Bochum Association

The Bochumer Verein was a vertically integrated mining group based in Bochum , to which several steelworks and collieries belonged and which at times employed over 20,000 people. It emerged in 1854 from the Mayer and Kühne cast steel factory and initially operated as the Bochum Association for Mining and Cast Steel Manufacture ( BVG ). Between 1926 and 1951, the company was part of the major Vereinigte Stahlwerke AG .

In 1965, the BVG finally merged with the Hütten- und Bergwerke Rheinhausen AG of the decades-long competitor Krupp . After various name changes, a successor company operates again as Bochumer Verein Verkehrstechnik GmbH .

history

Prehistory and beginnings

The trained watchmaker Jacob Mayer , who was interested in the possibilities of crucible steel casting at an early age and, in addition to his own (later successful) attempts, had already tried to uncover the secret of steel processing, which was closely guarded by the British side, closed with the in 1839 Eberhard Hoesch, who was still based in Düren at the time, signed a contract to operate a cast steel works. While Hoesch preferred a location near Aachen because of the proximity to his home and the Aachen coal field, Mayer wanted to build the plant because of the lower-sulfur coal deposits on the Ruhr . So the contract was terminated, and a little later Mayer found a financially strong partner in Eduard Kühne .

The history of the Bochum company began with the cast steel smelter, which Jacob Mayer founded in 1842 on what was then Essener Chaussee - today's Alleestraße - and which, through the merger with the businessman Eduard Kühne , traded as the Mayer & Kühne cast steel factory . The first products of the hut were semi-finished products in the form of steel bars, which were processed into tools, scissors and swords in the Sauerland and Siegerland forges. Despite the excellent properties of Bochum cast steel, which were proven by tests, it was only possible to end the predominance of British steel slowly. Mayer & Kühne later also started manufacturing files and springs. Mayer continued to develop his casting process, however, so that the workpieces were given their final shape and strength through the casting mold and not only through forging the semi-finished product: As early as 1847, the company was also producing cast steel bells, for which the Bochum Association later became famous Cannon barrels made of cast steel, which at that time still had to be finished at the company Kamp & Co. (the former company of the industrial pioneer Friedrich Harkort ) in Wetter . The steel molding process of the technically experienced Jacob Mayer was not protected by a patent , ignoring the technical possibilities of this process , but in 1852 Mayer received a patent for a "molding box with gas heating" from the Prussian Minister of Commerce, which was a component of the casting process. In the same year, Mayer & Kühne presented products made of cast steel in the form of three bells to the world for the first time at the Düsseldorf trade fair. The oldest surviving bell from the early days of Mayer & Kühne from 1845 is in the Hermann Grochtmann Museum in Datteln, bells from 1853 are in the German Tool Museum in Remscheid and in the parish of St. Nikolaus in Kasbach-Ohlenberg .

Most of the workers in the first few decades came from rural areas, there was no specialized training and there was little schooling. A report from the 1850s about the Bochumer Verein states that many workers worked in the factory in summer and returned to their rural home in winter, when a quieter period began in industry.

Foundation of the stock corporation

Since the banking industry was not yet familiar with the concept of fixed assets , loans were only granted for a short time and were rescheduled when they were due or canceled, which led to a permanent shortage of capital at Mayer & Kühne - even though the end of the March Revolution in 1849 and the introduction of tariffs on competing staff and pig iron from Great Britain brought an economic boost, this could not hide the structural problems in the financial base: Due to the rapid expansion of the company - especially through the construction of its own rolling mill - the financial possibilities were soon exhausted, so that the company Mayer & Kühne In 1854, to broaden the capital base under the direction of the Cologne banks A. Schaaffhausen'scher Bankverein and Sal. Oppenheim, it was converted into a stock corporation - the Bochum association for mining and cast steel production was born. Jacob Mayer kept technical management, but in 1855 Louis Baare took over the management of the company from the Cologne-Mindener Eisenbahn-Gesellschaft .

The cast steel patent was initially challenged by competitor Alfred Krupp , who had already torpedoed the conversion of the cast steel factory into a stock corporation through newspaper advertisements. At the World Exhibition in Paris in 1855 there was a scandal: Jacob Mayer agreed to have one of the bells exhibited there smashed and, by forging the fragments, to prove that his bells were made of cast steel and not cast iron , as Krupp had previously claimed . The proof was successful in the sense of the Bochumer Verein. There was also fierce competition between the Essen and Bochum companies for other products that were developed by Mayer and Krupp at about the same time - such as the cast steel cannons and later the seamless wheel tires - which was fueled by the arbitrariness of the patent system at the time.

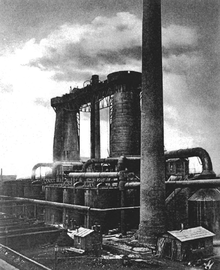

Development of the production facilities

Baare's first project was a large investment program in which the puddle and crucible steelworks were to be greatly expanded and a drum rolling mill and wheelset turning shop built - the program was completed around 1860 with the completion of the drum rolling mill. At around the same time, Krupp succeeded in driving a mandrel into a solid steel plate to form a closed ring, and Mayer in casting closed rings out of steel. Both “blanks” then only had to be rolled into a uniform ring on such a drum rolling mill in order to be used as the tire of a train wheel .

Eduard Kühne resigned in 1858 because of Baare's supremacy in the new form of organization. The friction that occurred between Baare, Mayer and the administrative board for the same reason was only resolved in the 1860s through an organizational equalization of Baare as general director and Mayer as technical director under the administrative board - before that, Mayer and Baare had threatened to join the Bochumer Verein leave. In 1859, Jacob Mayer was placed as a deputy to relieve the engineer Vital Daelen , who had previously worked for the Hörder Bergwerks- und Hütten-Verein . Right at the beginning of his activity, Daelen developed a design for a wheel tire for the railroad, so that the collaboration with Jacob Mayer began very fruitfully. In the period that followed, the product range for the rapidly expanding railways in Germany was expanded to include wheel sets and wheel tires for railways and trams . The breakthrough for the one-piece cast wheels invented by Jacob Mayer came in March 1860 when the Cologne-Mindener Eisenbahn-Gesellschaft ordered 400 wheel sets. Even Alfried Krupp, who had previously fought cast steel, could no longer ignore the success of the cast disc wheels and also started cast steel in 1863 in Essen and presented the first cast disc wheels in Paris in 1867. After Vital Daelen's departure from the Bochum Association in 1868, Otto Helmholtz became his successor and, after Mayer's death, also technical director.

It was not until 1863, after a long hesitation, that Bochum began to replace the puddling process previously used for the production of forgeable steel with the “wind freshening” in the Bessemer pear, invented as early as 1855 . This change brought about a two-hundredfold increase in productivity for steel, which is why Krupp decided to use it very quickly, while the Bochum administrative board saw the risks of the innovation too critically for a long time. However, the Bessemer wind freshening process could only be applied to low-phosphorus ores, which almost exclusively had to be imported and could only be bought from small ore mines in Siegerland. The Bessemerwerk was completed in 1865 at the same time as a rail rolling mill, as the Bessemer steel was easy to process into rail material. The Bessemerwerk was headed by Heinrich Köhler , who later developed into a competitor through the establishment of the Westfälische Stahlwerke AG in Weitmar.

The Bochum Association later made up for the delayed introduction of the Bessemer process compared to Krupp by upgrading to the "rapid process" at a very early stage: The pig iron for the Bessemer converter is not prepared in flame , but cupola furnaces and the ingots are cast not made in the very small round casting pit that was customary at the time, but with an elongated casting carriage system that decoupled the emptying of the Bessemer converter from the casting of the blocks in terms of time and space. Thanks to this acceleration, the BVG was able to realize up to 50 Bessemer batches per day at the beginning of the 1870s - only 8-10 batches per day were customary in the industry.

Since 1866, the Bochumer Verein developed into a powerful armaments company by setting up its own cannon workshop - gun barrels and, above all, casings, along with other armaments, were produced in large numbers in both world wars . Due to the smaller forging hammers, however, the Bochumer Verein never reached the rank of Krupp in the field of armaments, which in 1865 was one of the official reasons that the Sayner Hütte with its attached iron ore mines from Prussian state property sold to Krupp and not to the Bochumer Verein became: Krupp simply had more experience with gun manufacture and accordingly much greater capacities. The first order for the new cannon workshop came in 1866 from the royal Bavarian government shortly before the German-Austrian War .

At the end of 1867 the plant was finally connected to the network of the Bergisch-Märkische Eisenbahn-Gesellschaft and seven years later to the Rheinische Eisenbahn-Gesellschaft , which broke the transport monopoly of the BME. Until the company's own siding was completed, the goods had to be transported by horse to the Herne train station (until 1860 therefore "Herne-Bochum") of the Cologne-Mindener Eisenbahn-Gesellschaft .

At the Paris World Exhibition in 1867, a 15,000 kg bell "cast in one piece" was shown as the highlight, which caused a sensation. It later stood as a memorial in front of Torhaus 11 on the company premises until it was donated to the city of Bochum in 1979 and re-erected in front of Bochum's town hall. It is popular again as the town hall bell , but it no longer sounds due to damage suffered in World War II.

Founding period

Since the procurement of pig iron in sufficient quantity and quality caused increasing problems in the boom after the Franco-German War , the Mülheimer Hütte (1863–1874) with two own blast furnaces and a few ore mines was acquired in 1872 . From 1876 the pig iron was then produced in a separate blast furnace , construction of which began in 1873. The construction of the blast furnaces was directed by the engineer Franz Burgers , who had previously built the blast furnaces at the Mülheimer Hütte and after the completion of the Bochum plant in 1878, which was delayed by the recession in the middle of the 1870s, was brought in by August Thyssen to expand the blast furnace plants to the Schalker Verein. Since the BVG had financed its blast furnace system with expensive bank loans at the end of the Wilhelminian boom, it got into financial difficulties, so Louis Baare campaigned for the formation of a rail cartel to prevent ruinous competition between the plants. The cartel finally came about with the involvement of all important rail suppliers (Krupp, Phoenix, Dortmunder Union etc.).

As early as 1876, the Bochum Association put eight Siemens-Martin furnaces into operation, with which steel could be produced with the addition of scrap and lime. The Bochum association set up its SM steelworks based on the experience gained with the rationalization of the Bessemerwerk - the factory with its casting pit that stretched along the furnace was considered exemplary. Together with Krupp (16,000 t / a), the BVG (35,000 t / a) had almost a monopoly on SM steel in Germany until the end of the 1870s. The SM steel slowly replaced the high-quality crucible steel.

The Mülheimer Hütte was closed in 1874 in the middle of the depression phase; in total, almost half of the BVG workforce had been laid off by 1876. The recession was finally overcome in 1879 with protective tariffs on foreign goods and a resurgent demand for railroad equipment. In the following upswing, two more blast furnaces were built and blown up by 1886.

The Thomas process for steel production, introduced on a trial basis in 1881 , with which the phosphorus-rich iron - as it was found in Lorraine - could be processed into forgeable steel, did not meet the quality and cost expectations, so that foreign ore was still used and the Bessemer method was instructed. The decision to purchase the Thomas license and the concession for the phosphorus-rich Minette field “Fentsch” in Lorraine was based on a misjudgment by the technical director Otto Helmholtz , who then had to leave the BVG.

Since the small town of Bochum could not offer enough living space for the workers and their families immigrating from other regions, Louis Baare, who was general manager from 1855 to 1895, also got involved in the construction of living space and in 1858 had a "workers' house" built , which was replaced in 1872 by a new, much larger "Kosthaus" ( popularly called "Bullenkloster") with overnight accommodation for 1200 single workers, appropriate social rooms and a canteen. Part of the original factory residential complexes has been preserved, for example the apartment block in the street triangle Alleestraße, Wattenscheider Straße and Kohlenstraße and the settlement between Baarestraße and Alleestraße. Overall, almost the entire district of Stahlhausen can be traced back to the activities of the Bochumer Verein.

In addition to the construction of houses, the employees were tied to the company by a health and pension insurance that had already been introduced at the Mayer & Kühne company as a “support fund” and supplied with food by the company's own “consumer establishments”. It was only with the relief fund law from 1854 or the transition to a stock corporation that the BVG made a contribution to the fund contributions, so that the fund benefits then exceeded the legally required level - the standard for the permanent workforce was free treatment by the doctor, free medication , Sick pay as well as funeral expenses and widow and orphan benefits. In principle, the employer's contribution fluctuated depending on the economic situation, and the benefits provided by the support institutions to maintain loyalty to the company were largely based on length of service and employee status. In 1872 the various social institutions were combined in a separate stock corporation, which, however, was liquidated in 1876 due to a lack of subscribed shares and reintegrated into the BVG.

Louis Baare's attitude as patriarch , who managed his company strictly but also with responsibility for the workers, became a pioneer of the first accident insurance law in the German Reich through a memorandum of April 30, 1880 to Otto von Bismarck . Louis Baare's son Fritz Baare (1855–1917), who was General Director of the BVG until 1917, also continued his father's social policy.

In terms of wage policy, Louis Baare followed the trend towards group agreements. At the general assembly of the Bochumer Verein in 1875, he described the piecework wages as "Alpha and Omega" in order to reduce operating costs. Apart from highly specialized jobs and the simplest occupations, piecework wages are applied throughout the company. Baare went much further than the models in England. With piecework wages, the risk of market fluctuations was transferred to workers , especially during the start-up crisis . In fact, between 1873 and 1878 the workforce at the iron and steel works was reduced from over 4,000 to around 2,500, wage costs were halved, while production per man per day rose from 15 to 30 tons of steel. In order to discipline the workers, the Bochum Association introduced brand control as early as 1860 .

The products of the Bochumer Verein were also sold internationally. In 1873 there were already 23 sales agencies, twelve of them abroad. The products were also advertised through participation in international trade and world exhibitions - such as the 1873 World Exhibition in Vienna.

In 1879, the first of the three large railway companies in the Ruhr district, the Cologne-Minden Railway Company , was nationalized on the recommendation of an investigative commission. It was followed in 1880 by the Bergisch-Märkische Eisenbahn-Gesellschaft and in 1882 by the Rheinische Eisenbahn-Gesellschaft , which, however, did not lead to the expansion of the “raw material tariff” introduced for other goods since 1890 to all ores and coal until 1897. As a result of the state consolidation, uneconomical routes could be abandoned, which in previous years had attempted to counter the price dictated by connecting to several railway networks. The Bochum club also benefited from the new tariffs.

The attempts of the Bochumer Verein to position itself internationally through investments and to maintain important sales markets through local presence had little success: The participation in the company Tardy & Benech in Savona , Italy, from 1887 to the complete write-off in 1891 as well as the small one Engagement with the company Portilla, White & Co. in Seville , Spain, from 1887 to 1893 both ended as a loss-making business.

In 1889, the neighboring stock corporation for steel industry , which was founded in 1870 , was taken over by the Schalker Gruben- und Hüttenverein , which in turn was controlled by Thyssen. Founder of the company, first called Neues Stahlwerk KG Daelen, Schreiber & Co. , which later became a stock corporation, was Mayer's former deputy, Vital Daelen, who had set up his own business with his knowledge of the most profitable products. In the depression year of 1873/1874, however, the pig iron contracts, which were concluded too expensive during the boom, had such a devastating financial effect that August Thyssen had to step in as a partner. In 1875, the steel industry's Bessemer plant even had to be temporarily shut down. In addition to the expansion of the site and facilities, the acquisition of the company, which continued to operate relatively independently as a “steel industry”, meant access to the Engelsburg colliery for the Bochum association and around 850 new workers and “civil servants” (salaried employees). In the same year, the construction of complete railway wagons for goods traffic was started, which rounded off the business with the wheelsets to the finished product.

In 1912, a suspension cable car was built to directly connect the Carolinenglück colliery with the blast furnaces and operated until 1968 (when the coking plant and the blast furnaces were closed). The cable car crossed the developed in the 1960s Ruhrschnellweg (current A 40 ) via a October 2010 still existing protection bridge (to protect the traffic against falling coke fractions or transport vessels) with untergehängtem footbridge (coordinates 51 ° 29 ' N , 7 ° 11' O ).

As a new gas power station and blower machine hall on the site of the Bochum Association 1903 now " Jahrhunderthalle built" said Hall. Its iron structure had previously served as the company's exhibition hall at the 1902 industrial and commercial exhibition in Düsseldorf , where it was provided with a more elaborately designed facade and a bell tower. Overall, numerous improvements were introduced between 1880 and 1900: The generation of wind and electricity was taken over by gas engines instead of steam engines, the purchase of the Carolinenglück colliery and the expansion of their coking plant enabled the company's own coking plant to be shut down and a gas-based energy network between blast furnaces, Coking plant and the many consumers in the plant. The wagon construction and switch production were also greatly expanded. In the course of the modernization work, the outdated Bessemer and Siemens-Martin works were shut down in 1912.

Raw material base

For the supply of hard coal and coke for the four blast furnaces located on Gahlenschen Strasse until 1886, the Bochum Association gradually participated in several mines or took them over completely:

- 1868 United Maria Anna Steinbank colliery , but closed in 1904, field later sold to Stinnes

- 1889 Engelsburg colliery with briquette factory, through affiliation of the Society for Steel Industry

- 1890 Hasenwinkel colliery , sold to Stinnes in 1904

- 1900 Carolinenglück colliery with coking plant and Graf Moltke colliery

- 1907 Teutoburgia colliery

With the purchase of the Mülheimer Hütte in 1872, there were also some mostly smaller ore mines in Siegerland and Nassau, which were mostly closed until 1894 due to exhaustion:

- Wilhelmine mine and Hymensgarten

- Kuhlenwalderzug pits , water source, corner , Steinseifer Association, Wasenberg (Siegen district)

- Wäth and Gotthart mines (Wetzlar district)

- Klappertshoffnung mine, Feldberger Erbstollen (Siegen district)

- Hermann mine (Mülheim district)

After the annexation of Lorraine (1871), the Bochumer Verein also acquired the concession for the Minette field “Fentsch” near Kneuthingen in 1881 in order to secure its own supply of iron ore. The “Fentsch” mine was not opened until 1900, as the freight costs previously did not allow economic operation. Notable production volumes were only achieved there in the course of 1903/1904 - in 1914, 870,000 tonnes of ore was finally achieved with a workforce of 1,100. However, since the Thomas process had not prevailed at the BVG, the Lorraine ore was only sold and not used itself. The mine with the two tunnels "Louis Baare" and "Fahr" fell back to France after the First World War (French name: "Mine de Fontoy ", Knutange / Moselle). The impressive portal of the abandoned pit and the underground galleries have been preserved.

In order to reduce the dependence on low-phosphorus ores from Algiers, Spain and Africa, iron ore fields in Sweden were acquired in 1911: the Natorpsfeld mine near Norrköping and the Intrangetfeld mine in the province of Dalekarlien , as supply relationships already existed with Sweden.

In 1890, the concession for a limestone deposit near Wülfrath was bought in order to meet the demand for quick lime as an aggregate for steel production in the company's own limestone quarry - the Bochum quarry was not exhausted until 1958/1959. The former quarry is used as a landscape protection area by the German Alpine Association for climbing tours.

The quartzite required for the refractory kiln extension was also mined in the Hühnerberg quarry from the 1890s, but the stocks were exhausted very quickly.

The club management also acquired stakes in ore deposits in Norway and Finland, which supplied ore that could be used for the Bessemer process.

First World War

The mobilization of the army on August 1, 1914 caught the Bochum association unprepared - in 1912 the modernization of all four blast furnaces had just begun, stocks had been kept as tight as possible due to the current investments. Of the group's 16,000 men, 5200 were called up - at the same time, production had to be converted from the usual peace material to war goods such as artillery and bullet casings. Walter Borbet , employed as chief engineer, finally succeeded in casting durable artillery out of Siemens-Martin steel, as the crucible steel used up to now could not be produced in sufficient quantities. In addition, in 1916 Borbet introduced the Dwight-Lloyd process for smelting, in which fine-grain iron ore is first sintered into larger pieces in a so-called agglomeration plant before it enters the blast furnace. The BVG finally produced around 3000 gun barrels per month. The cutting of the ore deliveries from Algiers and Spain meant that two smaller Siegerland ore mines ( Eiserne Hardt and Silberwiese ) were bought.

In spite of the fact that the mechanical engineering industry was at full capacity during the war, numerous systems for remuneration of the gun barrels were built and put into operation. The scarcity of raw materials - especially nickel for alloying - led to intensive metallurgical research in order to still be able to satisfy the need for weapons.

In order to replace the workers drafted to the front, women (most recently almost 3,000) and prisoners of war (around 1,500) were increasingly deployed, as a result of which the workforce grew again to around 17,600 workers.

Weimar Republic

In the Versailles peace treaty , Germany was forced to destroy factories that were used to manufacture weapons - at the Bochumer Verein, the drop forge, presses, large parts of the remuneration systems and many processing machines in the mechanical workshops were therefore destroyed.

The Herne colliery Friedrich der Große was acquired in 1918, but sold again to Ilseder Hütte in 1921 , as the coal base was sufficient due to the merger with Gelsenkirchener Bergwerks AG in the Rhine-Elbe Union, but instead liquid funds for the new construction of the Höntroper Work were needed. The loss of the “Fentsch” iron ore mine was only partially absorbed in 1919 by the purchase of the unproductive Schnellenberg and Falkenberg iron ore mines in Siegerland.

In 1921, the considerations for the expansion of steel production capacities were given concrete form. However, there was no more space on the Alleestrasse and Stahlindustrie sites, so large areas were bought up in nearby Höntrop (coordinates 51 ° 29 ' N , 7 ° 10' E ). Initially, a steelworks ("Stahlwerk III") with four Siemens-Martin furnaces was planned , of which the first two went into operation in November 1924 and January 1925. In order to keep operating costs low, a tube rolling mill was built right next to the steelworks, in which the first tube was rolled in April 1924, although this was only in operation for a few years because the United Steelworks was already planning to concentrate tube production in Mülheim was. The entire heat supply was implemented "without a piece of coal" by aligning all firing systems to furnace gas from the blast furnaces on Gahlenschen Strasse and coke gas from the Carolinenglück colliery. To buffer the gas flows, two 70 m high gasometers with a capacity of 100,000 m³ were erected on the northern part of the site, directly on the works railway and gas connection to the Alleestrasse works. To reduce the need for fresh water, a sewage treatment and cooling system was built directly at the water tower, which was also set up to use rainwater. The hall complexes with a floor area of 31,400 m² (steelworks) and 38,100 m² (rolling mill) were built by the company Dortmunder Union Brückenbau . The tube rolling mill was even considered the largest in the world at the time. On the opposite side of Essener Strasse, a housing estate for employees and administrative buildings was built.

Hugo Stinnes , who had bought 50% of the shares from the property of the banker Hugo Herzfeld through an intermediary company with the participation of a banking consortium and was now the main shareholder of the Bochumer Verein, founded the mining group Rhein-Elbe-Union GmbH in 1920 to bundle the corporate interests of its German-Luxembourgish companies Bergwerks- und Hütten-AG , Gelsenkirchener Bergwerks AG (GBAG) and the newly acquired Bochumer Verein. Due to the resulting reorganization of the directorate, Wilhelm Baare resigned from his position as chairman of the directorate in 1922. Walter Borbet , who was also appointed General Manager in 1924 and who ran the BVG in a similarly patriarchal manner as Louis Baare, until his death became the chairman of the newly established board . Hans Baare , a son of Wilhelm Baare , also became a member of the board . Two years after Stinnes death, the Rhine-Elbe Union was dissolved; the companies involved merged in 1926 under the leadership of Hugo Stinnes' confidante Albert Vögler in the Vereinigte Stahlwerke AG . In the same year, the wagon factory and field railway construction at the Bochumer Verein are given up. Due to the metallurgical knowledge that had been gained in World War I, the crucible steel and Bessemer process was completely discontinued in favor of the Siemens-Martin process in 1925 and the corresponding parts of the factory shut down.

In January 1927, Vereinigte Stahlwerke AG founded Deutsche Edelstahlwerke AG in Bochum , into which, among other things, the stainless steel activities of the Bochumer Verein were incorporated - with that, the parts of the Society for Steel Industry located on today's Bessemerstraße left the Bochumer Verein - but became part of the Redesign of DEW 1929 reintegrated into the BVG as the steel industry plant . Also in 1929 the connecting line to the port of Grimberg on the Rhine-Herne Canal was completed, which significantly reduced the transport costs for the iron ore.

The occupation of the Ruhr had paralyzed the economy, and due to the associated general strike and the subsequent strikes that flared up again and again, the global economic crisis that set in at the beginning of the 1930s also hit the Bochum Association of the United Steelworks AG hard: in April 1930 alone, 600 workers had to be laid off . In September 1931, the prospect of cessation of operations in the new tube rolling mill was announced, which led to the dismissal of another 700 employees. Overall, the Bochum association's workforce shrank by almost 50 percent by 1932.

In 1932 a bathhouse was built for the workforce, which put an end to the previously unregulated bathing operation in the cooling ponds of the granulation plant for the blast furnace slag. In 1936 the bath was also opened to the general public, who used the slag bath extensively. At the end of the 1930s there were already around 4,000 medical prescriptions for the Bochum sulfur baths.

Period of National Socialism and World War II

When the Vereinigte Stahlwerke AG (VSt) was reorganized after the transfer of power in 1933, the Bochumer Verein became formally independent again as the Bochumer Verein für Gußstahlfabrikation AG on January 1, 1934 - at the same time the Rombacher Hütte was assigned to it as the Weitmar plant , which had been part of the operating group since 1926 Bochum had belonged to the VSt.

With effect from October 1, 1934, on the advice of the Wehrmacht , the Bochumer Verein took over the majority of shares in the ailing vehicle and mechanical engineering company Hanomag in Hanover with around 10,600 employees, in which the gun barrels from the Bochum production were assembled into complete weapons during the Second World War. This was a further step towards the vertical alignment of the group in the direction of the armaments company, which now united everything under one roof, from the extraction of raw materials to the finished weapon system. The disused Weitmar plant was modernized at the same time to manufacture armored domes for the Siegfried Line.

During the time of National Socialism , the Bochum Association was named a "National Socialist Model Company" in May 1937 because of its exemplary attitude towards the ideas of National Socialism , which was shaped by General Director Walter Borbet, which actively supported the influence of the NSDAP and the German Labor Front on the workforce - this award kept the BVG until the end of the war. Adolf Hitler himself paid a visit to the Bochum Association on April 14, 1935, during which he let Albert Vögler , Fritz Thyssen and Walter Borbet show him, among others, the Höntrop work. Before that, Reichswehr Minister Werner von Blomberg had visited the plant on February 20, 1935 and Hermann Göring on May 9, 1935, which in the following years led to the conclusion of extensive jacket contracts for arms production. The bell for the 1936 Summer Olympics in Berlin with the inscription “I call the youth of the world” was also cast by the BVG. Her whereabouts were forgotten after the war, but it was found again in 1956, but was so damaged by being dropped from the bell tower and being shot at that it could no longer be rung.

After the first electric arc furnace was commissioned on February 19, 1935 in the Alleestraße steelworks, two more electric furnaces followed by 1942, in which high-alloy stainless steels could be processed, for which the Siemens-Martin furnaces could not be used. The introduction of electric steel, which has been known since the turn of the century, was therefore introduced very late, which was essentially due to the wrong decision made by Walter Borbet, who for a long time stuck to the duplex process he had introduced with the use of pig iron and ore in Siemens-Martin furnaces. Such wrong technical decisions ultimately led, through high financial losses, to the fact that the German Edelstahlwerke, of which Borbet was also a member, were re-constituted in 1929 and moved to Krefeld - and Borbet was no longer a member of the new board. On the other hand, Borbet strongly advocated melting in high-frequency furnaces, so that, with the participation of DEW, Hochfrequenz-Tiegelstahl GmbH was founded in Bochum in 1934, into which the Bochum Association's stainless steel test melt, which had been in existence since 1924, was integrated. In 1938 a new press with 6000 t of pressure was installed in the Höntrop plant, which was dismantled in 1946 and brought to Great Britain - where it was never put into operation. In the mid-1950s, the Bochumer Verein bought the press back and put it back into operation at the Alleestraße location, where it is still working after a general overhaul in 2007.

Since the BVG's pressing and forging operations, despite all their efforts, were unable to satisfy the Wehrmacht's demand for bullet casings and gun barrels, Borbet pushed the centrifugal casting process developed by the Schalke Club since 1919 , which led to an increase in production and a reduction in production in this product segment, as homogeneous hollow bodies were not available More had to be turned from the solid, but came out of the centrifugal casting machine in almost its final form. After a visit to the Heereswaffenamt in 1928 and the purchase of licenses from Canada, the developments of the Schalker Verein and the BVG were finally combined in the Hochfrequenz-Tiegelstahl GmbH, so that from 1934 the BVG was the only company within the VSt. That followed this procedure worked. At the end of 1941, about one 8.8 cm anti-aircraft tube per hour was produced using the centrifugal casting process . Around 1940 the fifth blast furnace was completed and blown on. To prepare for war, a pure bomb and grenade production facility was set up in the Langendreer plant. The Langendreer plant of the Bochumer Verein was the factory of the former Westfälische (n) Drahtwerke Langendreer AG , which belonged to the United Steelworks, but was shut down in 1931 and taken over by BVG in 1939, rebuilt and put back into operation.

Although the social benefits of the Bochumer Verein were rather below average for a coal and steel company, continued detailed reporting on individual measures succeeded in establishing the impression that the BVG was particularly well positioned in this regard. The financial benefits from health insurance and expenses for social facilities such as the company kindergarten were kept rather low, however, the public visual design of the buildings and workplaces was carried out according to the specifications of the Office for Beauty of Work with relatively little additional effort - and with reporting and with advertised its own book social work . The convalescent home set up in Werdohl in 1938 was also built from the point of view of public health . In order to somewhat reduce the influence of the NSDAP on the German Labor Front , which in 1935 also included the business- oriented DINTA , the BVG founded its own professional education agency, which shows the tightrope walk between applause for the National Socialist ideas on the one hand and the striving for economic independence on the other. In 1935, in the spirit of National Socialism, the "leaders and followers of the Bochumer Verein [decided] to erect a memorial for the 745 comrades who died in the World War". It was erected in front of the Kosthaus on Baarestrasse and consisted, among other things, of a 13.5 m high and 27 t heavy sword cast by the Bochumer Verein with the inscription “The god who made iron grow, he didn't want servants”. Hermann Göring inaugurated the memorial designed by the sculptor Willy Meller and the architect Emil Rudolf Mewes on May 9, 1935. After the war it was demolished and melted down again.

Since the beginning of the Second World War , forced laborers have been used in Bochum companies who work under the most difficult conditions in mining and in the manufacturing industry. The Bochum association with more than 7,500 employees benefited the most. In total, more than a hundred camps were set up for the forced laborers in Bochum's urban area, four of them for the Bochum association: the “Goldbach” camp, another on the “Sauren Wiese” site, one in Weitmar and in 1944 on Brüllstrasse (in the area Today's road at the environmental park) the Bochum subcamp of the Buchenwald concentration camp , a subcamp that existed from the end of June 1944 until the camp was evacuated in March 1945. In December 1944, over 1,600 registered, predominantly Jewish, concentration camp prisoners were active there in construction and earthworks as well as in projectile production. At least 108 prisoners did not survive the inhumane living conditions in the camp. The camp was dissolved in March 1945 and the remaining 1,326 inmates were brought back to Buchenwald by train. During the entire period of this Buchenwald subcamp , the camp manager was Hermann Grossmann , who was sentenced to death in the main Buchenwald trial and executed in 1948.

After Walter Borbet's death in January 1942, Walter Alberts , who had previously managed Henrichshütte in Hattingen, was appointed chairman of the board by the VSt group management. However, Alberts was unable to tie in with the autocratic, patriarchal leadership style of his predecessor, which is why the influence of the VSt group management on the Bochum association increased again.

On November 4, 1944, the Allied bombardment was particularly aimed at the Bochumer Verein, which was occupied with more than 10,000 high-explosive bombs and over 130,000 incendiary bombs . The factory premises and the surrounding residential and business districts were badly destroyed, and the city was ablaze.

Albert Vögler, who had previously headed the umbrella company Vereinigte Stahlwerke AG , killed himself on April 14, 1945 after US troops marched into the Ruhr area.

post war period

Overall, the war damage to the plant's machines was not so severe; However, due to the failure of the electricity, gas and water supply for the entire city, production fell to around ten percent. The blast furnaces also cooled down. The Bochum Association was granted a limited production permit on October 8th, but in 1947 the order was given to dismantle important production facilities, which was partially blocked by passive resistance - by the end of the dismantling, a blast furnace and two SM steelworks with a total of ten were built Furnaces, two of the four electric steel furnaces, three of ten rolling mills, the spring workshop and all larger forging plants dismantled. One of the two characteristic gasometers of the Höntrop plant (popularly known as "Castor and Pollux") was demolished in June 1948 because it was no longer repairable due to its war damage. In 1949 Walter Rohland was commissioned to look for ways to improve the economic situation of the BVG and to plan new facilities.

In order to save the former cannon hall (mechanical workshop II) from dismantling , the Bochum association, which had already been battered by dismantling, got involved in the 73rd Katholikentag 1949 in Bochum, not entirely unselfishly . The establishment of the central fairground in the area of today's sports field and the allotment garden between Gahlenstrasse, Amtsstrasse and the Zeche President - with the blast furnaces as a backdrop - was supported by the Bochum Association. In fact, the British side initially decided not to dismantle the building intended for Yugoslavia and, after dismantling the machinery, as a festival hall (e.g. for boxing championships, concerts, etc.), instead negotiating the replacement of a newly constructed hall construction, which due to the prohibition of use for the Bochumer Verein would have had to be paid for by the state of North Rhine-Westphalia. Ultimately, an agreement was reached on the financing of the DM 2.7 million new construction, which was delivered to Yugoslavia in the period from February to June 1950, as the Bochum association was able to support the financing due to the industrial use as a point construction hall, which has now been permitted. The hall now houses Thyssen Krupp Weichenbau GmbH.

New beginning

On December 17, 1951, the Bochumer Verein was re-established as Gußstahlwerk Bochumer Verein AG , 50 percent of the Carolinenglück and Graf Moltke collieries remained with the Bochumer Verein, the other half went to GBAG. The start-up also marks the end of the dismantling for reparations and the limited investment capacity due to the limited production permit. This meant that the Bochum association was only able to participate very little in the upswing due to the reconstruction after 1947 (especially due to the currency reform ). The United States' Korean boom, fueled by the Korean War , could hardly be used. In accordance with the Allied reorganization plans, the “WURAG” cold rolling mill in Hohenlimburg became an independent subsidiary of the Bochum Association on November 1, 1951 with 788 employees. Likewise, the forging company “Union Christine” in Essen-Kupferdreh was incorporated from the former VSt. In 1952, Hanomag , which was taken over before the war, was split off again due to the AHK Act No. 27 on the unbundling of the coal and steel industry and in 1958 went to the Rheinstahl group, Hochfrequenz-Tiegelstahl GmbH was affiliated to Deutsche Edelstahlwerke AG - which resulted in the group restructuring after War was over.

One of the first new buildings of the newly founded BVG was a multi-purpose rolling mill in the Höntrop plant, where all rolling mills were to be concentrated in the long term due to the space available. The halls of the dismantled tubular rolling mill could continue to be used for the new block rolling mill built in 1953/1954, which was provided with a downstream semi-finished product and bar mill, which restored the semi-finished product capacities that were destroyed in the war but were important for the downstream operations. In the period from 1951 to 1954, the crude steel production capacities were brought back almost to the pre-war level through the reconstruction of a Siemens-Martin steelworks with five ovens and two electric ovens, so that the crude steel volume from approx.57,000 t / m (1951) to approx 100,000 t / m (1956) increase.

In the 1950s, the 20,000th bell left the factory in Bochum; Since many ( bronze ) bells had been confiscated and melted down during the war, there was a considerable need. A large bell of the company, consisting of six bells, hangs in the Reinoldikirche in Dortmund . The heaviest bell there weighs 6,500 kilograms and is rung regularly. On the occasion of the return of the island of Helgoland to Germany in 1952, the Bochum Association donated a steel bell for the St. Nicolai Church . In 1951, the world's first carillon with cast steel bells was presented, which has been in constant use in Bochum's town hall ever since. Another Bochum glockenspiel was given to the Clausthal mining academy at the time , it was overhauled in 2000–2001 and can play 400 songs on request. The high point of the skills of the BVG is the carillon consisting of 42 bells, which stood in front of the BVG / Krupp headquarters on Alleestraße in Bochum until dismantling in May 2007 and was re-erected in March 2011 - albeit incompletely - at the entrance to Bochum's Centennial Hall has been.

In September 1953 the new dormitory for single people on Essener Strasse, which offered space for 280 workers, was completed - the new building had become necessary because the old food house built in 1872 in the Stahlhausen district was destroyed during the war. In addition to the residential complexes in Stahlhausen and Höntrop, another residential area with company apartments was built in the Weitmar district (enclosed by Schützenstrasse, Brantropstrasse, Weitmarer Strasse and Kohlenstrasse) after the war . In the interests of health care, a health center was built on Bessemerstraße in 1954 , which housed the company doctors and its own health insurance.

The technical director Arthur Tix , who had been employed by the Bochumer Verein since 1922 and had risen to military economic leader under Albert Speer during the war , pushed the development of new casting processes after the war: at the Düsseldorf foundry fair in August 1956, the Bochumer Verein was able to use this since 1950 self-developed vacuum casting process impress the professional world with a void -free 257 ton casting. Arthur Tix remained on the board of directors of the Bochumer Verein until his retirement as smelter and shaped the Bochumer Verein through the realization that it was not possible to survive economically through the mass of steel produced, but rather through quality and special steels that the larger competitors did not offer . At the general meeting in 1956, the old name Bochumer Verein für Gußstahlfabrikation AG was finally adopted again.

In 1955/1956, Krupp's own raw material base was increased again with the acquisition of the Constantin mine . By participating in the Düsseldorf exploration union, a consortium together with August-Thyssen-Hütte, Dortmund-Hörder Hüttenunion , Phönix-Rheinrohr and Rheinische Stahlwerke AG , the concession for ore mining at the Bong Range in Liberia was granted in mid-1958 acquired, the Bochum association also secured access to iron ore again. The German-Liberian Mining Company (DELIMCO) founded for this purpose and the Bong Mining Company commissioned by it shipped the first ore concentrate from the opencast mine in the area of the ore mountain Zawea , which was also transported to the Ore Mountain via a specially built 80 km long railway line specially built loading pier in Monrovia is connected. The bong mine ceased operations in September 1990 when the bloody civil war reached the town that had developed around the mine.

On November 2, 1957, after the cast steel plant in Witten , the Bochumer Verein began producing steel using the Linz-Donawitz process, which was first successfully used in 1952 ("Oxygen steel plant Höntrop"), which gradually became Siemens-Martin Process, because the system technology is much simpler and therefore less capital-intensive: Instead of blowing air through the converter base, which is necessary for the Thomas or Bessemer process, with the LD process (also known as the "oxygen inflation process"), pure oxygen is sufficient Bubble surface of the liquid melt. Arthur Tix had already sent a delegation to Austria in 1954 because he was looking for alternatives to the Siemens-Martin process due to the high demand in the mid-1950s and the correspondingly high scrap costs, integration into the Krupp Group and difficulties with mining damage protection of the foundations led to a delay in commissioning and a downsizing of the implemented system: the two LD converters were only supplemented by one instead of the two planned electric ovens. The crude steel capacity of the BVG grew from 100,000 t / m to around 130,000 t / m.

Deutsche Edelstahlwerke AG was taken over by Thyssen at the end of the 1950s (with the Bochum plant, the former high-frequency crucible steel GmbH). After the shutdown of the steelworks, this area of the plant became the Thyssen precision casting plant (TFB Feinguss Bochum) in the 1970s, which was later taken over by the Doncasters company with a stopover at Triplex Loyd International. a. Manufactures turbine blades. Another part of the plant was taken over by the Bochum ironworks Heintzmann & Co in 1974 .

In mid-1962, the Bochum association, also known as the “sick man from the Ruhr” due to the steel crisis in the past, announced that it wanted to move away from the focus on semi-finished products (profiles, rails, etc.) and instead relied on flat steel, quality and stainless steels. For this purpose, an investment program of almost 500 million DM was launched, which was mainly reflected in the expansion of the Höntrop plant.

Takeover by Krupp

In the course of 1958, the Krupp Group received the right of first refusal for a total of 76 percent of the shares in the Bochum association, which suffered from poor capacity utilization during the steel crisis and financially, through the Swedish millionaire Axel Leonard Wenner-Gren, who was friends with Alfried Krupp von Bohlen and Halbach was posted. Wenner-Gren had already taken over 42 percent of the shares in the Bochumer Verein from the Rheinstahl group in 1954 in the course of the post-war unbundling of the coal and steel industry, which had already led to the spin-off of Hanomag from the Bochumer Verein, and was already with Gustav Krupp von Bohlen and Halbach friends. On December 27, 1963, a profit and loss transfer agreement with effect from January 1, 1963 and an initial term of 5 years was concluded with Hütten- und Bergwerke Rheinhausen AG , making the Bochumer Verein part of the Krupp Group. After the resolution of the general meetings of November 15 (Krupp) and December 10, 1965 (Bochumer Verein), the complete takeover of the Bochumer Verein by Krupp was finally completed and the name Bochumer Verein was given up. At the end of 1965, including the subsidiaries, 20,319 people were working for the Bochumer Verein - 17,787 of them in Bochum, 1,438 in Hohenlimburg (at the former "WURAG" Eisen- und Stahlwerke AG, since 1951 with BVG) and around 1,100 in Düsseldorf-Benrath (Capito & Klein ). The merged group of the Hütten- und Bergwerke Rheinhausen AG and the BVG was now called Fried. Krupp Hüttenwerke AG and had its seat in Bochum. In 1970 the production of bells was stopped because the demand for bells made of steel had plummeted in the post-war period. Nonetheless, Bochum bells were also used in exposed places, the most famous example being the four peace bells in Hiroshima . In the course of the takeover, rationalization and concentration measures were carried out, in the course of which the blast furnaces at the Bochum site were blown out in 1968, the fifth and last of which was only blown at the end of 1956 after the reconstruction. The Siemens-Martin steelworks in Weitmar (1968) and Höntrop (1982) and a large part of the rolling mills in the steel industry (since the end of the 20th century, the President's industrial park , Eco City Center and environmental park ) were shut down in sections.

present

“Cast steel factory” on Alleestraße

Apart from the area of the Bochumer Verein Verkehrstechnik GmbH in the eastern part of the site, only the hall complex of the former "Mechanical Workshop I" built in 1936 directly on Alleestraße, which is a listed building as the "Mewes Hall", is used industrially as a spare parts store. Torhaus 5 has been renovated and converted into a mixed office building, with the exception of the Centennial Hall complex and the Colosseum , all other structures were demolished - including the striking tower built in 1937 on Wattenscheider Strasse in 1990, which houses the remuneration system for large guns (in the form of Shaft furnaces for workpieces with a length of 9 m and a maximum diameter of 5 m). Another competition has been held since March 2009, and the realization of this competition began in September 2009 by tearing down the washrooms adjoining Mechanical Workshop I from the old stock of the Bochumer Verein in favor of a new parking garage.

Blacksmiths

Twenty years after the merger, the parent company Krupp parted with the forge at its original location in Alleestraße, which then, after a series of changes of ownership and name (since 1977 Fried. Krupp Stahlschmiede and Machining, FKS), Krupp Schmiedegesellschaft mbH, 1983/1984: Schmiedewerke Krupp-Klöckner GmbH (SKK), 1988: Vereinigte Schmiedewerke GmbH (VSG) after merging with the forging operations of Thyssen in Hattingen , 1993: VSG Verkehrstechnik GmbH took up the old name again in 1998 with the new company name Bochumer Verein Verkehrstechnik GmbH .

A defect in a rubber-sprung wheel tire constructed by VSG led to the ICE accident in Eschede on June 3, 1998 . As a result, there was a lawsuit lasting several years, in which, among other things, an engineer from the company was charged with negligent homicide. The proceedings were discontinued in April 2003 against payment of 10,000 euros.

BVV, with around 580 employees, is once again supplying the railway companies and producing, for example, the wheel tires for the ICE 1 . In addition, rubber-sprung wheel sets for trams are manufactured, the development and technical implementation of which the Bochumer Verein has pioneered.

The company has been owned by Full Hill Enterprises Ltd., a Chinese company, since March 20, 2017. The Full Hill Enterprises Ltd. acquired BVV for more than 100 million euros from Georgsmarienhütte in Osnabrück. After the company's turnover fell from 220 million euros in 2015 to below 200 million euros in 2017, the position as one of the world's leading companies in the industry should be maintained. In particular, this is intended to simplify access to the Chinese market.

Wheelset exhibition

The Bochumer Verein Verkehrstechnik GmbH maintains a wheels and wheelset exhibition in two rooms of its plant on Alleestraße, which was officially opened on November 12, 1985 as part of the 150th anniversary of the German railways. The exhibition shows almost 100 exhibits, from historic cast iron wheels with forged wheel tires to spoked wheels made of cast steel and monoblock wheels to modern light wheel discs with sound absorbers. In addition to individual wheels, complete wheel sets and components of points are also on display.

Tram station "Bochumer Verein / Jahrhunderthalle"

The Bochumer Verein is one of the namesake of the “ Bochumer Verein / Jahrhunderthalle ” urban railway station . A large-format picture was placed on one of the stairs from the connection level to the platform, showing the old bell foundry hall.

ThyssenKrupp Stahl, Höntrop plant

The Höntrop location was continuously modernized and expanded. For example, a UHP E furnace was set up for the oxygen converters, which were converted to the AOD process (Argon-Oxygen-Decarburization) in 1972, a continuous casting plant was put into operation, a hot wide strip mill in 1966 and a cold rolling mill in 1971 as well as two galvanizing plants for galvanizing (1987 ) and hot-dip galvanizing (1992) together with a new push pickling line (2001). The plant belongs to the Thyssenkrupp group in the form of ThyssenKrupp Nirosta GmbH (furnace and continuous casting plant) and Krupp Steel (rolling mills, galvanizing). Siemens-Martin-Stahlwerk III, on the other hand, was shut down and demolished in 1982. A warehouse belonging to the logistics company Panopa Logistik is located on the site of the tubular and later block rolling mill that was also demolished . The gas lines to supply the Höntrop plant from the premises on Alleestraße were dismantled between April 2006 and March 2007 - the only visible structure from the time the plant was built is the "tower" on Essener Straße, which contained a large hydraulic accumulator, and the hall segment, in which the associated pumps were. The Outokumpu Group , which took over ThyssenKrupp's stainless steel division Innoxum in 2012, announced at the beginning of January 2013 that it would close the electric steelworks in Höntrop with around 500 employees at the end of 2016. In fact, the electric steelworks and continuous casting plant were shut down on June 23, 2015, thus ending the history of steel production in Bochum.

Steel industry

The last still producing operation of the "steel industry", which after the Second World War still belonged to the Bochumer Verein, was the ThyssenKrupp switch factory in the former cannon hall / festival hall. After the rail friends cartel was uncovered in 2011, the ThyssenKrupp Group's track business was completely given up and operations in Bochum were closed at the end of 2014 after stocks had been sold off. What remains is the Doncasters investment casting company, which emerged from the former high-frequency crucible steel foundry in Bochum and currently employs around 400 people. All other buildings (forging and pressing plants, several rolling mills) were demolished.

Weitmar plant

From the Weitmar plant - the former Westphalian steelworks - only the administration building on Kohlenstrasse and the model warehouse - albeit fully clad - remain. The model hall was also used to tune carillons, as it was the only hall available in which there was no production and thus annoying noise. The entire factory premises form the Rombacher Hütte industrial park .

Langendreer plant

The Langendreer plant, which was used for bomb and grenade production at the BVG from 1939 to 1945, was leased to numerous medium-sized companies in 1945, together with the largely destroyed factory equipment - among other things, Fahrzeug-Werke Lueg maintained a repair shop for ambulances there and one company continued to manufacture Water meter, there was a concrete block plant, etc. In 1947 the entire plant was to be dismantled and the buildings laid down. In tough negotiations up to 1949, the British military administration was convinced that the current operations no longer had any connection to the BVG - the buildings initially remained and were only replaced by new buildings over time.

Management staff

- Louis Baare (General Manager 1855–1895)

- Fritz Baare (General Director 1895–1917)

- Wilhelm Baare (Chairman of the Board of Directors 1917–1922)

- Walter Borbet (CEO 1922–1942, born September 9, 1881 in Gelsenkirchen-Schalke , † January 4, 1942 in Bochum)

- Walter Alberts (born September 9, 1883 in Hagen ; † October 15, 1948 in Bochum)

- Arthur Tix (Technical Director, born December 16, 1897 in Darmstadt - † February 7, 1971 in Mainz )

- Hermann Poech (Operations Director , * July 24, 1895, † June 16, 1965)

- Heinrich Deist (since March 1949 steel trustee, after the re-establishment of the Bochumer Verein, chairman of the supervisory board 1951–1964)

- Franz Schily (director since 1942, board member since 1946, * December 25, 1892, † September 26, 1955)

- Hans Kallen (Chairman of the Supervisory Board 1964–1965 after the takeover by Krupp)

chronology

Tabular compilation of the development of the Bochumer Verein, number of employees up to 1925 from: Däbritz, Bochumer Verein .

| year | event | Workforce |

|---|---|---|

| 1842 | Founding of the Mayer & Kühne cast steel factory in Bochum | |

| 1845 | Commissioning of the plant on Essener Chaussee (today's Alleestraße) | 70 |

| 1852 | Exhibition of cast steel bells at the Düsseldorf trade exhibition | |

| 1853 | Commissioning of our own rolling mill | 240 |

| 1854 | Conversion to the Bochum Association for Mining and Cast Steel Manufacture | 200 |

| 1855 | Louis Baare becomes General Director

World exhibition in Paris, forging test of the bells in the Krupp dispute, installation of the first steam hammer |

300 |

| 1856 | Establishment of company apartments | |

| 1857 | Own kilns for the crucible lining bricks

Commissioning of another rolling mill (III) |

482 |

| 1858 | Completion of work on our own puddling plant for crude steel production

Eduard Kühne leaves the Bochum club |

560 |

| 1859 | Completion of work on drum rolling mill, wheel disc and axle turning shop

Vital Daelen is hired as Jacob Mayer's deputy |

385 |

| 1862 | 950 | |

| 1863 | First attempts with the Bessemer method | |

| 1864 | Purchase of the United Maria Anna Steinbank colliery | 1950 |

| 1865 | The BVG is subject to Krupp in the purchase of the Sayner Hütte with iron ore mines from Prussia. State property

Construction of hammer mill II Construction of a rail rolling mill and a Bessemer plant |

|

| 1867 | World Exhibition in Paris, town hall bell weighing 15,000 kg

Connection of the BVG to the Bergisch-Märkische Eisenbahn Witten - Bochum |

1760 |

| 1869 | Takeover of the municipal gas works on Essener Chaussee (Alleestraße)

Commissioning of the Bessemerwerk II |

2003 |

| 1870 | The steel industry company was founded in the neighborhood

Commissioning of the Bessemerwerk III and the crucible steelworks II |

2306 |

| 1871 | 3044 | |

| 1872 | Purchase of the (Cologne) Mülheimer Hütte with two blast furnaces | 3958 |

| 1872/73 | Start of construction of two blast furnaces | |

| 1873 | Construction of a Siemens-Martin plant

Participation in the world exhibition in Vienna |

4702 |

| 1874 | Closure of the Mülheimer Hütte

Connection of the BVG to the Rheinische Eisenbahn from Essen via Bochum Nord to Hörde |

4583 |

| 1875 | 4378 | |

| 1876 | Two blast furnaces are in operation

Almost a quarter of the workforce has been laid off during the recession |

3514 |

| 1878 | 3824 | |

| 1881 | Commissioning of the Thomas factory (formerly Bessemerwerk II) | 5102 |

| 1881 | Purchase of the Minette “Fentsch” concession in Lorraine | |

| 1882 | The third blast furnace goes into operation | 5780 |

| 1889 | Takeover of the Gesellschaft für Stahlindustrie with its own hammer, rolling, Bessemer and Siemens-Martin works

Purchase of the Engelsburg colliery |

6353 |

| 1890 | Purchase of the Hasenwinkel colliery

Purchase of the concession for limestone mining near Wülfrath The fourth blast furnace will be completed and will serve as a reserve while other furnaces are being relocated. |

8293 |

| 1892 | 8319 | |

| 1894 | 7865 | |

| 1895 | Louis Baare is replaced by his son Fritz

Construction of our own power plant with two dynamo machines |

7737 |

| 1900 | Purchase or construction of the Carolinenglück colliery with coking plant and Graf Moltke colliery

Opening of the Minette pit "Fentsch" |

10524 |

| 1902 | Commercial exhibition in Düsseldorf

Construction of a suspension cable car between the Carolinenglück coking plant and the blast furnace |

10687 |

| 1903 | Construction of the former exhibition hall on Alleestrasse as a gas power center | 10996 |

| 1904 | Closure of the United Maria Anna Steinbank colliery

Sale of the Hasenwinkel colliery Participation in the Louisiana Purchase Exposition (world exposition) |

11290 |

| 1907 | Construction of the Teutoburgia colliery | 10867 |

| 1912 | Construction of the Siemens-Martin-Werk II for direct use of pig iron and construction of the retaining wall ("Colosseum")

Construction of today's gatehouse 5 as a testing facility |

12546 |

| 1917 | Wilhelm "Willy" Baare becomes director after the death of his brother Fritz

The fifth blast furnace, which was started in 1915, is blown on |

16756 |

| 1912-1927 | The blast furnaces are modernized | |

| 1918 | Purchase of the Friedrich der Große colliery | 17643 |

| 1919 | Acquisition of the Schnellenberg iron ore mine in Siegerland | 21207 |

| 1920 | Hugo Stinnes is majority shareholder and Member of the BVG in the Rhein-Elbe-Union a | 22043 |

| 1921 | Sale of the Friedrich der Große colliery

Start of construction of the Höntrop plant with Siemens-Martin steelworks and tube rolling mill |

20327 |

| 1924 | Commissioning of the Siemens-Martin-Werk III (Höntrop) | 16272 |

| 1926 | United Stahlwerke AG founded, incorporation of the BVG | |

| 1927 | Founding of Deutsche Edelstahlwerke AG, in which the BVG's stainless steel operations are included | 11000 |

| 1930 | 14000 | |

| 1932 | 7930 | |

| 1933 | The BVG will formally become an independent subsidiary of Vereinigte Stahlwerke AG again | |

| 1934 | Hanomag comes to the BVG | 14000 |

| 1935 | Construction of the mechanical workshop II and commissioning of the first electric furnace on Alleestrasse | |

| 1938 | 19934 | |

| 1939 | Use of forced labor | 19910 |

| 1940 | 21659 | |

| 1941 | Start of the centrifugal casting process | 21296 |

| 1944 | Use of concentration camp prisoners

Heavy bombing, destruction of important central supply systems |

21035 |

| 1945 | 8998 | |

| 1947 | 9389 | |

| 1948 | 9717 | |

| 1949 | Katholikentag in Bochum (on the grounds and in the halls of the BVG) | 11823 |

| 1950 | 11502 | |

| 1951 | Re-establishment as "Gußstahlwerk Bochumer Verein AG" | 13058 |

| 1952 | Hanomag is split off again | |

| 1955 | Acquisition of the Constantin colliery | |

| 1956 | The vacuum casting process causes a sensation

Blowing on the fifth furnace The general meeting resolves to adopt the old name "Bochumer Verein für Gußstahlfabrikation AG" |

16000 |

| 1957 | Introduction of the Linz-Donawitz process for steel production: "Oxygen steelworks" in Höntrop | |

| 1958 | Participation in the exploration union for the development of Liberian iron ore deposits

Axel Leonard Wenner-Gren becomes majority shareholder |

|

| 1961 | Closure of the Engelsburg colliery | |

| 1964 | Completion of the new administration building on Alleestraße / Kohlenstraße | |

| 1965 | Merger with Krupp to form Fried. Krupp Hüttenwerke AG based in Bochum | 17787 |

| 1966 | Construction of the hot wide strip mill at the Höntrop plant | |

| 1968 | Blowing out the blast furnaces

Closure of SM steelworks 4 (Weitmar) |

|

| 1970 | Cessation of bell production

Complete closure of the Weitmar plant |

|

| 1971 | New cold rolling mill at the Höntrop plant | |

| 1976 | 10915 | |

| 1977 | Outsourcing of blacksmiths in Fried. Krupp steel forge and machining (FKS) | |

| 1979 | The town hall bell moves to the Bochum town hall | |

| 1980 | Change of name to Krupp Stahl AG | |

| 1982 | Closure of the SM plant in Höntrop | 6500 |

| 1983 | 5750 | |

| 1984 | Outsourcing of the forging plants to the Krupp-Klöckner Schmiedebetriebe

Closure of the rolling mills at the Höntrop plant |

|

| 1987 | Electrolytic galvanizing from Letmathe is set up in Höntrop

Demolition of the building of SM-Werk 3 in Höntrop |

|

| 1992 | Construction of the new hot-dip galvanizing facility in Höntrop | |

| 1999 | Demolition of the rolling mill halls in Höntrop | |

| 2007 | The hot strip mill rolled 100 million tons of steel in October

Excerpt from the administration building at Alleestrasse |

|

| 2008 | New walking beam furnace for the hot strip mill, new edging stand, new rolling cycle control, capacity increase to 4.2 million t / a | |

| 2009 | 3480 | |

| 2014 | Turnout construction in the "Steel Industry" section is closed | |

| 2015 | Höntrop's stainless steel plant and continuous casting plant are shut down | |

| 2017 | 580 | |

| 2017 | Sale of BVV to the Chinese company Full Hill Enterprises Ltd. |

literature

- Walther Däbritz : Bochum Association for Mining and Cast Steel Manufacture in Bochum. Nine decades of its history in the context of the economy of the Ruhr district. Verlag Stahleisen, Düsseldorf 1934.

- Social work. Bochum Association, Graphic Art Institute W. Hund sel. Wwe., Hattingen / Ruhr 1943.

- Cast steel. Bochum Association, Bochum 1935.

- Our factory. A small manual for visitors and friends of the Bochum association. Bochum Association for Cast Steel Manufacture, Bochum 1956.

- 100 years of cast steel. Gusstahlwerk Bochumer Verein AG, Bochum around 1952. Signature CAB5273 in the university library of the Ruhr University Bochum

- Lothar Gall : Krupp. The rise of an industrial empire. Siedler, Berlin 2000, ISBN 3-88680-583-2 .

- Gustav-Hermann Seebold , Alfred Wortmann: A steel company in the Third Reich. The Bochum Association 1927–1945. Peter Hammer Verlag, Wuppertal, 1981.

- Wolfhard Weber : Walter Borbet (1881-1942) . In: Wolfhard Weber (Hrsg.): Engineers in the Ruhr area. Aschendorffsche Verlagsbuchhandlung, Münster 1999, pp. 224–256.

- Walther Bacmeister : Louis Baare. A Westphalian business leader from the Bismarckian era. W. Bacmeister's National Publishing House, Essen 1937.

- Ulrike Robeck: The older halls of the Bochumer Verein as functional buildings and monuments of the iron and steel industry. von Zabern, Mainz 2010, ISBN 978-3-8053-4279-7 (= preservation of monuments and research in Westphalia . Volume 50, online , also dissertation at the University of Bochum 2008).

- Ulrike Robeck: Egon Erwin Kisch at the Bochum club. An attempt on the essence of the reporter , Klartext Verlag, Essen 2010, ISBN 978-3-8375-0418-7 .

- Bochum Association. Five years of reconstruction. Bochum Association, Bochum 1956.

- Hut newspaper. (BV works newspaper), years 22–35 (1952–1965)

- Lars Ulrich Scholl: Engineers of early industrialization. State and private technicians in the Kingdom of Hanover and on the Ruhr (1815–1873). Vandenhoeck & Ruprecht, Göttingen 1978, ISBN 3-525-42209-1 . (Chapters "Jacob Mayer" and "Employed engineers: Bochumer Verein")

- Walter Bertram: Jacob Mayer. The inventor of cast steel. On the 125th anniversary of his birthday on May 1, 1938. VDI-Verlag, Berlin 1938.

- Gustav Koepper: In Pluto's realm. Hikes through the shaft and hut in the Rheinisch-Westphalian industrial district. Alfred Schall, Berlin 1899. (Chapter 14: "The Bochum Association")

- Hans Hermann Oehler: The wheels and wheelset exhibition of the Bochumer Verein Verkehrstechnik GmbH. In: Dietmar Bleidick (Hrsg.) Bochum time points. No. 6, Bochum, January 2000, ISSN 0940-5453 , p. 20 ff.

- Andreas Zilt: Historical innovation research. The introduction of the oxygen steel process in West Germany. In: Manfred Rasch, Dietmar Bleidick (Hrsg.): History of technology in the Ruhr area / History of technology for the Ruhr area. Klartext-Verlag, Essen 2004, ISBN 3-89861-376-3 , pp. 710-729.

- Ulrich Wengenroth : Corporate strategies and technical progress in the German and British steel industry 1865–1895. Vandenhoeck & Ruprecht, Göttingen 1986, ISBN 3-525-36302-8 .

- The factory facilities of the Bochumer Verein. Höntrop plant, cast steel factory, Weitmar plant, steel industry plant. Bochum Association for Cast Steel Manufacture, Bochum 1938.

- The factory facilities of the Bochumer Verein. Cast steel factory, Höntrop works, Weitmar works, steel industry works, Langendreer works. Bochum Association for Cast Steel Manufacture, Bochum around 1940, DNB 578314037 .

- Gustav Schaar: Rationalization at the Bochumer Verein in the years 1910–1930. Blast furnace, Martinwerk I, II, III and tube rolling mill Bochum-Höntrop. Ludolph & Co., Bochum 1937. (also inaugural dissertation, Münster 1937.)

- Ralf Stremmel: Industry and Photography. The "Bochum Association for Mining and Cast Steel Production", 1854–1926. Aschendorff, Münster 2017, ISBN 978-3-402-13213-5

- Ingrid Wölk: Bochum (Bochum Association). In: Wolfgang Benz , Barbara Distel (eds.): The place of terror . History of the National Socialist Concentration Camps. Volume 3: Sachsenhausen, Buchenwald. CH Beck, Munich 2006, ISBN 3-406-52963-1 , p. 395ff.

- Paul Ufermann, Carl Hüglin: Stinnes and his corporations. Verlag für Sozialwissenschaft, Berlin 1924. (In particular the list of factory equipment on p. 105)

- Information sheet for the Open Monument Day on September 13, 1998 in Bochum, Press and Information Office of the City of Bochum

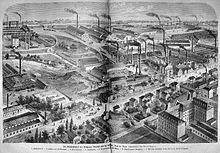

- Germany's great workshops. The Bochum Association . In: The Gazebo . Issue 32, 1875, pp. 541-546 ( full text [ Wikisource ]).

- Bochum Association. In memory of the Westphalian Association of Cities in Bochum, June 1896. Bochum 1896; urn : nbn: de: hbz: 6: 1-61077

- Fritz Claes: The Bochumer Verein and Marianne, his first colliery on the 100th anniversary of Louis Baare's death May 17, 1897. Self-published, Bochum 1996, ISBN 3-00-000931-0

Web links

- Homepage of today's company "Bochumer Verein Verkehrstechnik GmbH"

- Photo documentation Bochumer Verein

- Via the Bochumer Verein's works railway

- Arms production and air raid protection measures by the Bochum Association

- Documentation for the wheelset exhibition in tour no. 9 on bochum.de

- Description of all locations on this themed route as part of the Route of Industrial Culture

- The oldest steel bell in Germany as a tower recording in the Protestant church of Hermeskeil (video with sound)

- Early newspaper articles on the Bochum Association in the 20th Century press kit of the ZBW - Leibniz Information Center for Economics .

Individual evidence

- ^ Adalbert Frensdorff: Mayer, Jacob. In: New German Biography (NDB). Volume 16, Duncker & Humblot, Berlin 1990, ISBN 3-428-00197-4 , p. 543 f. ( Digitized version ).

- ↑ W. Bertram, p. 16f.

- ↑ W. Bertram, p. 22.

- ↑ Article about the find by Horst Erich Pforr in the Ruhrnachrichten , March 9, 2002.

- ^ Herbert Dieckmann: From the history of the Bochum association for mining and cast steel production . In: Stahl und Eisen , Volume 55, January 31, 1935, caption p. 114

- ↑ As of August 19, 2009: The bell is an unlabeled exhibit in the museum, but was identified using the photo in the magazine "Stahl & Eisen" and the inscription with the year.

- ^ Inscribed steel bell with handle crown, delivered from Bochum in 1853 according to the church protocols; confirmed by the Bochum Association, which wanted to buy back the bell after the Second World War. Documents are available in the parish.

- ↑ Jürgen Kocka: Employment conditions and worker existences. Foundations of class formation in the 19th century . Bonn 1990, p. 433.

- ^ Susanne Hilger: Social policy and organization. Forms of corporate social policy in the Rhenish-Westphalian iron and steel industry from the middle of the 19th century to 1933. Franz Steiner Verlag, 1996, ISBN 3-515-06972-0 , GoogleBooks

- ^ Toni Pierenkemper: Company history. An introduction to their methods and results. Franz Steiner Verlag, 2000, ISBN 3-515-07674-3 , GoogleBooks

- ^ Conrad Matschoss: A century of German mechanical engineering. From the mechanical workshop to the German machine factory 1819–1919. Julius Springer, Berlin 1919.

- ^ Answer of the Bochum Association for Mining and Cast Steel Manufacture in the Kölnische Zeitung to the doubts about the authenticity of the Bochum cast steel bells published by Alfred Krupp on September 22, 1854 lwl.org on the Westfälische Geschichte Internet portal

- ^ Krupp 1812–1912 For the 100th anniversary of the Krupp company and the cast steel factory in Essen. Published on the centenary of Alfred Krupp's birthday . Gustav Fischer, Jena 1912, p. 133 (signature WDL 123 Krupp in the Bochum city library)

- ↑ W. Bertram, p. 37.

- ↑ Lars Ulrich Scholl, p. 389.

- ↑ Lars Ulrich Scholl, p. 387.

- ↑ Wengenroth p. 85f.

- ↑ Bochum ( Memento of the original from December 17, 2007 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. on the museum platform nrw

- ↑ Documentation on the Carlswerk: rheinische-industriekultur.de

- ↑ Manfred Rasch , Gerald D. Feldman (eds.): August Thyssen and Hugo Stinnes. An exchange of letters from 1898–1922. CH Beck, Munich 2003, ISBN 3-406-49637-7 , p. 606, GoogleBooks

- ^ Hugo Racine: Burgers, Franz. In: New German Biography (NDB). Volume 3, Duncker & Humblot, Berlin 1957, ISBN 3-428-00184-2 , p. 46 ( digitized version ).

- ↑ Wengenroth p. 140 ff.

- ^ Hans-Ulrich Wehler: German history of society 1849-1914. CH Beck, Munich 1995, ISBN 3-406-32263-8 , p. 562. [online]

- ↑ Wengenroth, p. 224 and p. 242 f.

- ↑ Wengenroth, p. 183.

- ↑ Open Monument Day p. 26.

- ^ Settlements of the Bochumer Verein on www.ruhr-bauten.de

- ^ Susanne Hilger: Social policy and organization. Forms of corporate social policy in the Rhenish-Westphalian iron and steel industry from the middle of the 19th century to 1933. Franz Steiner, 1996, ISBN 3-515-06972-0 , p. 187, GoogleBooks

- ^ Gerhard Albert Ritter: Social insurance in Germany and England. Origin and main features in comparison. CH Beck, Munich 1983, ISBN 3-406-08960-7 , GoogleBooks

- ↑ Jürgen Kocka: Employment conditions and worker existences. Foundations of class formation in the 19th century . Bonn 1990, p. 427f.

- ↑ Dr. Ernst Jüngst: Festschrift to celebrate the 50th anniversary of the Association for Mining Interests in the Dortmund Upper Mining District in Essen 1858–1908 . Publishing house of the Berg- und Hüttenmännische Zeitschrift Glückauf, Essen 1908, p. 22.

- ^ Gerald Spindler: Law and corporate group. Mohr Siebeck, 1993, ISBN 3-16-146123-1 , p. 104, GoogleBooks

- ↑ Wengenroth p. 114

- ^ Walther Däbritz: Bochum association for mining and cast steel production in Bochum. Nine decades of its history in the context of the economy of the Ruhr district. Düsseldorf, 1934, p. 296ff.

- ↑ Route of industrial culture : Zeche Vereinigte Carolinenglück 2/3 (visited on December 29, 2012) The information board that is attached to the cycle path names the year 1912 for the construction of the suspension cable car.

- ↑ G. Schaar mentions 1913 as the year the cable car was built (p. 24 ff) and 1907 as the purchase for Carolinenglück by the BVG