Gebr. Eickhoff machine factory and iron foundry

The Gebr. Eickhoff engine works and iron foundry GmbH is a traditional medium-sized enterprises in Bochum in the field of mechanical engineering .

The company was founded in 1864 by Johann Henrich Carl Eickhoff (February 2, 1808, † September 11, 1864) as a foundry . Since then, the company has been active as a supplier for the mining of hard coal , ore and salt in the Ruhr area and in other mining areas worldwide. As a second pillar, the company uses the technical experience it has gained in mining to expand its business into other industries , such as the construction of gearboxes for wind turbines .

history

In 1871 the two sons of the company founder Carl (* April 5, 1845; † April 29, 1908) and Robert (* June 19, 1849; † August 8, 1904) took over the management from their mother Elisabeth (* November 28, 1808; †) July 11, 1888), who has been running the company since her father's death. Since then, the company has had the name that is still valid today. Robert Eickhoff was responsible for the technical area of the management, Carl Eickhoff for the commercial part.

The company's first location was on Landstrasse to Essen, in the direct vicinity of the Bochumer Verein . An indication of the company's growth is the establishment of its own company health insurance fund in 1885. During this period, switches and other track material were produced for the newly emerging trams in the Ruhr area . There was also the delivery of machine parts to the Bochumer Verein and Krupp .

After the death of Carl Eickhoff, his son Alfred sen. (March 12, 1884 - January 27, 1949) the company. At this point in time there were already 346 employees , the company was expanding into other mining areas and opening branches in Belgium and England, among others . From 1949 Alfred jun. (* September 28, 1910; † May 28, 1981) responsible for the management of the company, at the same time the company was converted into a GmbH .

In 1907 Eickhoff produced the first vibrating chutes , the essential components of which were protected by a patent from Robert Eickhoff. In 1914, the company began producing the cutting machines , with which the mechanization of hard coal mining began. This development was accelerated by the course of the First World War , when there was a lack of qualified miners and had to be replaced by machines . From 1929, belt conveyors for use above and below ground were also included in the production program.

In 1939 the factory moved to today's production facility in Wiemelhausen, around 2 km south of Bochum city center. The new building had already started in 1921. At the end of the Second World War , the factory was also badly damaged by air raids . It was rebuilt and continuously expanded in the following years. In 1964 the plant employed 1630 people. At the same time, the site was expanded into a high-performance foundry for cast iron and cast steel , the weight of the castings can be up to six tons . Today the foundry supplies specialties in high-quality alloys , starting with gray cast iron (GG), nodular cast iron (GGG) and cast steel (GS) to wear-resistant materials such as NiHard IV, which are required in the armoring of components subject to friction .

At the same time, the mechanical workshop was set up, in which the previously produced workpieces are machined .

Today the company is the world market leader in high-performance mining machinery for automated underground extraction and generates a group turnover of 360 million euros (2009) with around 1,600 employees worldwide (2010).

Mining machinery

The company's production program traditionally serves the mining industry with mining machines for ore , salt and hard coal . These machines are essentially divided into two product groups:

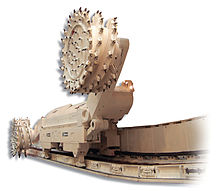

- The roadheading machines , which move a hemispherical milling head on a kind of excavator crawler chassis at the liftable and swiveling arm end. It is used to cut open tunnel sections underground, thus driving the two end tunnels in a counter-site process, between which Eickhoff's other main product mines the coal :

- Shearer loader . These are essentially box-shaped, narrow, long transmission with an electric drive , lift at both ends thereof and supporting arms can be reduced, and cylindrical at the upper end heads the coal from the seam milling . The shearer loader travels back and forth in the face between two partially cut tunnels, electrically driven by a winch that acts on a rack gear . The cut coal-rock mixture is brought to the track with chain conveyors under the shearer loader . The “roadway” is protected around the work path of the shearer loader in a U-shape by hydraulically controlled expansion shields that carry the load of the pressing overburden : a product u. a. of neighboring companies from the Ruhr area ( Westfalia in Lünen). Behind the cut section, after moving the machinery to the front, the longwall behind it is usually collapsed ( fracture displacement ), or waste rock that has been sorted out over the course of days is placed in the cleared areas ( blow displacement or centrifugal displacement ). The electrical output of the shearer loader can be up to 1,700 kW . In 2017, Eickhoff delivered a 17-meter-long and 100-ton shearer loader for the Prosper colliery in Bottrop , the last large-scale Eickhoff machine before the end of coal mining in Germany .

The tools of the company's machines come partly from the Ruhr area production. Among other brazed carbide - chisel the company Widia used in food at the cutting heads of coal cutting machines.

All mining machines are subject to the limitations of the dimensions of the shaft through which the components are to be conveyed underground . This is why the company's machines have a modular structure: compact housings that are connected to one another to form larger assemblies at the site underground . A high power density is required of them in the smallest of spaces . In addition, extreme requirements must the explosion protection of mining design are taken into account, as well as the often high temperatures that prevail underground, together with the additional heat generation from machine mining operations.

Other corporate activities

Due to the fluctuating order situation for decades, other products were temporarily worked on in order to reduce the company's dependence on mining :

- In the 1970s , packaging machines for welding electrodes were built.

- At the beginning of 1975, Eickhoff-Kleinewefers Kunststofftechnik was founded together with the Kleinewefers Group , which was renamed EKK Kleinewefers in 1978 and transferred in 1981 with the Battenfeld company to Battenfeld EKK Extrusionstechnik GmbH . At the end of 1989 the company was then completely merged with Battenfeld.

- At the end of 1981 the later Atlas Copco - Eickhoff Roadheading Technic was founded together with Atlas Copco . This company, renamed AC-Eickhoff GmbH in 1991, developed and sold roadheading machines for tunnel construction and road driving - but explicitly not for coal or ore mining. At the end of 1998 the company was merged again with the parent company Eickhoff.

- The Schalke ironworks , a specialist in Kokshandlingmaschinen belongs since 2001 Eickhoff Group.

But whenever the mining industry brought a large surge in orders, the company returned to the traditional clientele.

Eickhoff operates its own control and electronics development, including the production of circuit boards and their assembly, in order to be able to operate largely independently of supplier markets.

In particular, Eickhoff has established itself to this day as a specialist in the gearbox construction sector , especially for large gears that have to work quietly and with little wear. This can be seen, for example, in the market segment of gearboxes for wind turbines in addition to fan gearboxes in cooling tower construction .

Thanks to its continuous development as a family company for more than 140 years, Eickhoff has earned a good reputation in the Ruhr area . Since March 2014 the company has also been listed in the Route of Industrial Culture , themed route Bochum .

Eickhoff is currently building a new production facility in Klipphausen ( Meißen district ) to manufacture gearboxes for wind turbines in order to be able to meet the increased demand for gearboxes.

The Eickhoff company has been a close sponsor of the Theater Total project since 1995 and provides this youth tour theater with rehearsal, work and administration rooms.

literature

- Four generations, four epochs. Festschrift for the 100th anniversary of the company. Ed .: Gebr. Eickhoff Maschinenfabrik u. Eisengießerei GmbH, 1964.

Individual evidence

- ↑ Birthdays Carl, Robert, Elisabeth Eickhoff see inscriptions in the Eickhoff family crypt in Kortumpark Bochum

- ↑ Florian Langenscheidt , Bernd Venohr (Hrsg.): Lexicon of German world market leaders. The premier class of German companies in words and pictures . German Standards Editions, Cologne 2010, ISBN 978-3-86936-221-2 .

- ↑ The last of its kind . In: Frankfurter Allgemeine Zeitung of July 15, 2017, p. 20.

- ^ Commercial register Bochum HRB 981

- ^ Commercial register Bochum HRB 2102

- ^ Commercial register Gelsenkirchen HRB 1239 as well as the website of the company Eickhoff (as of April 2009)

Web links

- Company website

- Historical photos from the factory

- Description of this sight on the route of industrial culture