Prince Leopold mine

| Prince Leopold mine | |||

|---|---|---|---|

| General information about the mine | |||

|

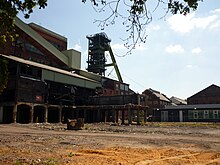

"Prince Leopold". The left headframe was demolished in April 2008. |

|||

| Funding / year | up to 1.5 million t | ||

| Information about the mining company | |||

| Employees | approx. 450 to 4500 | ||

| Start of operation | 1913 | ||

| End of operation | 2001 | ||

| Successor use | Cultural event | ||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

| Coordinates | 51 ° 40 '18 " N , 6 ° 59' 0.3" E | ||

|

|||

| Location | Hervest | ||

| local community | Dorsten | ||

| District ( NUTS3 ) | Recklinghausen | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Ruhr area | ||

The Fürst Leopold mine was a hard coal mine in the Dorsten district of Hervest .

Surname

The name of the mine goes back to the owner of the Bergregal around 1900, the Anholter registrar Leopold zu Salm-Salm (1838–1908).

history

One of the co-founders of the mine is the banker and later secretary of commerce Albert Müller .

Preparation and depth

At a depth of around 600 m, the Fürstlich Salm-Salm'sche Generalverwaltung came across coal during the “Fürst Leopold II” borehole in 1902 and put in the coal mine . Pit fields I and III were awarded to the Prince Leopold I, II and III unions in 1906 . Shortly afterwards the Gelsenkirchener Bergwerks-AG Consolidation took over the unions and fields IV to X. In 1910, all 10 fields for the Fürst Leopold union were combined to form the 21.2 km² “Fürst Leopold I” mine field . The sinking work for the Fürst Leopold 1 shaft began in November, followed six months later for the Fürst Leopold 2 . In December 1911, Bergbau-AG Consolidation divided the field again for tax reasons: The fields "Fürst Leopold" (16.1 km²) and "Fürst Leopold Continuation" (6.1 km²) were created. The preliminary final depths of 690 and 748 m respectively reached shafts 1 and 2 almost simultaneously in May 1912, when they encountered coal-bearing seams .

Prince Leopold

Promotion and expansion

The first coal was mined in January 1913 - 39,236 tons by the end of the year , and the workforce grew to around 450 workers. In 1914 a ring kiln brickworks was built west of the production shafts , which mainly produced for the colliery colony that was being built. In 1915 the shafts reached their final depths of 895 and 876 m.

strike

In November 1918, Hoesch AG acquired the kuxe of the unions for 21.75 million marks. From December 1918 to April 1919 the miners of the Dorsten colliery went on strike for higher wages and social benefits, the riots culminating in the murder of an office manager. In the collective bargaining negotiations, annual paid leave of 3 to 6 days, an average wage of 14 marks and the introduction of the 7-hour shift were achieved.

Prince Leopold / Baldur

Interest agreement and association

In 1920 the Hoesch AG cooperated with the Cologne-Neuessener Bergwerkverein and the Trier trade union (owner of the neighboring Baldur mine ). With inflation , there were further strikes for wage increases, which ended in the occupation of the Ruhr (Ruhrkampf). "Prince Leopold" was occupied by Belgian troops from February 1923 to December 1924. In 1926, work began on the underground network of "Fürst Leopold" (2nd level) and "Baldur" (3rd level) at a depth of around 700 m - shortly before the breakthrough , however, the work came to a standstill. In 1927, work began on its own mining port on the Wesel-Datteln Canal . In March 1930, the first coal from “Fürst Leopold” was transported to the port on the works railway and loaded onto barges there . After persistent sales problems, in July 1930 the Trier trade union (and with it the “Baldur” colliery) was transferred to the Cologne-Neuessener Bergwerkverein . Half a year later, the Hoesch AG and the Cologne-Neuessener Bergwerksverein merged to form the large company Hoesch-Köln-Neuessener AG for mining and smelting operations . A few months later the “Baldur” colliery was shut down. In order to use the remaining shafts for better ventilation of “Fürst Leopold”, the joint work was resumed. The breakthrough took place in June 1931 and the entire mine was henceforth called “Prince Leopold / Baldur”.

Because of the global economic crisis , the mine’s sales fell so sharply around 1933 that part-time shifts had to be taken and layoffs had to be pronounced. In the summer of 1934, Hervest and Holsterhausen were declared emergency areas due to high unemployment and poverty .

Second World War

From 1936 onwards, also due to the higher demand from the armaments industry , “Fürst Leopold / Baldur” was looking up again. Due to technical progress and the expansion both above and below ground , an annual output of over one million tons of hard coal was exceeded in 1939 . In 1944 around 660 prisoners of war were obliged to work underground. In March 1945, the daytime facilities were badly damaged in heavy air raids, while the air raid tunnels underground and in mine dumps protected around 700 citizens from low-flying aircraft.

reconstruction

After the end of the war, reconstruction and repair work began, so that regular production could be resumed in October 1945. As a result of the reorganization of the German coal and steel industry called for by the Allies, “Prince Leopold / Baldur” fell to Hoesch Bergwerks-AG to cover the hard coal needs of the Dortmund Westfalenhütte .

Underground, the timber reinforcement of the struts was replaced by steel reinforcement and the work was made easier with cutting machines and coal planers . Further expansion of the hoisting machines and processing led to higher performance also for the surface systems.

High pressure power plant

In order to replace the outdated boiler house and to meet the company's own requirements for steam, compressed air and electricity more economically, a high-pressure power plant was built in the early 1950s . In 1955, the in-house brick factory had to give way to the expansion to include a pressure gasification plant for the production of high-strength gas, which was mainly required by Essen-based Ruhrgas AG . In 1959 the Dorstener Bergwerk was incorporated into the re-established Hoesch AG .

Sales crisis

After the record years of 1956/1957 (almost 1.5 million tons of annual production with 4,250 employees), production had to be reduced to 1.2 million tons due to a persistent sales crisis. The reason for this coal crisis was the displacement of German hard coal by crude oil and cheaper imported coal, especially from the USA . Until about 1967 the workforce as well as the annual production were continuously reduced to 879,000 t for 1699 employees, but at the same time the shift performance (ton per man and shift) could be increased from 1.95 to 3.84 t / MS.

Prince Leopold / Wulfen

Incorporation into Ruhrkohle AG

In order to continue to operate German mining in a future-proof manner, Ruhrkohle AG was founded in 1968 , in which 80% of the mining mines were combined. The Hoesch AG transferred its mines, including "prince Leopold / Baldur" to RAG. Together with the “ Brassert ” and “ Wulfen ” collieries , “Fürst Leopold / Baldur” was incorporated into the Bergbau AG Herne / Recklinghausen division.

Since a network of “Wulfen” neither with “Brassert” nor with “ Auguste Victoria ” seemed realistic, the management decided in June 1970 to merge the “Fürst Leopold / Baldur” and “Wulfen” pits to form the “Fürst Leopold / Wulfen” mine .

Composite

As part of an exploration program to explore new deposits , deep boreholes in the “Wulfen” construction site in 1974 found further coal seams . In this way, the closure of the “Wulfen” mine, which was planned for 1975, was averted and the plans for the underground network began to take shape. In January 1975, the joint work between "Fürst Leopold" (3rd level - 838 m above sea level ) and "Wulfen" (2nd level - 990 m above sea level) began. The approximately 7.5 km route was driven within six and a half years. In July 1981 the former employee and Dorsten Mayor Hans Lampen lit the last tee. The network resulted in a construction area of 96.0 km² for the “Fürst Leopold / Wulfen” mine.

expansion

During the joint work, above all the systems above ground were modernized: Shaft 1 was converted from rack to skip conveyor in 1975/1976 , new screening machines and large sieves were installed and the conveyor routes were simplified. The most important change underground was the self- advancing shield support .

In 1983, a “raw coal stacking and equalization system” was put into operation in order to mix the extracted raw coal into a more uniform product. In order to be able to use shaft 1 on Baldur better as a weather shaft, it was sunk deeper to −1328.4 m above sea level. In 1997, “Fürst Leopold / Wulfen” achieved the highest annual production in the company's history with 2,400,350 t and around 3,000 employees.

Lippe mine

Verbund and closure

Despite demonstrations and vigils by the miners, the association with the Gelsenkirchen colliery “ Westerholt ” to the “ Lippe ” mine took place in 1998 . In 2001, funding for “Prince Leopold” was finally discontinued. The shafts Wulfen 1 and 2 and the shaft Baldur 1 were then filled . At the Fürst Leopold site, both shafts remained open except for the time being for ventilation and water lifting . After the decision to equip shaft 1 with submersible pumps for dewatering, shaft 2 could be filled in early 2019.

Todays use

Shaft 1 initially served as a weather and material shaft for the “Lippe” mine. The headframe was demolished on April 6, 2008. Numerous above-ground facilities such as coal washing and processing have now been canceled. Shafts 1 and 2 remain open for dewatering until further notice.

The headframe for shaft 2 from 1912/1913 was placed in the care of the Foundation for the Preservation of Industrial Monuments and History in 2015 .

The project company Fürst Leopold was founded in 2001 to develop concepts for new uses .

In the following period the area was used at irregular intervals for cultural events such as the ExtraSchicht . Guided tours can also be booked at Dorstener stadtinfo . The monthly Auf Leopold motorcycle meeting with up to 3,500 bikers has been held on the colliery site since summer 2004 .

The Creativ Quartier Fürst Leopold opened on the site acquired and converted by a private investor. In addition to cultural use, from 2013 the owner also relocated business and gastronomy in the renovated buildings of the former mine. In addition, the Leo , a socio-cultural center with a focus on youth welfare, was set up on the site . The newly established Fürst-Leopold-Platz forms the center of the area.

literature

- Mine Fürst Leopold / Wulfen (Ed.), H.-J. Krüger, H. Coen, H.-J. Wilkin: Mine Fürst Leopold / Wulfen 1913–1993. 80 years of coal mining in Dorsten. Dorsten 1988.

- Joachim Huske: The coal mines in the Ruhr area. 3rd edition, self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- Hermann, Wilhelm and Gertrude: The old mines on the Ruhr . Past and future of a key technology. With a catalog of the "life stories" of 477 mines. 6th edition, expanded by an excursus according to p. 216 and updated in energy policy parts, the 5th, completely revised and expanded edition 2003, post-processing 2002: Christiane Syré, final editing 2007 Hans-Curt Köster (= The Blue Books ). Langewiesche publishing house, Königstein i. Ts. 2008, ISBN 978-3-7845-6994-9 .

Web links

- Zeche Fürst Leopold on the website of the Association for Mining, Industrial and Social History Dorsten

- Articles and pictures at Industriedenkmal.de

- Photo gallery of the Zeche Fürst Leopold by Paul Klimek

- Description of this sight on the route of industrial culture

- Prince Leopold on LostAreas

References and comments

- ↑ Bergbau Dorsten: Hervester Straßen, Albert Müller ( Memento of the original from April 29, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. ; Retrieved June 19, 2016

- ↑ Backfilling of shaft 2 started . In: coal. The RAG Aktiengesellschaft employee magazine, year 2019, issue 3, p. 13.

- ↑ Recklinghäuser Zeitung of April 14, 2008

- ↑ Headframes. Industrial monuments in the Ruhr area. In: Frankfurter Allgemeine Zeitung . November 2, 2015, p. 13.

- ↑ creativquartier-fuerst-leopold.de ( Memento from December 12, 2015 in the Internet Archive )

- ↑ derwesten.de