Friedrich Heinrich colliery

| Friedrich Heinrich colliery | |||

|---|---|---|---|

| General information about the mine | |||

| Friedrich-Heinrich pit 1/2 | |||

| Mining technology | Underground mining | ||

| Funding / year | Max. 2,592,892 t | ||

| Information about the mining company | |||

| Employees | up to 8119 | ||

| Start of operation | 1912 | ||

| End of operation | 2012 | ||

| Successor use | Friedrich Heinrich / Rhineland West Mine |

||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

| Coordinates | 51 ° 29 '45 " N , 6 ° 32' 53" E | ||

|

|||

| Location | Kamp-Lintfort | ||

| local community | Kamp-Lintfort | ||

| District ( NUTS3 ) | Wesel | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Ruhr area | ||

The Friedrich Heinrich colliery is a former hard coal mine in Kamp-Lintfort . The mine was in 2001 part of the West colliery of the RAG . The Friedrich Heinrich colliery, together with the Niederberg colliery , formed the western border for hard coal mining in the Ruhr area . The name of the mine was given by Freiherr von Diergardt. The pit fields awarded to him were named after his first names Friedrich and Heinrich .

In 2020, the Kamp-Lintfort 2020 State Garden Show will take place on the former mine site of the Friedrich-Heinrich 1/2 mine .

history

The beginnings

On May 21, 1862, the Humboldt field was awarded . The award certificate was issued to the trades Friedrich Freiherr von Diergardt, Ferdinand Stein and Wilhelm Königs. The Berechtsame covered an area of 93.9 km 2 . The authorized person was thus somewhat larger than the authorized person from the Rheinpreußen colliery . The field was divided into three parts from January 18 to June 23, 1874. The eastern part of the field was given the name Friedrich Heinrich . In the years 1901–1904 test drilling was carried out in the field . In 1906 the public limited company Steinkohlenbergwerk Friedrich Heinrich was founded by a French banking group under the leadership of Société générale de crédit industriel et commercial (Paris). The then president of this bank, Albert de Montplanet, became the first chairman of the board . Only a few days after the company was founded, the company acquired the Friedrich Heinrich mine from the heirs of Baron von Diergardt. This mine field had a size of 29.4 km 2 . After the acquisition, the company decided to build a complete mine on 1200 acres . Franz Brenner became the first mine director ; he came from the German-Luxemburgish Mining and Hütten-AG . Brenner was commissioned by the company to plan and implement the construction of the mine.

The sinking of the shafts 1 and 2 began in 1907. The ground-breaking ceremony for the two wells was carried out in the middle of the pit box. Auxiliary structures made of timber framework were built for the sinking work. The sinking work for shaft 1 began in 1908 using the freezing method. A narrow-gauge railway was built above ground to transport material . During the sinking work in 1909, shaft 1 suffered a collapse of floating sand at a depth of 145 meters. In the same year, the freezing process was also started in shaft 2. In addition, the Friedrich Heinrich 3 field was acquired that year. The rightful now covered an area of 43.8 km 2 . Since the necessary infrastructure for the mine was lacking, several roads were built around the same time. Apartments for the miners were also built. For this purpose, the construction of the first colliery settlements, the old Friedrich-Heinrich settlement, began on the Lintfort Heide , which became the basis for the later town of Kamp-Lintfort. In 1910, there was another slurry of floating sand in shaft 1 at a depth of 244 meters. That same year, the shaft 2 reached at a depth of 306 meters carbon . In addition, Steinkohlenbergwerk Friedrich Heinrich AG, together with several other companies, participated in the founding of Niederrheinische Grunderwerbsgesellschaft mbH . In the following year, shaft 1 reached the Carboniferous at a depth of 307 meters. In the same year, the first level was set in shaft 2 at a depth of 350 meters and the second level at a depth of 400 meters.

The first years of operation

On July 1, 1912, coal mining began. The shaft was used as a delivery shaft, shaft 2 was used as a weather shaft. In the same year the construction of a coke oven battery with by-product plants began. The daytime facilities were generously built in a sophisticated architecture. In 1913, the sinking work on shaft 2 was resumed and the shaft was sunk deeper. The third level was set at a depth of 450 meters. In the same year, a coking plant was put into operation on pit 1/2 . In 1914, the sinking work on shaft 2 was resumed and the shaft was sunk deeper to the third level. Since 1914 the French company "Les Petit-Fils de François de Wendel & Cie" owned the majority of shares in "Friedrich Heinrich AG". The outbreak of the First World War had far-reaching consequences for the mine, as 50 percent of the employees were called up for military service. When the war broke out, the mine was placed under compulsory administration on the basis of an ordinance of the Federal Council. In 1915, a steam boiler exploded for days, killing four employees. Due to the First World War, all French people lost their supervisory board mandate. Due to the forced administration, the mine joined the so-called Transitional Coal Syndicate in 1916 . In 1917 the mine was sold to a new owner. The new owner was Rheinische Stahlwerke AG. In the same year, the fourth level was set in shaft 1 at a depth of 550 meters. In the following year, production started from the 3rd level.

On September 21, 1921, the Franco-German arbitration tribunal in Amsterdam issued a judgment that changed the ownership of the mine again. As a result of the judgment, the previous takeover of ownership was declared invalid and the old organs of the AG were put back into their functions. At the same time, the company resigned from the Rheinisch-Westphalian coal syndicate . In 1921 and 1922, a utility room, a locomotive shed, a pump house and a building for the mine fire brigade were built on the southern part of the factory premises. In 1924, shaft 2 was expanded. In the same year, the French group de Wendel took over 80 percent of the shares in the mine. Humbert de Wendel became the new chairman of the supervisory board. In 1925, under the direction of Werner Brand, steel pit punches were used in a face for the first time . In the same year, the mine took over a limited partner's participation in each of the ten coal trading companies of the Rheinisch-Westfälischen coal syndicate. In addition, the Northern Germany field was acquired this year. The field initially remained independent. In 1926 the mine rejoined the Rheinisch-Westfälischen Kohlen-Syndikat. In the same year, the alignment of the north field began. In addition, the mine participated in the establishment of the public limited company for coal utilization . In 1927 the fields Vluyn, Vluyn II and Heinrich were acquired. That same year, the shaft 2 to the 4th floor was durchschlägig . The Camp V field was acquired the following year. In the same year, the opening of the Northern Germany field began, when the sinking work for shaft 3 began.

The other years

In 1931 the Northern Germany field was completely taken over. The field had a size of 12.4 km 2 , the shaft 3 in the field had a depth of 381 meters. With the takeover of the Northern Germany field, the total entitlement had grown to 65 km 2 . To connect with the Northern Germany field, a breakthrough was made with the Northern Germany shaft on the first level. This year there were 39 party shifts . In 1932 there were 65 party shifts, in 1933 there were 37 party shifts and in 1934 there were 43 party shifts. In the same year, the development of the Camp V field began. In order to have its own land sales dealer, Wilhelm Wehnert Kohlenhandelsgesellschaft mbH was taken over in 1935. In 1936 the fields Vluyn, Vluyn II and Heinrich were transferred to Niederrheinische Bergwerks AG. As a result of this measure, the entitled persons were reduced, they now covered an area of 58.4 km 2 . In 1937 the Friedrich Heinrich colliery took over a substantial stake in the share capital of its sister colliery Heinrich Robert . In 1938 the sinking work on weather shaft 3 was resumed and the shaft was sunk deeper to the third level. The Friedrich Heinrich colliery acquired a stake in Steinkohlen-Elektrizitäts AG . The sinking work on weather shaft 3 was continued. In addition, the Humboldt 1 and Humboldt 2 fields were acquired. This increased the number of rights holders and now covered an area of 89.7 km 2 . By this point in time, Friedrich Heinrich's mine field had almost regained its old size. In 1940, shaft 3 was sunk to a depth of 474 meters. In the following year, shaft 1 was sunk to a depth of 642 and a new fourth level was set at a depth of 500 meters. The old 4th sole became the midsole. The Friedrich Heinrich company acquired a limited partner's participation in the coal trading company of the Rheinisch-Westfälischen Kohlen-Syndikats, and planning began for an expansion of the mine. In 1942, shaft 2 was sunk to the fifth level 600 m deeper. In addition, a coal plow was used on the mine for the first time . In 1943, the Friedrich Heinrich company began drilling in the Humboldt field for the upcoming freezing process for sinking shafts 4 and 5. Due to the effects of the war, the work was later interrupted and initially suspended. Towards the end of the Second World War , the coking plant in particular was badly damaged. The other plant facilities were also damaged to a large extent by bomb attacks.

The time after the world wars

After the end of the Second World War, the mine, like the entire Ruhr mining industry, was initially placed under the administration of the Allied military authorities. Reconstruction of the daytime facilities began in 1945. In the following year, the drilling work on operating section 4/5 was completed, only assembly work was carried out. The coking plant was also gradually replaced by a new building with new ovens from 1947. The 1st level and the 3rd level were the main conveying levels at the time. Alignment work was carried out on the 5th level. In 1949 the de Wendel Group received full control of its property. On June 24, 1952, there was a longwall breach , killing eight miners. That year the 5th level became the main production level. This floor was equipped with catenary locomotives for transporting the route . In addition, an underground signal box was put into operation. In 1953 the company took part in the founding of Kohlen & Erz GmbH in Duisburg, and the expansion of the coal washing plant began, and in the following year two more batteries were put into operation at the coking plant. The expansion of the coking plant was now finished for the time being. In 1956, the headframe at Shaft 1 was replaced by a tower hoisting system that was equipped with two four-rope vessel conveyors. Furthermore, in 1956, the sinking of the cableway shaft 4 began in the western field area, after an independent double shaft system was initially planned at this point before the Second World War . In 1958, the 400 meter bottom (mS) was set in shaft 4. All mining operations in the mine are now fully mechanized.

In 1960 the weather shaft 3 to the 3rd level was put into operation. In 1964, the weather shaft 4 to the 5th level was put into operation. The rights holders now covered an area of 118.7 km 2 . In 1967 the Alfred field was acquired. The excavation work was sunk deeper in shaft 3. In 1968 Ruhrkohle AG was founded and the Friedrich Heinrich colliery was incorporated into the newly founded Ruhrkohle AG. The negotiations with the bank de Wendel turned out to be very difficult and lasted until the end of 1969. The mining assets of the Friedrich Heinrich colliery were taken over by Ruhrkohle AG with effect from January 1, 1970. The mine was affiliated to "Bergbau AG Niederrhein". The weather shaft 3 was put into operation up to the 5th level. In 1974, the alignment of the 6th level began above a blind shaft. This sole was also known as the 885 meter sole. In the following year, a conveyor mountain was driven to further align the 885 meter bottom. In 1976 a carbon copy was made with the Pattberg and Rossenray construction sites of the Rhineland colliery. The right now covered an area of 123 km 2 . From 1978 onwards, the 885 meter bed was used as an additional conveyor bed. Due to a capacity adjustment at RAG's coke production, the mine’s coking plant was shut down that year.

The last few years

In 1983 the sinking work on shaft 2 was resumed and the shaft was sunk deeper. In the following year, shaft 2 was penetrated with the 6th level. In addition, a pilot hole was drilled to the Girondelle 5 seam this year. The seam was drilled at a depth of −950 m above sea level. In 1985, the sinking work on shaft 3 continued and the shaft was sunk deeper. In 1987 a breakthrough was made at shaft 3 with the Niederberg colliery. This was the first underground connection between the two mines. In 1988, the 1000 meter bottom was set in shaft 3. Planning began for a 1200 meter sole. On March 28, 1990, the Friedrich colliery went into a funding association with the Rhineland colliery. The sponsorship of Rossenray was taken over by Friedrich Heinrich. Shaft 3 went into operation in the same year up to the 1000 meter level. In 1991 the line conveyor was changed from carriage to belt conveyor. In 1993 it merged with the Rhineland composite mine to form the "Friedrich Heinrich / Rhineland composite mine". The production was concentrated on "Friedrich Heinrich 1/2" and the "Rheinland" production facilities with the exception of the "Rheinpreußen" 8 and 9 pits were shut down. In 2002 the association with the West Mine took place . In the West Mine, the Friedrich Heinrich shafts 1, 2 and 4 and the Rossenray 1 and 2 shafts were in operation, with the Friedrich Heinrich 4 shaft only being used as a weather shaft.

Promotion and workforce

Fatty coal and edible coal were extracted from the mine. The first workforce at the mine dates back to 1907, in that year 80 people were employed at the mine. The first production figures of the mine come from the year 1912, in that year 91,036 tons of hard coal were produced with 745 employees . In 1920, 851,366 tons of hard coal were mined, the workforce was 4127 employees. In 1925, the production exceeded the one million tons mark for the first time. This year, with 5,222 employees, 1,159,796 tons of hard coal were produced. In 1930 the production rose to around 1,750,000 tons of hard coal, the workforce in that year was 5970 employees. In 1940 the production rose to 2,370,745 tons of hard coal, the workforce was 5093 employees. In 1945, as a result of the effects of the war, production fell to around 549,000 tonnes of hard coal, and the workforce was 3525. In 1950 the production rose to 1,979,835 tons of hard coal, the workforce in that year was 7248 employees. In 1955, 8,119 employees produced 2,138,082 tons of hard coal. In 1960, 7,630 employees produced 2,400,393 tons of hard coal. In 1970 the production was around 2,500,000 tons of hard coal, the workforce was 5230 employees. In 1980, 4,770 employees produced 1,991,370 tons of hard coal. In 1986 the maximum production of the mine was achieved. This year, 2,592,892 tons of hard coal were extracted and the workforce was 4071. In 1992, 3366 people were still employed at the mine; 2,422,443 tons of hard coal were extracted. These are the last known production and workforce figures as an independent mine.

Current condition

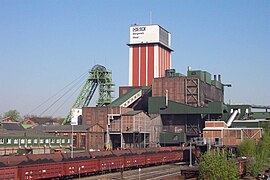

The extensive daytime facilities of the "Friedrich Heinrich" 1/2 colliery as well as the preserved headframe over shaft "Friedrich Heinrich" 2 and the headframe over shaft 1 are preserved as monuments. Shaft 4 of the Friedrich Heinrich colliery was demolished in 2017. Some buildings of the main shaft system 1/2 are still being demolished. The headframe and the headframe are retained. The Rhein-Waal University of Applied Sciences and Kamp-Lintfort has been located on part of the site since then . A mine locomotive is now at the Schroederstollen working group in Salzgitter.

Individual evidence

- ↑ a b c d e f g h i j k l m n o p q r s t u v w x y z aa ab ac ad ae af ag ah ai aj ak al am an ao ap aq ar Joachim Huske : Die Steinkohlenzechen in the Ruhr area. Data and facts from the beginning to 2005 (= publications from the German Mining Museum Bochum 144) 3rd revised and expanded edition. Self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- ↑ a b c d e f g h i j k l 100 years of mining in Kamp-Lintfort . In: Board of Directors Deutsche Steinkohle AG (Ed.): The reliable partner; The Chronicle. Heining & Müller, p. 11

- ↑ a b c d e f g h i j k l m n Walter Buschmann : Collieries and coking plants in the Rhenish coal industry, Aachen area and western Ruhr area. Gebr. Mann Verlag, Berlin 1998, ISBN 3-7861-1963-5 .

- ↑ a b c d e f g h i Wilhelm Hermann, Gertrude Hermann: The old collieries on the Ruhr. 4th edition, Verlag Karl Robert Langewiesche, successor Hans Köster KG, Königstein i. Taunus 1994, ISBN 3-7845-6992-7 .

- ^ A b c d Günter Streich, Corneel Voigt: Zechen Dominanten im Revier. 2nd expanded and revised edition, Verlag Beleke KG, Nobel-Verlag GmbH, Essen 1999, ISBN 3-922785-58-1 .

- ↑ a b c d e f g h i j k l m n o p q r s t u v Gerhard Gebhardt: Ruhrbergbau. History, structure and interdependence of its societies and organizations. Verlag Glückauf GmbH, Essen 1957

- ↑ a b c d e f Karl-Heinz Stenmans: Ending the coal mining on the left Lower Rhine. In: Gesamtverband Steinkohle eV (Ed.): Steinkohle 2013. together concept Werbeagentur GmbH, Herne and Essen 2013, ISSN 0343-7981 , pp. 39–41

- ↑ a b Joachim Huske: The hard coal mining in the Ruhr area from its beginnings to the year 2000. 2nd edition. Regio-Verlag Peter Voß, Werne 2001, ISBN 3-929158-12-4

- ↑ http://www.schroederstollen.de/aegel5.htm

Web links

- Description of this sight on the route of industrial culture

- The Friedrich Heinrich mine (BW West) in Kamp-Lintfort