fridge

A refrigerator (also known in Austria as an ice box ) is a cabinet-shaped device that is usually operated electrically , but sometimes also with fuel , and automatically keeps the temperature inside it low. The inside of the refrigerator is cooled by means of a cooling unit, which is often located on the rear and regulated by a temperature controller. There are also refrigerators based on evaporative cooling or using low outside temperatures.

Refrigerators are used to store food , medicines , chemicals , etc. Due to the lower temperature, chemical reactions and biological processes that make food inedible and medicines unusable, for example, take place more slowly.

The typical operating temperature inside household refrigerators is between 2 ° C and 8 ° C. The housing of the cooling compartments is thermally insulated in order to keep the energy consumption to maintain the difference to the ambient temperature low. Refrigerators are one of the most widespread and regularly used household appliances and account for a significant proportion of household electricity consumption.

history

Cooling was already achieved in ancient times by transporting ice from the mountains to places and using it in deep cellars (so-called ice cellars ) to store food.

In 1748, William Cullen showed the first artificial cooling at the University of Glasgow . An important further development was the use of ammonia by Ferdinand Carré in 1859.

Until around 1950, wooden ice boxes fed with ice from the factory or pond (stored in the cellar under sawdust) were also used. Inside they contain a vessel made of soldered zinc sheet. At the top, ice (crushed or in one piece, for example icicles) is poured in, at the bottom the dripping water is collected, in the middle there is a chamber surrounded by ice, which holds the refrigerated goods on (marble) compartments and is closed with a door. In Graz , the addresses Eisteichgasse (settlement) near the former brick clay pits and Am Eisbach and the town of Eisbach are reminiscent of this form of wintry ice extraction. In Vallorbe , the ice from Lac de Joux for Paris was loaded onto the railroad, and Zell am See supplied ice for German breweries.

1876, the German engineer and entrepreneur developed by Carl von Linde 's fundamental to science and technology Linde process . His invention made it possible to improve the reliability of the compressor and the entire refrigeration machine so that it was suitable for industrial use. Now water ice could be produced industrially all year round; one was no longer dependent on natural ice . Its first development was still operated with ammonia at that time . This substance is toxic, corrosive and not only caused leaks but also a foul odor, so it wasn't until the 1920s that refrigerators became suitable for household use since the development of substitute chemicals. In the 1930s it became the basic equipment of private households in the USA and Cuba ; in 1937 every second American household had a refrigerator.

The first European refrigerator was developed in 1929 by the Zschopauer Motorenwerke JS Rasmussen , founded by Jørgen Skafte Rasmussen . The Deutsche Kühl- und Kraftmaschinen GmbH in Scharfenstein emerged from the DKW- Kühlung brand in 1931 .

The first refrigerators were operated with chloromethane (methyl chloride, CH 3 Cl), ammonia or sulfur dioxide ; this caused problems for the storage of the moving parts in the compressor and, in the event of leaks, the escape of toxic gases or deflagrations . From 1930 onwards, chlorofluorocarbons (CFCs) were technically produced and soon used as refrigerants in refrigerating machines. This avoided the problems mentioned. In the 1980s, the ozone hole over the Antarctic was discovered and scientific evidence was provided that CFCs depleted the ozone layer. In the Montreal Protocol , the signatory states committed themselves not to use CFCs any more.

The first CFC-free refrigerator in the world in recent times was produced in 1992 by the Saxon company "dkk Scharfenstein" (later under the name " Foron "). The development was initiated by Greenpeace and the Hygiene Institute Dortmund under the direction of Harry Rosin . The first CFC-free refrigerator of this type was converted by Lare GmbH as a laboratory device for the Hygiene Institute in Dortmund. At that time, the manufacturers of refrigerators were not yet interested in introducing this technology. Since the year 2000, household and commercial refrigerators with flammable refrigerants have been more and more represented on the market. The system uses what is known as the “ Dortmund Mixture ”, a mixture of propane and butane that neither enlarges the ozone hole nor increases the greenhouse effect, but is flammable.

With the spread of electric current and the refrigerator lost its precursor, the electroless freezer , attractive. The word ice cabinet (in Austria ice box ) is still used colloquially for the refrigerator in use today.

Before refrigerators were generally affordable for private households, small cold stores were operated mainly in the 1950s and 1960s by freezing communities , in which mainly frozen food was stored.

Refrigerator production at VEB Kühlautomat Berlin 1988

Collective freezers in Alblasserwaard, Dutch cinema news from 1956

functionality

With all refrigerator types, heat is extracted from the interior of the refrigerator by means of heat exchangers and given off to the environment (see refrigeration machine and heat pump ). Depending on how this is achieved, a distinction is made between three types: compressor refrigerators, absorption refrigerators and refrigerators with Peltier elements .

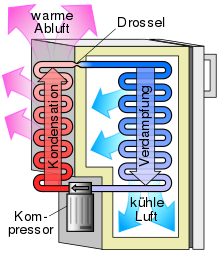

Compressor refrigerator

The cooling systems commonly used in households and industry are based on this principle: In a compressor refrigerator, a gaseous refrigerant is adiabatically compressed by a compressor , which heats the refrigerant. In the condenser, which consists of black cooling coils attached to the rear of the device, the heat is released into the environment, causing the medium to condense . Then it flows through a throttle to reduce the pressure - e.g. B. an expansion valve or a capillary tube - and then further into the evaporator inside the refrigerator. Here, the evaporating refrigerant takes the necessary heat of evaporation (evaporative cooling ) from the cooling compartments and flows as gas to the external compressor. A compressor refrigerator has the same function as a heat pump, it only differs in the use of heat exchangers. The temperature is controlled with a thermostat that switches the compressor on or off depending on the desired temperature.

Absorption refrigerator

The absorption refrigerator works with a water-ammonia mixture in a hydrogen atmosphere . In the cooker , ammonia and water are separated into gaseous ammonia and water by adding heat (e.g. gas flame, electrical heating, solar heat). Then the liquid water and the gaseous ammonia are passed on through various pipe systems. The gaseous ammonia condenses in the condenser by cooling; here the refrigerator gives off heat to the environment. The liquid water flows through a thin pipe into the evaporator in the interior, usually in the icebox. There it comes into contact with the hydrogen and evaporates due to the low partial pressure , the hydrogen serves to equalize the pressure - this is where the refrigerator cools. Then the gaseous ammonia in the absorber is brought back into solution with the cooled water from the cooker.

A detailed functional description can be found in the article on the diffusion absorption chiller . Absorption refrigerators are z. B. used in motor vehicles or camping equipment. At least when operated electrically, they are less efficient than compressor refrigerators. If they are operated directly with gas or engine waste heat, they are about as efficient as compressor devices thanks to the direct use of primary energy . Since they have no moving parts apart from the working fluid, they are practically silent; this property gives them a wide range of applications such. B. as a minibar in hotel rooms . For use in particularly remote areas, there are also absorption refrigerators that run on petroleum or petrol.

Electrolux is practically the sole European market leader for small absorption refrigerators for mobile homes, caravans and hotel rooms (2008) (product name Electrolux RM nnn ). Identical devices are also sold under the name " Dometic ".

Advantages of absorption refrigerators

- Noiseless and vibrationless

- Operation with fuel gases ( propane is common ) possible

- No wearing parts

Disadvantages of the absorber cooling system

- Poor efficiency , thus higher energy consumption

- A drop in output from 35 ° C outside temperature possible

- Sensitive to movement and tilt

- Defined design of the absorber cooling system

- More expensive than comparable compression refrigerators due to low production figures

Thermoelectric refrigerator (cool box)

So-called cool boxes based on the thermoelectric principle ( Peltier effect ) are available for mobile use . They work with 12 or 24 V DC and have been developed for use in vehicles and boats. They are much smaller and lighter than refrigerators and can often also be used for heating. The devices are less efficient than compressor refrigerators. While a compressor refrigerator consumes around 0.5 watts of electrical power for 1 watt of cooling power, a Peltier element requires around 2 watts for the same energy transport, this value being strongly dependent on the difference between the interior temperature and the ambient temperature. The efficiency information applies to a temperature difference of around 20 K. Using these devices in the household does not make sense in terms of energy. However, some of these devices have a 230 V mains voltage connection.

The cooling capacity of these devices is much lower than that of conventional household compressor refrigerators.

construction

A typical table-top refrigerator (standing model) has a capacity of approx. 150 liters and weighs approx. 40 kg. A fridge-freezer has a capacity of approx. 250 liters and weighs around 65 kg.

There are different room layouts for refrigerators. The best known and most common is the variant with a large outer door and an inner flap to the freezer compartment in the upper area. The freezer compartment usually has a maximum capacity of 20 liters, the refrigerator compartment can be up to 250 liters (possibly larger).

Other variants have separate doors for the fridge and freezer. They are called a fridge-freezer. The compartments can be one above the other or next to one another; The latter version is particularly popular in the USA and usually has an integrated ice cube maker and, optionally, an additional drinks flap in the large door of the refrigerator segment. Such a "side-by-side" refrigerator - also known as an American refrigerator - can hold more than 500 liters (refrigerator compartment around 350 liters, freezer compartment around 150 liters).

Larger versions, for example, have a double door to the refrigerator area above and a very wide drawer for the freezer segment below. These variants are called the French refrigerator.

business

Temperature zones

There are different temperature zones in a modern household refrigerator:

- It is warmest upstairs, where cooked dishes and jams can be stored well.

- In the middle range, dairy products (yogurt, cheese) are in good hands.

- It is coldest at around 2 ° C in the compartment above the vegetable compartments. Perishable things like meat and sausage belong here.

- The drawers at the bottom are good for fruit and vegetables at around 8 ° C. Under the cover, temperature and humidity are suitable for preserving vitamins and the appearance of the goods.

- It's relatively warm in the door compartments, but cool enough for butter and eggs.

- Some modern refrigerators also have a 0 ° C cooling zone, which is supposed to keep food fresh for a particularly long time.

- Another innovation is the equipment of an extra compartment for fruit and vegetables with LEDs , which continue to light up when the door is closed. These are, for example, two flashing LEDs that simulate the blue and green components of sunlight. In this way, the natural protective mechanisms of fruit and vegetables are to be activated in order to counteract the vitamin breakdown that occurs when stored in the dark.

Ambient temperature

For refrigerators with freezer compartments, especially with freezer compartments, the ambient temperature of the installation location specified by the manufacturer, specified as the climate class , must be taken into account:

- Climate class SN (subnormal)

- Ambient temperatures from +10 ° C to +32 ° C

- Climate class N (normal)

- Ambient temperatures from +16 ° C to +32 ° C

- Climate class ST (subtropics)

- Ambient temperatures from +16 ° C to +38 ° C

- With this class, a device can consume 10% more energy than the normal class in order to receive the same energy label (e.g. A ++)

- Climate class T (tropics)

- Ambient temperatures from +16 ° C to +43 ° C

- With this class, a device can consume 20% more energy than the normal class in order to receive the same energy label (e.g. A ++)

While a low ambient temperature around the installation site initially helps to save energy, apparently paradoxically, falling below the minimum temperature leads to thawing in the ice / freezer compartment. This is due to the fact that the refrigerator compartment and the freezer compartments usually have a common compressor, which is regulated by a thermostat in the refrigerator compartment. When the outside temperature is low, e.g. B. 8 ° C, the compressor rarely needs to run to z. B. to ensure a temperature of 6 ° C in the refrigerator. This activity of the compressor is not sufficient to counter the significantly larger difference ( heat flow ) between the outside temperature and the temperature in the freezer, e.g. B. −18 ° C to work. Apart from that, lubricants in the compressor can become too viscous below the minimum operating temperature.

Refrigerators of climate class SN therefore often have a heater in the vicinity of the thermostat in the cold room of approx. 8 watts. Sometimes the incandescent lamp (usually: 15 watts) is simply not switched off in order to extend the operating temperature from climate class N to SN.

Selection advice

If you want to save energy by installing a refrigerator in an unheated room where permanent temperatures below 10 ° C can be expected, you must bear in mind that the freezer compartment of a fridge / freezer combination will not work if the cooling load of the refrigerator section is too low . If refrigerators and freezers or freezers are in cold locations, it must be taken into account that the manufacturers specify minimum temperatures for reliable operation or a long service life. This depends on the viscosity of the compressor lubricants used.

For commercial users there are cooling devices such as B. Wall cooling shelves (for the presentation of mainly packaged food), free cooling counters, beer coolers or refrigerators with glass doors loaned by beverage manufacturers. All of these devices are naturally less efficient than closed devices. The chest shape, which is advantageous anyway, is often provided with self-closing transparent lids or blinds so that the heat input from customers and air currents can be kept low.

Energy demand

In Central Europe, the energy requirement is defined for ambient temperatures between +16 ° C and +32 ° C and classified as climate class N. The energy consumption label (colloquially energy label ) from 1998 is used to support the purchase decision. The EU Commission has defined a uniform, binding template for the label. The energy efficiency classes range from G to A and reflect the state of the art at the time. The A + and A ++ extensions were introduced in 2003 for particularly energy-saving refrigerators and freezers, each of which is even better than energy efficiency class A and represents very low energy consumption.

The European Parliament adopted the Directive 2010/30 / EU in May 2010, a new regulation applicable from 2011 in energy efficiency classes for household appliances. In addition to classes A + and A ++, class A +++ was introduced and shown on the energy label. The new A + can use 5% more energy than the old A + class and the new A ++ can use 10% more.

Old directive for household appliances: 92/75 / EEC for refrigerators: directive 94/2 / EC Amendment: directive 2003/66 / EC

New directive for household appliances: 2010/30 / EU for refrigerators: Regulation (EU) No. 1060/2010

The new guideline stipulates that since July 2011 no worse household appliances with compressors than Class A may be brought onto the market (e.g. absorber appliances may still be significantly worse).

In 1983 the Rocky Mountain Institute (RMI) built a Sun Frost refrigerator with only 0.19 kWh / l per year (22 W / m³), the heat exchanger of which was attached to the outside of the building and half of the cooling energy required was generated passively. The RMI held a development of devices with even lower consumption values, e.g. B. by vacuum insulation layers , for possible. The most economical fridge / freezer combinations achieve consumption values of 0.48 kWh / l per year (55 W / m³, at 25 ° C ambient temperature) like the Blomberg CT 1300A (no longer available in stores) or 0.34 kWh / l per year ( 39 W / m³, at 21 ° C) the Sun Frost RF16. A comparable device in energy efficiency class A requires 1.26 kWh / l per year (144 W / m³, as of 2006). Much more economical are pure refrigerators without a freezer compartment. These are recommended if there is a separate freezer anyway.

Defrosting, maintenance

Maintenance by defrosting refrigerators is a measure to prevent wasted energy. When the refrigerator door is opened, warm air enters the interior of the refrigerator. If the door is closed, the refrigerator will lower the internal temperature again. Since colder air and in particular the evaporator surfaces increase the condensation rate of the water vapor in the air and at the same time reduce the evaporation rate, the saturation vapor pressure is reduced . The water vapor brought into the refrigerator by opening it with the ambient air condenses on the surfaces and freezes. The icing of the cooling surfaces reduces the cooling performance , as the ice layer has an insulating effect. This means that the refrigerator has to use more energy (electricity) for the same output. In order to reduce energy consumption again, the layers of ice must be removed from time to time. This can be done either manually or automatically using different techniques. In the automatic defrosting process, a distinction is made between a cold room temperature above 0 ° C, which allows defrosting at the set temperature, typically refrigerators, and a cold room temperature well below 0 ° C, as used in freezers.

Manual defrost

Until the development of automatic defrosting processes, both refrigerators and freezers had to be defrosted manually. In many freezers or fridge / freezer combinations without No-Frost technology, this is still necessary for the freezer compartment. To defrost a cold room, the refrigerated goods must first be temporarily stored in another cold room or well insulated. The cooling unit can then be switched off and the door opened, causing the ice to begin to thaw. The process can be accelerated by having a fan or fan heater in front of the door blowing warm air into the refrigerator compartment. Alternatively, a saucepan with hot water can be placed in the freezer compartment. When the door is closed, defrosting is much faster. Any condensation water collects in a special tray or in the lower area of the refrigerator.

fridge

In models from the middle price range, automatic defrosting for the refrigerator compartment has been common since the 1980s, while it is only common in the freezer compartment in catering-grade models. Fridges of earlier years of construction must be defrosted manually by switching them off for a few hours and letting the ice layer, which has formed on the inside rear wall of frozen condensation water , run off by liquefying it into a separate container or removing it manually. One technique for avoiding this problem is to use a circulating air system inside the refrigerator to ensure that the air is fed to an evaporator - outside of the actual refrigerator - where ice then forms. This evaporator in turn defrosts itself regularly and the resulting liquid is caught in a bowl outside the device and can evaporate there, supported by the compressor waste heat. This means that the air in the refrigerator is dry and hardly any ice can form.

Another technique used e.g. B. was used in the refrigerator compartment of the refrigerator / freezer BBC-Duplo from the 1970s, consists in that a heating plate is attached to the back of the plate-shaped evaporator, which is mounted vertically in the upper rear area of the refrigerator compartment (20 watts for the device mentioned) is automatically switched on when the compressor is brought to a standstill by the thermostat and then switches off at the same time when it is restarted. Any defrost water that may be present is collected in a flat funnel, which is integrated in the inner rear wall and has the outlet on the back of the refrigerator. There the water is led downwards to an open container by means of a hose. This is heated by the refrigerant line directly at the outlet of the compressor - where it reaches relatively high temperatures - so that the defrosted water can more easily evaporate into the environment; thereby it also contributes to the cooling of the compressed cooling medium in the condenser; part of the energy used in the defrosting heating plate is recovered here.

Since around 1995, the cooling surface for the refrigerator compartment has often been integrated into the inner rear wall, as the evaporator must be better protected for safety reasons due to the introduction of the flammable refrigerant R600a . After the cooling phase, you wait until the surface has reached 5 ° C so that the frost layer that has formed there thaws. The water runs down to a funnel-shaped channel and through a 10 mm opening to the outside into a cup above the compressor, whose waste heat allows the condensed water to evaporate. During operation, it must be ensured that as little as possible of the refrigerated goods touches the rear wall, otherwise condensation water could partially run over the refrigerated goods into the refrigerator compartment. The drain hole must be kept free from obstruction. Some have to be covered with dust caps that are inserted into the drainage opening with a resilient extension. A straw, for example, is suitable for tapping the drain, which is recommended once a year. With these types of appliances, only a possibly existing freezer compartment needs to be defrosted.

freezer

In order to implement automatic defrosting even when the temperature in the refrigerator compartment is below freezing point, it is necessary to separate the actual refrigerator compartment from the room in which the air is cooled to the target temperature. During the cooling phase, a fan blows the cold air into the freezer compartment. The devices are designed in such a way that air circulates through all compartments and re-enters the refrigerator compartment as a circuit. Since the rate of condensation of the water vapor contained in the air is particularly high on the cooling fins, it is mainly deposited there as frost. A heater defrosts the cooling fins at set time intervals, and the layer of ice emerges from the device as water via a channel and ends up in an evaporation container. As the fan does not run during the defrosting phase, the freezer compartment remains cooled. This technology not only prevents the cooling fins from icing up, but also reduces the humidity in the entire device and almost no more ice layers form.

An initial disadvantage of this technology, known as No-Frost , is higher energy consumption. However, this is put into perspective, since energy waste due to ice formation and the defrosting processes are avoided. This fact is taken into account by allowing no-frost devices to consume 20 percent more with the same energy efficiency class . By increasing efficiency, it was possible to significantly reduce the additional consumption due to the No-Frost technology in current devices.

Star designation for freezer compartments

| Labelling | temperature | Usage and performance specifications |

| <0 ° C | not suitable for storing frozen food (mainly for ice cubes) | |

| * | ≤ −6 ° C | suitable for short-term storage of frozen food (approx. 1 week) |

| ** | ≤ −12 ° C | suitable for storing frozen food for up to approx. 2 weeks |

| *** | ≤ −18 ° C | suitable for long-term storage of frozen foods |

| **** | ≤ −18 ° C | Suitable for long-term storage of frozen food, suitable for freezing without thawing frozen food that has already been stored |

source

Related refrigeration equipment

Freezer / chest

Freezers and chest freezers work on the same principle as a refrigerator, but with an internal temperature of −18 ° C and colder, which enables long-term storage of frozen food. Food can also be frozen with 4-star freezers. Many appliances also have a quick freeze switch (which either resets itself or has to be reset) that permanently switches the compressor on. In this way, the frozen food is cooled to well below −18 ° C, so that larger quantities can be frozen without thawing frozen food that has already been stored. In many cases, the devices are also equipped with a separate quick freezer (it is usually located at the top and has a separate flap, while the other freezer compartments work like a drawer ).

Chest freezers are suitable for storing frozen food in larger pieces (e.g. whole meat). Their shape (cold air sinks downwards, so less of it escapes when the lid is opened than when the door of a freezer is opened), their energy consumption is lower, especially where the lid is opened frequently, for example in supermarkets, this is beneficial noticeable. In the household, however, it is a disadvantage that the contents are on top of each other and are therefore not as clearly arranged as in a freezer. When defrosting or cleaning, the water that accumulates also collects on the floor of the freezer and is therefore not so easy to remove. Some freezers therefore have a lockable drain or a removable tray to catch the water.

Cooling shelf

In supermarkets, special open cooling devices are used to keep food that needs permanent cooling easily accessible for customers. Since, unlike with closed cooling devices, there is a constant exchange with the warmer ambient air, the energy consumption is significantly higher.

In the past, freezers with access from above were covered overnight with simple plastic lids; sliding lids made of insulating glass (double-pane, metallized) have been common since around 2005.

Freezer showcases with access from the front (increase sales per area) have self-closing insulating glass doors with hold-openers and pane heating to prevent condensation. Signs such as "Select - then do not open" are intended to keep the heating low.

At the front of refrigerated shelves without doors, a constant stream of cold air flows downwards, which is caught there, cooled and slowly blown out again at the top. At night they are closed with aluminized foam plastic curtains.

While in the past the waste heat from these refrigeration machines was given off at every cooling device in the business premises, the waste heat in newer business premises is conducted via an insulated refrigerant pipe circuit to an energy center, which is used for air conditioning (heating, cooling, ventilation) of the rooms and for hot water preparation.

Problems

environmental issues

Refrigerators used in households work on the compressor principle. The CFC- containing refrigerants that have been used as refrigerants for a long time are ecologically very questionable as they have a strong ozone-depleting effect. In addition, the foams used in the insulation were also inflated with CFCs. However, since CFCs are only released when the refrigerator is scrapped, the refrigerators in question should not be replaced prematurely for this reason. When foaming agents are used in the 1990s, for. B. switched to n-pentane . Since the mid-1990s, other refrigerants such as isobutane or R134a have primarily been used in newer cooling devices. Refilling refrigerators or air conditioning systems with refrigerants originally containing CFC is prohibited or only permitted with suitable CFC-free replacement refrigerants.

Health risks

According to a study by Jean-Pierre Hugot from the Paris Hôpital Robert Debré , it could be that the climatic conditions inside a refrigerator favor the spread of certain cold-loving microbes such as Yersinia and Listeria . These microorganisms can cause Crohn's disease (a disease of the digestive system).

According to the Federal Institute for Risk Assessment , the antibacterial silver coatings used by many manufacturers are superfluous in refrigerators. One possible consequence of using antibacterial silver coatings is the transfer of silver particles into food. Silver inhibits bacterial growth, but is largely harmless to the human organism, therefore (in addition to gold and aluminum) it is also approved as a food coloring.

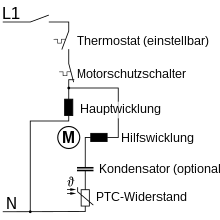

Repairs

Components such as the compressor , the compressor starting device and the thermostat are exposed to higher stresses. While the replacement of a thermostat can be carried out by almost any electrical company, if the compressor is damaged, you usually have to contact the device manufacturer's repair service or a specialist company for refrigeration technology. Replacing a compressor can be so expensive that replacing the entire cooling device should be more economical, since not only the compressor but also the entire refrigerant charge must be replaced. The starting device is exposed to high currents and high temperature differences. In the case of refrigerators designed to be customer-friendly and environmentally friendly, it can be replaced separately from the compressor.

If a cooling surface made of aluminum, usually made by roll-bonding and inflation, has been perforated - for example by unsuitable help during defrosting by scratching or bumping - it is hardly worth repairing. There is a gluing process, but it is time-consuming and the refrigerant circuit must also be checked for leaks in a specialist workshop and then refilled. The area to be glued is only accessible from the outside, while the pressure works from the inside. A bond is highly stressed by moisture and frequent strong temperature changes. A broken pipe to the rear of the evaporator appears to be easier to repair. Copper pipe can be soldered well.

turn on

If a compressor refrigerator is switched off, the compressor can not restart immediately against the pressure that is still present in the condenser . Only after some time (one to two minutes) does the pressure equalize through the throttle and the condenser and restart is possible again. The control built into the refrigerator automatically observes this waiting time. However, if the plug is pulled during operation, it should only be plugged in again after a few minutes in order not to unnecessarily overload the compressor drive. If the plug is plugged in again immediately, a (self-resetting) motor protection switch causes a waiting time after unsuccessful start attempts .

Transport and Storage

If a compressor refrigerator designed for standing operation has been transported horizontally for a long time, lubricant may have shifted from the compressor into the cooling circuit. In this case, the refrigerator should be left in its normal position for about twelve hours before it is used again. This gives the lubricant enough time to flow back into the compressor.

If a used refrigerator is temporarily taken out of service, the refrigerator door should remain open to prevent the formation of mold .

Because of the refrigerant they contain, cooling machines (including cooling units) fall under UN number 3358 . However, special provision 291 exempts from ADR as long as it contains less than 12 kg of gas. If it contains a non-flammable gas, UN number 2857 applies. Here, too, there is a special provision 119 that does not require the ADR to be used in these refrigerating machines for up to 12 l or kg of gas. In household refrigerators, the maximum amount of flammable refrigerant is set at 0.15 kg.

Lock-in trap for children

Fridges originally had a snap-in locking mechanism that couldn't be opened from the inside. At that time, discarded refrigerators were not taken back by retailers, but disposed of or put down elsewhere. With the compartments removed, one or two small children could hide in them. If the door was pulled shut or if the door of an at least sloping cupboard fell shut, the child was acoustically isolated and the air supply was shut off. It was not uncommon for fatal accidents to occur. For this reason the Refrigerator Safety Act was enacted. As a result, the refrigerators were equipped with only magnetically closing rubber hollow bead seals that can be pressed open with relatively little force.

Operation on the Sabbath

Since the light is switched on by opening the refrigerator door and the refrigerator operation may be set to an open door, Orthodox Jews are not allowed to use the refrigerator on the Sabbath if their religious rules are strictly interpreted. In this case, the door switch can be mechanically blocked or the refrigerator can be switched to Sabbath mode beforehand using a switch , which switches off all actions by opening the door.

See also

- Ecodesign Directive Lot 12 and Lot 13

Web links

- How a compressor refrigerator works (at student level, LEIFI )

Individual evidence

- ^ Encyclopædia Britannica, 2004.

- ↑ The main buyers of the Zeller ice cream ( Memento of the original from June 25, 2012 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. www.brgzell.salzburg.at, accessed on January 2, 2015.

- ↑ a b Commission Directive 94/2 / EC (PDF; 1.8 MB), accessed on January 2, 2015

- ↑ The energy efficiency classes A to G [deadlink] service.hea.de , accessed on May 20, 2016.

- ↑ Commission Directive 2003/66 / EC (PDF; 241 kB), accessed on January 2, 2015. eur-lex.europa.eu

- ↑ DELEGATED REGULATION (EU) No. 1060/2010 of the Commission (PDF; 4.7 MB), accessed on January 2, 2015. eur-lex.europa.eu

- ↑ Where do the drops in our fridge come from? www.kids-and-science.de , accessed on January 2, 2015.

- ↑ HEA - Association for Efficient Energy Use e. V. on no-frost systems

- ↑ Directive 2003/66 / EC (…) on energy labeling for electrical household refrigerators and freezers (…) , accessed on May 27, 2010 In: Official Journal of the European Union.

- ↑ Test fridge-freezer combinations by Stiftung Warentest In: test.de and test 07/2012

- ↑ service.hea.de service.hea.de , accessed on May 20, 2016.

- ^ Jean-Pierre Hugot, Corinne Alberti, Dominique Berrebi, Edouard Bingen, Jean-Pierre Cézard: Crohn's disease: the cold chain hypothesis . In: The Lancet . tape 362 , no. 9400 , 2003, p. 2012–2015 , doi : 10.1016 / S0140-6736 (03) 15024-6 .

- ↑ Federal Institute for Risk Assessment: Antimicrobial interior coating for refrigerators is superfluous (PDF; 84 kB).

- ↑ Jürgensen and Tiedemann: Propane in hermetic refrigeration devices and heat pumps In: KI Luft- und Kältetechnik 3/2003, accessed on July 1, 2015.

- ↑ Fee Anabelle Riebeling: Magnetic doors prevent death in the refrigerator. In: 20 minutes . June 9, 2015, accessed September 23, 2015 .

- ↑ Peter Glaser: Kosher Machines. In: futurezone.at/. October 19, 2013, accessed January 16, 2018 .