Construction of the World Trade Center

The construction of the World Trade Center (WTC) began with the planning in 1962 and ended with the official inauguration of the Twin Towers on April 4, 1973. The measure was conceived as an urban renewal project to achieve the revitalization of Lower Manhattan . The client of this project was the New York port authority, the Port Authority of New York and New Jersey (Port Authority or PANYNJ for short). After extensive negotiations between the Port Authority and the state governments of New Jersey and New York , an agreement was reached to support the location on Radio Row on the Lower West Side of Manhattan for the World Trade Center project. In order to make the contract acceptable to New Jersey, the New York Port Authority agreed to take over the bankruptcy estate of Hudson & Manhattan Railroad, now known as the Port Authority Trans-Hudson (PATH), to continue commuting from New Jersey Transport Lower Manhattan.

The twin towers were designed as framed tubular structures and thus offered the tenant an open floor plan, as the surfaces were not interrupted by columns or walls ("tube-in-tube" means tube-in-tube). The inner tube was formed by the steel core with the elevator shafts, while the outer tube was clearly visible as a facade. The entire wind load was carried by the outer shell of the building, which was designed as a steel grid. The inner core of the skyscraper carried the vertical gravitational forces , which resulted in a lightweight construction.

The elevator system consisted of two so-called sky lobbies and a system of local elevators. This construction method kept the structural core of the towers small, as significantly fewer elevator shafts were required. This meant that up to 75 percent of the floor space could be used. The previously common arrangement with continuous lift shafts often only allowed 50 percent of usable space per floor. The design and construction of the World Trade Center Twin Towers included many other innovative techniques. For example, for the construction of the WTC a large excavation pit had to be made, which was secured by a back-anchored diaphragm wall . Construction of the north tower (WTC 1) began in August 1968, and the south tower (WTC 2) began in 1969. The generous use of prefabricated components helped the construction process to proceed quickly. In December 1970 the first tenants moved into the north tower and into the south tower in January 1972. Four more, so-called low-level buildings, were built as part of the World Trade Center in the 1970s with a uniform facade. The seventh building was erected in the mid-1980s.

The two twin towers were targeted by terrorist attacks in 1993 and 2001 and were destroyed as a result of the second attack.

planning

Design and construction

On September 20, 1962, the American architect Minoru Yamasaki was commissioned, together with the architecture firm Emery Roth & Sons, to lead the World Trade Center Project (WTCPJ). He came up with the idea of the Twin Towers. Yamasaki originally submitted a concept to the New York port authority that included twin towers, each with 80 floors. This concept was rejected because the client's request for one million square meters of office space could not be met. To meet the requirements, each tower had to be 110 stories high. This corresponded to a total office space of 930,000 square meters. The elevators were an important obstacle to the building height. The higher the building, the more employees, the more elevators would be needed. At the expense of the office space, more space would have been required for the building technology. Yamasaki and the engineers therefore decided on a new elevator system: express elevators with a large capacity (55 people) take employees to the 44th and 78th floors, the so-called " sky lobbies ". From there, the local elevators take you to all the other floors of a “block”, with the local elevators “stacked” within the same elevator shaft. By reducing the number of elevator shafts required, the usable area per floor was increased from a maximum of 62% in previous skyscrapers to 75%. The World Trade Center was the second skyscraper to use the sky lobbies after the John Hancock Center in Chicago . This system was adopted from the New York subway system, which had stations reserved for local trains and express stations on which all trains stopped.

On January 18, 1964, Minoru Yamasaki presented his design to the public. Yamasaki's World Trade Center design was unusual. He split the main building into two almost identical towers, which he placed side by side in front of a large open area. Each of the towers consisted of a simple cuboid shape, which should impress just because of its height. The towers had a square footprint of about 207 feet (63 m) on each side, so each tower had an area of about 4,000 square meters. In order to break up the severity of the building, Yamasaki covered the surface with a fine latticework that could not deny its similarity to Gothic tracery . The latter was particularly evident on the ground floor, where the vertical ribs merged into high, ogival windows. Because Yamasaki suffered from a fear of heights, the buildings were designed with only 18-inch (45 cm) wide, non-opening office windows. At the same time, these narrow windows should give the building occupant a feeling of security. In between there were columns coated with an aluminum alloy, which should give off a warm color effect.

The World Trade Center complex consisted of six buildings within a 65,000 square meter superblock. In the center stood the Twin Towers, surrounded by three multi-storey buildings and the 22-storey Vista Hotel (WTC 3). The individual buildings were connected to one another by bridges and tunnels. Shops, bars, cafes, banks and more than 60 restaurants for locals, tourists and employees complemented the 930,000 square meters of office space.

The American Institute of Architects and other groups have voiced criticism of the aesthetics of World Trade Center design. Lewis Mumford, author of The City in History , and others in charge of town planning criticized the project, calling this and other new skyscrapers just "glass and metal cabinets". Broadcasters expressed concerns that the Twin Towers would cause interference to television reception for viewers in and around New York City. In response, the New York Port Authority offered the broadcasters a new TV transmitter on the World Trade Center. The Linnean Society of the American Museum of Natural History was also against the Trade Center project, as they believed the towers would endanger migratory birds .

The structural engineers of Worthington, Skilling, Helle & Jackson worked on the development of the tube-frame-structure-system, which was to be used in the buildings, so that Yamasaki's conception of minimum floor space with maximum usable area could be implemented. The Port Authority Engineering Department designated engineers Joseph R. Loring & Associates as electrical engineers and Jaros, Baum & Bolles as mechanical engineers. Tishman Reality & Construction Company was the general contractor for the World Trade Center project. Guy F. Tozzoli, Director of the Port Authority's World Trade Department, and Port Authority Chief Engineer Rino M. Monti led the project.

Structural engineering

As an intergovernmental agency, the New York Port Authority was not subject to local New York City laws and ordinances, including their building codes. Still, the New York Port Authority required architects and civil engineers to follow New York City building codes. At the time the World Trade Center was being planned, new building codes were being drafted to replace the old 1938 version. The structural engineers adapted the drafts to the new building regulations of 1968 and combined the “progressive techniques” in the building shape.

Yamasaki and engineers John Skilling and Leslie E. Robertson worked out a structural plan that made it possible to build the WTC as the tallest building in the world , both in terms of design and construction. In contrast to the usual high-rise buildings, whose outer skin was hung like a curtain from the inner supporting structure, the outer skeleton of the twin towers actually had a supporting function. The tube-frame concept introduced by Fazlur Khan was an important innovation. It made it possible for the towers, as one of the first high-rise buildings of their time, to be designed as a "tube-in-tube" system. The inner tube was formed by the core with the elevator shafts, while the exterior was clearly visible as a facade. The outer skin of the towers consisted of a stable network of 59 steel columns on each side of the building. Consoles were welded to the inside to which the false ceilings were attached. By connecting these two "tubes" using the 80 cm high connecting beams of the false ceilings, a high level of stability of the building was achieved. The entire wind load was carried by the outer shell of the building, which was designed as a steel grid. The inner core of the skyscraper only carried the vertical gravitational forces, which resulted in a lightweight construction. The structural analysis of the main parts of the World Trade Center was performed on an IBM 1620 computer .

When creating the interior structure, more and more prefabricated modular elements were used. The quality of the structural steel and the panel thickness were reduced with increasing building height, since the building structure has to support a correspondingly decreasing building mass proportional to the height. A36 steel was used for the supporting structure . This is a standard steel alloy used as general structural steel in the United States. The A36 standard was developed by the American Society for Testing and Materials (ASTM), an organization for established standards. A36 is a standard carbon steel with no alloy additives and a density of 0.28 lb / in³ (7.8 g / cm³). A36 steel in plates, rods, and other shapes with steel thickness less than 8 inches (200 mm) has a minimum yield strength of 250 N / mm² (Newtons per square millimeter) and a tensile strength of 400 to 550 N / mm². With a steel thickness of more than 8 inches (over 200 mm), the yield point is reduced to 220 N / mm² while the tensile strength remains the same. This steel is easy to weld and is also used for rivet and screw connections. A441 steel was also used for the outer core . This is a standard carbon steel with manganese, copper and silicon alloy components, which gives the steel a high level of corrosion resistance. Furthermore, the A441 is characterized by its higher minimum yield strength of 350 N / mm² for use with high loads on structures. Approx. 60% of the steel plates required for construction were produced in Japan to ASTM standards or their equivalent.

The pipe-frame system required 40 percent less structural steel than conventional high-rise constructions. From the 7th floor to the ground floor and then further down to the foundation, the steel columns were installed at a distance of 3 m. From the surface of the earth, the steel supports were set 20–26 m deep into the foundation. The facade structure of the towers consisted of 236 square external steel columns with a cross-section of 36 × 36 cm. Depending on the panel thickness and the installation location in the building, the steel supports were made with lengths of 3.65 m to 11.60 m. In order to simplify the installation of the external steel supports, they were not installed individually but in modules that were manufactured outside the construction site. These steel column modules consisted of three external steel columns that were welded to three transverse parapet panels so that a gap the width of a window was created between the columns. The steel column module had a height of three floors, two floors were completely covered and after the lower and upper parapet slab half a floor each survived. The support brackets for the floor ceilings were welded to the inside of the parapet panels. The steel column modules were screwed together. The fasteners for general steel structures are high strength bolts or welds. The project specifications for this correspond to ASTM standards A325 or A490. The screw connections had to be calculated and installed in such a way that, due to a sufficiently high clamping force, even under operational loads, no shear forces could take effect across the screw axis. This means that the forces that occurred were absorbed in the middle of the “span” of the columns and parapet plates. The parapet plates were installed on each floor in order to transmit the shear stress between the steel column modules in such a way that together they formed a resistance against forces acting on the side. The joints between the steel column modules were offset vertically so that the connecting joints between neighboring steel column modules were not on the same floor.

All the elevator shafts, the sanitary rooms , three stairwells each and other utility rooms were housed in the inner core of the tower . The cores had a rectangular base area 27 m wide and 40 m long and each contained 47 steel columns that reached from the foundation to the roof of the towers. The inner core was constructed in such a way that it supported the weight of the towers. From the 66th floor, conical steel supports were used. On the lower floors, the steel supports consisted of welded box sections, which were continued in an ascending manner on the upper floors as flange sections. The structural core in WTC 1 (north tower) was aligned with the longitudinal axis from east to west. In WTC 2 (south tower) it was oriented from north to south. The technical floors had no office space. All of the supply facilities required for the entire building system, such as electrics, water and air supply, air conditioning, etc. were located on them . As an exception for the technical floors, the stairwells here were outside the inner core.

The large, column-free space between the facade structure and the inner core was bridged with prefabricated ceiling elements. The ceiling elements carried their own weight as well as that of the payloads, improved the lateral stability of the outer walls and divided the wind loads under the outer walls. The ceiling structure consisted of a 10 cm thick layer of lightweight concrete, which was applied to a permanent formwork made of trapezoidal sheet metal. This rested on steel lattice girders about 70 cm high. A ceiling element (6 m wide and up to 18 m long) consisted of four so-called bridge girders in the longitudinal direction and four further girders in the transverse direction. The bridge girders were laid in a 2 m grid. The upper and lower chords of a girder consisted of 2 L steel profiles each. The "bridge" in between consisted of a continuous, serpentine round steel with a diameter of 28 mm. The ceiling element was screwed to the outer wall support with two bolts at the top and the damping unit was connected to the outer wall support at the bottom. The floor (i.e. the lightweight concrete layer with trapezoidal sheet metal?) Was screwed to the inner core support. The damping unit was manufactured in a sandwich construction. The outer layers are purely elastic (spring principle), the filling layer consists of incompressible viscoelastic material (damping principle), which had the task of reducing the vibrations caused by building use. The "document capacity" was designed for 5 kips (1 kip ( kilo-pound ) equals 1000 pounds, or 453 kg). For the wider office area, the ceiling element had to span a width of 18 m, in the narrow area the span was 11 m.

The “hat truss” system (or “ truss bridge boom ”) was installed on the 107th floor up to the top of the building on the 110th floor. In order to be able to install a high communication antenna in each of the towers, a system was developed that enabled the load to be redistributed between the outer and inner core of the building. This was achieved by using a steel girder construction in the form of double-T girders, which were installed in the horizontal and vertical planes. At the corners of the inner core, two steel girders were mounted diagonally from the 110th floor top edge to the outer core of the tower on the 107th floor. In the middle of the inner core, two steel girders per side were also installed in a diagonal arrangement from the 110th floor top edge to the outer core of the tower on the 107th floor. After the two towers were completed in 1978, a 110 m high communication antenna was installed in the north tower only.

Effects of wind forces

An important risk factor for planners are the wind forces acting on a building. In the case of very high houses, a perfect combination of sufficient elasticity and necessary stability in the wind is of great importance. Compared to traditional structures such as the Empire State Building , which have thick, heavy masonry for the fire protection of steel structural elements and thus also offer better resistance to wind forces, the pipe-frame system with an inner core and an outer column structure made the Preservation of the light structure, but the wind problems had to be solved. In order to make the towers less sensitive to massive wind forces, their designers moved the load-bearing metal structure onto the outer skin of the building and connected the facades with steel girders. Engineer Robertson built models of the twin towers that were tested in the wind tunnel at Colorado State University and the National Physical Laboratory in the UK . Numerous simulations and calculations were used to determine the maximum wind pressure the World Trade Center could withstand and how the structure of the towers behaved under these conditions. The towers were constructed in such a way that they could withstand fluctuations of over 90 cm. The experiments were also carried out to assess how much swaying the towers the building users could endure. The test subjects were invited to free eye exams. The actual purpose of the experiment was to show them a simulated swaying building in order to find out which swaying could still be tolerated. Many test subjects reacted to these tests with negative symptoms such as dizziness and other symptoms of illness. One of the key engineers, Leslie Robertson, worked with Canadian engineer Alan Garnett Davenport to develop the viscoelastic damper. By installing these dampers between the ceiling elements and the outer structure, some of the vibrations were absorbed. Together with some other structural changes to the building, the fluctuations were reduced to an acceptable level.

Effects of a plane crash

Comprehensive safety tests, simulations and calculations preceded the construction of the WTC. The engineers and structural engineers on this project had also considered the possibility of a plane crash. From past experience, when a B-25 bomber fell on the 79th floor of the Empire State Building in July 1945 , and because of two other near-misses on skyscrapers, people wanted to be prepared for the worst. Chief Engineer Leslie Robertson developed a scenario for the largest airplane in the world at the time, the Boeing 707 . The National Institute of Standards and Technology (NIST) found a three-page paper on which it was noted that the analysis of the effects of an aircraft accident did not use the Boeing 707's speed of 896 km / h, but a jet with a flight speed of 970 km / h. The original documentation for this study was lost when the World Trade Center collapsed. After the bomb attack in February 1993, John Skilling was approached about this accident study, where he found that the building structure would still be standing with the effects of the accident. However, this study did not consider how the structure would behave in the event of a fire resulting from an airplane crash. It has been assumed that the World Trade Center, with its steel structure, behaves in exactly the same way as the heavy masonry and steel structure in the Empire State Building.

Fire protection precautions

In order to protect the external structure of the towers including all ceilings against the risk of fire, fire-resistant materials according to the Standard Test Method for Air Erosion of Sprayed Fire-Resistive Materials (SFRMs) were used. The steel supports (and beams?) Of the World Trade Center were sprayed on by the construction company Tishman Reality and Construction Company with the special fire-resistant plaster vermiculite in the form of a three millimeter thin film. Vermiculite, also known as vermisole, is an expanded aluminum-iron-magnesium silicate that belongs to the group of mica minerals. It is a purely natural product. Vermiculite is used as fire protection, cold and heat protection and for sound insulation in high-rise buildings. This product had previously been tested on so-called standard fires , but such standard fires do not reach the comparable temperatures of a kerosene fire. Originally, a mixture was planned for fire protection that should contain around 20 percent asbestos . This layer of insulation was designed to prevent the temperature of the steel girders from rising above 1100 degrees Fahrenheit (593 ° C) in the event of a fire - a temperature at which steel loses 50% of its strength. At the end of the 1960s a discussion broke out in the USA as to whether asbestos causes cancer. Work with asbestos-containing building materials was then stopped. The north tower had already been built up to the 40th floor, when vermiculite was used for the next floors and for the south tower. In order to save weight, plasterboard walls were chosen for the fire protection of the building core.

In 1968, New York City building codes were changed. In some points of fire protection they have been toned down compared to the old version. The new regulations made it possible to install only three staircases in the WTC towers instead of six, as would have been required under the older building regulations.

After a fire in the north tower in February 1975, the fire protection measures in the WTC were improved. The fire spread to six floors before it could be extinguished. After the 1993 bombing, an inspection team found that the fire protection measures were inadequate. The New York Port Authority was about to replace them. Up to September 11, 2001 (terrorist attack on the WTC), an improvement in fire protection was carried out and completed on 18 floors in WTC 1 (north tower). This improvement also affected all floors the plane hit. Fire protection was improved on 13 floors in the south tower, but only three floors were directly affected by the effects of the plane impact. In 1968, New York City building codes did not require sprinklers for high-rise buildings, except for the underground spaces. After the major fire of 1975, the New York Port Authority decided to install sprinkler systems in the World Trade Center. By 1993, 97% of the south tower (WTC 2) and 85% of the north tower (WTC 1) were equipped with sprinkler systems. The entire system was completely retrofitted by 2001.

Construction stages

In March 1965, the New York Port Authority (developer) began purchasing property on the World Trade Center side of Manhattan. By July 1965, 75% of the required building area had already been bought by the port authorities, or a sale was about to be concluded with the owners. On March 12, 1966, the commissioned Ajax Wrecking and Lumber Corporation started demolishing the buildings on the planned construction site. A total of 164 buildings had to give way to the construction of the World Trade Center.

foundation

The groundbreaking ceremony was carried out on August 5, 1966, marking the beginning of the construction of the foundations of the World Trade Center. The building site on which the World Trade Center stood was not given by nature, but rather the result of embankments made by previous generations. Solid ground was only found at a depth of around 20 meters. In addition, the ground was damp and the entire area had to be specially protected against the ingress of water from the Hudson River . Before the actual excavation of the foundation could begin, a retaining wall had to be built around the intended foundation of the World Trade Center. For this purpose, a 6.70 m wide trench was dug in sections down to the solid ground (about 21 m deep). The resulting cavity was filled using the slurry method (suspension) with bentonite , a mixture of water and clay, as a supporting liquid. This kept the water out of the pit. A steel cage was then inserted and poured with concrete, the supporting liquid being squeezed out. In 1964, the civil engineer Christian Veder developed the diaphragm wall construction in the basic construction. The construction pit was supported with multiple anchored diaphragm walls, which resulted in a one-kilometer-long construction pit enclosure, also known as a “bathtub” in the specialist literature. The purpose of this "bathtub" was not to take in water, but to keep water out. In this way, protected from water ingress from the nearby Hudson River, the foundation for the World Trade Center could be built. This method was used in place of traditional drainage methods. The lowering of the groundwater level would have caused damage to large housing estates near the construction site that were not on deep foundations. The slurry process was developed with expert advice from New York Port Authority Chief Engineer John M. Kyle Jr. carried out. Montreal-based company Icanda, a subsidiary of the Italian technology company Impresa Costruzioni Opere Specializzate (ICOS), began erecting the diaphragm wall in December 1966. Construction of the diaphragm wall was completed after 14 months. Only now could the excavation of the foundation begin. Due to the construction of the WTC, the PATH trains had to be operated via a raised tunnel to the Hudson Terminal until the new PATH station was built in 1971.

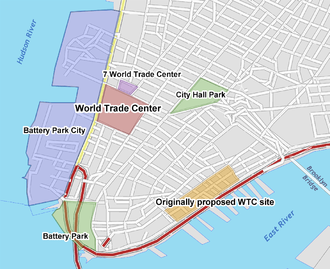

The foundation excavation for the WTC project amounted to 920,000 cubic meters of soil material. In order to save the costs of transporting the excavation to landfills in New Jersey, the client donated the soil material to the City of New York. This used the excavation as filler material to expand the coastline across Manhattan's West Street. The erection of a sheet pile wall prevented the filling material from flushing away. Thus a 210 m wide and 452 m long piece of land could be reclaimed from the Hudson River. In this way, the city of New York was given a property worth 90 million US dollars (based on 1968 that would correspond to 660 million US dollars today), since Battery Park City was later built on this property .

Construction of the twin towers

In August 1968, construction work on WTC 1 (north tower) began. Construction on WTC 2 (south tower) began in January 1969. Karl Koch Erecting Corp. was commissioned by the client to carry out and monitor the entire steel work. The Aluminum Company of America was contracted to work on the aluminum facade. The New York Port Authority signed steel supply contracts with the Pacific Car and Foundry Company, Laclede Steel Company and Granite City Steel Company in January 1967 for a total of $ 74 million (today's equivalent to $ 565 million). As a cost-saving measure, the New York Port Authority selected many different steel suppliers who supplied smaller quantities of steel instead of purchasing large quantities of steel from a single source, such as Bethlehem Steel or US Steel . In February 1967 the & Construction was commissioned to monitor the WTC project.

The use of prefabricated modules, such as the steel girder element for the facade or the floor element, contributed to reducing the construction time and costs of the WTC project. These modules were manufactured in a steel processing company under strict quality control. The steel parts were stored in the Penn Central shipyard in Jersey City, from there they were brought to the construction site in the early hours of the morning through the Holland Tunnel and lifted to the intended location by crane. Larger steel components were brought to the construction site with tugs. Four special hydraulic cranes, which are suitable for use on high-rise buildings, were required to lift the heavy loads. The Favco Standard 2700 Crane , manufactured by Favelle Mort Ltd. from New South Wales, Australia, also known as the "kangaroo crane", met these requirements. This crane was used until the freight elevators in the inner core of the World Trade Center could continue this work. In addition, four crane systems in the form of mobile land drilling rigs were used.

A tower consisted of three modules, separated by two so-called sky lobbies on the 44th and 78th floors. When the towers were built, the construction of the inner core had to be started first, because the freight elevators for the transport of the building materials had to be housed there. Then the facade could be redrawn; As a result, the expansion of the inner core was always a few floors ahead of the facade. The inner core was connected to the facade by floor elements. The supply systems, the air shafts and the telephone cables ran under the floor elements on each floor. The buildings were equipped with complex heating and energy systems that were state-of-the-art for the time. After nine years of planning and four years of the demolition phase and the creation of the foundation, the construction phase of the towers was carried out simultaneously. In January 1970 the construction phase in the north tower had reached the 43rd floor, while work was being carried out on the south tower on the 9th floor. Both towers were built at the same speed. The construction schedule envisaged around 10 days for the construction of three floors with steel girders per tower. The Karl Koch Erecting Corp. had a $ 22 million assembly contract based on meeting that schedule. On the 41st, 42nd, 75th and 76th floors of both towers, heavy mechanical equipment was installed for the building systems, which is why the floor on these floors had to be reinforced. The same was necessary for the module sections on the 44th and 78th floors ( sky lobbies ). From the 9th floor up, the prefabricated floor elements were used.

In 1970 the hauliers went on strike, delaying the transport of material to the construction site. Since there was not enough space on the construction site for the storage of building materials, all material deliveries had to be made just-in-time, that is, a certain component had to be at its certain installation location at a certain time. Computerized work flow plans prevented an error in the schedule or the delivery of materials from delaying construction progress. The New York Port Authority tried other means of moving material. Helicopters were also used, among other things. In this transport method, a helicopter lost its steel load in the Kill Van Kull (waterway in the New York port area). Several other mishaps occurred during the construction phase, including the interruption of the telephone network in Lower Manhattan because the telephone cables had been cut by ramming. On March 16, 1970, a truck ran over a propane tank; six workers were injured in the explosion. A total of 60 workers were killed in construction accidents while the World Trade Center was being built.

The topping-out ceremony for WTC 1 (north tower) took place on December 23, 1970, after which the first tenants moved into their offices. The topping-out ceremony for WTC 2 (south tower) took place on July 19, 1971. The first tenants were able to move into the south tower in January 1972. On April 4, 1973, the official inauguration of the Twin Towers was carried out.

The original estimates of the construction costs for the World Trade Center of US $ 350 million could not be met, so that the New York Port Authority put the estimated total costs at up to US $ 575 million in December 1966 (corresponds to today: US $ 4,521 million. Dollar). This announcement drew criticism from the ranks of private real estate firms and other institutions in New York City of the WTC project. In the opinion of the critics, the New York Port Authority gave an unrealistically low estimate, calculating that the project would end up costing US $ 750 million. When construction of the Twin Towers was completed, the total cost to the New York Port Authority was $ 900 million (the equivalent of $ 5,167 million today). The World Trade Center project was funded through tax-free bonds from the New York Port Authority.

Other WTC buildings

The World Trade Center complex consisted of six free-standing buildings, a shopping center underneath (The Mall) and underground stations.

In addition to the Twin Towers - WTC 1 (north tower) and WTC 2 (south tower) - WTC 3 with 22 floors was designed by Skidmore, Owings and Merrill as a hotel building between 1978 and 1979. This building was rented by the Marriott hotel group (formerly Vista Hotel). WTC 4 , WTC 5 and WTC 6 were eight- to nine-story buildings that were erected by the same team that designed the Twin Towers. The 47-story WTC-7 building was built in 1987 north of the World Trade Center side. It was designed by Emery Roth & Sons and built on a substation of the energy supplier " Con Edison ".

The World Trade Center complex included an underground shopping arcade that housed shops and restaurants. Several subway lines and two PATH lines to New Jersey were housed in underground train stations .

technical changes

In the course of time, numerous structural changes were made in order to meet the tenants' demands on the Twin Towers. The changes were made in accordance with the New York Port Authority using the Port Authority Alteration Review Manual to ensure the structural integrity of the buildings. In many cases, openings were cut in the floors and new stairs were built into the rental offices to connect the floors. Some steel beams were reinforced in the core to store heavy loads, such as large amounts of files that tenants had to accommodate on their floors.

After the 1993 bombing, repairs were carried out on structural elements in the lower levels of WTC 1 (north tower). The greatest damage occurred at levels B1 and B2, with considerable structural damage also at level B3. The primary columns were not damaged, but the secondary steel beams were badly affected. Floors damaged by the explosion had to be restored to restore structural support to the steel beams. The diaphragm wall was in danger from the bomb explosion, as the loss of the floor slabs meant that the lateral support was no longer guaranteed to counteract the pressure from the Hudson River water on the other side. The refrigeration system at level B5 was badly damaged; as a result, the air conditioning in the entire WTC complex failed and had to be replaced for a limited period. After critical lines and signaling in the original fire alarm system had been destroyed by the bomb explosion, a new fire alarm system had to be installed. These installations, which were carried out in both towers, took years to complete and were not yet completed at the time of the September 11, 2001 attacks.

facts and figures

- From 1942 to 1972 Austin J. Tobin, Executive Director of the Port Authority, oversaw the planning and development of the World Trade Center.

- On September 20, 1962, Minoru Yamasaki was entrusted with the management of the World Trade Center project, in collaboration with the architecture firm Emery Roth & Sons.

- On January 18, 1964, Minoru Yamasaki presented his design to the public.

- In March 1965, the New York Port Authority (developer) began purchasing property on the World Trade Center side of Manhattan.

- On March 12, 1966, the commissioned Ajax Wrecking and Lumber Corporation began demolishing the buildings on the planned construction site.

| WTC complex | Data |

|---|---|

| architect | Minoru Yamasaki |

| structural engineer | Leslie Earl Robertson |

| Client | Port Authority of New York and New Jersey |

| architecture | Emery Roth & Sons, Minoru Yamasaki Associates |

| Structural engineering | Leslie E. Robertson & Associates, RLLP

Skilling, Helle & Jackson, Christiansen Robertson |

| General contractor | Tishman Construction Corp. |

| restoration | Leslie E. Robertson & Associates, RLLP |

| Building supervision | Karl Koch Erecting Corp. |

| planning phase | 1958-1966 |

| Foundation (WTC complex) | Data |

|---|---|

| start of building | 5th August 1966 |

| depth | 21-26 m |

| Length of the diaphragm wall | 1108 m (building site enclosure) |

| Thickness of the foundation wall | 92 cm |

| Excavation of the foundation | 920,000 cubic meters |

| 1 WORLD TRADE CENTER - north tower | Data |

|---|---|

| Built | 1966-1973 |

| height | 417 m |

| Total height with antenna tip | 527 m |

| Antenna height | 110 m |

| Installation of the last steel beam | December 23, 1970 |

| 2 WORLD TRADE CENTER - south tower | Data |

|---|---|

| Built | 1966-1973 |

| height | 415 m |

| Installation of the last steel beam | July 19, 1971 |

| Features for both towers | Data |

|---|---|

| Construction type | External columns with stiffening core |

| Function / use | office building |

| Office space per tower | 418,500 square meters |

| Passenger lifts per tower | 98 (including 23 express elevators) |

| Load express elevator | 55 people |

| Speed express elevator | 8 m / s |

| Freight lifts per tower | 6th |

| facade | Glass, aluminum |

| Windows per tower | 43,600 |

| Facade per tower | 236 steel beams |

| Inner core per tower | 47 steel beams |

| Crossbar | steel |

| Ceiling beams | steel |

| Ceiling tiles | 10 cm lightweight concrete in trapezoidal sheet metal |

| Number of floors | 110 |

| Underground floors | 6th |

| Parking space per tower | 2,000 cars (underground) |

| Wind resistant up to | 240 km / h |

| Dimensions at the foot | 63.4 m × 63.4 m |

| Steel weight per tower | 100,000 tons |

| Total weight per tower | 500,000 tons |

| Load-bearing capacity of the floor per floor | 1,300 tons (plus dead weight) |

| Floor damping elements per tower | 11,000 pieces |

| Power cables per tower | 4,800 km |

| Opening of the towers | April 4th 1973 |

| Complete completion of the towers | 1977 |

| Construction costs per tower | $ 700 million |

| Partial building | Built | Floors | Office space | Elevators |

|---|---|---|---|---|

| 3 World Trade Center Marriott World Trade Center |

1978 | 22nd | - | |

|

4 World Trade Center - Southeast Plaza Building (Commodites Exchange Building) |

1978 | 9 | 78,500 square meters | 13 |

| 5 World Trade Center - Northeast Plaza Building (Dean Witter Building) |

1972 | 9 | 100,703 square meters | 9 |

|

6 World Trade Center U.S. Customs House |

1975 | 8th | 74,691 square meters | 12 |

|

World Trade Center 7 (US government and financial companies) |

1984-1987 | 47 | 174,000 square meters |

Coordinates: 40 ° 42 ′ 42 " N , 74 ° 0 ′ 49" W.

literature

- Dissecting the Collapses. In: Civil Engineering Magazine. Volume 72, No. May 5, 2002.

- The World Trade Center - A Modern Marvel. (DVD)

- Jeff L. Brown: Landmarks in American Civil Engineering History. In: Civil Engineering Magazine. November – December 2002, No. 11-12, volume 72.

- Sonja Bullaty: World Trade Center Remembered. Abbeville Press, 2001, ISBN 0-7892-0764-8 .

- Eric Darton: Divided We Stand. 1st Edition. Basic Books, 2001, ISBN 0-465-01727-4 .

- Judith Dupré: Skyscrapers. 2nd edition. Black Dog & Leventhal Publishers, New York 2008, ISBN 978-1-57912-787-9 , pp. 68-69.

- Judith Dupré: Skyscrapers. Black Dog & Loventhal, New York 1996, ISBN 1-884822-45-2 , pp. 66-67.

- World Trade Center Building Performance Study. Federal Emergency Management Agency, New York (USA)

- Angus K. Gillespie: Twin Towers. Rutgers University Press, Newark (USA) 1999, ISBN 0-8135-2742-2 .

- Bill Harris: The World Trade Center. 2001, ISBN 0-7624-1315-8 .

- Erwin Heinle: Towers of all times - of all cultures. 3rd edition. Deutsche Verlags-Anstalt, Stuttgart 1997, ISBN 3-421-02931-8 , p. 305.

- Valeria Manferto de Fabianis: World Trade Center. K. Müller, Cologne 2002, ISBN 3-89893-011-4 .

- Chandra Mukerji: Intelligent Uses of Engineering and the Legitimacy of State Power. In: Technology and Culture. Volume 44, No. October 4, 2003.

- Nadine M. Post: Debris Mountain Starts To Shrink. In: Engineering News Record. October 2001.

- Nadine M. Post: Massive Assault Doomed Towers. In: Engineering News Record. September 2001.

- Nadine M. Post: No Code Changes Recommended In World Trade Center Report. In: Engineering News Record. April 2002.

- Nadine M. Post: WTC's 'Bathtub' Stabilization Is More Than 70% Complete. In: Engineering News Record. April 2002.

- Jake Rajs: Sometime Lofty Towers. Brown Trout Publishers, 2001, ISBN 0-7631-5472-5 .

- Leslie E. Robertson: A Life in Structural Engineering. In: Seven Structural Engineers. Pp. 66-85.

- Debra K. Rubin: WTC Cleanup Agency Begins Ramping Up Operations. In: Engineering News Record. No. June 26, 1946.

- Debra K. Rubin: WTC Pushes the Envelope. In: Engineering News Record. March 2002.

- Victoria Sherrow: The World Trade Center Bombing. Enslow Publishers, 1998, ISBN 0-7660-1056-2 .

- Peter Skinner: World Trade Center. Metro Books, 2002, ISBN 1-58663-612-X .

- Peter Skinner: World Trade Center. Silver Dolphin, 2002, ISBN 968-5308-94-2 .

- Charles J. Ziga: New York Landmarks. Dove Tail Books, 1999, ISBN 0-9636673-0-0 , pp. 62-63.

Web links

- New York: A Documentary Film - The Center of the World - Building the World Trade Center, an 18-minute film, with construction footage, produced by the Port Authority in 1983 (English)

- World Trade Center - Skyscraper Museum (English)

- NIST and the World Trade Center (English)

- New York's World Trade Center - A Living Archive - by author Eric Darton (English)

Individual evidence

- ^ Hudson & Manhattan Railroad: Operational History. hudsoncity.net, accessed June 21, 2011 .

- ^ A b Peter Christener: World Trade Center New York - The Twin Towers. Retrieved August 22, 2009 .

- ^ The World Trade Center "bathtub" . In: Felsbau, Rock and Soil Engineering . No. 3 , 2004, ISSN 0174-6979 , p. 56-67 .

- ^ Milton Esterow: Architect Named for Trade Center. In: New York Times. September 21, 1962.

- ↑ a b Ada Louise Huxtable: A New Era Heralded. In: New York Times. January 19, 1964.

- ^ Ada Louise Huxtable: Biggest Buildings Herald New Era. In: New York Times. January 26, 1964.

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. 9.

- ^ Otis History: The World Trade Center, Otis Elevator Company , accessed July 31, 2009.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 76.

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. 7.

- ↑ a b WTC info , accessed on August 22, 2009.

- ↑ Nancy Pekala: Profile of a lost landmark; World Trade Center. In: Journal of Property Management. January 11, 2001.

- ^ A b Ada Louise Huxtable: Who's Afraid of the Big Bad Buildings. In: New York Times. May 29, 1966.

- ↑ Skyscraper ( Memento of the original from January 27, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , accessed August 24, 2009.

- ↑ Edward Steese: Marring City's Skyline. In: New York Times. March 10, 1964.

- ^ Alden Whitman: Mumford Finds City Strangled By Excess of Cars and People. In: New York Times. March 22, 1967.

- ^ Murray Schumach: TV Group Objects to Trade Towers. In: New York Times. February 20, 1966.

- ^ TV Mast Offered on Trade Center , New York Times, February 24, 1966.

- ^ Clayton Knowles: Big Trade Center Called Bird Trap. In: New York Times. March 16, 1967.

- ^ National Construction Safety Team: Final Report on the Collapse of the World Trade Center Towers . NIST, September 2005, p. 1, Chapter 1. (PDF)

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, pp. XXXVIII.

- ^ World Trade Center - Some Engineering Aspects. sydney.edu.au, accessed June 21, 2011 .

- ^ National Construction Safety Team: Final Report on the Collapse of the World Trade Center Towers . NIST, September 2005, pp. 5–6, Chapter 1. (PDF)

- ^ RE Taylor: Computers and the Design of the World Trade Center. ASCE, Structural Division 92 (ST-6), December 1966, pp. 75-91.

- ↑ a b c d National Construction Safety Team: Final Report on the Collapse of the World Trade Center Towers . NIST, September 2005. (PDF)

- ^ Steel Construction Manual. 8th edition. second revision. American Institute of Steel Construction, 1986, Chapter 1, pp. 1-5.

- ↑ ASTM A441 / A441M - Withdrawn 1988: Specification for High Strength Low Alloy Structural Manganese Vanadium Steel. astm.org, accessed June 21, 2011 .

- ^ MG Lay, TV Galambos: Welded continuous Frames and their Components Test on A36 and A441 Steel Beam Columns. June 1964.

- ↑ a b c Structural Steel and Steel Connections , accessed August 31, 2009.

- ^ American Iron, Steel Institute: The World Trade Center - New York City. Contemporary Steel Design (American Iron and Steel Institute) 1964, 1 (4)

- ↑ a b c d e National Construction Safety Team: Final Report on the Collapse of the World Trade Center Towers . NIST, September 2005, p. 10. (PDF)

- ^ George J. Tamaro: World Trade Center "Bathtub": From Genesis to Armageddon. nae.edu, archived from the original on December 2, 2008 ; Retrieved June 21, 2011 .

- ↑ a b c d National Construction Safety Team: Final Report on the Collapse of the World Trade Center Towers . NIST, September 2005, p. 8. (PDF)

- ^ Thomas W. Eagar, Christopher Musso: Why Did the World Trade Center Collapse? Science, Engineering, and Speculation. tms.org, accessed June 21, 2011 .

- ^ A b c H. S. Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. 8.

- ↑ kip. sizes.com, accessed June 21, 2011 .

- ↑ Holm Altenbach: A directly formulated bending theory for viscoelastic single and multi-layer shells . In: Technical Mechanics . No. 3 , 1986 ( uni-magdeburg.de [PDF; accessed on June 21, 2011]).

- ^ The Center of the World - New York: A Documentary Film (Construction Footage). pbs.org, accessed June 21, 2011 .

- ↑ James Gloss, Eric Lipton: City in the Sky. Times Books, 2003, p. 138.

- ↑ A. David, Fanella, Arnaldo T. Derecho, SK Ghosh: Design and Construction of Structural Systems. (NCSTAR 1-1A), National Institute of Standards and Technology, September 2005, p. 65.

- ↑ a b c America Rebuilds: A Year at Ground Zero - Quick Facts. pbs.org, accessed June 21, 2011 .

- ↑ James Gloss, Eric Lipton: City in the Sky. Times Books, 2003, pp. 139-144.

- ↑ James Gloss, Eric Lipton: City in the Sky. Times Books, 2003, pp. 160-167.

- ↑ The Tower Builder and the Tragedy. In: Spiegel Online. Retrieved June 21, 2011 .

- ↑ James Glanz, Eric Lipton: The Height of Ambition. In: New York Times. 2002.

- ^ Leslie E. Robertson: Reflections on the World Trade Center. In: The Bridge. Volume 32, Number 1, 2002, National Academy of Engineering

- ^ Fahim Sadek: Baseline Structural Performance and Aircraft Impact Damage Analysis of the World Trade Center Towers. (NCSTAR 1-2 appendix A), NIST 2005, pp. 305-307.

- ↑ Eric Nalder: Twin Towers Engineered To Withstand Jet Collision. In: Seattle Times. February 27, 1983, accessed June 21, 2011 .

- ^ A b H. S. Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. 153.

- ↑ VERMISOL vermiculite. vtt-group.com, archived from the original on May 12, 2008 ; Retrieved June 21, 2011 .

- ^ World Trade Center data. wtc-terrorattack.com, accessed June 21, 2011 .

- ↑ Ronald Hamburger, William Baker, Jonathan Barnett, Christopher Marrion, James Milke, Harold "Bud" Nelson: World Trade Center Building Performance Study. (PDF; 5.4 MB) fema.gov, accessed on June 21, 2011 .

- ↑ NCSTAR 1-6, (p LXVII-LXIX) NIST recorded improved floors on floors 77, 78, 85, 88, 89, 92, 96, and 97 and 5 floors with unspecified floors. Although the refractory replacement was specified to be 1.5 inches (38 mm) thick, NIST determined that the average thickness should be 2.5 inches (64 mm). (NCSTAR 1–6A p XL) NIST concluded its report with the statement: "The existing condition of the fireproof floor thickness in the WTC flooring system did not play a significant role in the aircraft impact."

- ↑ Jim Dwyer, Kevin Flynn: 102 Minutes. Times Books, 2005, pp. 9-10.

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1) National Institute of Standards and Technology, September 2005, p. 162.

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. 163.

- ↑ David D. Evans, Richard D. Peacock, Erica D. Kuligowski, W. Stuart Dols, William L. Grosshandler: Active Fire Protection Systems. (NCSTAR 1-4), National Institute of Standards and Technology, September 2005, p. 14.

- ^ Joseph C. Ingraham: Port Agency Buys Downtown Tract. In: New York Times. March 29, 1965.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 61.

- ^ Jackhammer's Bite Pavement to Start Trade Center Job. In: New York Times. August 6, 1966.

- ↑ Edith Iglauer: The Biggest Foundation. In: New York Times. 4th November 1972.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 68.

- ↑ The mole never sleeps - 40 years of soil mechanics and foundation engineering at Graz University of Technology. presse.tugraz.at, April 14, 2004, accessed on June 21, 2011 .

- ^ A b Maurice Carroll: A Section of the Hudson Tubes is Turned into Elevated Tunnel. In: New York Times. December 30, 1968.

- ↑ Martin S Kapp: Tall Towers wants Sit on Deep Foundations. In: Engineering News Record. July 9, 1964.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 71.

- ^ New York Gets $ 90 Million Worth of Land for Nothing. In: Engineering News Record. April 18, 1968.

- ↑ a b Timeline: World Trade Center chronology . PBS - American Experience, accessed August 24, 2009.

- ↑ Contracts Totaling $ 74,079,000 Awarded for the Trade Center. In: New York Times. January 24, 1967.

- ↑ Peter Kihss: Trade Center Job To Go To Tishman. In: New York Times. February 27, 1967.

- ^ Michael T. Kaufman: Trade Center is Doing Everything Big. In: New York Times. June 6, 1969.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 88.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, pp. 92-94.

- ^ Construction of the WTC towers. wtc-terrorattack.com, accessed June 21, 2011 .

- ↑ a b 9/11 Research , accessed on August 29, 2009.

- ↑ LS field: Superstructure for the 1,350-ft World Trade Center. Civil Engineering-ASCE, 1971, pp. 66-70.

- ^ Robert D. McFadden: 300 Tugboats Idle as Men Walk Out for Doubled Wage. In: New York Times. 2nd February 1970.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 91.

- ↑ Maurice Carroll: Phones Disrupted by a Pile Driver. In: New York Times. March 19, 1969.

- ↑ Lawrence Van Gelder: Propane Blast Hits Trade Center. In: New York Times. March 17, 1970.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 70.

- ^ Angus K. Gillespie: Twin Towers: The Life of New York City's World Trade Center. Rutgers University Press, 1999, p. 69.

- ^ Questions on the Trade Center. In: New York Times. December 24, 1966.

- ↑ Phillips, Mc Candlish: Estimate Raised for Trade Center. In: New York Times. December 29, 1966.

- ^ Brian J. Cudahy: Rails Under the Mighty Hudson: The Story of the Hudson Tubes, the Pennsy Tunnels, and Manhattan Transfer. Fordham University Press, 2002, Chapter 3.

- ^ John H. Allan: Bonds: Port of New York Authority to Raise $ 100-Million. In: New York Times. February 28, 1968.

- ^ Therese McAllister, Johnathan Barnett, John Gross, Ronald Hamburger, Jon Magnusson, May 2002, "WTC3". World Trade Center Building Performance Study, FEMA

- ^ Therese McAllister, Johnathan Barnett, John Gross, Ronald Hamburger, Jon Magnusson: WTC4, 5, and 6. World Trade Center Building Performance Study, FEMA May 2002.

- ^ Therese McAllister, Johnathan Barnett, John Gross, Ronald Hamburger, Jon Magnusson: WTC7. World Trade Center Building Performance Study, FEMA May 2002.

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. XLIV.

- ^ HS Lew, Richard W. Bukowski, Nicholas J. Carino: Design, Construction, and Maintenance of Structural and Life Safety Systems. (NCSTAR 1-1), National Institute of Standards and Technology, September 2005, p. XLV.

- ↑ Eugene Fasullo: Experiences of the Chief Engineer of the Port Authority. (PDF; 1.9 MB) interfire.org, pp. 120–122 , accessed on June 21, 2011 .

- ↑ Port Authority Risk Management Staff: Complex Overview. (PDF; 1.9 MB) interfire.org, p. 27 , accessed on June 21, 2011 .

- ↑ Ennala Ramabhushanam, Marjorie Lynch: Structural Assessment of Damage Bomb for World Trade Center. In: Journal of Performance of Constructed Facilities. 8 (4), pp. 229-242.

- ↑ David D. Evans, Richard D. Peacock, Erica D. Kuligowski, W. Stuart Dols, William L. Grosshandler: Active Fire Protection Systems. (NCSTAR 1-4), National Institute of Standards and Technology, September 2005, p. 44.

- ^ One World Trade Center (1973). structurae.net, accessed June 21, 2011 .

- ^ World Trade Center. (No longer available online.) Newyork-net.de, archived from the original on June 25, 2011 ; Retrieved June 21, 2011 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ The end of the twin towers. In: Spiegel Online. Retrieved June 21, 2011 .