang University of the Arts .

position

The main area of the Zeche Zollverein with the systems shaft 12 and shaft 1/2/8 is located in the north-eastern Essen district of Stoppenberg , directly adjacent to the districts of Katernberg and Schonnebeck . It is located between the streets Gelsenkirchener Straße, Fritz-Schupp-Allee, Arendahls Wiese and Haldenstraße. The main entrance with the familiar view from the front of the double-headed headframe is on Gelsenkirchener Straße. The Zollverein coking plant is located between Arendahls Wiese, Köln-Mindener Straße and Großwesterkamp. The three complexes have been part of the overall World Heritage ensemble since 2001.

The shaft 3/7/10 facility is located around one kilometer east of it on the Am Handwerkerpark road in the Katernberg district.

The shaft 4/5/11 facility is located about two kilometers north of the main site on Katernberger Strasse in the Katernberg district. Today the Triple Z start-up and business center uses the former colliery building.

The shaft 6/9 facility was located around one kilometer south of the main site between the streets Gelsenkirchener Strasse, Im Natt and Hallostrasse. All buildings and facilities were demolished with the abandonment of the southern field in 1979; today the area is covered by forest and new housing estates.

The tailings of the Zeche Zollverein are located in the surrounding Essen districts of Stoppenberg and Altenessen ( Schurenbachhalde ) as well as in Gelsenkirchen-Feldmark .

story

1834–1890: early phase

The colliery was founded by the industrialist Franz Haniel , who was looking for suitable coking coal deposits to produce the coke fuel he needed for steelmaking. In 1834 he succeeded in breaking through the marl layer for the first time in Essen-Schönebeck . In this way, the course for the Zollverein colliery was set there. During mutation bores in the Katernberg area , among other things, a particularly rich coal seam was drilled, which was named after the German Customs Union founded in 1833 . In 1847 Franz Haniel founded the mining trade union Zeche Zollverein and distributed the shares, the so-called Kuxe , within his family. Haniel, who was co-owner of the steelworks union Jacobi, Haniel & Huyssen (later Gutehoffnungshütte ), planned to incorporate the Zeche Zollverein into the Sterkrader Werke. Zollverein would have become the first smelter mine in the Ruhr area. His plan failed because of the veto of the other shareholders of the steelworks union Jacobi, Haniel & Huyssen .

When choosing the location, the Cologne-Minden Railway also played an important role, the route of which was also opened in 1847. The route runs directly north of the colliery area, which guarantees a good connection to the railroad, which was a new type of transport at the time.

The land for the construction of the first Zollverein shaft system was provided by the landowner Schwartmann , also known as Bullmann , who was also involved in the union . Therefore, the area of the foundation shaft system was soon called the Bullmannaue . The current street name of the driveway to the 1/2/8 mine is based on this.

The sinking work for shaft 1 of the Zollverein colliery began on February 18, 1847 under the manager Joseph Oertgen, after whom a street in the Ottekampshof colony in the Katernberg district was later named. The coal mountains should be approached at a depth of 130 meters. Due to water ingress, however, coal production did not begin until 1851. In order to regulate the water inflow, another shaft, shaft 2, was sunk in addition to shaft 1, which was put into operation in 1852.

For the first time, two externally identical Malakow towers were built over the shafts as a conveyor system; this example of a twin building with a common machine house between the shafts was later repeated on other mines when a double shaft system was built .

From 1857, in addition to the shaft system 1/2, several kilns were operated as a preliminary stage to a coking plant . From 1866 they were replaced by a modern coking plant with machine ovens.

In 1880, the sinking of a second separate conveyor system in Katernberg began. Shaft 3 went into operation in 1882. The daytime facilities were extensively expanded by the architect Dreyer. The shaft received a German Promnitz type strut frame as a conveyor system. As early as 1890, 1 million tons of usable hard coal was brought to light. This made the Zeche Zollverein the mine with the highest annual production in Germany.

1890–1918: expansion

Due to the favorable economic situation in the coal and steel sector, a more extensive, very extensive expansion of the mine building was carried out in the following years . H. the underground infrastructure. In the northern part of Katernberg on the border to Gelsenkirchen-Heßler , the Zollverein 4/5 double shaft system was built between 1891 and 1896 with a conveyor and cable car shaft and a shaft designed purely for ventilation . At the same time, a new type of coking plant was put into operation on this shaft.

In 1895 another shaft (shaft 6) was sunk in what is now the Stoppenberg district. This went into operation in 1897 and was equipped for the first time with a double strut frame, as it was designed for the parallel guidance of conveyance and cable travel.

The mine buildings of Zollverein were still problematic in terms of weather management (i.e. the air circulation underground). After several firedamp -Unglücken the pits were equipped gradually with small weather shafts. So came about:

- From 1897 to 1899, next to shaft 3, shaft 7. It received a small conveyor system.

- From 1897 to 1900, next to shaft 1/2, shaft 8 was initially not provided with a conveyor system.

- From 1903 to 1905, next to shaft 6, shaft 9 was initially not provided with a conveyor system.

Subsequently, the shaft system 1/2/8 was renewed, shaft 1 received a German strut frame instead of the Malakow tower . Furthermore, the processing , the so-called coal washing, and the coking plant were completely renovated.

- In 1909 a new extraction shaft was sunk on the 3/7 shaft. After the completion of shaft 10 in 1914, the processing facilities on this shaft were expanded and a new coking plant was put into operation.

- In 1914, shaft 9 of Annex 6/9 was added to the cable car shaft by the construction of a conveyor system. that is, it was expanded for the transport of people and material.

The usable production rose to 2.5 million tons of hard coal during the First World War .

1918–1932: crisis and modernization

From 1920 onwards, the Zollverein union, which until then had been owned by the Haniel industrialist family, increasingly cooperated with Phönix AG for mining and smelting operations . The management of the colliery was completely placed in the hands of Phönix AG and an interest group was founded.

Renewal and repair measures were carried out under their direction; Shaft 2 received a headframe and it was decided to renew the shaft system 4/5. The sinking work for shaft 11 began in 1922. In 1926 the work was completed. Above ground, shafts 4 and 11 were equipped with similar headframes and the daytime facilities 4/5/11 were renewed accordingly. In return, the coking plant on mine 4/5/11 was taken out of service.

When the Phönix AG was taken over by the Vereinigte Stahlwerke AG in 1926, the Zeche Zollverein was assigned to the Gelsenkirchener Bergwerks-AG (GBAG) and from then on belonged to the Gelsenkirchen group. Under their direction, the coking plants were gradually shut down.

In 1928, GBAG began building a complete new shaft system designed as a central conveyor system . With a production capacity of 12,000 tons of coal per day, shaft 12 took over the entire coal production of the previous four plants with a total of eleven shafts. The architects Fritz Schupp and Martin Kremmer designed the shaft system, which was considered an architectural and technical masterpiece and was trend-setting for functional, functional industrial construction - this is how the structure of the influential school of New Objectivity follows . The mine was considered the most modern and "most beautiful mine in the world".

The solid-walled double- gantry headframe erected in 1930 became the model for many central conveyor systems built later. The bay took on 1 February 1932, the promotion and in 1937 after the then Director General of the Gelsenkirchen Mining AG- Albert Vogler named "Schacht Albert" (from 1941 "bay Albert Vogler").

1932–1968: Shaft XII

The output of the Zeche Zollverein was increased immensely by this measure. In 1937 it reached 3.6 million tons with 6,900 employees. The coking plant at shaft 1/2/8 was reopened in the previous year as a small new building with 54 coke ovens and produced 200,000 tons of coke annually. In 1937, the old double strut structure above shaft 6 was replaced by a new two-storey strut structure with only one extraction.

The Zollverein colliery survived the Second World War with relatively little damage. In 1953, an annual production of 2.4 million tons was achieved again, which means that Zollverein again took the top position among West German hard coal mines.

After the transition to Rheinelbe Bergbau AG as the successor company of the old GBAG, an extensive renovation and rationalization of the operation of all Zollverein shaft systems was carried out.

The headframe above shaft 1 was replaced by a full-walled new building in 1958. At the same time, from 1960 to 1964 a complete redesign of the shaft system 1/2/8 was carried out by the architect Fritz Schupp . In 1964, shaft 2 received the previously dismantled headframe from shaft 2 of the closed coal mine Friedlicher Nachbar , Bochum-Linden, as a new conveyor system.

From 1961 a central coking plant with 192 ovens was operated on a western site, which was expanded to 304 ovens in the 1970s. The coking plant has long been considered the most modern coking plant in Europe, in which 10,000 tons of coal were refined into 8,600 tons of coke every day . Due to the steel crisis and the resulting drop in demand for coke, the coking plant was shut down on June 30, 1993.

Between 1962 and 1964 the four outer shaft systems were combined. Shaft 4 was decommissioned as a production shaft in 1962. The headframe was handed over to the Zeche Holland in Wattenscheid for the expansion of a new central shaft. The shaft 3 and 7 conveyor systems were also dismantled. In 1967 the production on the pits 4/5/11 and 6/9 was stopped. The sole extraction remained in shaft 12.

In 1968 the Zeche Zollverein was transferred to the Bergbau AG Essen of the Ruhrkohle AG .

1968-1986: RAG

After the mine was taken over by RAG, the mechanization and rationalization of the mining operations continued. The production of Zollverein continued to be approximately 3 million tons per year. In 1974 the association with the Zeche Holland in Wattenscheid was carried out. Shaft Holland 3/4/6 was abandoned as a production site and continued to be operated as a cable car and weather shaft system together with some shafts from the Bonifacius colliery in Essen-Kray.

From 1980 onwards, with the removal of the last deposits of fatty coal in the Sonnenschein seam, mining was shifted to the north. The southern and eastern shafts were gradually abandoned. From 1982 a funding association was operated with the neighboring Nordstern colliery . In return, the Holland construction site was given up in 1983.

The output of this Nordstern-Zollverein composite mine reached another 3.2 million tons annually. After another slump in sales for Ruhr coal, the decision to give up the Zollverein mining site was decided in the 1983 coal round.

On December 23, 1986 all remaining conveyor systems of Zollverein were shut down. The coking plant was operated until 1993. Shafts 2 and 12 are still used today for dewatering . The pit water that is pumped into the open here and channeled into the Emscher comes from disused mines in the north and northeast of Essen, in Wattenscheid, Gelsenkirchen, Gladbeck, Bottrop, Herne, Herten, Recklinghausen, Oer-Erkenschwick and Datteln.

In retrospect, the remaining daytime facilities of shaft 12, shaft 1/2/8, shaft 4/5/11 and shaft 3/7/10 were preserved for a new use and as an industrial monument.

Change from industrial structure to industrial culture

Following closure in 1986 the country bought North Rhine-Westphalia the Ruhrkohle AG from the site of Shaft XII that already decommissioning under monument stood. The total area of the Zeche Zollverein is the largest monument in the city of Essen. In the following years, the area of Shaft XII was redeveloped. The construction works Zeche Zollverein Schacht XII GmbH ended their renovation work in 1999. From 1998 to 2008 the development company Zollverein mbH (EGZ) founded for this purpose , the Zollverein Foundation and the Industrial Monument Preservation and Historical Culture Foundation were responsible for the maintenance and use of the decommissioned facilities; since 2008 these tasks have been bundled in the Zollverein Foundation . On December 14, 2001, pits 12 and 1/2/8 as well as the Zollverein coking plant were added to the list of UNESCO World Cultural and Natural Heritage .

The nomination as a UNESCO World Heritage Site in 2001 marked the beginning of the further expansion of the site: the architect Rem Koolhaas and his Rotterdam Office for Metropolitan Architecture 2001/2002 developed the master plan for redesigning the site into a lively cultural and business location.

In autumn 2003, the development company Zollverein together with the then Essener Verkehrs-AG announced a regional design competition. A corresponding “Zollverein design” was sought for tram line 107 , which runs from Gelsenkirchen to the south of Essen and stops at the Zollverein site. In January 2004, the readers of Zollverein 31/8 magazine selected the design by Freiwild Kommunikation from the ten best of a total of 44 submissions .

In the summer of 2006, the extensive renovation of the coal washing plant based on designs by the OMA / Böll consortium, consisting of the Dutch architecture firm OMA by Floris Alkemade and the Essen architecture firm Heinrich Böll, was completed after almost three years. The Heinrich Böll architectural office, for example, renovated the representative part of the colliery ensemble and took on the planning and execution of the SANAA building. The architectural office Böll is considered to be one of the most influential offices in the field of renovation of industrial plants in the Ruhr area. Heinrich Böll is the nephew of the author of the same name. The converted coal washing plant in Shaft 12 houses the Ruhr Visitor Center on the Route of Industrial Culture and the Ruhr Museum . The authentically preserved facilities of the colliery and coking plant are now accessible as a Zollverein monument trail. A new 55 m long gangway, which is based on the existing ribbon bridges, leads visitors to the Ruhr visitor center at a height of 24 m. The Erich Brost pavilion was built on the roof of the coal washing plant as part of the renovation. All kinds of events take place here.

The former boiler house was converted by Norman Foster for the Red Dot Design Museum . On the adjoining site of shaft 1/2/8, the former wash house is now the seat of the NRW choreographic center (redesigned by Christoph Mäckler Architects ), the former machine house houses the Zollverein art shaft and the Margaretenhöhe ceramic workshop has been located in the former construction warehouse since 1987 . The Phenomania experience field is on shaft 3/7/10 .

The former coking plant houses exhibition rooms for contemporary art. The accessible room installation Palace of Projects by Ilya & Emilia Kabakov is shown as a permanent exhibition . From August 26th to December 3rd, 2006, the ENTRY2006 - How will we live tomorrow - was on view in the coal washing plant . 300 objects by designers and architects from 20 countries were shown in a large exhibition.

In June 2006, the construction of the Zollverein cube based on designs by the Japanese architects SANAA was completed. Although it is not on the original colliery site, but at its entrance, it is counted as part of the overall ensemble.

There are several restaurants and cafes.

criticism

The conversion of the buildings for cultural purposes involved considerable interventions in the existing structure: in order to create usable areas and air-conditioned rooms and to meet fire protection regulations, parts of the machinery were removed and scrapped, facades changed and installations made. This affects the overall aesthetic and technical composition of the architects Schupp and Kremmer. While the general public perceives Zollverein as a flagship project of “industrial culture”, experts complain about the massive encroachment on the existing structure associated with the renovation, making the coal washing plant, for example, a “Potemkin village of monument preservation”: the industrial appearance obscures the extent of the loss of original substance.

Ruhr Museum

On 9 January 2010, designed as a permanent exhibition opened new Ruhr Museum , far south of Essen city as Ruhrlandmuseum resident in the coal washing. The exhibition rooms have been used for various temporary exhibitions since August 2006, such as Entry 2006 - How will we live tomorrow? and Gold vor Schwarz (2008) with the treasures of the Essen Cathedral Treasury .

Folkwang University of the Arts

In addition to locations in Essen-Werden, Duisburg, Bochum and Dortmund, the Folkwang University of the Arts has been using the Zollverein cube of the Japanese architects' office SANAA as the second Essen campus since 2010. For the 2017/2018 winter semester, a new university building was opened in the immediate vicinity (architects: MGF-Architekten, Stuttgart), which houses the design department.

Zollverein Park

In order to make the colliery and the adjacent coking plant accessible to the public and tourists, the Zollverein Park , designed by the Oberhausen planning group in collaboration with F1rstdesign, LichtKunstLicht AG and the observatory, was completed at the end of 2012 . The concept is based on the claim to carefully incorporate existing structures into the redesign and to take the history of the location into account. New paths, squares and pavilions were created and installations and a lighting concept designed. The care of the vegetation is still in the foreground.

Industrial nature

In addition to the buildings of the colliery and coking plant, an enormously diverse flora and fauna has developed. The artificial, technogenic substrates such as tailings and track ballast are mostly poor in nutrients and, depending on their compaction, have a low water storage capacity. Such locations are ideal habitats for heat-loving animal and plant species. Depending on the development and design of the area, different vegetation stages can be found on the site, from sparse vegetation on raw soil (open areas on the heap of the sculpture forest), pioneer vegetation and tall forebear communities (track areas around the coal washing plant) through bush stadiums to the pre-forest (industrial forest on the heaps). Such flora and fauna, which developed on former industrial and commercial areas, is called industrial nature in the Ruhr area. Due to the richness of species, it is of enormous importance for the preservation of urban biodiversity. This industrial nature is unique in Germany and is accordingly a unique selling point for the Ruhr area. Along with the Duisburg-Nord landscape park, Zollverein is one of the most biodiverse industrial wastelands in the Ruhr area.

Movie and TV

- Since September 2006, photos of the Zeche Zollverein have been an integral part of the scene transition in the RTL daily soap Alles was geht in Essen .

- In the film Superstau , Ralf Richter comes home from work at Zeche Zollverein at the beginning of the film .

- In the film The Miracle of Bern , the Zollverein colliery can be seen in the background at the beginning.

- In the music video In Town by the German rapper Favorite , the Zeche Zollverein can be clearly seen.

- The feature film Die Frühhreifen is about life in the Ruhr area in the 1950s and shows many scenes around the Zeche Zollverein.

Postage stamps

On July 10, 2003 , Deutsche Post AG issued a stamp with the Zollverein motif. Heinz Schillinger designed the special stamp.

Current

In addition to the renovation measures already mentioned, the Zollverein has meanwhile become a prestige object in the Ruhr area. Since being awarded the title “World Heritage”, Zollverein has been an international meeting point for large cultural projects such as the international world music fair “ WOMEX ” or “ ExtraSchicht ” - the night of industrial culture in the Ruhr area as well as for smaller-scale concerts, so the WDR Big Band is more regular Guest and also the hip-hop group “ Fettes Brot ” as part of the TRIDEM. Every year the Zechenfest takes place with live music. The numerous construction projects on and around Zollverein are intended to create a wide range of cultural activities for many different interests over the next few years.

An outside inspection of the entire facility is always possible. The visitor center offers indoor tours, some of which are led by former miners .

See also

literature

in alphabetical order by authors / editors

- Heinrich Böll, Hans Krabel: Working on Zollverein. Projects at the Zeche Zollverein shaft XII since 1989. Klartext-Verlag, Essen 2010, ISBN 978-3-89861-912-7 .

- Delia Bösch: Discover Zollverein - On the way on the world heritage. 3rd, extended edition, Essen 2007, ISBN 3-9809846-0-5 .

- Wilhelm Busch and Thorsten Scheer: Symmetry and Symbol. The industrial architecture by Fritz Schupp and Martin Kremmer. Cologne 2002, ISBN 3-88375-616-4 .

- Walter Buschmann : Collieries and coking plants in the Rhenish coal industry. Aachen Revier and western Ruhr area (= The architectural and art monuments of North Rhine-Westphalia. Vol. 1: Rhineland ). Mann, Berlin 1998, ISBN 3-7861-1963-5 , pp. 414-485.

- Walter Buschmann: The coal washing plant of the Zeche Zollverein - a case of overuse in the world cultural heritage. In: Preservation of monuments in the Rhineland. No. 3, 2015, ISSN 0177-2619 , pp. 115-124.

- Walter Buschmann: Zollverein colliery and coking plant in Essen (= Rheinische Kunststätten . Issue 319). 2nd Edition. Rhenish Association for Monument Preservation and Landscape Protection, Cologne 2010, ISBN 978-3-86526-058-1 .

- Veronika Grabe (ed. :): Zollverein World Heritage Site. The past and present of the Zollverein colliery and coking plant. = The Zollverein world heritage site. Klartext-Verlag, Essen 2008, ISBN 978-3-89861-844-1 (German / English).

- Gunnar Gawehn: Zollverein. A Ruhr area mine in the industrial age 1847 to 1914 , Klartext, Essen 2014, ISBN 978-3-8375-0916-8 .

- History workshop Zollverein (Ed.): Zeche Zollverein. Insights into the history of a large mine. Klartext-Verlag, Essen 1996, ISBN 3-88474-507-7 (2nd, revised edition, ibid 1999).

- Joachim Großmann: Walks through Zollverein. The mine and its industrial landscape. Klartext-Verlag, Essen 1999, ISBN 3-88474-794-0 .

- Keil, P. & E. Guderley (eds.) (2017): Species diversity of industrial nature - flora, fauna and mushrooms at Zollverein in Essen. - Treatises from the Westphalian Museum of Natural History 87: 1-320. ISBN 978-3-940726-51-3

- Wilhelm Hermann, Gertrude Hermann: The old mines on the Ruhr. Past and future of a key technology. (= The Blue Books ). With a catalog of the "life stories" of 477 mines. 6., a photo excursion “Zollverein Weltkulturerbe” by Udo Haafs according to p. 216, expanded and updated edition. Langewiesche Köster, Königstein im Taunus 2008, ISBN 978-3-7845-6994-9 .

- Eitel Mantowski, Claudia Hellwig, Frank Münschke (eds.): The Koker on Zollverein. Zollverein-Koker talk about their work and life at the Zollverein coking plant. Klartext-Verlag, Essen 2012, ISBN 978-3-8375-0690-7 .

- Udo Mainzer : Zollverein: A world-class architectural monument of industrial history. In: Preservation of monuments in the Rhineland. No. 3, 2005, ISSN 0177-2619 , pp. 98-103.

- Heike Oevermann: About dealing with the industrial heritage. A discourse-analytical study of urban transformation processes using the example of the Zeche Zollverein. Klartext-Verlag, Essen 2012, ISBN 978-3-8375-0834-5 .

- Dietmar Osses: coal, coke, culture. The coking plants of the Zollverein colliery. Foundation for the preservation of industrial monuments and culture of history, Dortmund 2002, ISBN 3-935783-09-4 .

- Birgit Parakenings: Zeche und Kokerei Zollverein: The World Heritage Site (= workbooks of the Rhenish Monument Preservation 70). Wernersche Verlagsgesellschaft, Worms 2006.

- Birgitta Ringbeck: Zollverein World Heritage Site - What does the UNESCO Convention oblige you to do? In: Preservation of monuments in the Rhineland. No. 3, 2005, ISSN 0177-2619 , pp. 104-106.

- Thorsten Scheer : The dark side of modernity. The foundation of the monument from the autonomy of the work of art In: Symmetry and Symbol. The industrial architecture by Fritz Schupp and Martin Kremmer. Cologne 2002, pp. 73-80.

- Thorsten Seifert - Zollverein before 1900 - founding and expansion years in: Conference proceedings (old) Mining and Research in NRW 2012, online.

- Rolf Tiggemann: Zollverein Shaft XII. From the largest colliery in the world to a world heritage site. Klartext-Verlag, Essen 2007, ISBN 978-3-89861-741-3 .

- Zeche Zollverein e. V .: The Zeche Zollverein. Sutton, Erfurt 2008, ISBN 978-3-86680-320-6 .

- Zollverein Foundation (ed.): ZOLLVEREIN - World Heritage and Future Workshop , JOVIS Verlag 2018, ISBN 978-3-86859-476-8 .

Web links

- Description of this attraction and anchor point as part of the Route of Industrial Heritage

- Zollverein website with a map of the complete Zollverein World Heritage Site (PDF; 616 kB)

- UNESCO world cultural heritage

- The Zollverein ring promenade as a funding project of the NRW Foundation

- Thomas Mayer Photo archive with a large selection of photos from the Zeche Zollverein

- Zollverein on stadtpanoramen.de

- Virtual tour of the WDR customs association area with hotspots for your own contributions (Flash required)

- Photos (1990–2007) of the Zeche Zollverein by Harald Finster

- Photographs and history of the Zollverein colliery on industriedenkmal.de

- Zollverein Park on landscape architecture today - a portal of the bdla

- Zollverein Park on 100 years of landscape architecture - an online exhibition of the 100 most important projects of the past 100 years

- Press release - RAG is moving back to the Zollverein World Heritage Site

- http://ruhrzechenaus.de/essen/e-zollverein.html

Individual evidence

- ^ Sebastian Hellmann: Halden of the Zeche Zollverein. Retrieved September 14, 2020 .

- ↑ See in detail Andreas Koerner / Klaus Scholz / Wolfgang Sykorra : One was never a stranger. The Essen mining colony Schönebeck and its district . Edition Rainruhr, Essen 2009, 158 pages, ISBN 978-3-9811598-9-9 .

- ↑ Historical overview

- ↑ Excerpt from the list of monuments of the city of Essen ; Retrieved January 5, 2017

- ↑ Excerpt from the Geo Info System of the city of Essen

- ↑ Zollverein Coal Mine Industrial Complex. German UNESCO Commission V., accessed on October 8, 2013 (press release from the 25th session of the UNESCO World Heritage Committee on December 14, 2001 in Helsinki).

- ↑ Hans Kania: What is Zollverein? In: Hartmut John, Ira Mazzoni (eds.): Industrial and technical museums in transition: Perspectives and location determinations. Bielefeld 2005, pp. 109–144, here p. 133. Cf. Andreas Rossmann: Geschichtsabriss im Ruhrgebiet. In: Frankfurter Allgemeine Zeitung No. 276 of November 25, 2004, p. 37. online

- ^ Website of the Folkwang University of the Arts

- ↑ Report on derwesten.de from July 18, 2016 Marcus Schymiczek: The new Folkwang University building at Zollverein is taking shape.

- ^ Zollverein Park . Landscape architecture portal today from bdla . Retrieved March 25, 2014.

- ^ Zollverein Park . Online exhibition of the 100 most important landscape architecture projects of the past 100 years. Retrieved March 25, 2014.

- ↑ Industrial landscape of the Ruhr area. Series “Pictures from Germany” ( Memento from August 9, 2016 in the Internet Archive ). BRIEFMARKEN-ARCHIV.DE, accessed on July 21, 2015.